Overview

The term “CFM,” or Cubic Feet per Minute, is essential for grasping a fan’s air movement capacity, which directly influences applications in HVAC systems and cooling devices.

Understanding this metric is crucial, as higher CFM ratings signify a fan’s capability to circulate more air. This is vital for maintaining optimal temperature and air quality, ultimately enhancing both system efficiency and user comfort.

Therefore, recognizing the significance of CFM not only informs technical decisions but also elevates overall performance in air management solutions.

Introduction

In the realm of fan technology, the measurement of Cubic Feet per Minute (CFM) serves as a pivotal standard that dictates the effectiveness of air movement within various systems. This metric transcends mere numerical value; it embodies the efficiency and performance of HVAC systems, cooling fans, and ventilation equipment, influencing critical aspects such as energy consumption and indoor air quality.

As industries evolve and the demand for optimal airflow solutions intensifies, a comprehensive understanding of CFM becomes essential for engineers and designers alike. This exploration delves into the historical development of airflow measurement and the critical factors that affect fan performance, revealing the profound impact of CFM on engineering practices and everyday applications.

Ultimately, this discussion sheds light on the significance of CFM in enhancing system efficiency and ensuring comfort across diverse environments.

Define CFM: Understanding Cubic Feet per Minute in Fan Technology

The term cfm meaning fan, or Cubic Feet per Minute, serves as a pivotal metric for measuring the volume of air a fan can transport within a minute. This measurement holds significant importance in applications such as HVAC systems, cooling devices, and ventilation machinery. The cfm meaning fan indicates that a higher CFM rating signifies a fan’s capacity to circulate more air, which is vital for sustaining optimal temperature and air quality across various environments. In HVAC setups, for instance, the appropriate CFM is essential to ensure that air distribution meets the specific requirements of the space, thereby enhancing comfort and efficiency.

Understanding cfm meaning fan is essential not only for engineers and designers when selecting blowers but also for optimizing system performance. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a diverse range of DC input Tube Axial units and Centrifugal Blowers, engineered for performance, efficiency, and low noise. Real-world applications demonstrate that devices with differing CFM ratings are suited for various tasks; high-CFM units are typically employed in industrial settings requiring substantial air volumes, while lower-CFM units may suffice in residential contexts.

Recent studies underscore the impact of accessories on fan performance, revealing that while components like filters and guards can bolster reliability in challenging conditions, they may also lead to significant pressure loss, ultimately affecting circulation and static pressure characteristics. Johann Tang, Product Specialist at Oriental Motor USA Corp., remarks, “Using accessories such as filters, screens, or finger guards can increase the reliability and life of fans in dusty or wet environments, but they will also affect the air flow and static pressure characteristics.” This highlights the necessity of considering the cfm meaning fan ratings in conjunction with accessory selections to achieve the desired airflow without compromising performance.

As we approach 2025, the significance of CFM in HVAC systems continues to escalate, with average CFM ratings showing considerable variation across different fan types, highlighting the importance of understanding cfm meaning fan. For example, typical residential ceiling fans may have ratings associated with cfm meaning fan that range from 1,500 to 5,000, whereas industrial units can surpass 20,000 CFM. Furthermore, Gagner-Toomey Associates provides a comprehensive portfolio of DC input units and blowers, showcasing the diversity inherent in ventilation technology, including sizes from 15 to 280mm for Tube Axial units and 15 to 225mm for Centrifugal Blowers, with IP protection available in most models. As engineers navigate the intricacies of fan selection, understanding cfm meaning fan remains essential for delivering effective and efficient airflow solutions. To deepen your understanding of fans and related topics, consider exploring additional resources that delve further into fan technology and its applications.

Contextualize CFM: Importance in Engineering and System Design

In engineering and design, the cfm meaning fan is essential for ensuring setups function at peak efficiency. Particularly in HVAC systems, understanding cfm meaning fan is critical for achieving the appropriate airflow necessary for optimal temperature regulation and air quality. Inadequate ventilation can lead to overheating, increased energy consumption, and discomfort in both residential and commercial environments. Research indicates that insufficient ventilation can cause energy usage to rise by up to 30%, significantly impacting operational costs.

Furthermore, in electronic devices such as computers and industrial equipment, effective cooling is paramount to prevent overheating and ensure optimal functionality. Engineers must meticulously calculate and select fans based on their CFM ratings, which refer to cfm meaning fan, to meet the specific ventilation requirements of their designs. This careful selection not only enhances reliability but also contributes to overall energy efficiency. The relationship between cfm meaning fan and energy usage in cooling setups is particularly significant, as improving air movement can yield substantial energy savings. Practical applications underscore the critical role of cfm meaning fan in engineering design. For example, in HVAC systems, industry leaders assert that maintaining appropriate CFM levels, which is related to cfm meaning fan, can enhance system efficiency by up to 25%. Additionally, case studies demonstrate that companies prioritizing cfm meaning fan in their designs achieve superior performance outcomes, reinforcing the necessity of this metric in engineering practices. A recent case study illustrates how Loganair’s commitment to efficient operations has improved regional connectivity, showcasing the broader impacts of management across various sectors. Moreover, Hegeman’s insights on constructing the entire engine emphasize the vital role of ventilation and cooling in engineering design, further underscoring the significance of cfm meaning fan in achieving optimal performance.

Trace the Origin: Historical Development of CFM Measurement

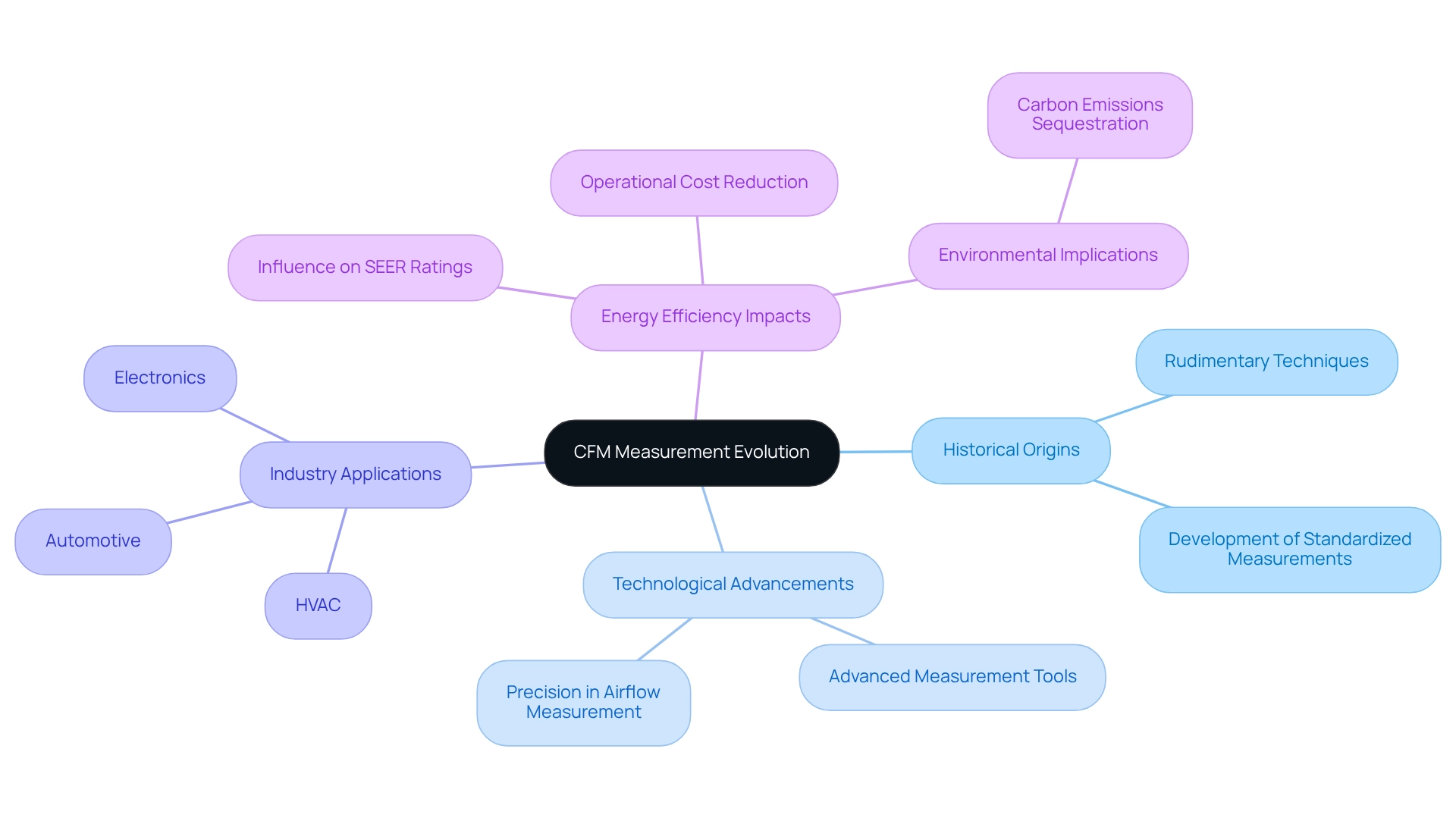

The assessment of air movement has its origins in the early engineering attempts to develop efficient ventilation and cooling systems. Initially, engineers relied on rudimentary techniques to measure air movement. However, as technology progressed, the demand for precision led to the development of advanced tools. The establishment of standardized measurements, especially with the term CFM meaning fan, revolutionized the ability to quantify air movement accurately, thereby improving design and performance evaluations.

With the proliferation of electronic devices, the importance of CFM meaning fan has become increasingly evident, especially in applications that necessitate effective cooling solutions. Today, CFM meaning fan is recognized as a fundamental metric across various industries, including HVAC, automotive, and electronics. Its critical role in system design and performance enhancement underscores the necessity of maintaining optimal ventilation levels to boost efficiency and reduce operational costs.

Historical case studies, such as those analyzing the Seasonal Energy Efficiency Ratio (SEER), demonstrate how CFM directly impacts energy efficiency benchmarks. Sustaining optimal CFM meaning fan levels is essential for achieving high SEER ratings, which indicate improved energy efficiency and lower operational costs. As highlighted by Airflow Sciences Corporation, “It is like a prison for carbon emissions, where CO is permanently sequestered, miles away from the world above ground, where it can no longer pose a risk to the climate.” This statement emphasizes the broader implications of air movement measurement in addressing environmental challenges. Additionally, specific measurements such as 5.2″, 7.5″, and 9.7″ exemplify the evolution of air measurement techniques, providing tangible illustrations that reinforce the discourse on this critical subject.

Identify Key Characteristics: Factors Influencing CFM Performance

The performance of CFM, which is the cfm meaning fan in technology, is shaped by several critical characteristics, including fan design, blade shape, and motor power. Larger blades possess the capability to move more air, resulting in higher ratings, which is referred to as cfm meaning fan. Additionally, the angle of the blades is a crucial factor; steeper angles typically enhance movement efficiency. Environmental conditions, such as air density and temperature, significantly affect the performance of the cfm meaning fan. For example, at higher altitudes, reduced air density can diminish the cfm meaning fan of a fan.

A practical illustration of cfm meaning fan can be observed in a warehouse measuring 25′ L x 50′ W x 75′ H, which requires between 14,000 to 15,000 CFM to maintain optimal circulation. Insights from the TREE House project further underscore the importance of grasping building science principles, particularly in relation to energy efficiency and system integration. This project highlighted the necessity for knowledgeable leadership in building science to ensure successful outcomes, directly applicable to fan design and its influence on CFM performance.

As noted by insulation contractor Nate Adams, “This truly was a team effort!” Engineers must carefully consider the cfm meaning fan and these characteristics when selecting fans for specific applications to achieve the desired air movement and efficiency. Furthermore, utilizing CFM calculators helps engineers understand cfm meaning fan, which proves beneficial in determining the required airflow for specific spaces, making this a valuable resource in the design process.

Conclusion

Understanding Cubic Feet per Minute (CFM) is essential for anyone involved in the design and implementation of airflow systems. This metric quantifies the volume of air moved by fans and plays a critical role in ensuring optimal performance across various applications, including HVAC systems, industrial machinery, and electronic devices. A careful selection of fans based on their CFM ratings can lead to significant improvements in energy efficiency and overall system reliability.

Historical developments in airflow measurement have established CFM as a fundamental standard guiding engineers and designers in their work. As technology has advanced, the precision of airflow measurement has evolved, underscoring the importance of maintaining optimal CFM levels to enhance operational efficiency and reduce costs. Real-world applications illustrate that prioritizing CFM in system design can lead to substantial performance gains and energy savings.

Factors such as fan design, blade shape, and environmental conditions influence the effectiveness of CFM. Recognizing these variables is crucial for engineers tasked with creating effective airflow solutions. By leveraging tools like CFM calculators, professionals can ensure that their designs meet the specific airflow requirements necessary for optimal performance.

In summary, a comprehensive understanding of CFM is indispensable for achieving effective airflow solutions that enhance comfort, improve energy efficiency, and support sustainable engineering practices. As industries continue to evolve, the significance of CFM will only grow, reinforcing its status as a vital component of modern engineering and design.

Frequently Asked Questions

What does CFM mean in relation to fans?

CFM stands for Cubic Feet per Minute and is a key metric that measures the volume of air a fan can transport in one minute.

Why is CFM important in HVAC systems?

CFM is crucial in HVAC systems as it ensures that air distribution meets the specific requirements of a space, enhancing comfort and efficiency.

How does a higher CFM rating affect a fan’s performance?

A higher CFM rating indicates a fan’s capacity to circulate more air, which is vital for maintaining optimal temperature and air quality in various environments.

Are there different CFM ratings for different applications?

Yes, devices with varying CFM ratings are suited for different tasks; high-CFM units are typically used in industrial settings, while lower-CFM units may be adequate for residential contexts.

What impact do accessories have on fan performance?

Accessories like filters and guards can enhance reliability in challenging conditions, but they may also cause significant pressure loss, affecting air circulation and static pressure characteristics.

What are typical CFM ratings for residential and industrial fans?

Typical residential ceiling fans have CFM ratings ranging from 1,500 to 5,000, while industrial units can exceed 20,000 CFM.

What types of fans does Gagner-Toomey Associates produce?

Gagner-Toomey Associates produces a variety of DC input Tube Axial units and Centrifugal Blowers designed for performance, efficiency, and low noise.

Why is understanding CFM essential for engineers and designers?

Understanding CFM is essential for engineers and designers to select appropriate blowers and optimize system performance for effective airflow solutions.