Overview

This article provides a comprehensive comparison of blowers and fans, emphasizing their distinct functions and characteristics.

- Fans are specifically designed for low-force, high-volume air movement.

- Blowers are engineered for high-force, concentrated airflow.

This critical distinction is underpinned by technical specifications such as flow rate and static pressure. Furthermore, practical applications in electronics engineering illustrate that the choice between blowers and fans hinges on specific needs, including energy efficiency and noise levels. Understanding these differences is essential for making informed decisions in various engineering contexts.

Introduction

Grasping the distinctions between blowers and fans is essential for electronics engineers navigating the complexities of airflow management across diverse applications. Although both devices play critical roles in air movement, they fulfill distinct purposes that can profoundly influence system efficiency and performance.

As engineers explore the technical specifications and operational principles of these air-moving devices, they inevitably encounter a pivotal question: how does one select the appropriate device for specific engineering challenges, particularly when energy efficiency and noise levels are of paramount concern?

By examining these differences, engineers not only enhance their design decisions but also optimize functionality in demanding environments.

Define Blowers and Fans: Core Functions and Characteristics

When comparing , it is clear that both are , yet they serve distinct functions and operate on different principles. A fan is primarily designed to transport large volumes of air at low force, making it suitable for general ventilation and cooling applications. Fans generate airflow through spinning blades that move air broadly and with low force, which is ideal for enhancing comfort in various environments. Conversely, a blower is engineered to produce greater force and speed, enabling it to move air through ducts or against resistance. This characteristic makes blowers particularly efficient in scenarios requiring concentrated airflow, such as and industrial operations.

The fundamental distinction in the blower vs fan comparison lies in their force ratio: fans typically operate at a ratio of up to 1.11, while air movers function within a range of 1.11 to 1.2. This indicates that fans are better equipped to handle higher static pressures, rendering them indispensable in situations where airflow must overcome significant resistance.

HVAC professionals underscore the when considering blower vs fan for specific applications. For instance, a recent case study highlighted a facility that by replacing conventional units with , resulting in a 30% reduction in energy consumption while maintaining optimal air quality. This exemplifies the in boosting system efficiency and performance.

Understanding the differences in between air circulators and ventilators is crucial for engineers. While circulators excel in distributing air across large areas, ventilators are designed for , making them essential for applications that require precise air control. As the demand for grows, the decision between air movers and ventilators will increasingly impact system design and operational efficiency.

Compare Technical Specifications: Flow Rate, Static Pressure, and Operation Principles

When comparing blowers and fans, several must be considered:

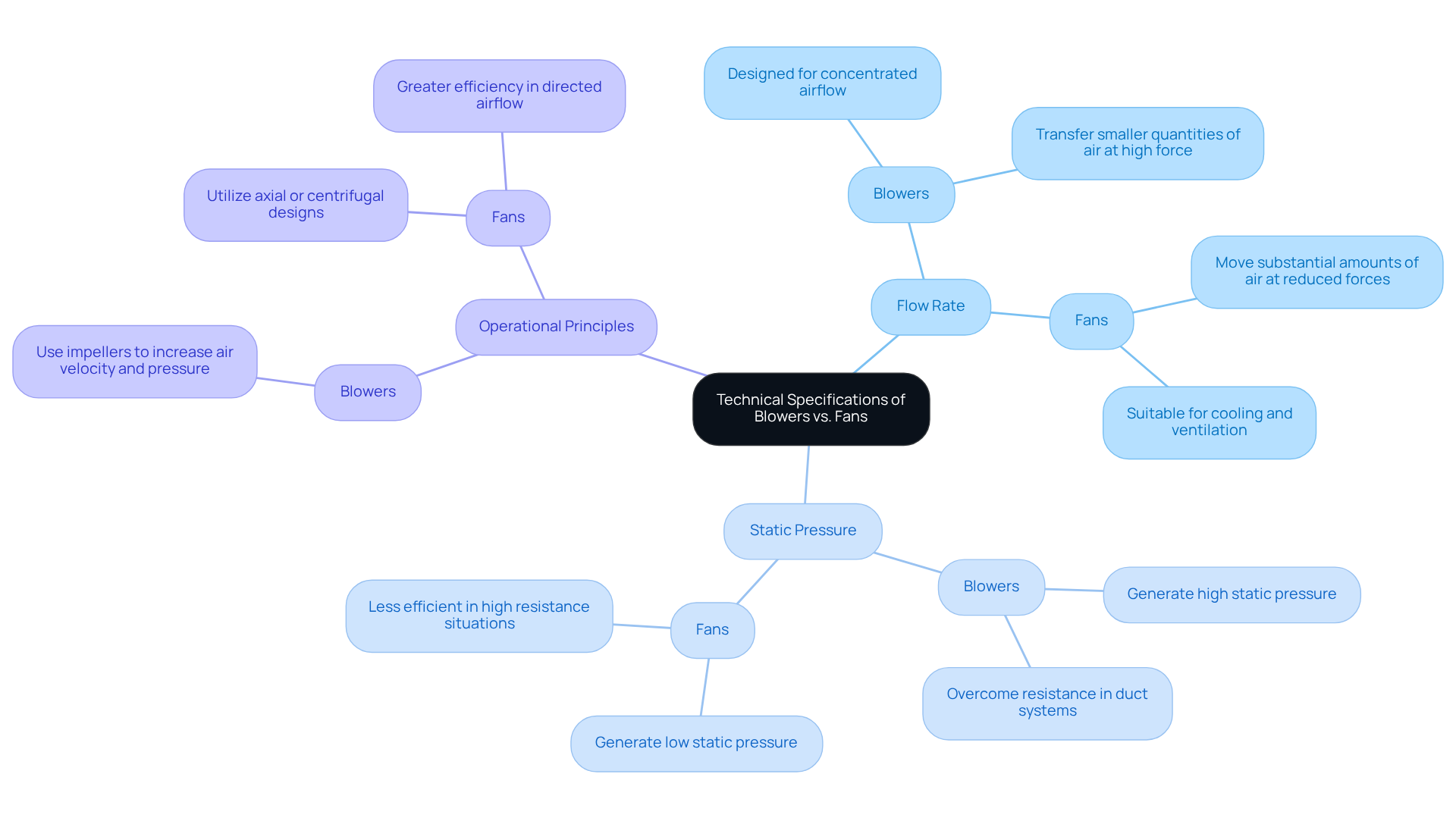

- Flow Rate: This metric indicates the volume of air moved per unit of time, typically measured in cubic feet per minute (CFM). Fans are designed to move substantial amounts of air at reduced forces, rendering them suitable for applications like cooling and ventilation. In comparison, regarding , blowers are engineered for transferring smaller quantities of air at elevated force, making them appropriate for scenarios that require .

- : This refers to the resistance to airflow within a system. In the comparison of blower vs fan, it is noted that fans typically generate low static pressure, which restricts their efficiency in situations with considerable . In contrast, when discussing blower vs fan, blowers can create greater static pressures, allowing them to overcome resistance in duct systems or other restricted areas, thereby ensuring .

- : Fans generally utilize axial or centrifugal designs to generate airflow, while blowers employ impellers to increase air velocity and pressure. This essential design distinction leads to differing performance traits, particularly in the blower vs fan debate, where fans demonstrate in scenarios that require directed airflow against resistance.

In real-world scenarios, the efficiency of air-moving devices is illustrated through various case studies. For instance, piezoelectric blowers have shown considerable benefits in , achieving flow rates of nearly 30 l/min with static pressures of 6 Pa, underscoring their effectiveness compared to conventional devices. Additionally, understanding the operational principles of these devices is crucial for engineers, as highlighted by industry experts who emphasize the importance of based on specific project requirements, such as noise sensitivity or energy efficiency.

Evaluate Applications: Choosing Between Blowers and Fans for Electronics Engineering

In the realm of electronics engineering, the choice between depends on the specific requirements of each application.

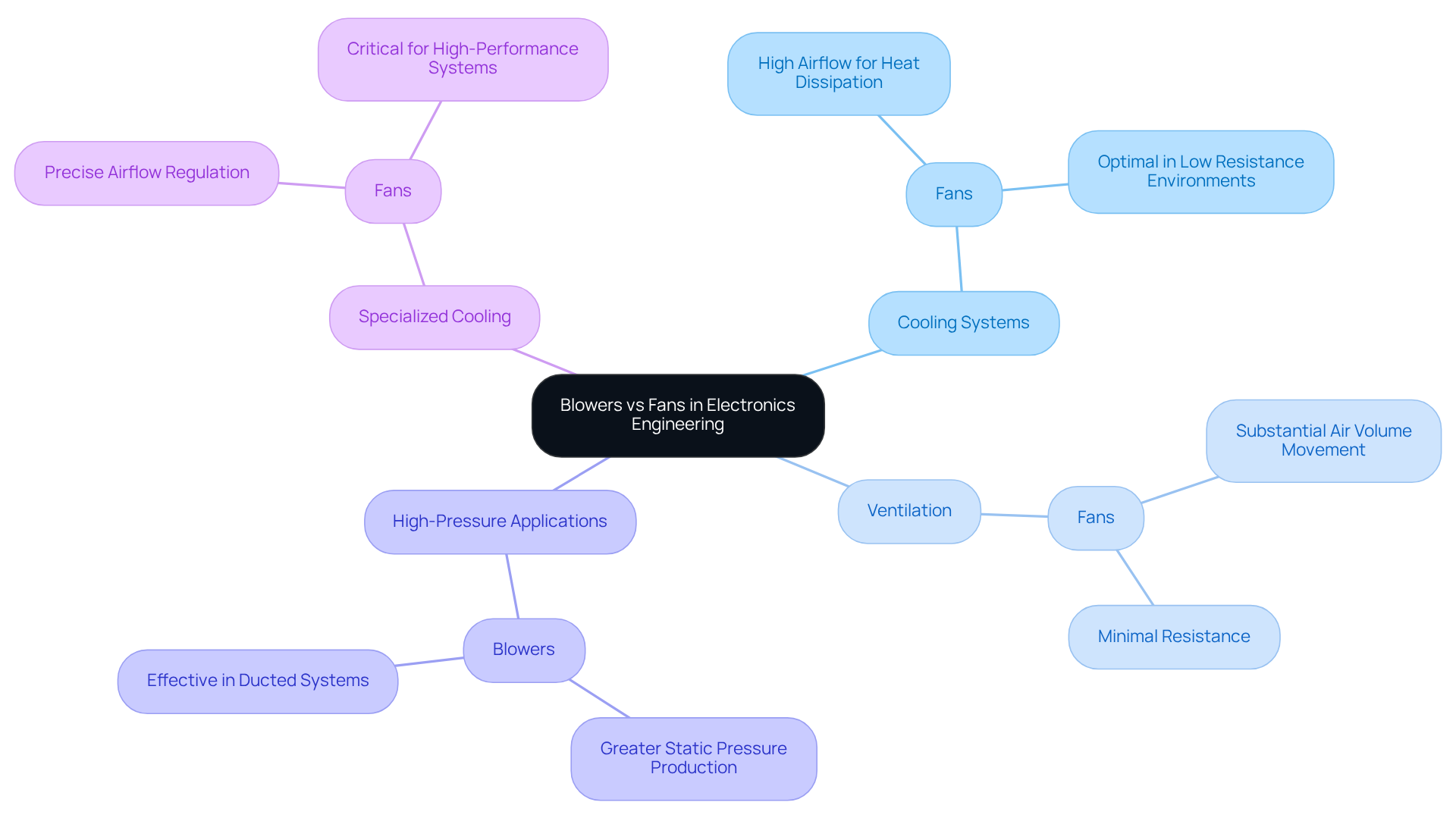

In like CPUs and GPUs, the choice between blower vs fan is significant, as fans are predominantly utilized due to their ability to generate necessary for . They excel in environments with minimal airflow resistance, making them an optimal choice.

- Ventilation: For general airflow in enclosures or rooms, fans are favored for their capacity to move substantial volumes of air with minimal resistance. This ensures a comfortable environment, crucial for both equipment and personnel.

- : Conversely, when considering blower vs fan, blowers are indispensable in situations where air must be channeled through ducts or against considerable resistance, such as in . Their capability to produce greater static pressure makes them suitable for these demanding applications.

- : In specialized cooling scenarios, such as those found in laser systems or high-performance computing environments, fans are employed to ensure . This regulation is vital for maintaining optimal operating temperatures, thus safeguarding equipment performance.

Consider Energy Efficiency and Noise Levels

When considering , it is essential to take into account and .

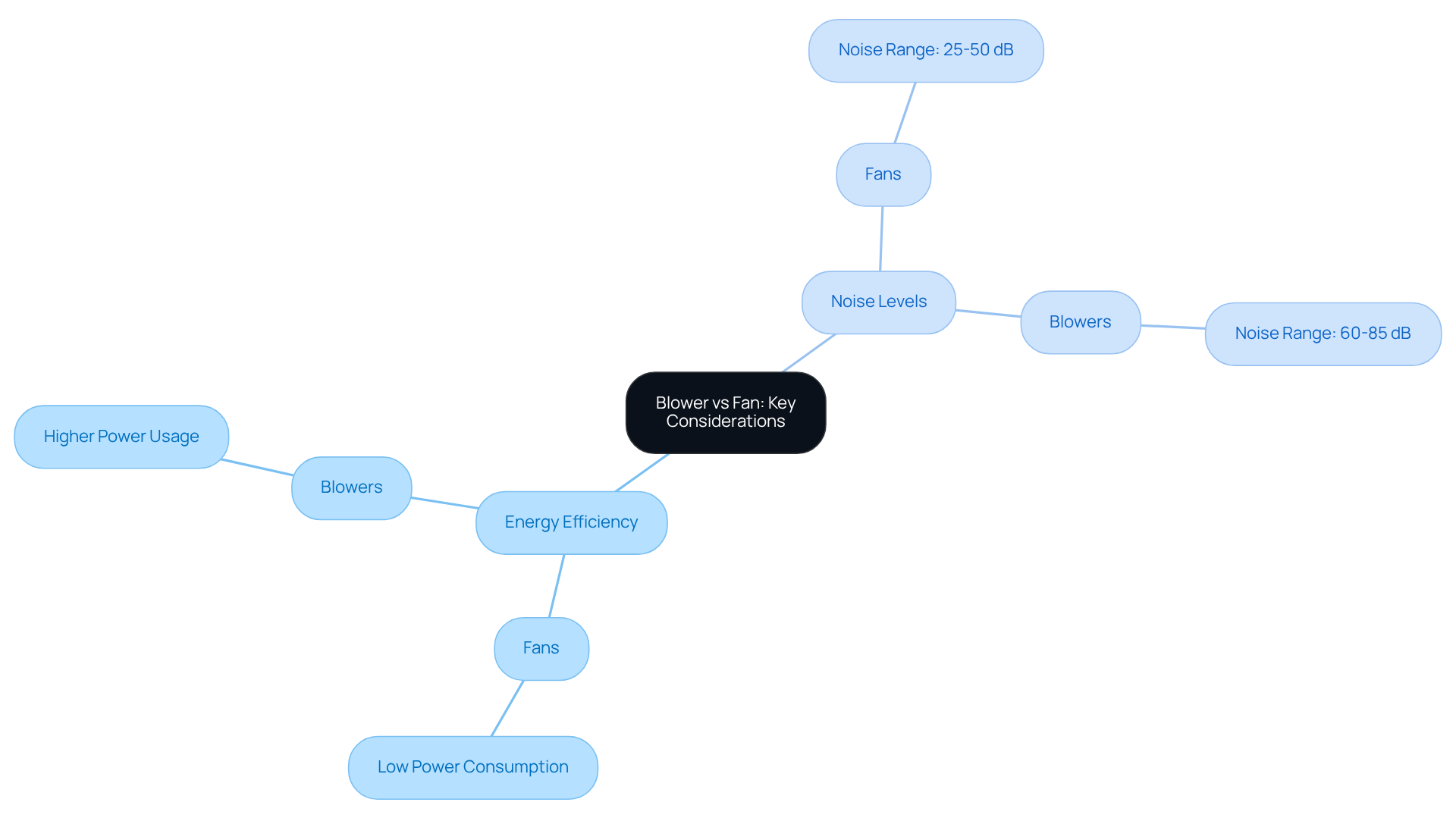

- Energy Efficiency: Fans generally exhibit , consuming less power due to their lower operational pressures. This characteristic makes them ideal for applications where . Conversely, blowers require more energy to generate higher-pressure airflow, which results in increased noise levels, making them suitable for .

- Noise Levels: Fans typically operate at lower noise levels, ranging from 25 to 50 dB, rendering them preferable in environments where sound is critical, such as residential or office settings. In contrast, blowers, especially those operating at high speeds, can generate noise levels ranging from 60 to 85 dB. This increased noise may significantly impact sensitive contexts, where maintaining a quiet environment is crucial.

Ultimately, the choice between a should be based on the , including airflow needs, pressure demands, energy efficiency, and acceptable noise levels. Selecting the right type of fan for specific applications is crucial to ensure .

Conclusion

Understanding the differences between blowers and fans is essential for electronics engineers aiming to optimize air movement across various applications. Both devices perform the critical function of air movement, yet they do so with distinct characteristics and operational principles tailored to specific needs. Recognizing these differences empowers engineers to make informed decisions that enhance system efficiency and performance.

Key aspects such as flow rate, static pressure, and operational principles highlight the distinctions between blowers and fans. Fans excel in generating high airflow with low resistance, positioning them as ideal solutions for general ventilation and cooling. Conversely, blowers are specifically engineered for high-pressure applications, effectively moving air through ducts and overcoming significant resistance. This distinction is pivotal when selecting the appropriate device for tasks like cooling electronic components or ensuring optimal HVAC performance.

Ultimately, the choice between blowers and fans can greatly influence energy efficiency and noise levels in electronic systems. As the demand for energy-efficient solutions escalates, a thorough understanding of the specific requirements for each application will guide engineers in selecting the right air-moving device. By leveraging the insights provided, professionals can optimize their designs, ensuring both effective airflow and enhanced operational efficiency in their projects.

Frequently Asked Questions

What are the main functions of blowers and fans?

Blowers and fans are mechanical devices for air movement, but they serve distinct functions. A fan transports large volumes of air at low force for general ventilation and cooling, while a blower produces greater force and speed to move air through ducts or against resistance.

How do blowers and fans differ in their operation?

Fans generate airflow through spinning blades that move air broadly and with low force, ideal for enhancing comfort. In contrast, blowers are engineered for concentrated airflow, making them efficient in scenarios requiring higher force, such as HVAC systems and industrial applications.

What is the force ratio for fans and blowers?

Fans typically operate at a force ratio of up to 1.11, while blowers function within a range of 1.11 to 1.2. This indicates that fans are better suited for handling higher static pressures.

Why is it important to choose the right device between blowers and fans?

Selecting the appropriate device is crucial as it can significantly impact system efficiency and performance. For example, a case study showed that replacing conventional units with high-efficiency fans led to a 30% reduction in energy consumption while maintaining optimal air quality.

What is the difference between air circulators and ventilators?

Air circulators excel in distributing air across large areas, while ventilators are designed for targeted airflow. This distinction is essential for applications requiring precise air control.

How is the demand for energy-efficient solutions affecting the choice between blowers and fans?

As the demand for energy-efficient solutions increases, the decision between using air movers (blowers) and ventilators will increasingly influence system design and operational efficiency.