Overview

The key differences between CFM (Cubic Feet per Minute) and static pressure are critical factors that significantly impact cooling efficiency. CFM measures the volume of air moved, while static pressure indicates the resistance to airflow within a system. Understanding this distinction is essential for professionals aiming to optimize temperature regulation across various applications, from data centers to HVAC systems.

Achieving a balance between high CFM, which is necessary for effective heat dissipation, and adequate static pressure, which is required to overcome resistance, is vital. This balance not only enhances cooling efficiency but also ensures reliable performance in complex environments.

By focusing on these parameters, industry experts can implement systems that maximize efficiency and effectiveness.

Introduction

Understanding the dynamics of cooling systems presents a complex challenge, particularly when distinguishing between two critical factors: CFM (Cubic Feet per Minute) and static pressure. These metrics are pivotal in determining the effectiveness of air circulation and temperature regulation across various environments.

This article will delve into the nuances of CFM and static pressure, exploring their distinct impacts on cooling efficiency and the balance necessary for optimal performance. When one is prioritized over the other, significant consequences can arise. By leveraging this knowledge, we can enhance system design and functionality, ensuring that cooling systems operate at their best.

Define CFM and Static Pressure in Cooling Systems

CFM, or Cubic Feet per Minute, is a critical metric that quantifies the volume of air a fan or blower can move in one minute, and it is essential to understand cfm vs static pressure in this context. This measurement is essential for evaluating the efficiency of temperature regulation systems, such as those offered by Gagner-Toomey Associates, in circulating air within a designated area.

With a diverse product line that includes DC input tube axial fans and centrifugal blowers—featuring options with IP protection and various sizes—Gagner-Toomey delivers solutions that are optimized for both performance and efficiency. Notably, higher CFM values correlate with increased airflow, which significantly enhances thermal performance by facilitating rapid heat dissipation across various applications, including the electronics and automotive sectors.

Conversely, static force refers to the resistance encountered by air as it traverses a refrigeration system, which includes ducts, filters, and other components, illustrating the concept of cfm vs static pressure. This force is measured in inches of water gauge (in. wg) and is vital for comprehending how effectively a system can sustain airflow against these resistances.

An elevated atmospheric force indicates that the system is capable of efficiently propelling air through more constricted pathways, a crucial factor for effective temperature regulation in complex environments. Gagner-Toomey’s innovative temperature regulation solutions, which incorporate integrated custom temperature control systems alongside a wide array of thermal management products, are designed to achieve superior fixed force, ensuring optimal performance even in demanding applications.

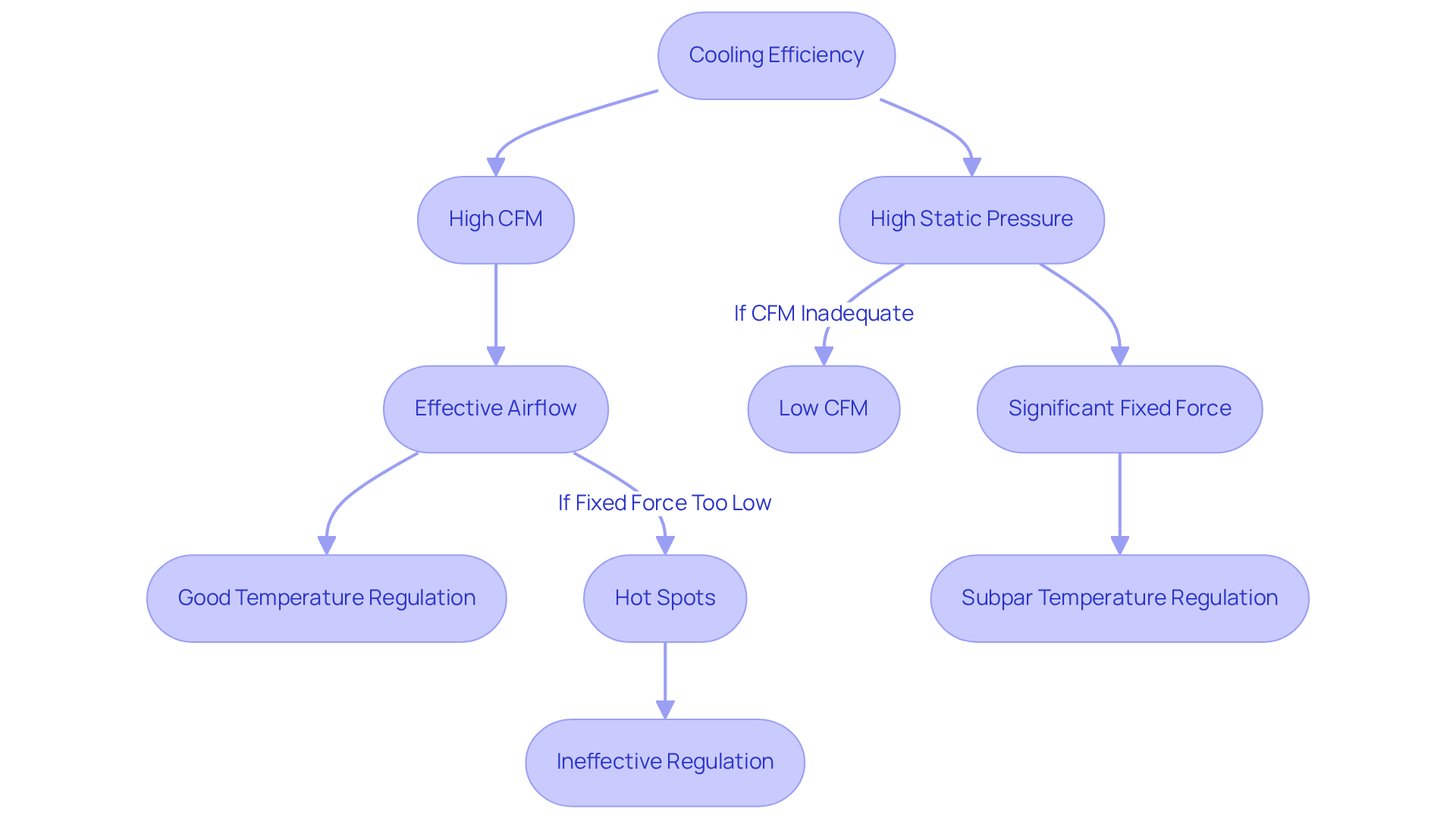

Evaluate the Impact of CFM and Static Pressure on Cooling Efficiency

The connection between CFM and fixed force is crucial in assessing refrigeration efficiency, particularly in the context of CFM vs static pressure. A system designed with high CFM effectively moves large volumes of air, which is particularly beneficial in environments requiring rapid heat dissipation. However, if the fixed force is too low, the airflow may not cover all regions efficiently, resulting in hot spots and ineffective temperature regulation.

Conversely, a system with significant fixed force can overcome resistance in ducting and filters, ensuring that air reaches its intended location. Yet, if the CFM is inadequate, the system may struggle to supply sufficient airflow, leading to subpar temperature regulation. Therefore, achieving a balance between CFM vs static pressure is essential for optimizing refrigeration efficiency.

Compare Advantages and Disadvantages of CFM and Static Pressure

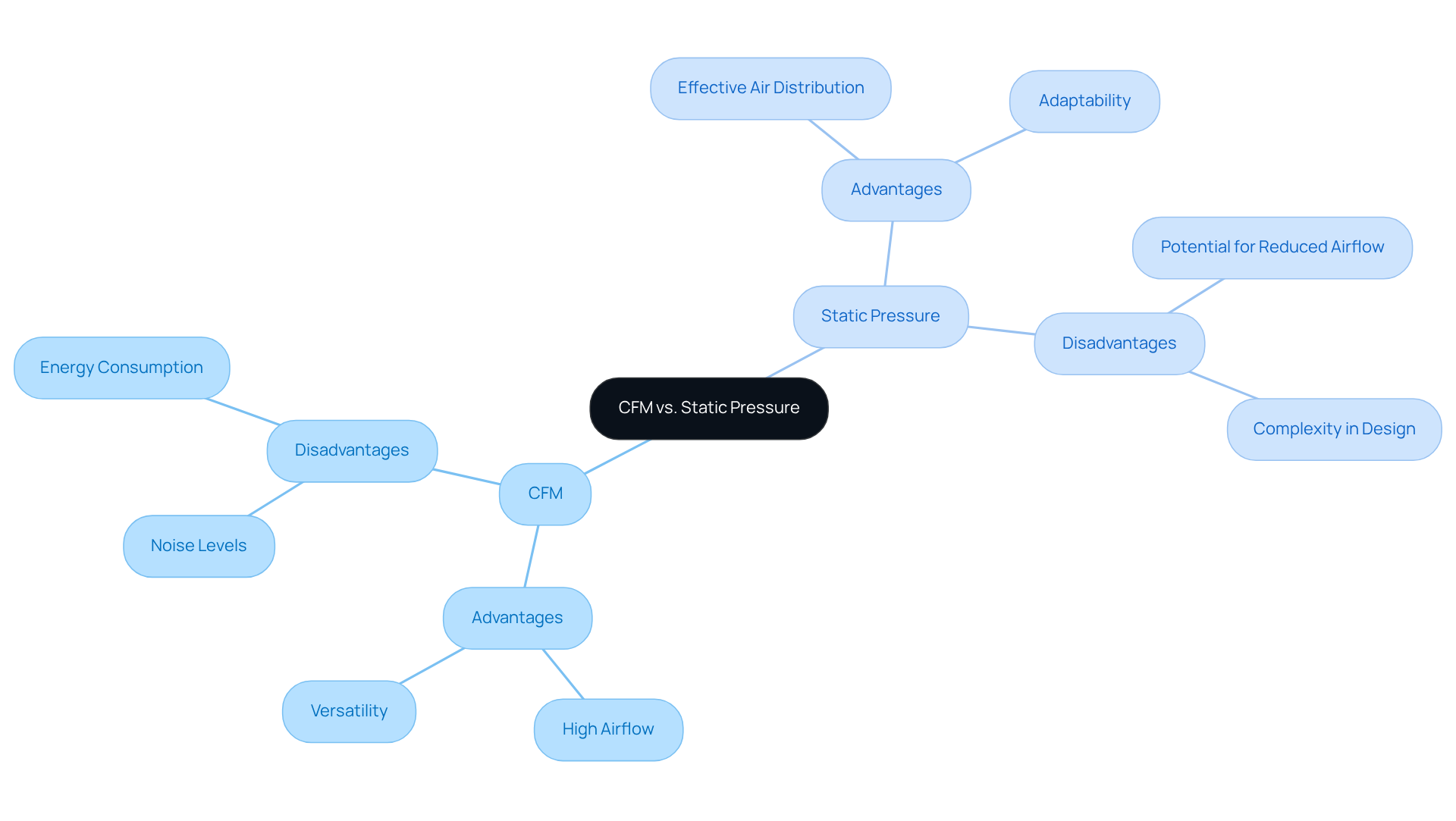

When comparing CFM and static pressure, several advantages and disadvantages emerge:

Advantages of CFM:

- High Airflow: Systems with high CFM can quickly remove heat, making them ideal for high-performance applications.

- Versatility: High CFM fans can be utilized in various setups, accommodating different temperature control needs.

Disadvantages of CFM:

- Noise Levels: Fans designed for high CFM may produce more noise, which can be a concern in sensitive environments.

- Energy Consumption: High airflow systems can consume more energy, impacting operational costs.

Advantages of Static Pressure:

- Effective Air Distribution: High static pressure systems can maintain airflow in complex ductwork, ensuring even cooling.

- Adaptability: These systems can be tailored to work with various filters and components without sacrificing performance.

Disadvantages of Static Pressure:

- Potential for Reduced Airflow: If static pressure is prioritized without adequate CFM, airflow may be compromised, leading to inefficiencies.

- Complexity in Design: Systems needing high fixed force may require more elaborate designs, heightening installation and upkeep difficulties.

Identify Suitable Applications for CFM and Static Pressure

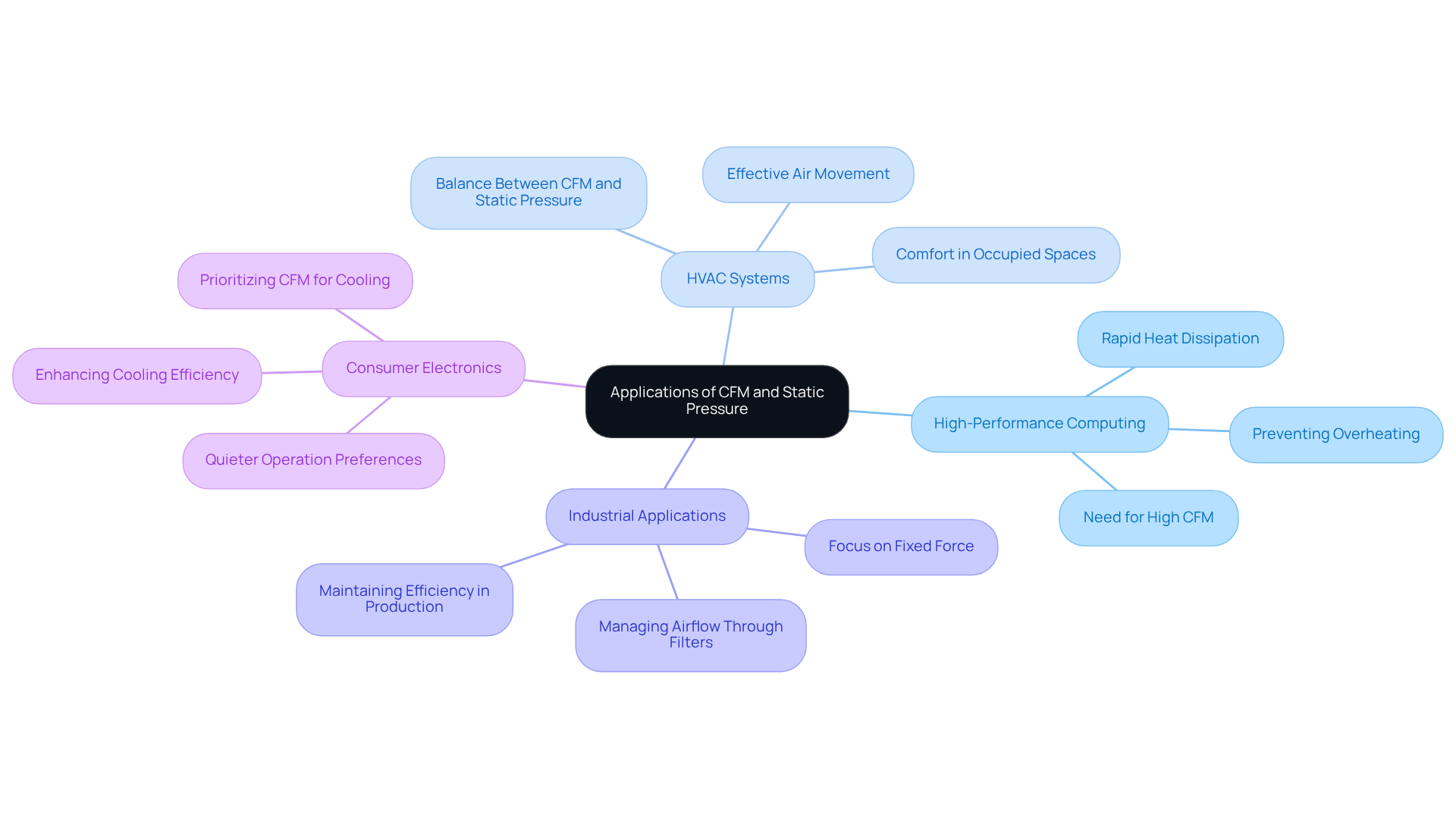

Different applications benefit from varying emphasis on CFM and static pressure:

-

High-Performance Computing (HPC): Environments such as data centers and server rooms necessitate high CFM to rapidly dissipate heat generated by dense electronic components. Maximizing airflow is critical to preventing overheating, ensuring optimal performance.

-

HVAC Systems: In both residential and commercial HVAC systems, achieving a balance between CFM vs static pressure and air resistance is essential. Elevated air resistance allows for effective air movement through duct systems, while considering CFM vs static pressure guarantees adequate airflow for comfort in occupied spaces.

-

Industrial Applications: Within manufacturing environments, a focus on fixed force is often emphasized to ensure that air reaches all sections of intricate equipment. Systems designed for high static pressure are adept at managing airflow through filters and other obstructions, maintaining efficiency in production processes.

-

Consumer Electronics: For smaller devices like gaming consoles or laptops, prioritizing CFM can significantly enhance cooling efficiency without markedly increasing noise levels, aligning with consumer preferences for quieter operation.

Conclusion

Understanding the differences between CFM (Cubic Feet per Minute) and static pressure is essential for optimizing cooling systems. These two metrics are pivotal in determining the effectiveness of air circulation and temperature regulation across various environments. By balancing CFM and static pressure, one can significantly enhance the efficiency of systems utilized in high-performance computing, HVAC, and industrial applications.

This article elaborates on the significance of CFM in facilitating high airflow for rapid heat dissipation, while also highlighting the importance of static pressure in overcoming resistance within ductwork and filters. It outlines the advantages and disadvantages of each metric, emphasizing that while high CFM can lead to noise and energy consumption concerns, prioritizing static pressure may complicate system design and potentially reduce airflow.

Ultimately, the relationship between CFM and static pressure is crucial for effective temperature regulation. It is vital for professionals and enthusiasts alike to consider the specific requirements of their applications to ensure optimal performance. Whether designing a cooling system for a data center or selecting a fan for consumer electronics, understanding the interplay between these two factors can lead to improved efficiency and operational success.

Frequently Asked Questions

What does CFM stand for and why is it important in cooling systems?

CFM stands for Cubic Feet per Minute, and it quantifies the volume of air a fan or blower can move in one minute. It is essential for evaluating the efficiency of temperature regulation systems in circulating air within a designated area.

How does CFM relate to thermal performance in cooling systems?

Higher CFM values correlate with increased airflow, which significantly enhances thermal performance by facilitating rapid heat dissipation across various applications, such as in the electronics and automotive sectors.

What is static pressure in the context of cooling systems?

Static pressure refers to the resistance encountered by air as it moves through a refrigeration system, including ducts and filters. It is measured in inches of water gauge (in. wg) and is crucial for understanding how effectively a system can maintain airflow against these resistances.

Why is it important to understand the relationship between CFM and static pressure?

Understanding the relationship between CFM and static pressure is vital for comprehending how efficiently a system can propel air through constricted pathways, which is essential for effective temperature regulation in complex environments.

What products does Gagner-Toomey Associates offer for cooling systems?

Gagner-Toomey Associates offers a diverse product line that includes DC input tube axial fans and centrifugal blowers, featuring options with IP protection and various sizes, optimized for performance and efficiency.

How does Gagner-Toomey ensure optimal performance in demanding applications?

Gagner-Toomey incorporates integrated custom temperature control systems and a wide array of thermal management products designed to achieve superior fixed force, ensuring optimal performance even in demanding applications.