Overview

This article provides essential insights that electronics engineers must master regarding heat pipes, which are crucial for effective thermal management in electronic systems. It begins by addressing the operational mechanics of heat pipes, followed by an exploration of the various types and their design considerations. By demonstrating the significance of heat pipes, the article underscores their role in maintaining optimal performance and tackling the increasing thermal challenges presented by modern electronic devices.

Introduction

In the realm of modern electronics, efficient thermal management has become paramount as devices grow more powerful and compact. At the heart of this challenge lies the innovative technology of heat pipes, which utilize the principles of phase change to facilitate rapid heat transfer. These remarkable devices not only enhance the performance of electronic systems but also contribute to energy conservation and environmental sustainability.

As industries increasingly seek effective cooling solutions, understanding the various types of heat pipes, their operational mechanics, and design considerations is essential for engineers aiming to optimize thermal management in their applications.

This article delves into the fundamentals of heat pipes, exploring their diverse applications and the critical factors that influence their integration into electronic systems.

Explore the Fundamentals of Heat Pipes

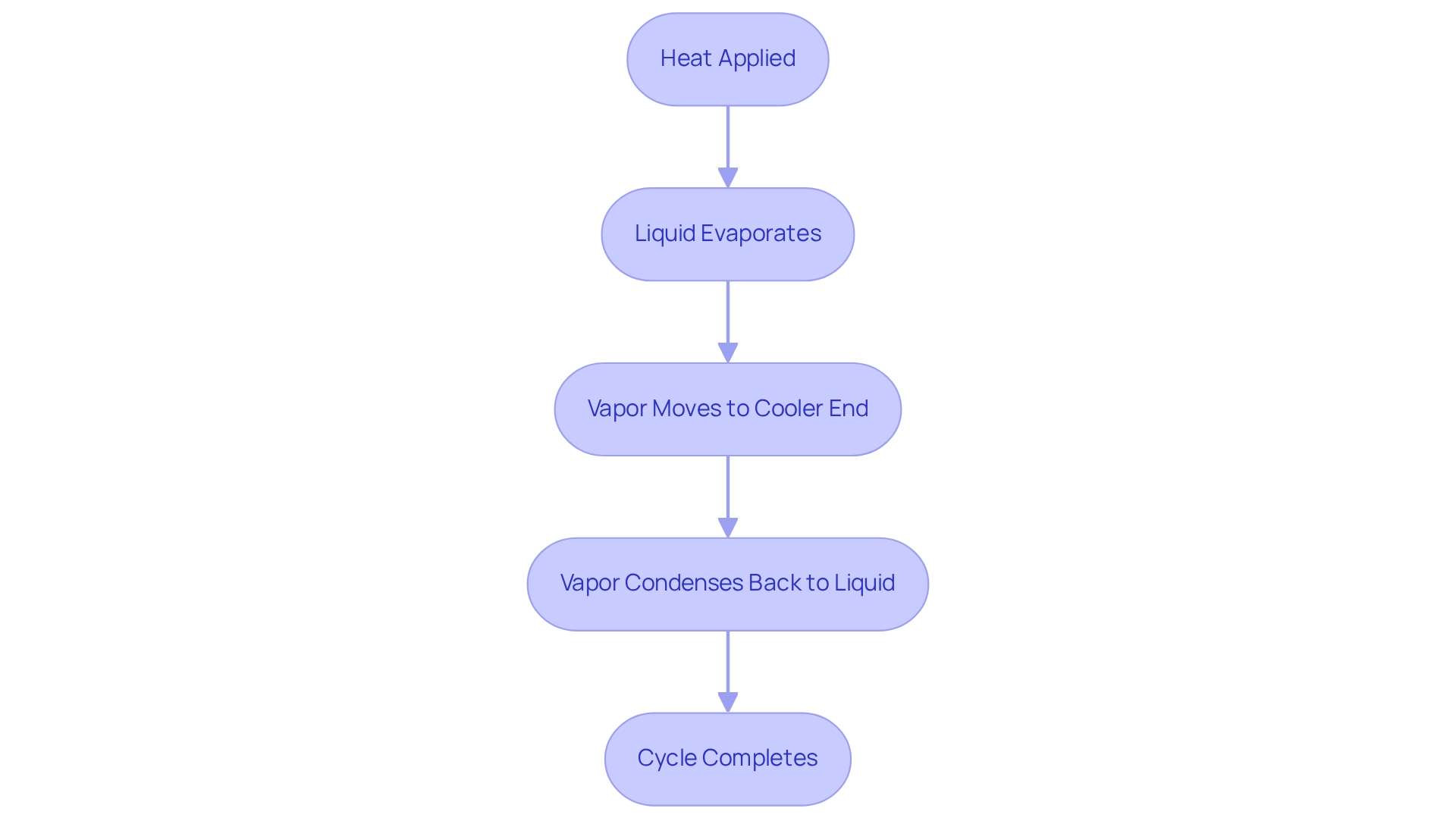

Heatpipes are that represent temperature control instruments leveraging the principles of phase change to facilitate effective energy transfer. Comprised of a sealed metal container filled with a minimal amount of working fluid, a heatpipe operates through a straightforward yet efficient cycle. When heat is applied to one end of the heatpipe, the liquid evaporates, generating vapor that migrates toward the cooler end of the heatpipe. There, it condenses back into liquid, thereby completing the cycle. This system enables rapid energy transfer with minimal temperature variation, making thermal conduits, particularly heatpipe designs, adept at addressing the .

As the world’s leading producer of both standard and custom air-movers for cooling, Gagner-Toomey Associates offers a comprehensive array of , which includes sophisticated , DC input Tube Axial fans, and various cooling fins. The thermal transfer market is experiencing notable growth, projected to expand significantly due to the escalating demand for across diverse sectors. This trend underscores the critical role of temperature control in modern electronics. Engineers have noted that heatpipes are not only eco-friendly—containing minimal working fluid and requiring no energy for operation—but are also in . Understanding the is vital for engineers aiming to integrate these devices into their designs. Recent advancements in heatpipe technology from Gagner-Toomey Associates continue to improve their efficiency and usability, making them a crucial component in the temperature regulation toolkit for electronics engineers. For further information regarding our , including our extensive product range, we invite you to visit our website or locate a distributor today.

Identify Different Types of Heat Pipes and Their Applications

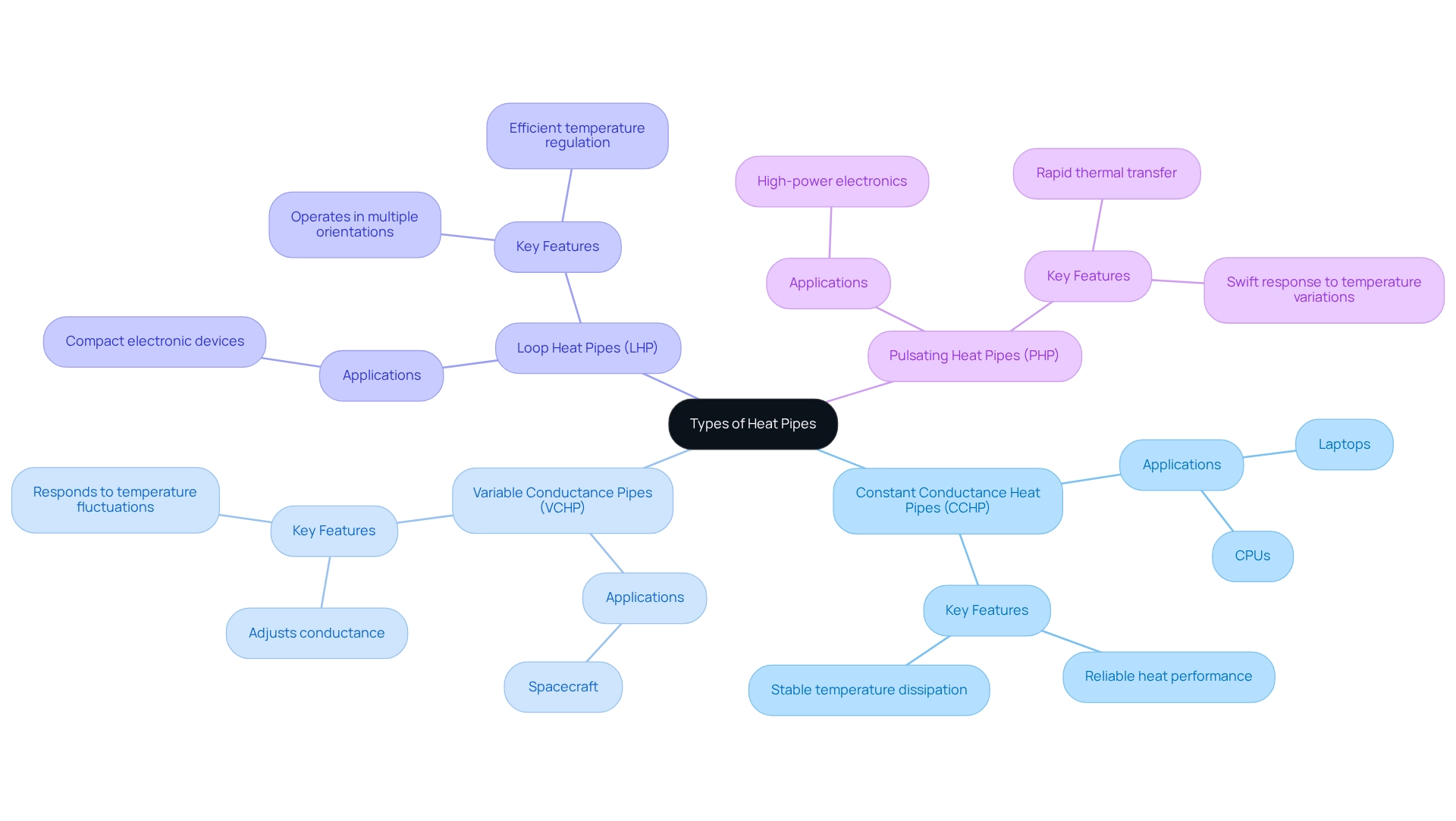

serve as vital components in , and they can be categorized into several types based on their design and application:

- Constant Conductance Heat Pipes (CCHP): As the most common variety, CCHPs deliver reliable . Their dependable effectiveness makes them a preferred choice in laptops and CPUs, where stable temperature dissipation is critical.

- Variable Conductance Pipes (VCHP): These pipes adjust their conductance in response to temperature fluctuations between the evaporator and condenser. This adaptability renders VCHPs ideal for applications with changing thermal demands, particularly in spacecraft, where thermal conditions can shift rapidly.

- Loop Heat Pipes (LHP): Engineered for , LHPs operate effectively in multiple orientations. This versatility proves especially advantageous for compact electronic devices that require efficient temperature regulation in confined spaces.

- Pulsating Heat Pipes (PHP): Utilizing a two-phase flow mechanism, PHPs excel in applications that necessitate , such as high-power electronics. Their design facilitates a swift response to temperature variations, thereby enhancing overall system performance through the use of a heatpipe.

Understanding these distinct varieties of heatpipe empowers engineers to select the most , ensuring optimal performance in electronic applications. The is on an upward trajectory, driven by the increasing demand for and . Industry insights indicate that the standard thermal conduits segment is projected to achieve significant global sales by 2028, highlighting substantial opportunities for customization and innovation in emerging markets. Furthermore, temperature conduits enhance the effectiveness of solar energy systems, underscoring their adaptability and significance in contemporary temperature control strategies.

Understand the Operational Mechanics of Heat Pipes

The operation of heatpipes is fundamentally rooted in thermodynamic and fluid mechanics principles, which are essential for in electronics. Key components include:

- Wicking Structure: This vital internal feature facilitates the return of the to the evaporator. Various materials, such as sintered metal or mesh, can be utilized to optimize performance. The configuration of the wicking system significantly impacts the conduit’s efficiency, as it regulates fluid flow and overall heat conductivity.

- Working Fluid: Water is typically employed as the working fluid; however, alternatives may be chosen based on specific temperature ranges and application requirements. The choice of liquid is critical, as it directly influences the and operational limits of the system.

- : The thermal conduit operates through a continuous cycle of evaporation and condensation. Upon the application of heat, the fluid at the hot end evaporates, producing vapor that travels to the cooler end, where it condenses back into liquid. This phase transition is crucial for , enabling conduits to manage temperature loads efficiently.

A recent study on ultra-slim conduction devices featuring composite wick structures demonstrated that these innovative designs significantly enhance under various conditions, rendering them ideal for . This aligns with findings that efficient conductivity, internal composition, physical characteristics, and cooling component features of heatpipe systems must be considered when selecting heat transfer systems.

As Dan Holohan aptly stated, “If you can’t afford to do it right, how can you afford to do it twice?” This underscores the importance of proper design and execution of temperature conduits in climate control solutions. By understanding these operational mechanics, engineers can tailor fluid conduit designs to meet specific , ensuring optimal performance in their applications. Furthermore, the statistic that spring-loaded metal screws provide the highest TIM preload at approximately 520 Pa highlights the significance of effective used in conjunction with thermal conduits.

Integrate Heat Pipes into Electronic Systems: Design Considerations

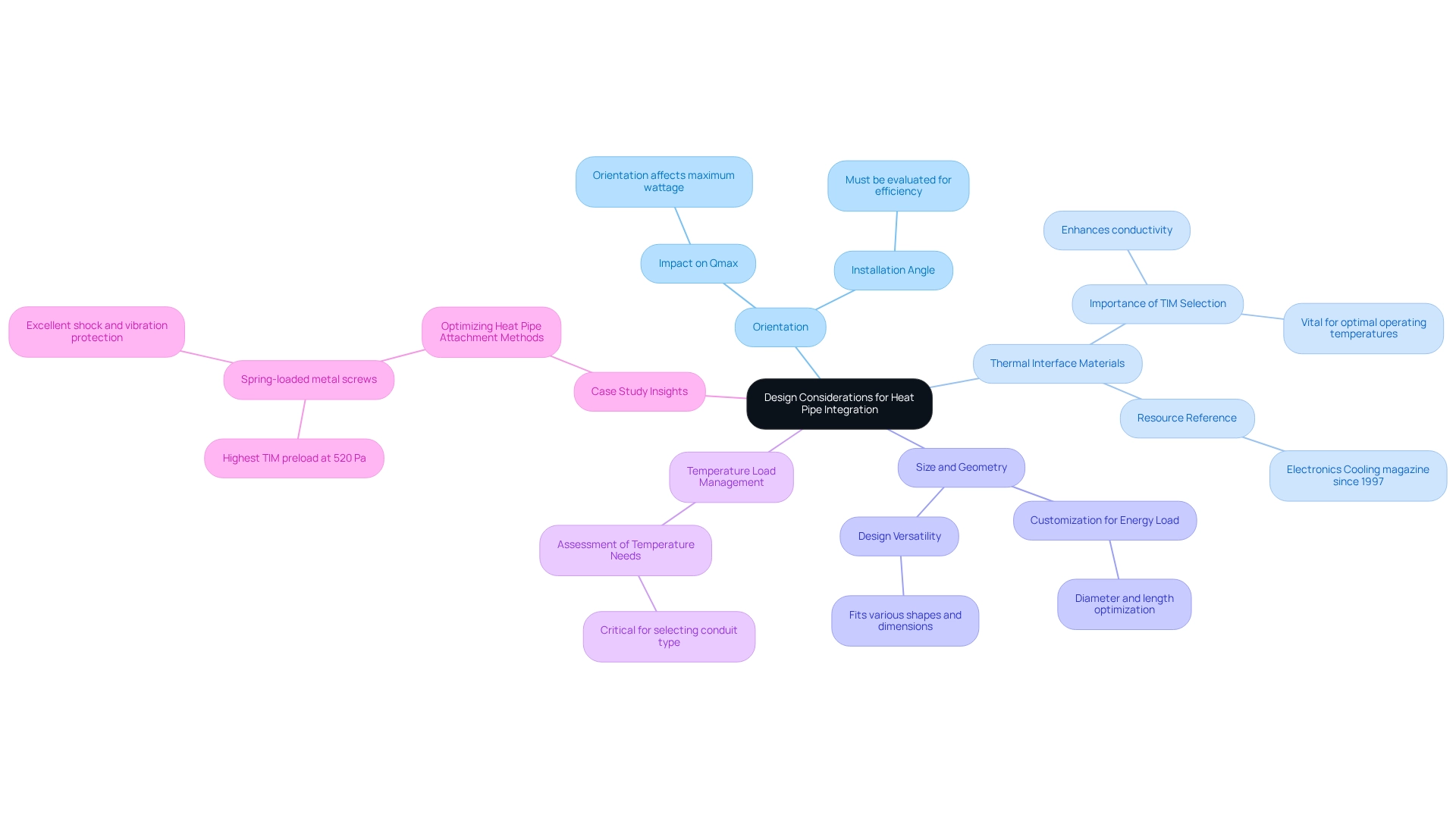

Incorporating into electronic systems demands meticulous attention to several critical design considerations:

- Orientation: The effectiveness of thermal conduits is significantly influenced by their alignment, given the gravitational impacts on fluid motion. Engineers must meticulously evaluate the installation angle to optimize efficiency; incorrect orientation can lead to suboptimal heat performance. As specialists have observed, , the maximum wattage it can efficiently carry. This insight underscores the in achieving optimal temperature regulation.

- : The selection of TIM between the energy source and the thermal pipe is crucial for enhancing conductivity. The appropriate TIM ensures efficient heat transfer, which is vital for maintaining optimal operating temperatures in electronic components. The importance of selecting suitable TIM is supported by the , a resource for heat analyses since 1997.

- Size and Geometry: Heat conduits can be tailored to fit various shapes and dimensions, offering design versatility. However, optimizing the diameter and length of the transfer medium according to the specific energy load requirements of the system is essential. This customization can significantly impact the overall effectiveness of .

- : A thorough understanding of the anticipated temperature load is critical for selecting the appropriate type and size of thermal conduit. Engineers must conduct a comprehensive assessment of the temperature needs of the components being cooled to ensure that the can handle the expected temperature output.

A case study focused on improving thermal transfer device attachment techniques revealed that spring-loaded metal screws provide the highest temperature interface preload, approximately 520 Pa, delivering excellent shock and vibration protection. This method not only secures the cooling sink to the conduit but also enhances the overall reliability of the temperature control system. The findings from this case study emphasize the significance of in electronic systems, and by addressing these considerations, engineers can successfully integrate heatpipe technology into their designs, significantly enhancing the of electronic systems.

Conclusion

The exploration of heat pipes underscores their pivotal role in the efficient thermal management of modern electronic devices. By leveraging the principles of phase change, heat pipes facilitate rapid heat transfer while minimizing energy consumption. Their diverse types—such as Constant Conductance, Variable Conductance, Loop, and Pulsating Heat Pipes—each cater to unique applications, enabling engineers to tailor solutions to the specific thermal challenges encountered across various industries.

Understanding the operational mechanics of heat pipes, particularly the significance of the wicking structure and working fluid, is essential for optimizing their performance. Moreover, integrating heat pipes into electronic systems necessitates careful consideration of orientation, thermal interface materials, size, geometry, and heat load management. These design considerations are crucial for maximizing the efficiency and reliability of thermal management solutions.

In conclusion, as electronic devices continue to evolve in power and compactness, the demand for effective heat management solutions like heat pipes will only intensify. Their capability to enhance performance while supporting energy conservation and sustainability renders them indispensable in the engineer’s toolkit. By prioritizing the integration of advanced heat pipe technologies, industries can secure optimal thermal performance, paving the way for the next generation of innovative electronic systems.

Frequently Asked Questions

What are heatpipes and how do they work?

Heatpipes are advanced thermal tubes that utilize the principles of phase change to facilitate effective energy transfer. They consist of a sealed metal container filled with a small amount of working fluid. When heat is applied to one end, the liquid evaporates into vapor, which then moves to the cooler end where it condenses back into liquid, completing the cycle and enabling rapid energy transfer with minimal temperature variation.

What advantages do heatpipes offer in temperature control?

Heatpipes are particularly adept at managing temperature challenges in powerful and compact electronic devices. They are eco-friendly, containing minimal working fluid and requiring no energy for operation, making them essential for maintaining optimal performance in temperature control systems.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s leading producer of standard and custom air-movers for cooling. They provide a comprehensive range of temperature regulation solutions, including sophisticated heatpipe thermal conduits, DC input Tube Axial fans, and various cooling fins.

What is the current trend in the thermal transfer market?

The thermal transfer market is experiencing significant growth due to the increasing demand for effective cooling solutions across various sectors, highlighting the critical importance of temperature control in modern electronics.

Why is it important for engineers to understand heatpipes?

Understanding the fundamentals of heatpipes is vital for engineers who aim to integrate these devices into their designs, as they play a crucial role in temperature regulation in electronic systems.

How is Gagner-Toomey Associates advancing heatpipe technology?

Gagner-Toomey Associates is continuously improving the efficiency and usability of heatpipe technology, making them an essential component in the temperature regulation toolkit for electronics engineers.