Overview

The title ‘Understanding PWM Fan Meaning and Its Role in Electronics Cooling’ aims to define PWM fans and elucidate their importance in cooling electronic systems. PWM fans, which employ pulse width modulation for speed control, are essential for effective temperature regulation in electronics. They adjust their speed in response to thermal demands, enhancing performance, reducing energy consumption, and minimizing noise levels. This understanding is crucial for optimizing electronic systems and ensuring their longevity.

Introduction

In the realm of electronics cooling, the evolution of fan technology has given rise to a sophisticated solution: PWM fans, or Pulse Width Modulation fans. These advanced devices distinguish themselves from traditional counterparts by offering dynamic speed control that responds to the specific thermal demands of a system. This adaptability not only enhances cooling efficiency but also minimizes energy consumption and noise, establishing PWM fans as essential components in modern thermal management strategies.

As the demand for effective cooling solutions escalates, particularly in sectors such as computing and automotive, understanding the mechanics, benefits, and applications of PWM technology is crucial for engineers and designers alike.

This article delves into the significance of PWM fans, elucidating their operational advantages and exploring their pivotal role in optimizing performance across various electronic systems.

Define PWM Fans and Their Importance in Electronics Cooling

The term pwm fan meaning refers to PWM units, or Pulse Width Modulation units, which are advanced ventilation devices that use pulse width modulation to precisely control their rotation. Unlike conventional cooling units that operate at a fixed rate, the pwm fan meaning involves units that dynamically adjust their rotational speed according to the system’s thermal demands. This adaptability is essential for efficient electronics temperature regulation, highlighting the pwm fan meaning of improved heat management and significantly reducing energy consumption and noise levels.

By optimizing rotational speed, the pwm fan meaning is highlighted as PWM units ensure ideal operating temperatures for sensitive electronic components, thereby enhancing both performance and longevity, particularly in the context of the rapidly growing PC enclosure market, projected to expand at a CAGR of 4.50% from 2024 to 2031. This growth holds particular significance for those interested in pwm fan meaning, as their ability to adjust speed based on thermal requirements positions them as a preferred choice in .

Industry leaders assert that this adaptability makes PWM devices, often referred to as pwm fan meaning, superior to conventional models in terms of performance and efficiency, with experts emphasizing their critical role in advancing thermal management. Furthermore, as axial blowers are expected to dominate market share during this period, their integration with pwm fan meaning technology becomes increasingly vital for effective electronics temperature regulation.

Recent testimonials from clients, including feedback from Gagner-Toomey Associates, highlight the efficacy of PWM devices, reinforcing the pwm fan meaning as indispensable components in contemporary thermal management strategies. Gagner-Toomey Associates, recognized as a leading supplier of , leverages its extensive range of DC input devices and centrifugal blowers to meet the diverse needs of engineers across multiple sectors. Their consultative approach and strong distributor relationships further bolster their ability to provide responsive customer service in the context of pwm fan meaning implementations, ensuring that engineers access optimal solutions for their cooling requirements.

Explain the Working Mechanism of PWM Fans vs. DC Fans

PWM units utilize a four-pin connector, where the fourth pin transmits a PWM signal to the motor. This signal comprises a series of on-off pulses that regulate the average power supplied to the fan, facilitating precise adjustments in speed. Conversely, DC supporters typically employ a three-pin connector, operating at a constant voltage, which results in a fixed speed unless manually modified.

The dynamic capability of PWM devices to adjust their rotation in response to real-time thermal conditions markedly enhances their efficiency. Specifically, [PWM devices alter their rate based on temperature sensor signals](https://acdcecfan.com/pwm-vs-dc), allowing them to minimize energy consumption and reduce noise when optimal temperature management is unnecessary, making them particularly advantageous in environments with fluctuating temperatures.

It is essential for engineers to verify motherboard connections to ensure compatibility with fan types, as this can significantly impact performance. Research indicates that while DC enthusiasts may advocate for restricted voltage-regulated speeds, they lack the adaptability and precision of PWM models, which embody the [PWM fan meaning](https://gagner-toomey.com/what-does-pwm-mean-for-fans-key-characteristics-and-applications) that is vital for meeting rapidly changing thermal demands.

For example, the ASUS TUF Gaming B660-Plus is engineered to accommodate both PWM and DC cooling systems, which emphasizes the PWM fan meaning and the increasing acknowledgment of [PWM technology’s advantages](https://gagner-toomey.com/7-key-benefits-of-pwm-controlled-fans-for-electronics-engineers) in contemporary electronics.

Furthermore, a case study on speed control mechanisms reveals that although some DC devices can support voltage-regulated speeds, they are less flexible and precise than PWM units, rendering them inadequate for swiftly changing temperature requirements. As Ruth Rowley from Overclockers UK notes, the PWM fan meaning is highlighted by advancements in PWM technology, which are revolutionizing temperature management solutions within the electronics industry.

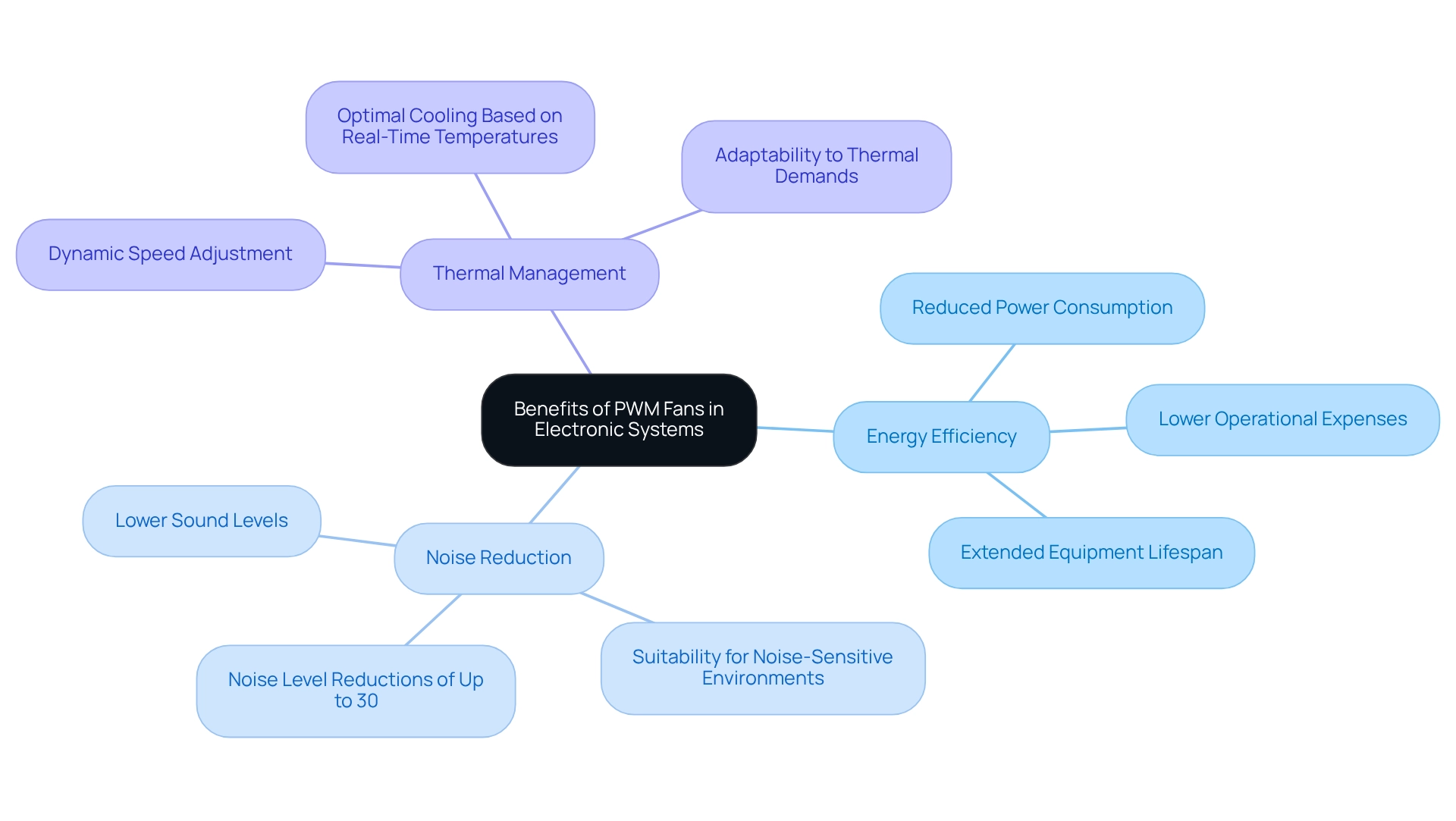

Highlight the Benefits of Using PWM Fans in Electronic Systems

The pwm fan meaning illustrates the numerous advantages that PWM devices present for electronic systems. Their energy efficiency stands out; by modulating their speeds in accordance with cooling demands, they substantially decrease power consumption. For instance, systems equipped with PWM devices can achieve energy savings that not only lower operational expenses but also extend the lifespan of the equipment. Current configurations featuring dual PWS-902 PSUs illustrate this potential, demonstrating approximately 400 watts usage at rest, thereby highlighting the opportunity for reduced energy expenditure.

Furthermore, the pwm fan meaning indicates that PWM devices are exceptional in their ability to minimize noise, operating at lower sound levels than traditional DC models. This attribute renders them particularly suitable for environments where acoustic comfort is critical, such as home theaters and quiet office spaces. Case studies reveal that systems utilizing PWM devices can realize noise level reductions of up to 30% compared to , significantly enhancing the overall user experience. The case study titled ‘Noise Reduction Benefits of PWM Fans: Enhancing Acoustic Comfort’ underscores these findings by providing a comprehensive context for the evidence supporting the pwm fan meaning in relation to noise reduction claims.

The precise control of motion enabled by PWM technology is also vital for effective thermal management, highlighting the pwm fan meaning. In data centers, for example, PWM cooling systems dynamically adjust their speeds based on real-time server temperatures, ensuring optimal cooling while curbing energy costs. This adaptability not only bolsters system performance but also aligns with the increasing demand for energy-efficient solutions in the electronics sector. As noted by Annie Chan, Account Manager of CCHV and EAGLE enthusiast, ‘In the past 17 years, we have assisted 32 nations and over 400 clients such as home appliance, car headlamp, power supply, commercial lighting, etc.,’ emphasizing the widespread application of PWM devices across various industries. The integration of PWM units represents a strategic decision for engineers striving to balance performance with budget considerations, as they must weigh both performance advantages and cost-effectiveness when selecting between PWM and DC models.

Identify Applications and Use Cases for PWM Fans in Electronics

PWM devices play a crucial role across various applications, including , automotive electronics, and industrial machinery. In personal computers, they are vital components of CPU coolers and chassis ventilators, effectively regulating temperatures during intensive tasks. For automotive applications, PWM devices are essential for managing engine temperature, ensuring that vehicles operate efficiently under diverse loads. In industrial environments, these devices are utilized for temperature regulation of equipment, preventing overheating and enhancing reliability and performance. Their adaptability to fluctuating thermal conditions positions PWM devices as the preferred solution in scenarios where effective cooling is imperative.

Moreover, the efficiency of PWM devices is underscored by their capacity to absorb significant heat. For instance, models like the thermoelectric element 9501/127/040 B achieve a peak heat absorption capability of 38W, illustrating their importance in contemporary electronics. As Chi Xu notes, “More interestingly, the energy consumption significantly varies with traffic allocation strategies and virtual CPU affinity conditions, which was not seen in conventional physical machines.” This observation highlights the relevance of PWM fan meaning in the context of optimizing energy efficiency and minimizing noise levels, making these fans suitable for .

Conclusion

The exploration of PWM (Pulse Width Modulation) fans underscores their critical role in modern electronics cooling. By dynamically adjusting their speed based on real-time thermal demands, PWM fans deliver a level of efficiency and adaptability that traditional DC fans cannot match. This capability not only enhances cooling performance but also significantly reduces energy consumption and noise, rendering them indispensable across various applications, from personal computers to automotive systems and industrial machinery.

The advantages of PWM fans extend beyond mere cooling efficiency; they also contribute to operational cost savings and prolonged equipment lifespan. Systems equipped with these fans can operate at lower power levels and noise outputs, fostering a more comfortable environment in spaces where acoustics are paramount. Evidence presented in case studies highlights the tangible benefits of PWM technology, including substantial reductions in energy use and noise levels, which enhance user experience and system reliability.

In conclusion, understanding and integrating PWM fans into electronic systems is essential for engineers and designers striving for optimal performance and efficiency. As the demand for effective cooling solutions continues to grow across industries, adopting PWM technology emerges as a strategic choice that balances performance with energy efficiency. Embracing this advanced cooling solution not only addresses immediate thermal management needs but also aligns with the broader goals of sustainability and innovation in the electronics sector.

Frequently Asked Questions

What does PWM fan mean?

PWM fan refers to Pulse Width Modulation units, which are advanced ventilation devices that use pulse width modulation to control their rotational speed based on the system’s thermal demands.

How do PWM fans differ from conventional cooling units?

Unlike conventional cooling units that operate at a fixed rate, PWM fans dynamically adjust their rotational speed according to the thermal requirements of the system, allowing for more efficient temperature regulation.

What are the benefits of using PWM fans?

The benefits of PWM fans include improved heat management, reduced energy consumption, lower noise levels, and enhanced performance and longevity of sensitive electronic components.

What is the projected market growth for PC enclosures and how does it relate to PWM fans?

The PC enclosure market is projected to expand at a CAGR of 4.50% from 2024 to 2031, highlighting the increasing significance of PWM fans in modern temperature management solutions.

Why are PWM fans considered superior to conventional models?

Industry leaders assert that PWM fans are superior due to their adaptability, which enhances performance and efficiency in thermal management compared to conventional models.

What role do axial blowers play in relation to PWM fans?

Axial blowers are expected to dominate market share and their integration with PWM fan technology is vital for effective electronics temperature regulation.

How has Gagner-Toomey Associates contributed to the PWM fan market?

Gagner-Toomey Associates is recognized as a leading supplier of innovative temperature control solutions, offering a range of DC input devices and centrifugal blowers to meet the needs of engineers, and providing responsive customer service for PWM fan implementations.