Overview

This article presents best practices for selecting super silent fans in electronics, highlighting essential criteria such as sound level, air movement capacity, energy efficiency, and durability. It begins by addressing the challenge of choosing the right fan, then expands on specific factors to consider, including the fan’s operating conditions and performance metrics. By providing a comprehensive framework, the article equips engineers with the necessary tools to select fans that not only enhance user comfort but also meet stringent technical requirements.

Introduction

Selecting the right silent fan is crucial for enhancing the functionality and comfort of electronic systems, yet this process often presents challenges for engineers and designers. As the demand for quieter environments escalates in spaces such as home theaters and offices, it becomes essential to grasp the critical factors involved in choosing super silent fans. This raises pertinent questions:

- What challenges emerge when balancing noise reduction with cooling efficiency?

- How can one adeptly navigate the complexities of fan specifications to ensure optimal performance?

Addressing these inquiries is vital for achieving the desired outcomes in modern electronic applications.

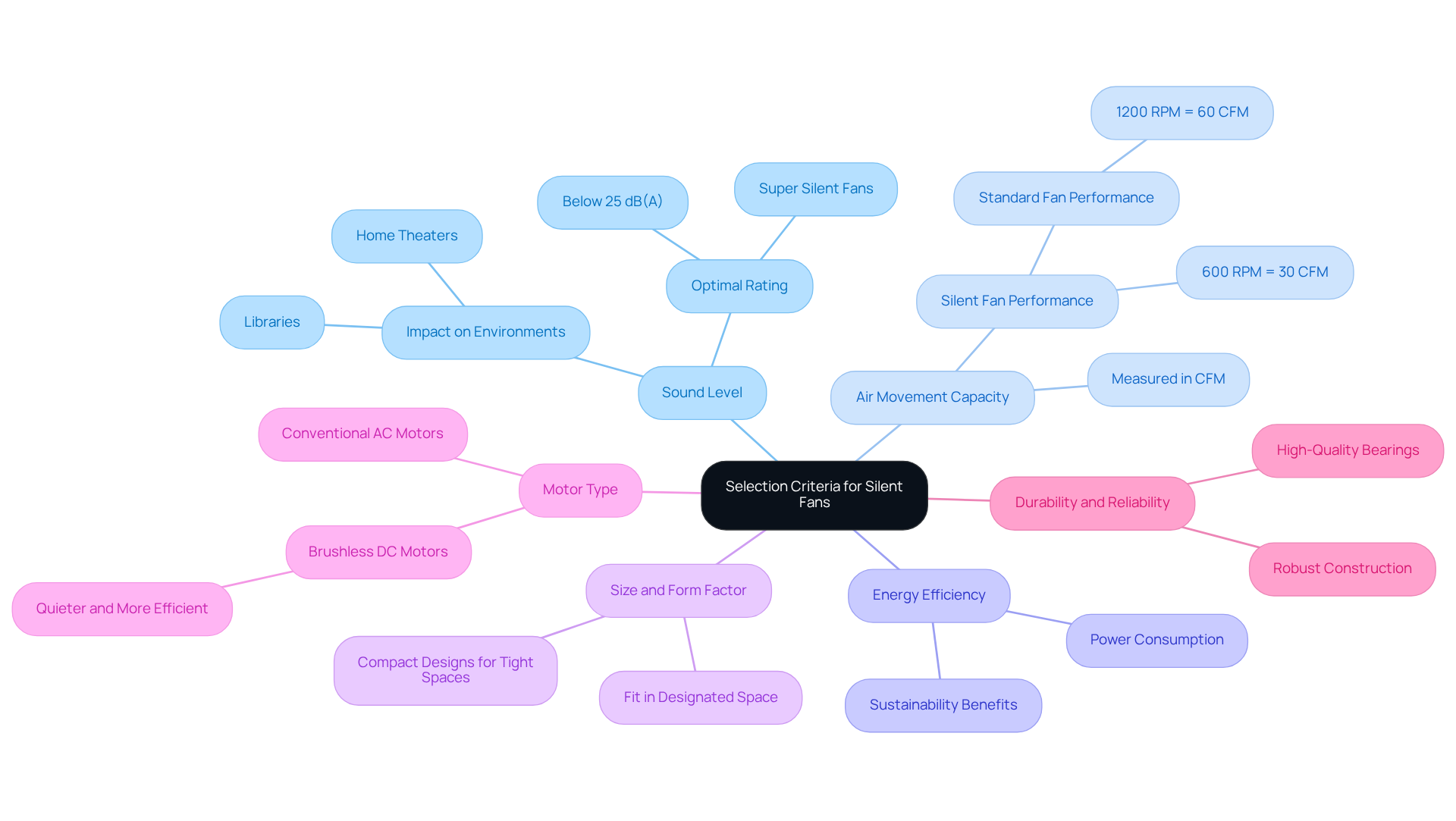

Define Selection Criteria for Silent Fans

When selecting silent fans, it is crucial to consider the following criteria:

- : Aim for with a rating below 25 dB(A) to achieve optimal quiet operation. This is particularly vital in sound-sensitive settings such as home theaters and libraries, where are essential for .

- : Evaluate the fan’s air movement, measured in CFM, to ensure it meets your cooling needs. For instance, a silent fan operating at 600 RPM typically produces around 30 CFM, while a standard fan at 1200 RPM can reach about 60 CFM. Striking a balance between airflow and noise is essential for effective cooling.

- : Choose devices that use less power while providing adequate cooling. Energy-efficient devices not only reduce operational expenses but also aid sustainability efforts, rendering them perfect for contemporary electronic applications.

- Size and Form Factor: Ensure the fan fits within the designated space and adheres to the physical constraints of your application. are often necessary for installations in tight spaces, enhancing versatility.

- Motor Type: are typically quieter and more efficient than conventional AC motors, making them a favored option for silent appliances. Their design helps to lower noise levels while preserving functionality.

- : Choose devices that are designed to endure challenging conditions. Look for features such as and robust construction, which enhance longevity and reliability in various applications.

By thoroughly assessing these criteria, engineers can select super silent fans that not only fulfill operational standards but also enhance user comfort and satisfaction.

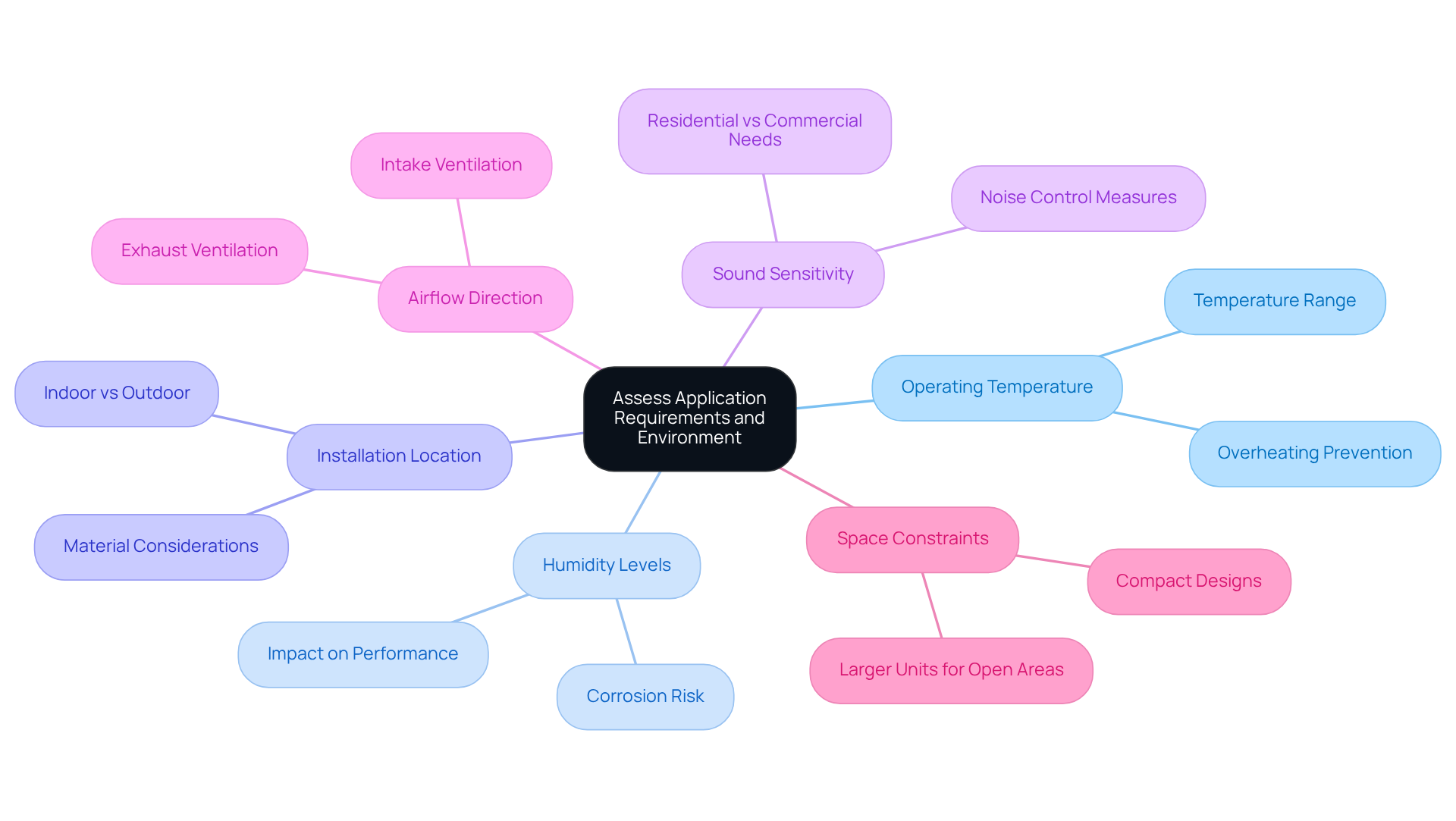

Assess Application Requirements and Environment

To effectively assess application requirements and environment, consider the following critical factors:

- : It is essential to determine the temperature range in which the fan will operate. Fans must be capable of functioning efficiently within these limits to .

- : High can significantly . Ensure the selected fan is rated for the environmental conditions it will encounter.

- : Identify whether the fan will be installed indoors or outdoors, as this decision will influence the choice of materials and design features.

- : Assess the auditory tolerance of the environment. For example, devices located in residential areas or quiet offices necessitate stricter noise control measures.

- Airflow Direction: Consider the . Some applications may require intake ventilation systems, while others may need exhaust ventilation units.

- Space Constraints: Assess the available space for installation. may be necessary for limited spaces, while larger units may be suitable for open areas.

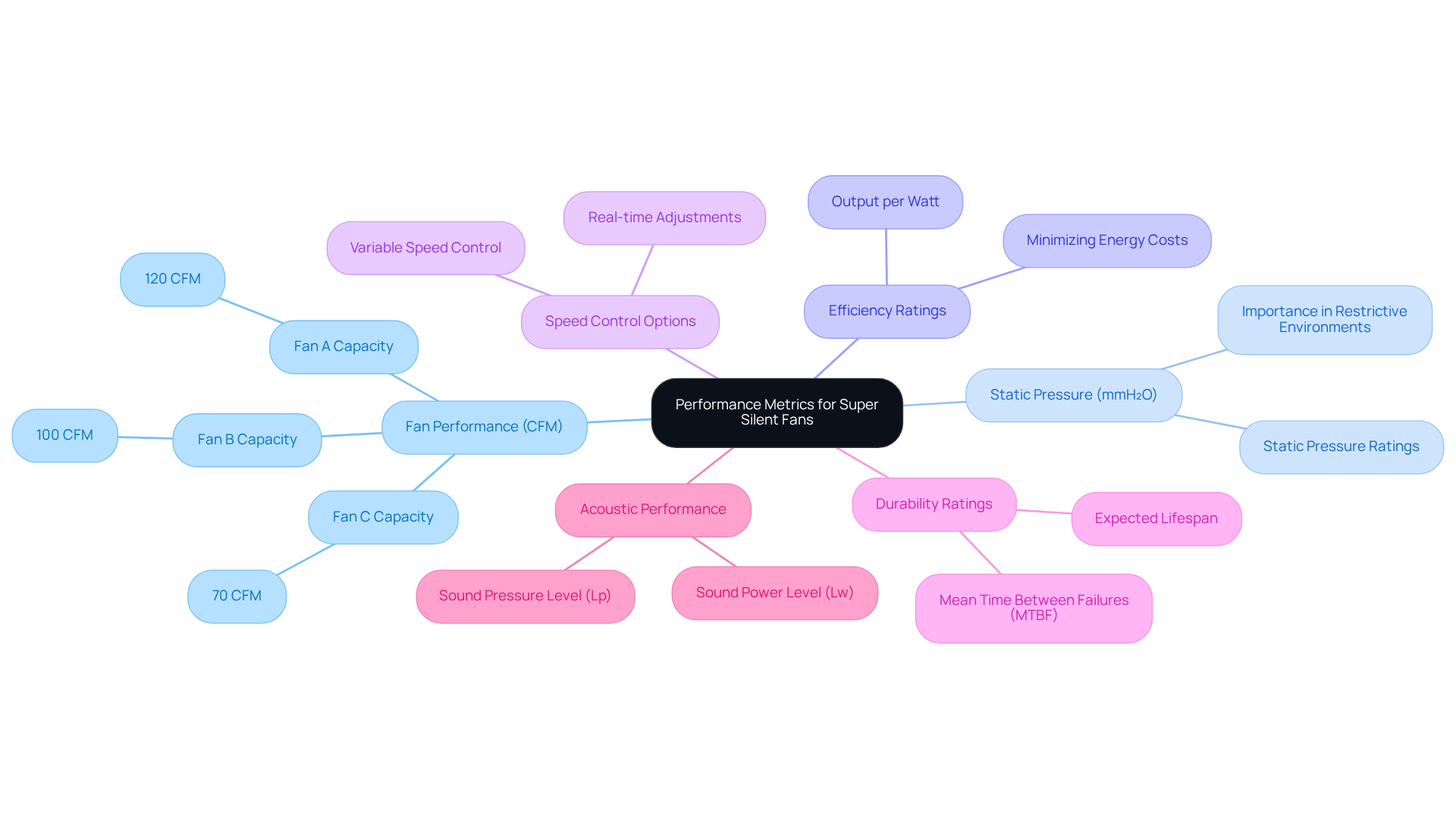

Evaluate Performance Metrics for Optimal Functionality

When evaluating the , considering several key factors that can significantly impact your application is essential.

- Fan Performance (CFM): Begin by evaluating the fan’s capacity, which is measured in cubic feet per minute (CFM). For example, Fan A boasts a capacity of 120 CFM, Fan B offers 100 CFM, and Fan C provides 70 CFM. Ensure that the selected capacity meets the specific of your application, as insufficient ventilation can lead to overheating.

- (mmH₂O): Next, assess the fan’s ability to overcome resistance in the . Elevated static pressure ratings are critical for applications featuring restrictive passageways, such as those with filters or radiators, where air must be forced through dense barriers. As noted by Johann Tang, “It’s important to know that even though maximum values for airflow and static pressure are specified, the fan will not output both maximum values at the same time.”

- : Look for devices that feature high efficiency ratings, which indicate exceptional output per watt of energy consumed. This is particularly vital for minimizing energy costs and enhancing overall system efficiency.

- : Opt for devices equipped with variable speed control. This feature allows for real-time adjustments to airflow based on cooling requirements, thereby improving efficiency while effectively managing sound levels.

- : Investigate the expected lifespan and reliability of the fan, especially in demanding environments. Seek fans with high Mean Time Between Failures (MTBF) ratings to ensure long-term effectiveness.

- Acoustic Performance: Review the fan’s sound power level (Lw) and sound pressure level (Lp) ratings. These metrics are crucial for ensuring that the fan operates within acceptable noise limits, aligning with your project’s .

Moreover, reducing system impedance is vital for optimal fan operation, as emphasized by Comair Rotron. Understanding these performance metrics, along with insights from case studies on air movement and static pressure, will assist engineers in selecting the appropriate for their specific applications.

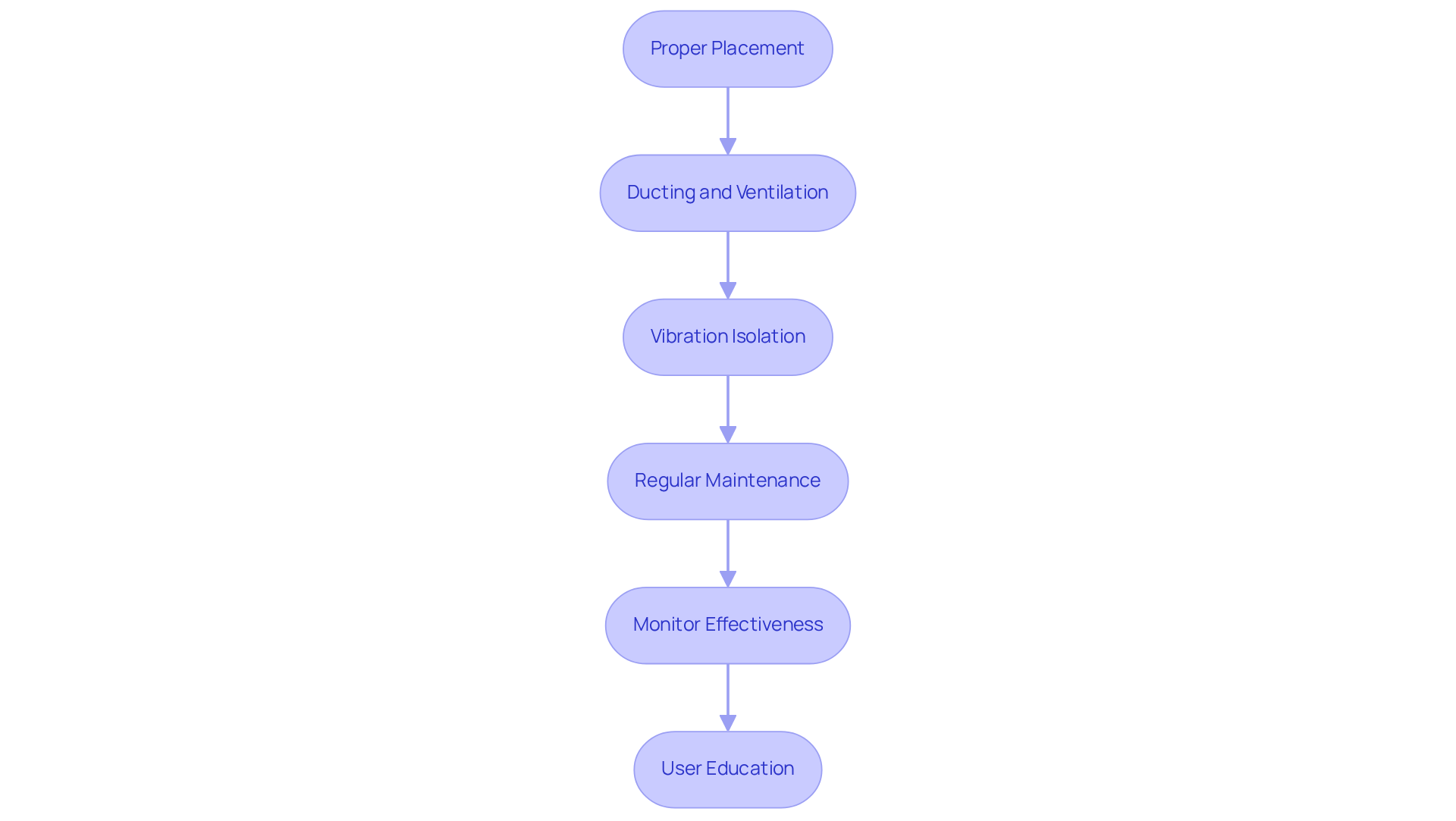

Implement Best Practices for Fan Integration

To effectively integrate into your systems, it is essential to adhere to the following best practices:

- Proper Placement: Strategically arrange ventilators to enhance circulation and . Ensure that intake and exhaust fans are positioned to promote effective air circulation, which is vital for sustaining optimal thermal efficiency.

- Ducting and Ventilation: Install and reduce sound. A thoughtfully constructed duct system can improve and significantly lessen the requirement for elevated fan speeds, resulting in sound reductions of up to 12.5% at lower speeds due to enhanced air movement organization and decreased turbulence. As noted by Sanjay Bhat, “The results show that the duct significantly decreases both average and peak sound levels, with reductions of up to 12.5% at lower fan speeds due to enhanced airflow streamlining and diminished turbulence.”

- : Utilize vibration isolation methods to reduce sound transmission. Employing materials like mass-loaded vinyl or acoustic foam can effectively diminish vibrations that contribute to sound, ensuring a quieter operational environment.

- : Schedule routine maintenance to clean fan blades and inspect for wear. Dust buildup can result in higher sound levels and reduced efficiency, making preventive maintenance crucial for optimal operation. Regular cleaning and lubrication of moving parts are vital, as highlighted in the case study on “Cleaning and Lubrication,” which emphasizes that maintaining a clean and lubricated system results in smoother operation and a quieter home environment.

- Monitor Effectiveness: Utilize and noise levels. This data is invaluable for identifying issues early and informing maintenance schedules, ultimately enhancing system reliability.

- User Education: Educate users on the significance of and proper operation. Understanding the influence of these elements can greatly prolong the longevity and functionality of quiet ventilators, ensuring they operate at . Insights from specialists such as Dale Price underscore that and efficiency of silent devices.

By following these best practices, you can ensure that silent fans are effectively integrated into your electronic systems, enhancing both performance and user comfort.

Conclusion

Selecting super silent fans for electronic applications transcends merely minimizing noise; it necessitates a comprehensive approach that integrates various criteria, application requirements, performance metrics, and best practices for integration. By thoroughly understanding and implementing these factors, engineers can ensure that their selected fans not only operate quietly but also efficiently satisfy the cooling demands of their systems.

Key arguments include:

- The critical importance of sound level

- Air movement capacity

- Energy efficiency

- The specific environmental conditions in which the fans will function

Furthermore, evaluating performance metrics such as CFM, static pressure, and efficiency ratings is essential for identifying the most suitable fan. Adopting best practices for fan integration—such as proper placement, ducting, and regular maintenance—enhances both the functionality and longevity of these silent devices.

Ultimately, the selection and integration of super silent fans are crucial for establishing optimal electronic environments. By prioritizing the best practices outlined and grasping the intricate balance between noise reduction and cooling efficiency, engineers can significantly elevate user comfort and system performance. Embracing these best practices will not only facilitate quieter operations but also contribute to the sustainability and reliability of electronic systems in the future.

Frequently Asked Questions

What sound level should I look for in silent fans?

Aim for silent fans with a sound level rating below 25 dB(A) to ensure optimal quiet operation, especially in sound-sensitive environments like home theaters and libraries.

How is the air movement capacity of a fan measured?

The air movement capacity of a fan is measured in CFM (Cubic Feet per Minute). For example, a silent fan operating at 600 RPM typically produces around 30 CFM, while a standard fan at 1200 RPM can reach about 60 CFM.

Why is energy efficiency important when selecting silent fans?

Energy efficiency is important because it reduces operational expenses and supports sustainability efforts, making energy-efficient fans ideal for modern electronic applications.

How do I determine the appropriate size and form factor for a silent fan?

Ensure the fan fits within the designated space and meets the physical constraints of your application. Compact designs are often necessary for installations in tight spaces.

What type of motor is recommended for silent fans?

Brushless DC motors are recommended as they are typically quieter and more efficient than conventional AC motors, helping to lower noise levels while maintaining functionality.

What features should I look for to ensure durability and reliability in silent fans?

Look for features such as high-quality bearings and robust construction, which enhance the longevity and reliability of the fans in various applications.