Overview

The article underscores the critical steps engineers must undertake when selecting the most suitable fans for cooling applications. It highlights the necessity of comprehending airflow, static pressure, and various fan types. Furthermore, it emphasizes the evaluation of project requirements and the implementation of proper installation and maintenance practices. These steps are vital to ensure optimal performance and enhance energy efficiency.

Introduction

In the realm of modern engineering, the significance of effective cooling solutions is paramount. As technology evolves and devices grow increasingly compact, the demand for efficient cooling fans has surged, necessitating a comprehensive understanding of their functionality and application.

Engineers must navigate a complex landscape, from the fundamentals of airflow and static pressure to the diverse types of fans available, to ensure optimal performance. This article explores the essential aspects of cooling fans, including:

- How to identify project requirements

- Evaluate specifications

- Implement best practices for installation and maintenance

Equipped with the right knowledge and strategies, professionals can enhance system efficiency and reliability, ultimately contributing to the success of their projects in an ever-evolving technological landscape.

Understand Cooling Fan Basics

Cooling fans, recognized as the best fans for cooling, are essential devices that facilitate heat dissipation across various applications by effectively moving air. They use the best fans for cooling to generate air movement, which reduces temperatures by replacing warm air with cooler air. Understanding key concepts is crucial:

- Airflow (CFM): This metric, measured in cubic feet per minute (CFM), indicates the volume of air a fan can move. Typically, higher CFM ratings correlate with enhanced cooling performance, making the selection of the best fans for cooling a critical factor.

- Static Pressure: This term describes the resistance a fan must overcome to push air through a system. A solid grasp of static pressure is vital for selecting the appropriate fan for specific environments, particularly in areas with limited ventilation.

- Fan Types: Familiarity with various fan types is imperative. Gagner-Toomey Associates offers a diverse range of DC input Tube Axial units, ranging from 15 to 280mm, alongside an extensive selection of DC input Centrifugal Blowers, sized from 15 to 225mm. Axial blowers are typically employed in high airflow scenarios, while centrifugal blowers are considered the best fans for cooling in high-pressure contexts, making them suitable for various temperature regulation needs. These devices are optimized for performance, efficiency, and low noise, with IP protection available in most models upon request.

Grasping these fundamentals enables engineers to accurately assess their temperature management requirements and choose the best fans for cooling solutions. Recent studies underscore the significance of the best fans for cooling, even in conditions previously deemed unsuitable, indicating that fans can serve as a viable alternative to air conditioning, particularly as global temperatures rise. For instance, a home with R-38 insulation can significantly benefit from strategic fan positioning to enhance circulation and temperature control. As Ed Kisiel, a builder, remarked, “He sealed the holes for the wires, and note the white caulk at the bottom of the wall,” highlighting the importance of sealing gaps to optimize airflow. As the industry evolves, ongoing research, such as the case study titled ‘Future Research Directions for Use Effectiveness,’ will further clarify the efficiency of ventilation devices across diverse climatic conditions, ensuring engineers have the insights needed to adapt their temperature regulation strategies as necessary. Furthermore, the call for further investigation into the efficacy of electric appliances during heatwaves emphasizes the importance of such devices in addressing current climatic challenges.

Identify Project Requirements for Cooling Fans

To effectively identify the requirements for ventilation fans in your project, it is essential to follow these critical steps:

- Determine Heat Load: Calculate the total heat generated by the components requiring temperature regulation. This entails summing contributions from various sources, including floor area, windows, personnel, IT equipment, and lighting. A practical rule of thumb for air conditioning calculation is to determine the floor area of the room by multiplying the width by the depth in meters and then multiplying this by 20 to yield a British Thermal Unit (BTU) for the space. Utilizing thermal analysis tools or manufacturer specifications can significantly aid in this process.

- Define Ambient Conditions: It is vital to understand the environmental conditions in which the fan will operate. This includes assessing temperature ranges and humidity levels, as these factors have a substantial impact on fan performance and efficiency. Recognizing that ambient conditions can influence the selection of the best fans for cooling is crucial for optimizing system performance.

- Assess Space Constraints: Evaluate the physical space available for fan installation. Consider dimensions, airflow pathways, and any potential obstructions that could hinder airflow.

- Evaluate Noise Levels: In applications sensitive to noise, it is imperative to select fans specifically designed for quiet operation. This consideration is crucial in environments where sound levels can affect productivity or comfort.

- Evaluate Reliability Needs: Determine the expected lifespan and reliability requirements based on the application, especially in critical systems where failure is unacceptable. Understanding the financial metrics related to temperature control solutions, as highlighted in case studies, can profoundly influence project assessment and decision-making.

By thoroughly evaluating these factors, engineers can ensure they select the best fans for cooling that meet their project’s specific requirements, ultimately enhancing system performance and efficiency. Furthermore, it is important to recognize that cooling solutions represent significant non-compute energy users in data centers, making efficient fan selection vital for energy management.

Explore Different Types of Cooling Fans

Cooling devices come in various types, each tailored for specific applications and performance requirements:

- Axial Units: These units facilitate air movement parallel to their axis, making them ideal for applications demanding high air movement at low pressure. Commonly found in computer enclosures and HVAC systems, they play a critical role in effective air circulation.

- Centrifugal Blowers: Designed to draw air into the center and expel it at a right angle, centrifugal blowers excel in high-pressure environments, particularly in industrial settings where robust air circulation is essential. Gagner-Toomey Associates offers a comprehensive selection of centrifugal blowers, ranging in size from 15 to 225mm, optimized for performance and efficiency, with options for IP protection available upon request.

- Blower Units: A specific subset of centrifugal units, blowers are engineered to generate higher pressures and are frequently utilized in scenarios requiring concentrated airflow, such as cooling systems for electronic devices. In industrial contexts, blower units are crucial for maintaining optimal temperatures in machinery and equipment.

- DC Units: Operating on direct current, DC units are recognized for their energy efficiency and quiet operation, making them particularly suitable for sensitive electronic applications where noise reduction is paramount. Gagner-Toomey Associates stands as the world’s largest manufacturer of standard and custom DC input fans, offering sizes from 15 to 280mm to ensure low noise operation.

- EC Fans: Electronically commutated fans combine the benefits of AC and DC technologies, delivering high efficiency and variable speed control, which are increasingly vital in contemporary electronics. The integration of fan control circuits is becoming essential, as it allows for enhanced management of airflow and energy consumption with the best fans for cooling.

- Miniature Solutions: Gagner-Toomey Associates also provides miniature blower and fan options starting from dimensions as compact as 15x3mm, addressing consumer demands and facilitating temperature regulation in confined spaces.

By understanding these fan types and their respective applications, engineers can make informed decisions to effectively meet specific temperature control requirements. The expertise of Gagner-Toomey Associates in offering technical and application support is indispensable as engineers navigate the complexities of selecting the appropriate fan type for their needs.

Evaluate Fan Specifications and Performance Metrics

When selecting cooling fans, engineers must meticulously assess the following specifications and performance metrics:

- Air Movement (CFM): It is essential to confirm that the fan’s air movement rating meets or surpasses the calculated heat load needs; insufficient air circulation can result in overheating and system failure. Gagner-Toomey Associates offers a broad product line of DC input Tube Axial fans, ranging from 15 to 280mm, optimized for performance and efficiency.

- Static Pressure: Evaluating the fan’s static pressure rating is crucial to ensure it can effectively overcome any resistance in the airflow path, which is vital for maintaining optimal cooling performance. Their centrifugal blowers, available in sizes ranging from 15 to 225mm, are engineered to deliver the required static pressure for various applications.

- Power Consumption: Analyzing the fan’s power requirements is necessary to ensure alignment with energy efficiency goals, particularly in systems where power consumption is a critical factor. Notably, fan efficiencies can vary, with some models achieving an efficiency rating of 0.69, which should be considered in the context of overall system performance. Gagner-Toomey’s supporters are designed for low power usage without sacrificing performance.

- Noise Level (dBA): Reviewing the noise level specifications is important to ensure they fall within acceptable limits for your application, as excessive noise can be disruptive in many environments. Gagner-Toomey Associates focuses on low-noise designs, making their products suitable for sensitive environments.

- Durability and Lifespan: Prioritizing devices with high durability ratings and extended operational lifespans is essential, especially in critical contexts where reliability is paramount. Their extensive portfolio includes robust solutions designed for long-term use in demanding conditions.

- Speed Control Options: Considering fans equipped with variable speed control allows for adjustable airflow to meet varying temperature management demands. Gagner-Toomey’s innovative designs frequently include this feature, enhancing adaptability in temperature regulation.

- IP Protection: Ensuring that the fan models meet the necessary IP protection standards is crucial for applications exposed to dust and moisture, thereby enhancing the reliability of the cooling solution.

A thorough assessment of these metrics is essential, as not all supporters of the same size will perform equivalently. For instance, the impact of external conditions on fan performance must be considered during system design. According to the case study titled ‘Guidelines for Fan Selection,’ it is critical to assess flowrate requirements and compare efficiencies to identify the best fans for cooling based on specific operational conditions. This study highlights the importance of airflow CFM and static pressure in fan selection, influencing overall system efficiency and effectiveness. By adhering to these guidelines, engineers can ensure they select devices that not only meet performance criteria but also contribute to improved energy efficiency and system reliability.

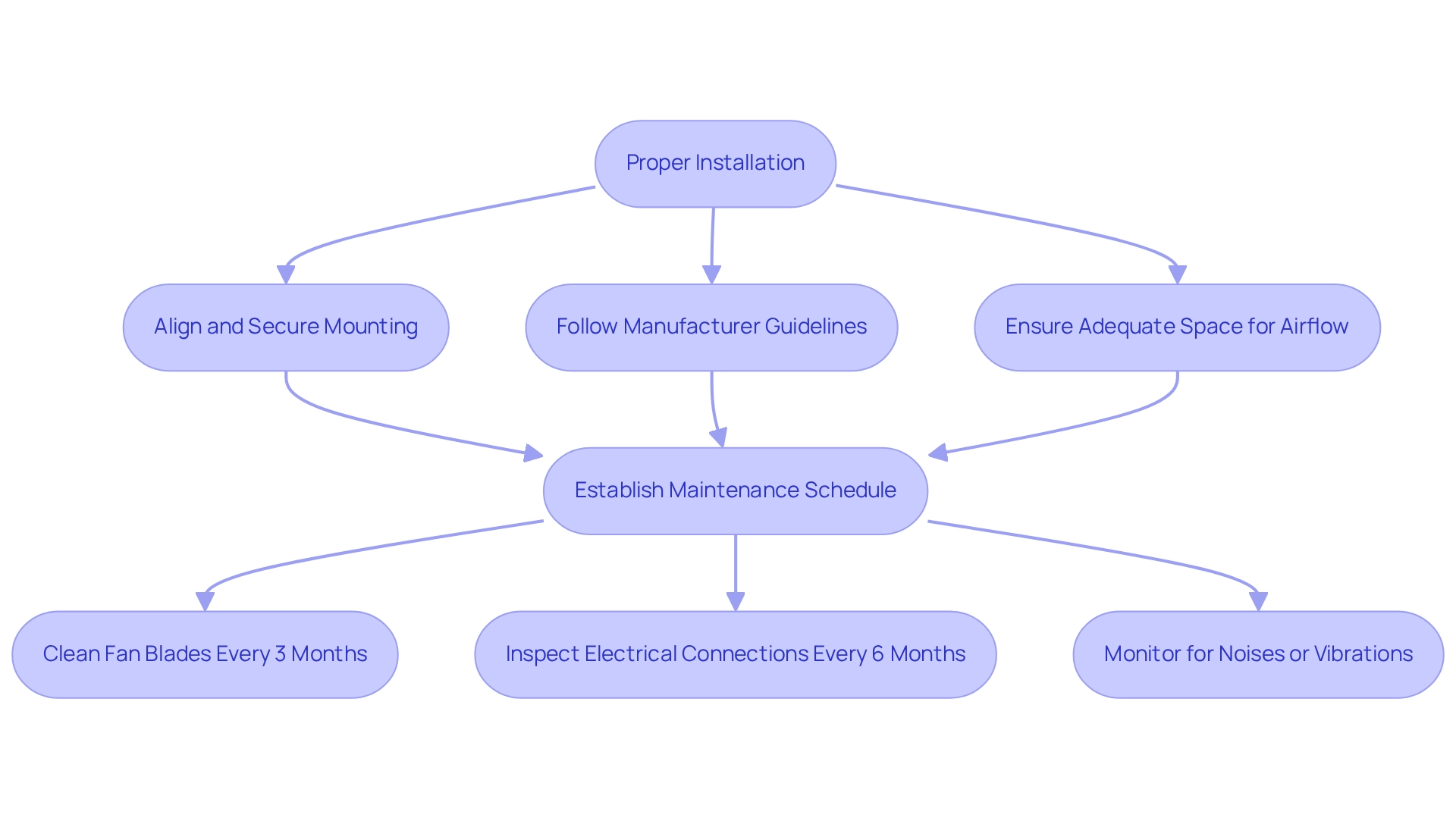

Implement Proper Installation and Maintenance Practices

To ensure optimal performance and longevity of the best fans for cooling, it is essential to implement effective installation and maintenance practices. Proper alignment and secure mounting are crucial to minimize vibration and noise, which can adversely affect the performance of the best fans for cooling. Adhering to manufacturer guidelines for electrical connections and airflow direction optimizes efficiency. Additionally, allowing adequate space around the fan for airflow and maintenance access facilitates easier upkeep.

Maintenance: Establishing a consistent maintenance schedule is vital, including regular cleaning of fan blades and housing to prevent dust buildup that significantly impedes airflow. It is recommended to perform this cleaning every three months or more frequently in dusty environments. Inspecting electrical connections and wiring for signs of wear or damage at least once every six months ensures safe and reliable operation. Monitoring for unusual noises or vibrations during operation is critical, as these may indicate underlying mechanical issues that require attention. Promptly replacing worn or damaged components maintains optimal performance and prevents further complications, with real-world examples like Kooltronic’s products showcasing the best fans for cooling that illustrate the effectiveness of tailored cooling solutions designed for specific applications. These devices not only enhance operational efficiency but also exemplify best practices in installation and maintenance. Adherence to these guidelines can lead to improved performance. By following these recommendations, engineers can maximize the efficiency and lifespan of their cooling fans, ensuring reliable operation in their applications. Gagner-Toomey Associates’ commitment to excellence in customer service and product representation further supports engineers in achieving these goals.

Conclusion

Effective cooling solutions are essential in the modern engineering landscape, where the demand for efficient cooling fans is on the rise. Understanding the fundamentals of cooling fans—including airflow, static pressure, and the various types available—equips engineers with the knowledge necessary to assess project requirements and select the appropriate fans. By determining heat load, defining ambient conditions, and evaluating space constraints, professionals can identify the specific needs of their projects, ultimately leading to enhanced system performance.

Evaluating fan specifications and performance metrics is critical to ensuring that selected fans can meet the demands of their applications. Key considerations such as airflow, static pressure, power consumption, and noise levels must be meticulously analyzed to achieve optimal efficiency and reliability. Furthermore, implementing best practices for installation and maintenance contributes significantly to the longevity and effectiveness of cooling systems. Regular cleaning, inspection, and prompt replacement of damaged components ensure that fans operate at peak performance, thereby reducing the risk of system failure.

In conclusion, the role of cooling fans in engineering projects is paramount. By leveraging the right knowledge and strategies, professionals can significantly enhance system efficiency, reliability, and overall project success in an increasingly complex technological environment. Prioritizing effective cooling solutions is not merely an option—it is a necessity for navigating the challenges of modern engineering.

Frequently Asked Questions

What are cooling fans and why are they important?

Cooling fans are essential devices that facilitate heat dissipation by effectively moving air, which helps reduce temperatures by replacing warm air with cooler air. They are recognized as the best fans for cooling across various applications.

What does airflow (CFM) mean in relation to cooling fans?

Airflow, measured in cubic feet per minute (CFM), indicates the volume of air a fan can move. A higher CFM rating typically correlates with enhanced cooling performance, making it a critical factor in selecting the best fans for cooling.

What is static pressure and why is it important?

Static pressure refers to the resistance a fan must overcome to push air through a system. Understanding static pressure is vital for selecting the appropriate fan for specific environments, especially in areas with limited ventilation.

What types of cooling fans are available?

There are various types of cooling fans, including DC input Tube Axial units and DC input Centrifugal Blowers. Axial blowers are used in high airflow scenarios, while centrifugal blowers are suited for high-pressure contexts, catering to different temperature regulation needs.

How can cooling fans serve as an alternative to air conditioning?

Recent studies indicate that cooling fans can effectively manage temperatures in conditions previously deemed unsuitable for fan use, making them a viable alternative to air conditioning, especially as global temperatures rise.

What factors should be considered when selecting ventilation fans for a project?

Key factors include determining heat load, defining ambient conditions, assessing space constraints, evaluating noise levels, and understanding reliability needs. Each factor plays a crucial role in ensuring the selected fans meet specific project requirements.

How can heat load be calculated for a space?

Heat load can be calculated by summing the total heat generated by components needing temperature regulation, including floor area, windows, personnel, IT equipment, and lighting. A common method is to multiply the room’s width by depth in meters and then multiply by 20 to yield the British Thermal Unit (BTU) for the space.

Why is understanding ambient conditions important for fan selection?

Ambient conditions, such as temperature ranges and humidity levels, significantly impact fan performance and efficiency. Recognizing these factors helps optimize system performance when selecting the best fans for cooling.

What considerations should be made regarding noise levels when selecting fans?

In environments sensitive to noise, it is essential to select fans designed for quiet operation, as sound levels can affect productivity and comfort.

Why is reliability important in cooling fan selection?

Reliability is crucial, especially in critical systems where failure is unacceptable. Understanding the expected lifespan and reliability requirements can profoundly influence project assessment and decision-making.