Overview

The article delineates ten compelling benefits of DC power fans for electronics engineers, underscoring their:

- Energy efficiency

- Quiet operation

- Versatility

- Enhanced control

- Longevity

- Environmental benefits

- Smart integration

- Cost-effectiveness

- Ease of installation

These advantages firmly establish DC power fans as superior alternatives to AC fans. They not only diminish operational costs and environmental impact but also elevate overall performance and user comfort across diverse electronic applications.

Introduction

In the rapidly evolving landscape of electronics, the demand for efficient cooling solutions has reached unprecedented levels. DC power fans have emerged as a transformative solution for electronics engineers, delivering numerous benefits that enhance performance, sustainability, and user experience. As engineers grapple with the intricacies of thermal management, a critical question arises: how can these innovative fans not only optimize energy consumption but also facilitate quieter, more versatile applications across diverse industries? Delving into the advantages of DC power fans presents a compelling argument for their integration into contemporary electronic designs.

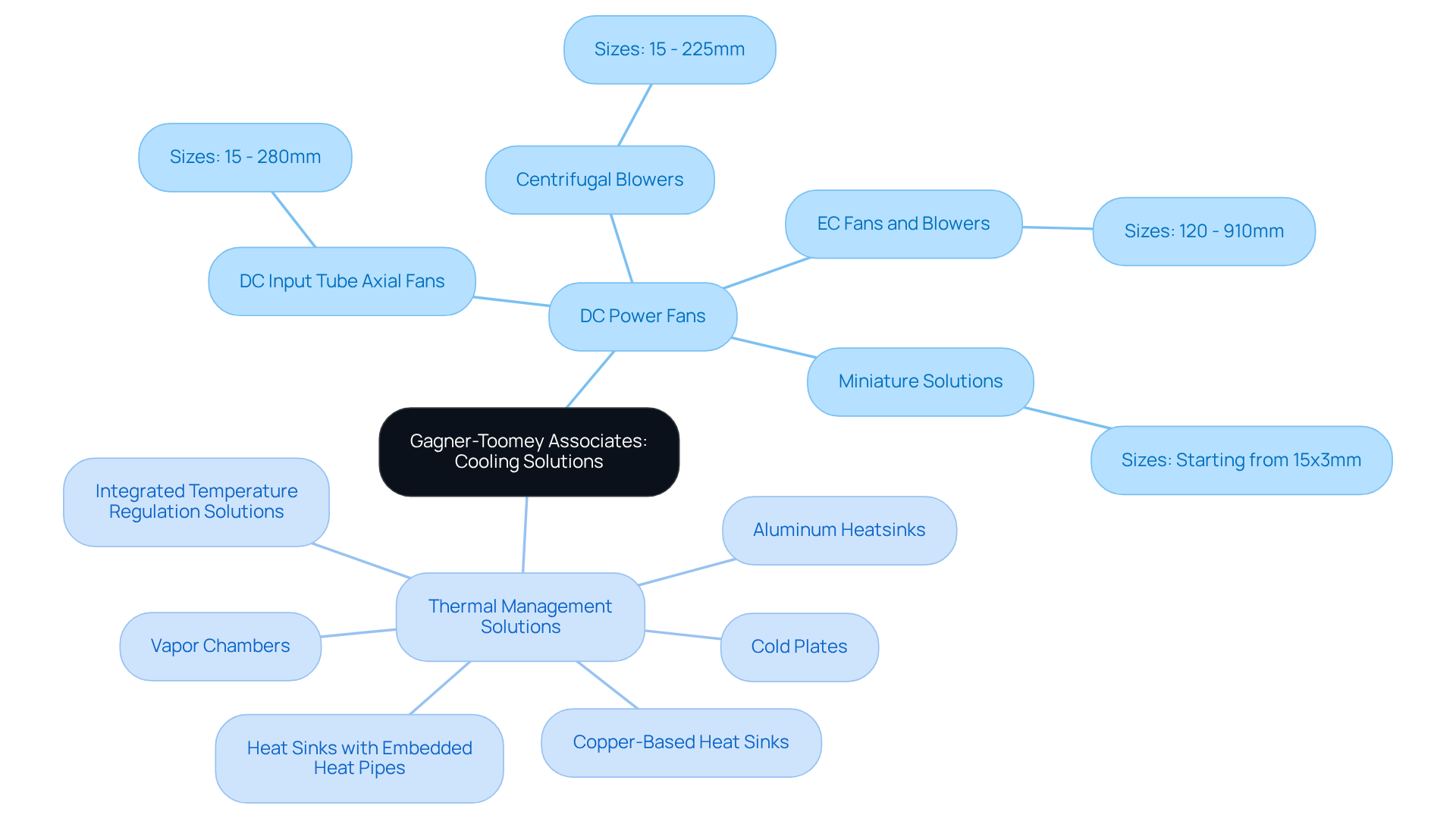

Gagner-Toomey Associates: Innovative Cooling Solutions for Electronics Design

Gagner-Toomey Associates stands at the forefront of innovative temperature control solutions specifically tailored for the electronics industry. By optimizing performance and efficiency, the company showcases a diverse portfolio of manufacturers specializing in both standard and custom DC power fans. The dc power fan plays a critical role in effective thermal management within electronic systems, ensuring devices operate within safe temperature ranges, thereby enhancing overall reliability and performance.

Product Offerings:

- DC Input Tube Axial Fans: Sizes ranging from 15 – 280mm.

- Centrifugal Blowers: Sizes ranging from 15 – 225mm.

- EC Fans and Blowers: Ranging in size from 120-910mm.

- Miniature Solutions: Standard and custom designs starting from 15x3mm.

- Thermal Management Solutions: Including extruded aluminum heatsinks, copper-based heat sinks, heat sinks with embedded heat pipes, vapor chambers, cold plates, and integrated temperature regulation solutions.

Utilizing advanced technologies and a consultative approach, Gagner-Toomey Associates empowers engineers to tackle intricate thermal challenges, fostering trust in electronics design. Their unwavering dedication to customer-focused service, coupled with robust connections to key decision-makers across various sectors, further solidifies their reputation as a leading sales organization delivering innovative solutions in cooling, energy management, and RF technologies.

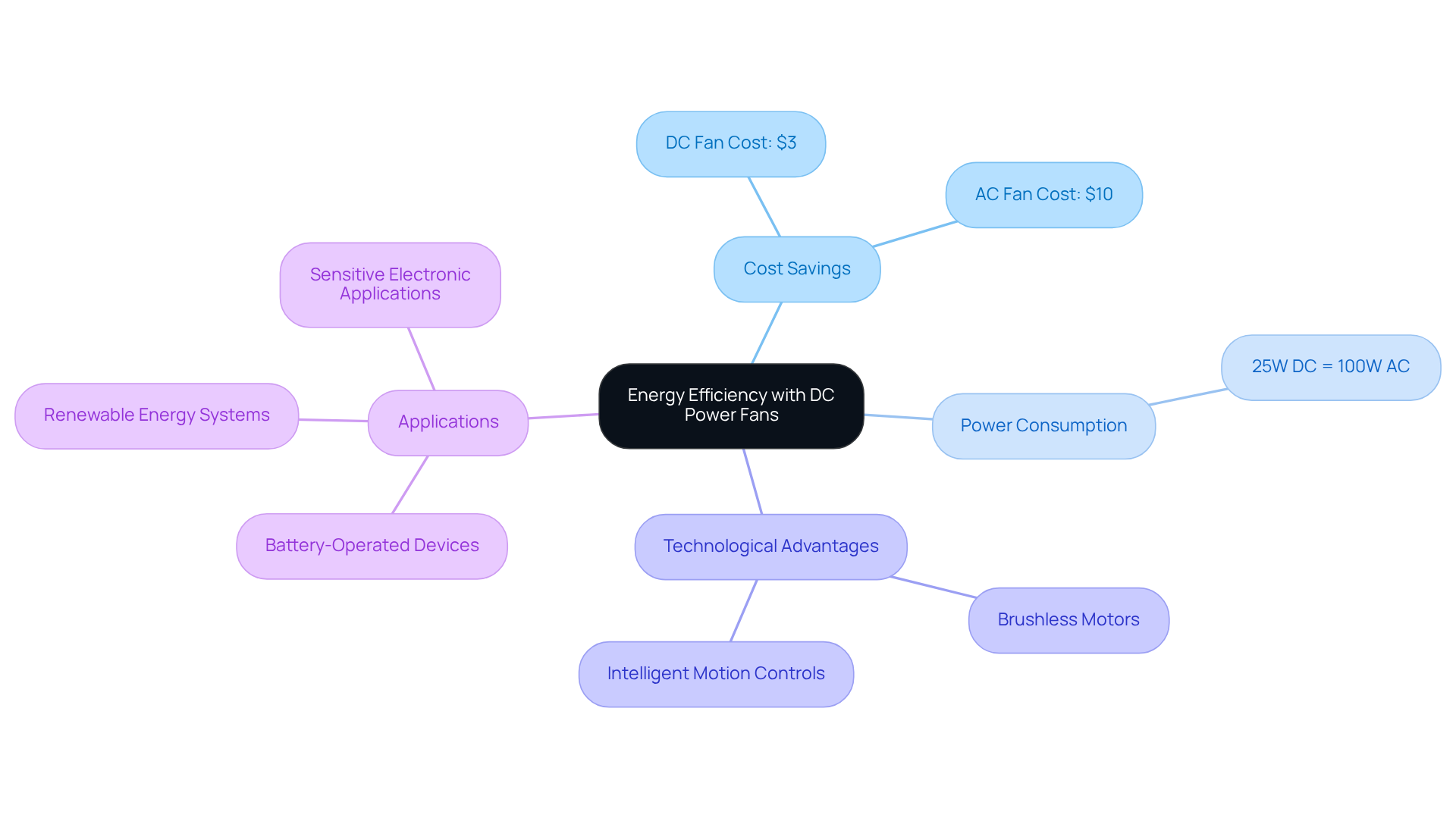

Energy Efficiency: Lower Power Consumption with DC Power Fans

Gagner-Toomey Associates’ DC units are engineered for exceptional energy conservation, utilizing significantly less electricity compared to their AC counterparts. This efficiency stems from the integration of brushless motors alongside advanced electronic controls, which effectively minimize energy waste. By implementing Gagner-Toomey’s DC power fan technology, engineers can substantially reduce the energy footprint of their designs, leading to lower operational costs and a diminished environmental impact. This is particularly advantageous in scenarios where energy efficiency is paramount, such as in battery-operated devices and renewable energy systems.

For example, employing a DC power fan like the Gagner-Toomey model incurs an electricity cost of up to $3, whereas an AC fan costs $10 for equivalent airflow, demonstrating a remarkable reduction in power consumption. Furthermore, a 25-watt Gagner-Toomey DC power fan can provide the same airflow as a 100-watt AC fan. The inclusion of intelligent motion controls in select Gagner-Toomey DC power fan units enhances air circulation while maintaining low energy consumption, making them ideal for sensitive electronic applications.

Gagner-Toomey offers an extensive array of DC input Tube Axial units, ranging from 15 to 280mm, alongside a comprehensive selection of DC input Centrifugal Blowers, available in sizes from 15 to 225mm, including the DC power fan, with IP protection options accessible in most models upon request. As the demand for energy-efficient solutions escalates, Gagner-Toomey’s dedication to the DC power fan technology is increasingly recognized as vital for sustainable development within the electronics industry.

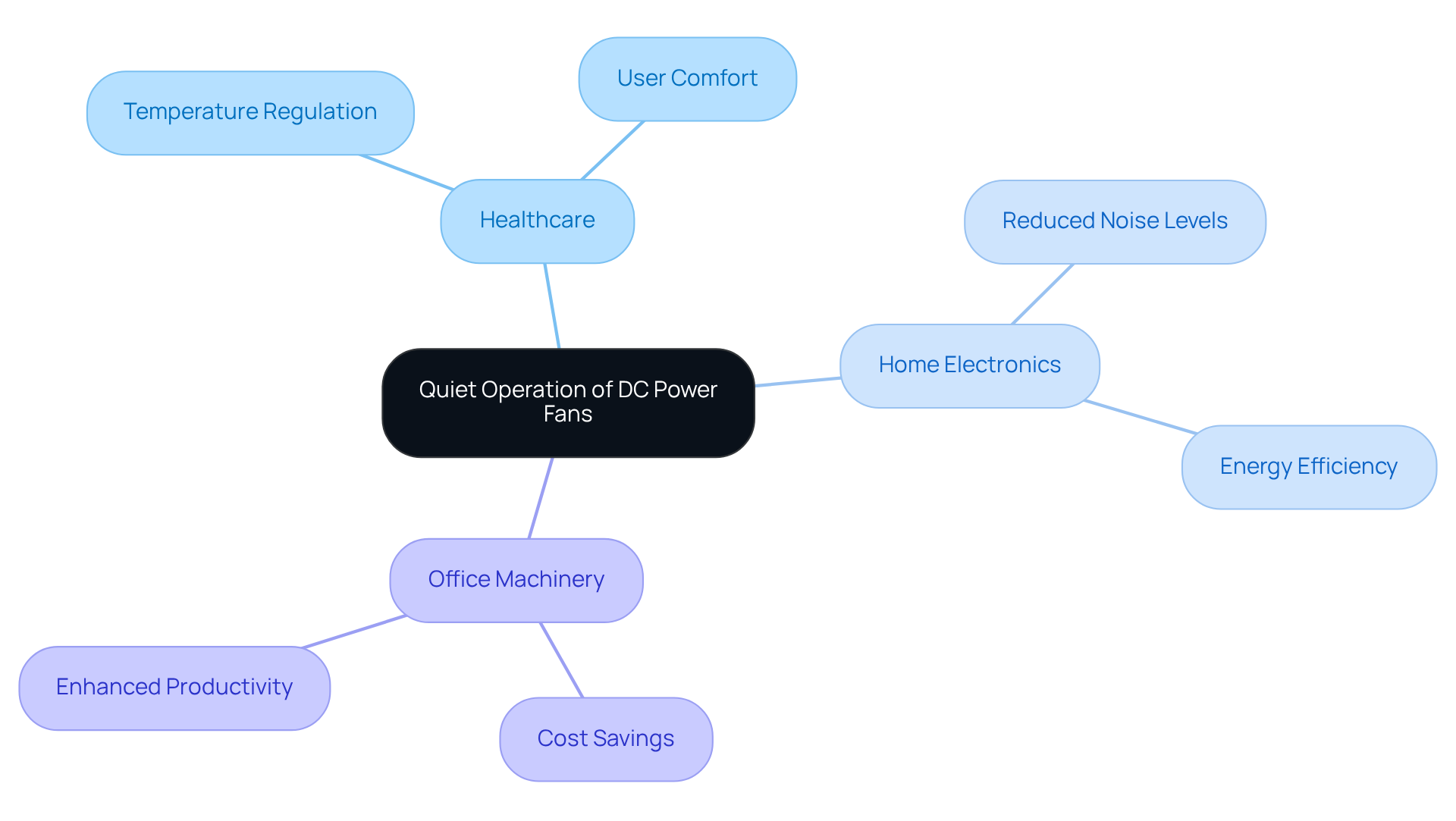

Quiet Operation: Reduced Noise Levels with DC Power Fans

DC power fans are notable for their exceptionally quiet operation, distinguishing them from traditional AC models. This advanced motor technology in DC power fans significantly reduces operational noise, making them particularly suitable for environments where sound levels are critical—such as medical equipment, home electronics, and office machinery.

In healthcare settings, maintaining a tranquil atmosphere is essential; engineers have noted that the silent operation of DC power fans facilitates efficient temperature regulation without causing disturbances to patients or staff. As Dave Leon, owner of Planet Fitness, remarked, “Big Ass Fans help us to cut down on our air conditioning load and our utility bill. We cut 15 percent off our bill at a time when everybody else is seeing a 20 percent increase.”

This capability is further enhanced by noise reduction technologies integrated into these devices, such as a dc power fan, achieving noise levels as low as 20 dBA, which significantly improves user comfort. Engineers consistently stress the importance of acoustic comfort in electronic designs, asserting that quieter operation from a dc power fan can lead to enhanced user satisfaction and improved product performance.

Consequently, DC enthusiasts not only provide efficient cooling solutions using a dc power fan but also foster a more pleasant and productive environment.

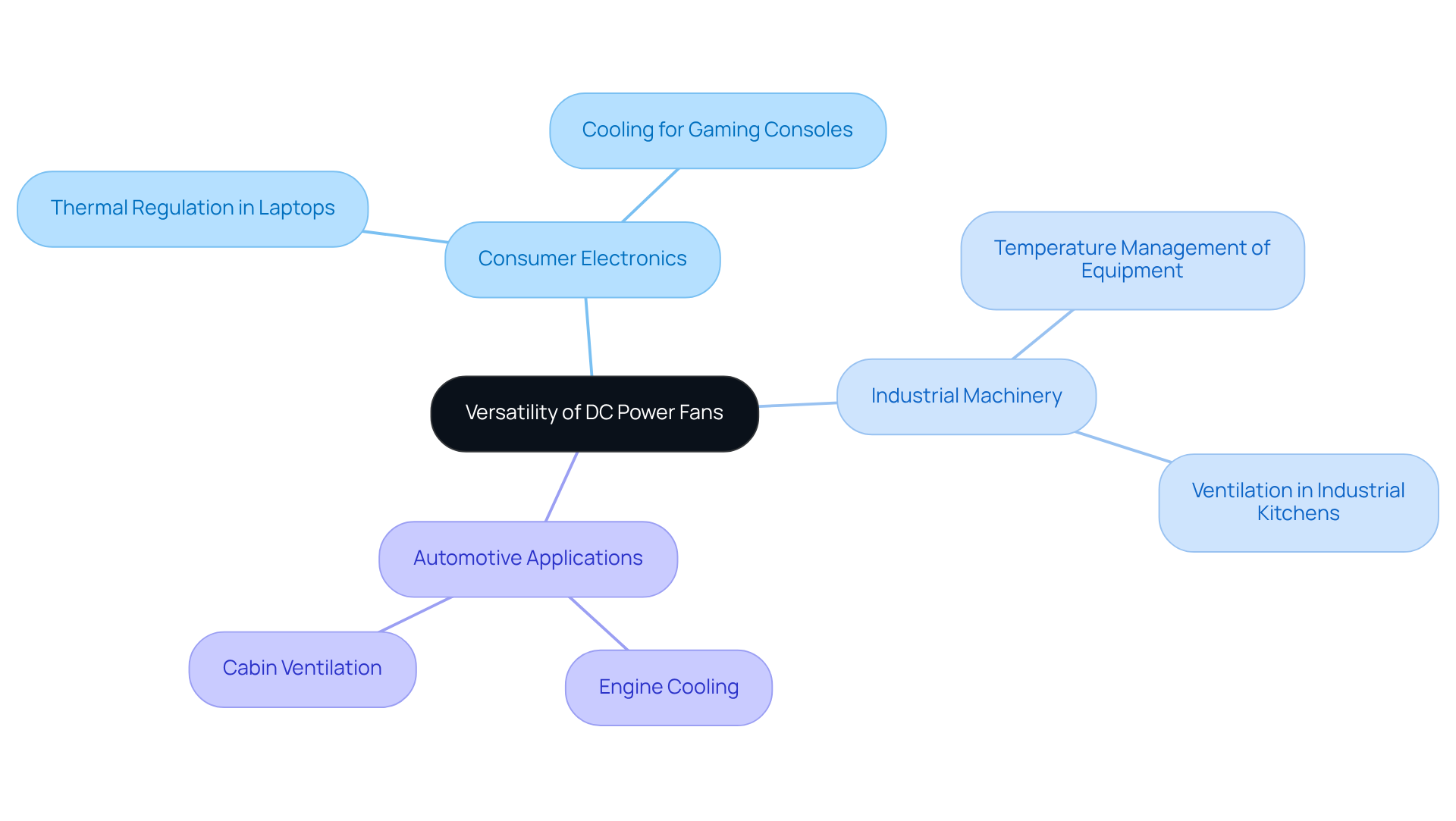

Versatility: Wide Range of Applications for DC Power Fans

DC power fans are remarkably versatile, finding applications across a spectrum of industries, including consumer electronics and industrial machinery. Their efficiency at varying voltage levels makes the DC power fan ideal for use in devices such as computers, servers, HVAC systems, and automotive applications. This adaptability not only enables innovative temperature control solutions but also ensures optimal performance in diverse environments.

For instance, in consumer electronics, DC blowers are essential for maintaining thermal regulation in laptops and gaming consoles. In industrial settings, they play a critical role in the temperature management of machinery and equipment. Furthermore, automotive systems utilize a DC power fan for effective engine cooling and cabin ventilation, underscoring the crucial role of these fans in enhancing performance and reliability.

As industry leaders emphasize, the ability of DC supporters to seamlessly integrate into various systems highlights their significance in contemporary engineering solutions. According to WEG, ‘WECM – WEG Electronically Commutated Motors have been designed to meet various types of motor fan applications such as exhaust and ventilation systems for poultry farms, parking lots, tunnels, industrial kitchens, and applications that require safety and reliability.’

Moreover, the increasing market demand for direct current cooling devices in consumer electronics illustrates their essential role in energy conservation and sustainability initiatives, as evidenced by programs such as the City of Ann Arbor’s commitment to reducing emissions through electrification.

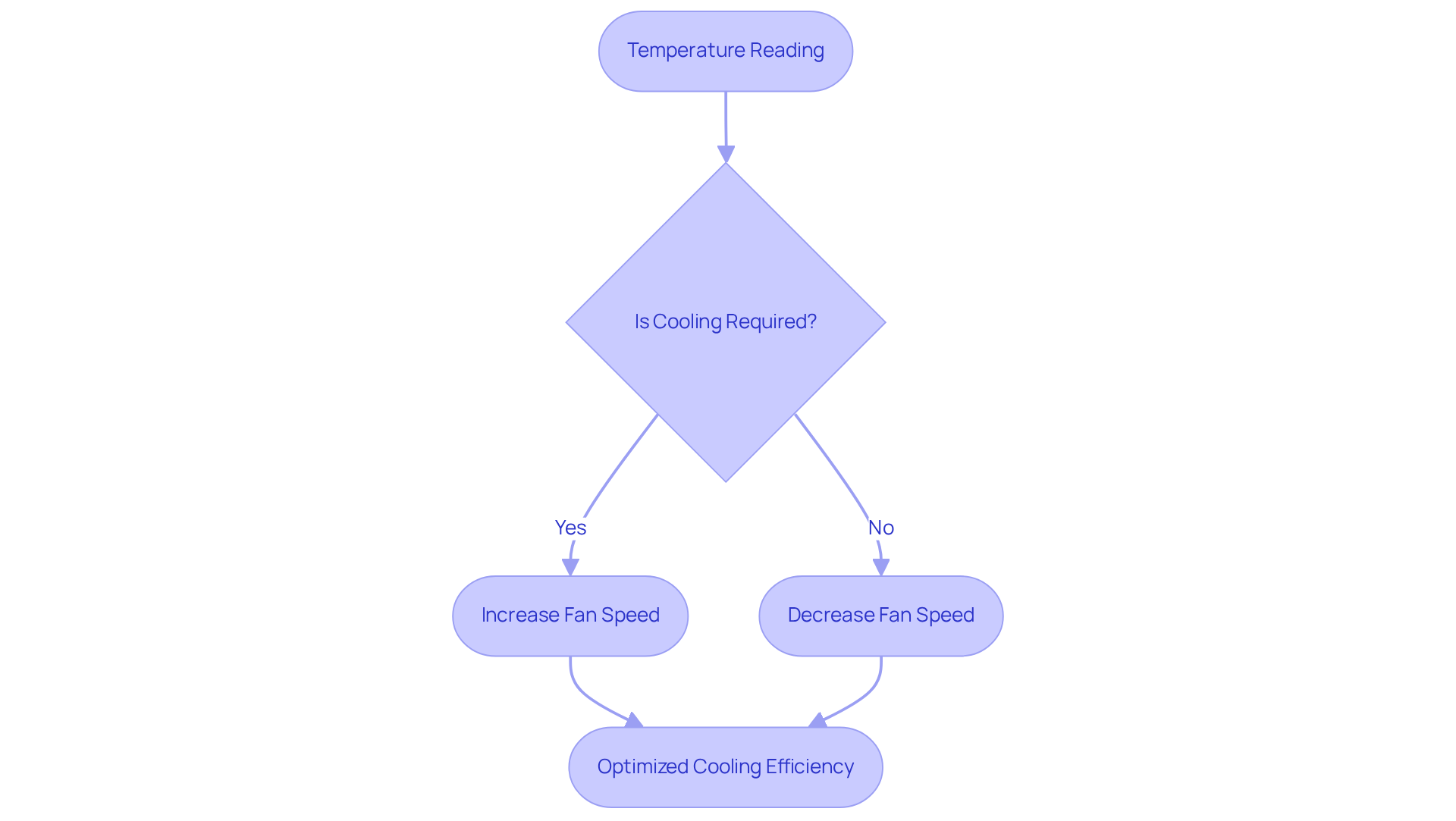

Enhanced Control: Advanced Speed and Flow Management with DC Power Fans

DC electrical devices significantly enhance speed and flow management features, empowering engineers to tailor thermal performance to specific requirements. By employing techniques such as pulse-width modulation (PWM) control, engineers can dynamically adjust fan speeds in response to temperature readings or system demands. This not only optimizes cooling efficiency but also contributes to energy savings by reducing fan speed when full capacity is unnecessary. Such control mechanisms are essential for sustaining optimal operating conditions in sensitive electronic applications.

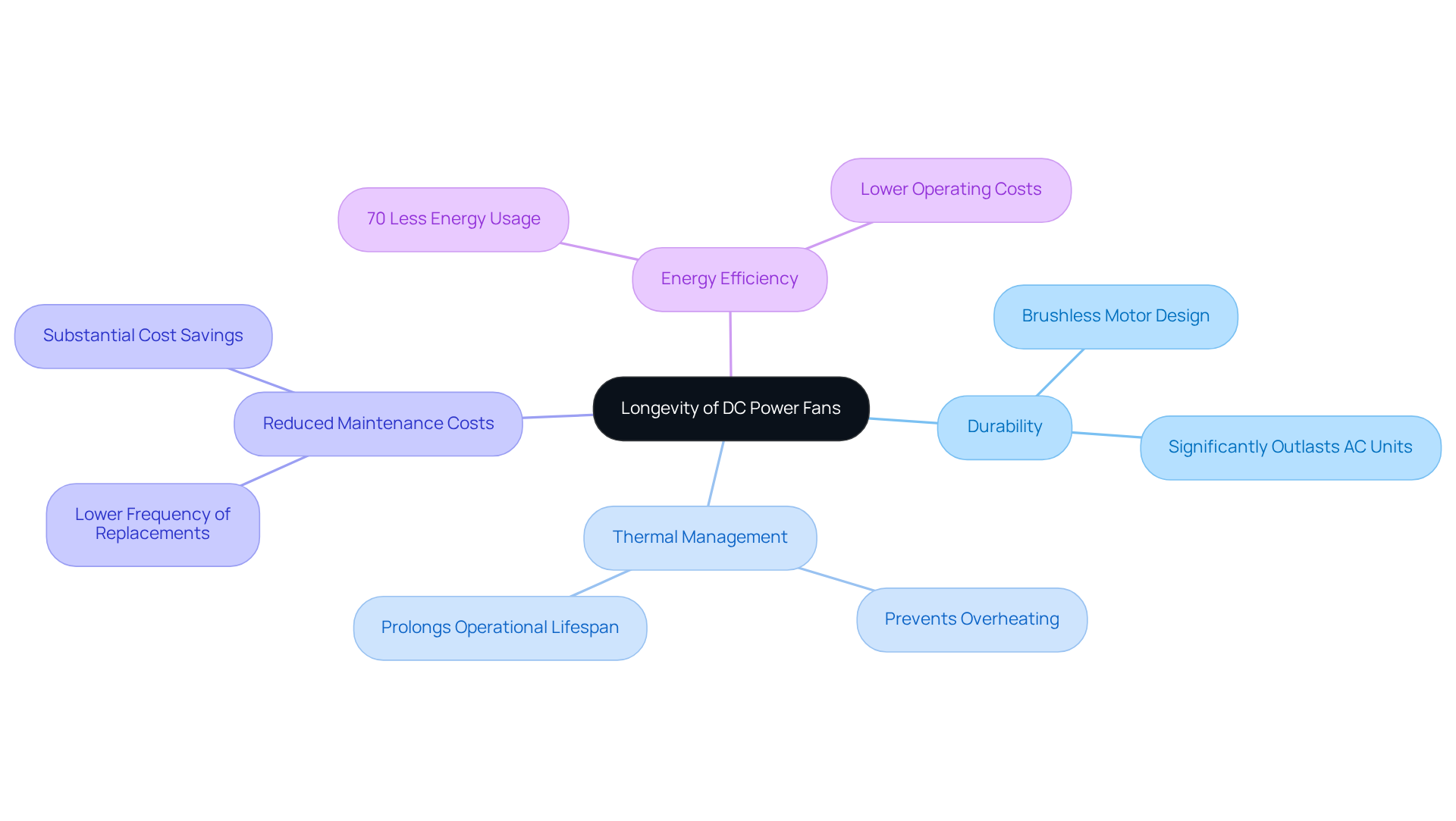

Longevity: Increased Lifespan of DC Power Fans

DC power fans are notable for their remarkable durability, significantly outlasting traditional AC units. This resilience is attributed to their brushless motor design, which effectively reduces wear and tear commonly associated with mechanical brushes. Moreover, enthusiasts of the DC power fan excel in thermal management, adeptly preventing overheating and thus prolonging their operational lifespan. For engineers, this translates into substantial reductions in maintenance costs and a decreased frequency of replacements, positioning DC devices as a dependable choice for long-term applications.

Industry leaders emphasize that the reduced maintenance expenses associated with brushless DC devices can yield considerable financial benefits over time. As Sam Pelonis notes, “DC enthusiasts utilize up to 70 percent less energy to generate the same output as conventional AC types,” further underscoring their value across various electronic applications.

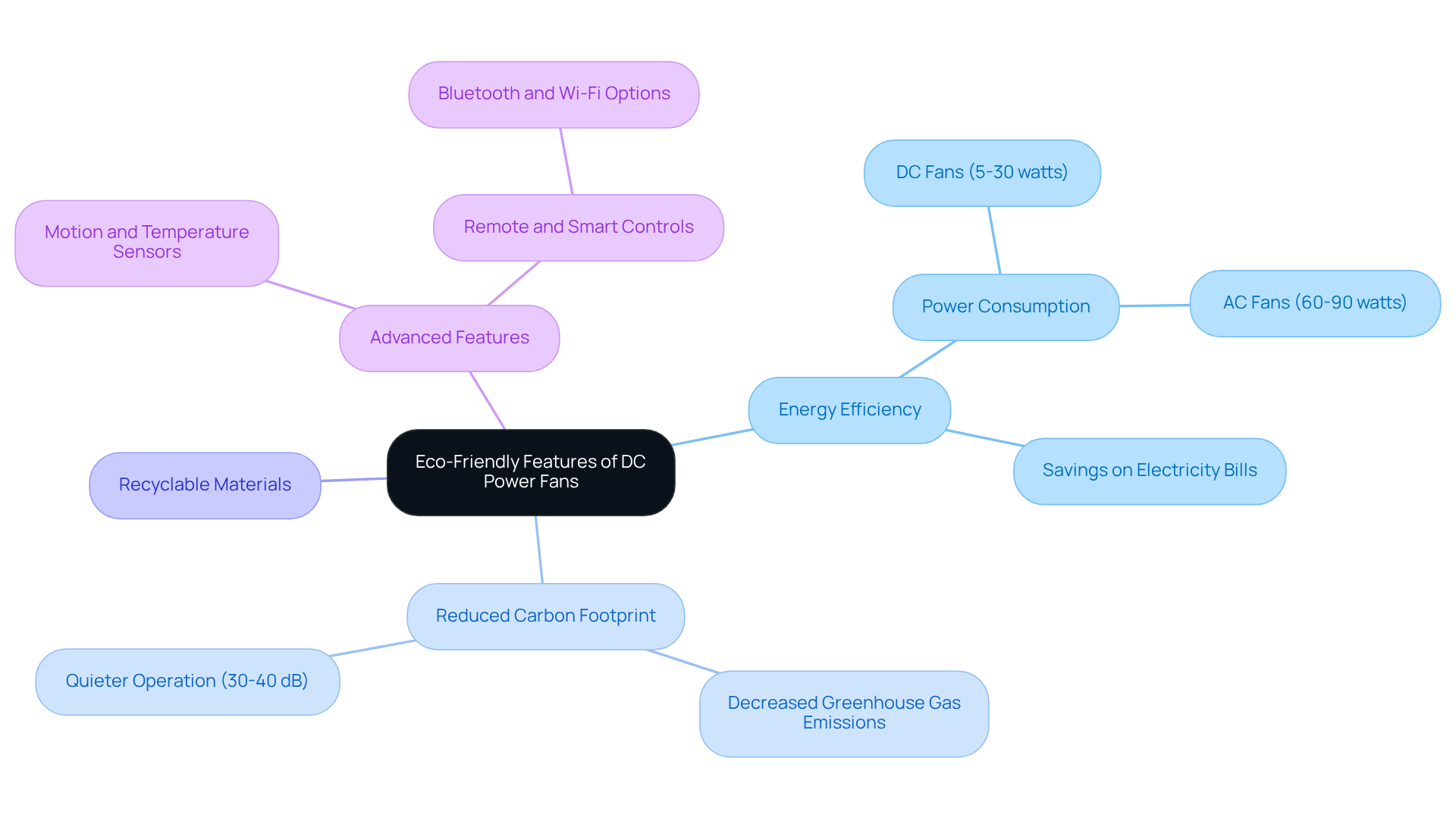

Environmental Benefits: Eco-Friendly Features of DC Power Fans

DC energy devices are pivotal in enhancing environmental sustainability, characterized by their energy-efficient operation and significantly reduced carbon footprint. Offered by Gagner-Toomey Associates, these devices typically consume between 5-30 watts, compared to the 60-90 watts used by traditional AC units. This difference not only leads to substantial savings on electricity bills but also diminishes greenhouse gas emissions associated with power production. Such a lower power draw not only benefits users financially but also fosters a greener home environment.

Gagner-Toomey Associates provides an extensive selection of DC input Tube Axial devices (ranging from 15 – 280mm) and Centrifugal Blowers (from 15 – 225mm), all optimized for performance, efficiency, and minimal noise. Many modern DC models are constructed from recyclable materials, further enhancing their eco-friendly profile. Furthermore, premium models often feature advanced capabilities, including:

- Motion and temperature sensors that adjust airflow based on room occupancy and temperature.

- Remote or wall controllers, with some models offering Bluetooth and Wi-Fi options for enhanced user convenience.

Engineers focused on sustainability can confidently select DC power fans from Gagner-Toomey Associates as a responsible cooling solution. As one engineer noted, these devices provide exceptional value for money while operating quietly, making them ideal for nighttime use. Operating at a noise level of approximately 30-40 dB, DC units are particularly suitable for bedrooms, nurseries, and meditation spaces. The synergy of energy efficiency, reduced operational noise, and sustainable materials positions DC devices as a premier choice for environmentally conscious designs within the electronics sector.

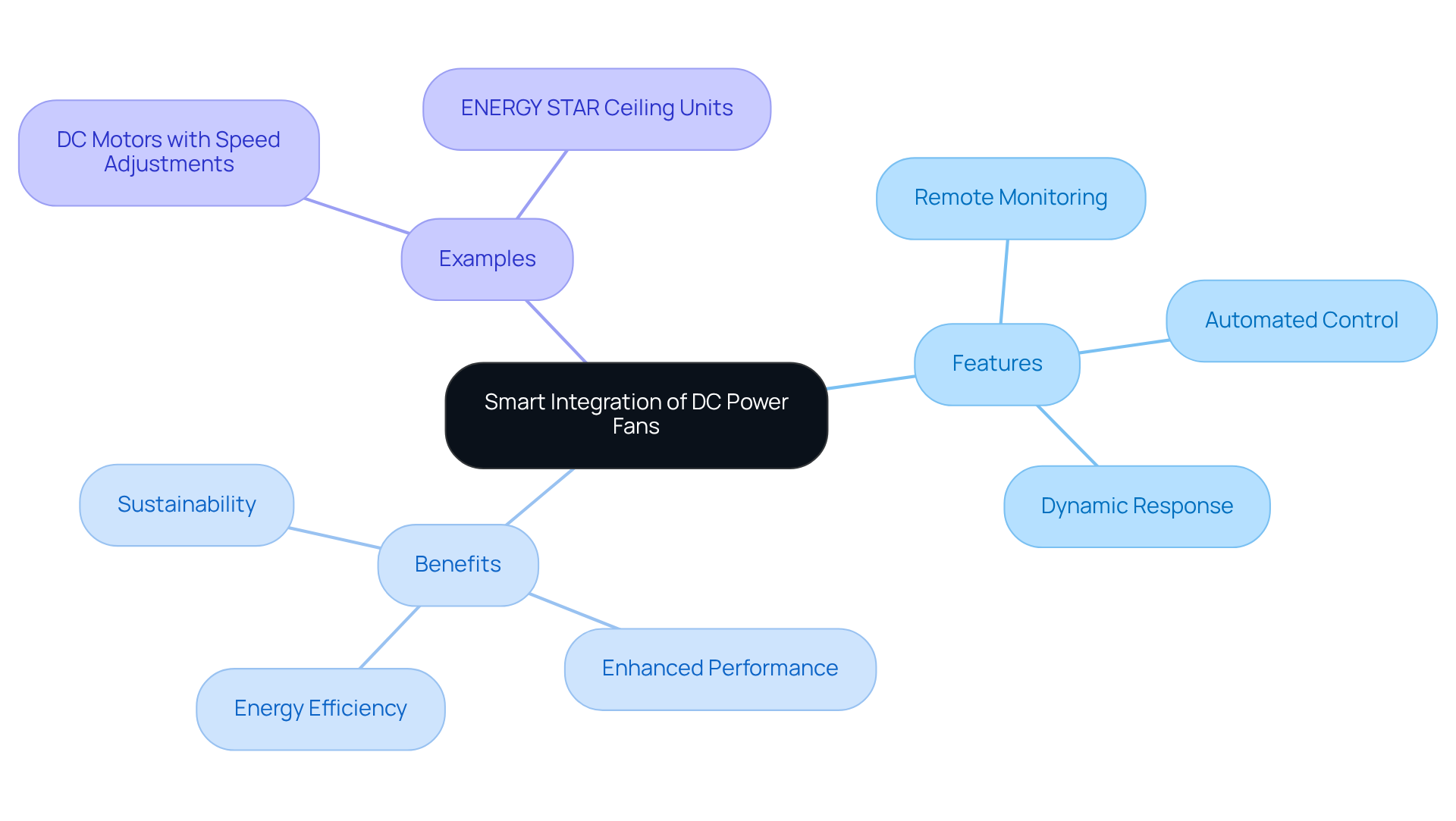

Smart Integration: Incorporating Technology with DC Power Fans

DC power fans are increasingly being integrated with smart technologies, enabling features such as remote monitoring and automated control. This integration presents a solution to the challenge of effective temperature regulation, allowing engineers to develop intelligent temperature control systems that dynamically respond to real-time data. Such systems enhance performance in accordance with environmental conditions.

For instance, contemporary DC motors can automatically adjust their speed based on temperature fluctuations, ensuring effective temperature regulation while significantly reducing energy consumption. This capability proves particularly advantageous in applications requiring precision and adaptability, such as those that involve a DC power fan in sensitive electronic environments.

Recent advancements in DC axial ventilation technology, including aerodynamic blade designs and energy-efficient motors, have yielded notable efficiency improvements. ENERGY STAR ceiling units, for example, achieve energy savings of up to 64% compared to traditional models.

Industry leaders assert that the future of cooling systems is rooted in these intelligent integrations, which not only enhance user comfort but also support sustainability efforts by minimizing electricity usage.

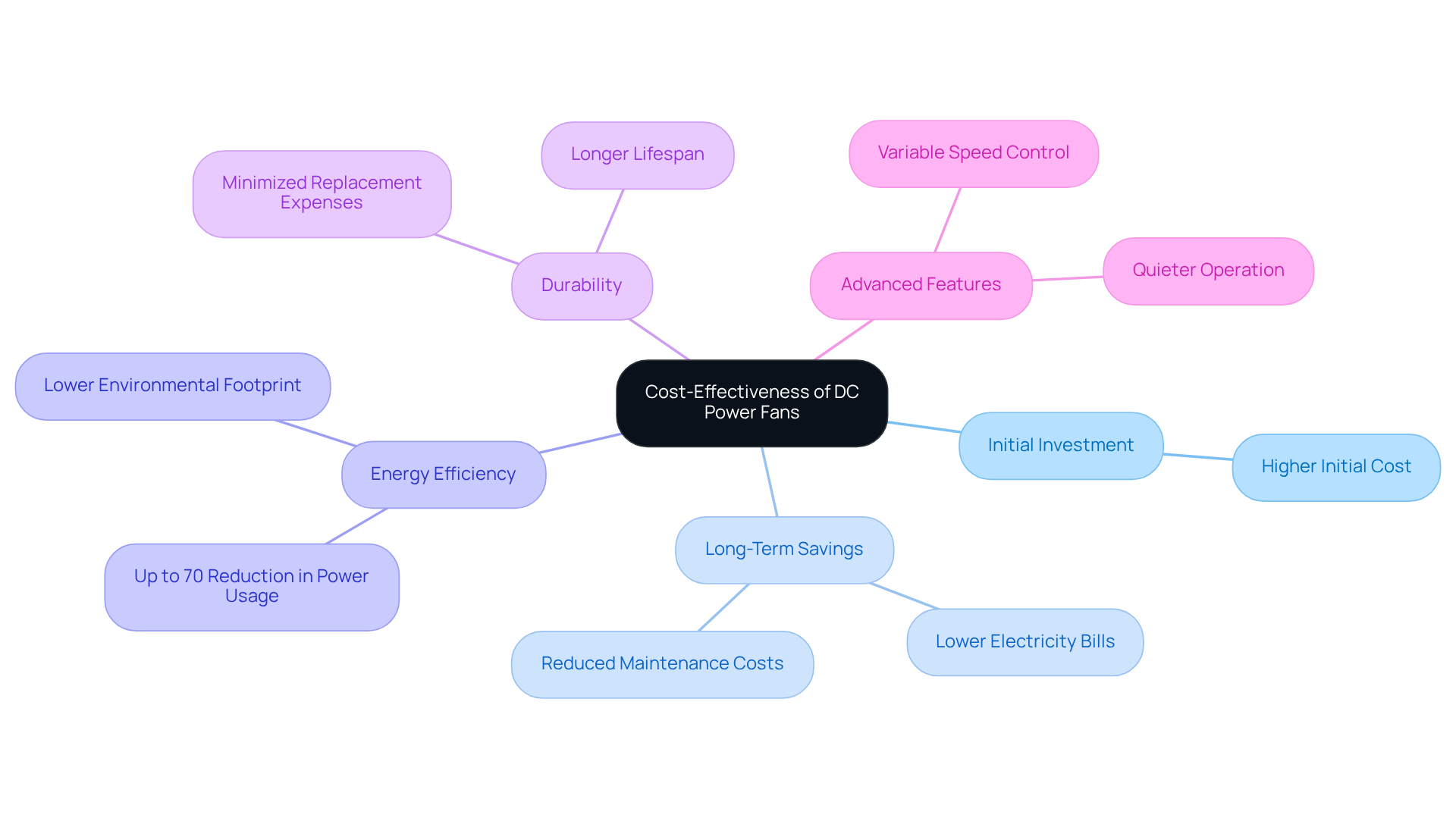

Cost-Effectiveness: Budget-Friendly Solutions with DC Power Fans

While the initial investment in DC power fan units may surpass that of traditional AC models, the long-term cost savings position them as a financially prudent choice. Their superior energy efficiency translates to reduced electricity bills, while their robust durability minimizes maintenance and replacement expenses. Furthermore, the advanced features of the DC power fan—such as variable speed control and quieter operation—contribute to enhanced system performance, solidifying its value proposition. Engineers can effectively justify the upfront costs by evaluating the total cost of ownership throughout the fan’s operational lifespan.

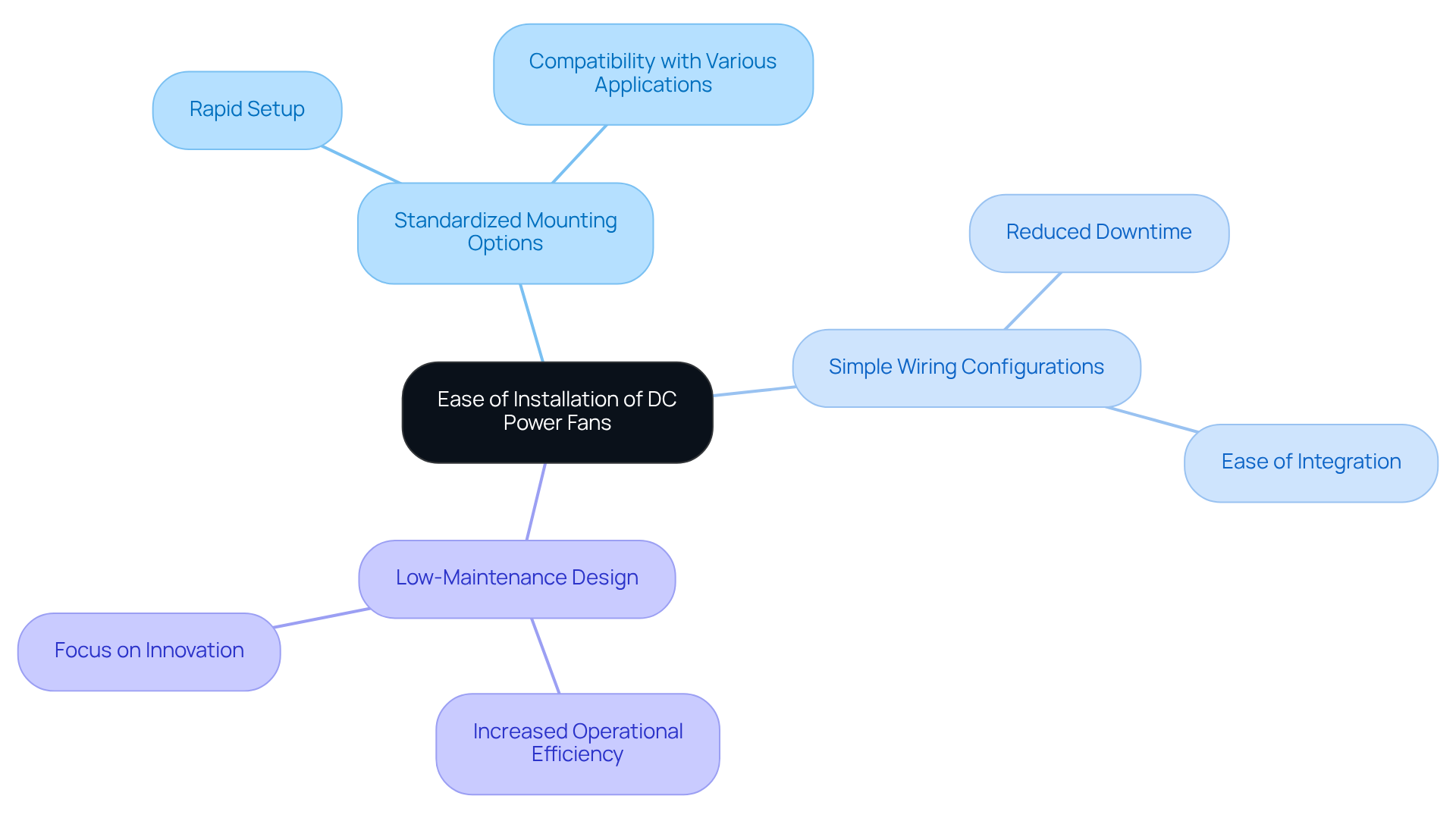

Ease of Installation: Simplified Setup and Maintenance of DC Power Fans

DC motors are engineered for straightforward installation and maintenance, establishing them as a preferred choice among engineers. Many models feature standardized mounting options and simple wiring configurations, which facilitate rapid setup across a variety of applications. Their low-maintenance design empowers engineers to devote less time to upkeep, allowing for a greater focus on innovation. This practicality proves especially advantageous in dynamic development environments where efficiency is crucial.

For instance, engineers have noted that the simplicity of DC electrical devices significantly reduces downtime during maintenance, enabling seamless integration into existing systems. Data indicates that maintenance tasks for DC units can be completed in a fraction of the time compared to traditional AC units, further emphasizing their effectiveness.

Ultimately, the maintenance ease associated with the DC power fan not only boosts operational efficiency but also fosters the ongoing advancement of engineering projects.

Conclusion

DC power fans embody a transformative technology for electronics engineers, presenting numerous advantages that significantly bolster the performance and efficiency of electronic systems. Their capacity for quiet operation, reduced energy consumption, and versatile applications positions them as an optimal choice across diverse industries. The integration of DC power fans into designs not only enhances thermal management but also promotes sustainable practices within the electronics sector.

Key insights throughout the article highlight:

- The energy efficiency of DC power fans in comparison to traditional AC models

- Their diminished noise levels

- Their adaptability across various applications

Moreover, the advanced control features, longevity, and straightforward installation associated with DC power fans emphasize their practicality and economic viability. As engineers increasingly prioritize eco-friendly solutions, the significance of DC power fans escalates in achieving both performance and sustainability objectives.

In summary, adopting DC power fan technology is not merely a choice but a strategic decision for engineers dedicated to innovation and efficiency. The incorporation of these fans into electronic designs facilitates enhanced performance, lowers operational costs, and fosters a commitment to environmental responsibility. As the electronics landscape continues to evolve, harnessing the benefits of DC power fans will undoubtedly contribute to a more sustainable and efficient future in technology.

Frequently Asked Questions

What is Gagner-Toomey Associates known for?

Gagner-Toomey Associates specializes in innovative temperature control solutions for the electronics industry, focusing on optimizing performance and efficiency through a diverse portfolio of DC power fans.

What types of fans does Gagner-Toomey Associates offer?

They offer several types of fans, including DC Input Tube Axial Fans (15 – 280mm), Centrifugal Blowers (15 – 225mm), EC Fans and Blowers (120 – 910mm), and Miniature Solutions starting from 15x3mm.

What thermal management solutions does Gagner-Toomey provide?

Their thermal management solutions include extruded aluminum heatsinks, copper-based heat sinks, heat sinks with embedded heat pipes, vapor chambers, cold plates, and integrated temperature regulation solutions.

How do Gagner-Toomey’s DC power fans contribute to energy efficiency?

Gagner-Toomey’s DC power fans use brushless motors and advanced electronic controls to minimize energy waste, resulting in significantly lower power consumption compared to AC fans. For example, a 25-watt DC fan can provide the same airflow as a 100-watt AC fan.

What are the cost savings associated with using Gagner-Toomey’s DC power fans?

Using a Gagner-Toomey DC power fan can incur an electricity cost of about $3, while an equivalent AC fan costs around $10, demonstrating a significant reduction in operational costs.

How do DC power fans impact noise levels?

DC power fans are designed for exceptionally quiet operation, with noise levels as low as 20 dBA, making them suitable for environments where sound levels are critical, such as medical equipment and office machinery.

Why is quiet operation important in certain environments?

In settings like healthcare, silent operation of DC power fans helps maintain a tranquil atmosphere, facilitating efficient temperature regulation without disturbing patients or staff.

What advantages do Gagner-Toomey’s DC power fans offer in electronic design?

Their DC power fans provide efficient cooling solutions while enhancing user comfort through reduced noise levels, which can lead to improved product performance and user satisfaction.