Overview

This article presents a comprehensive comparative analysis of cooling fans in relation to motor performance, meticulously assessing their types, efficiency, and suitability for various applications. It underscores the critical importance of selecting the appropriate type of fan:

- Axial fans are ideal for high airflow at low pressure,

- Centrifugal fans excel in high-pressure environments.

Furthermore, it emphasizes that effective temperature regulation is essential for preserving motor longevity and performance. This assertion is bolstered by data on the efficiency and operational characteristics of leading brands, such as SANYO DENKI and SPAL, providing a solid foundation for informed decision-making in fan selection.

Introduction

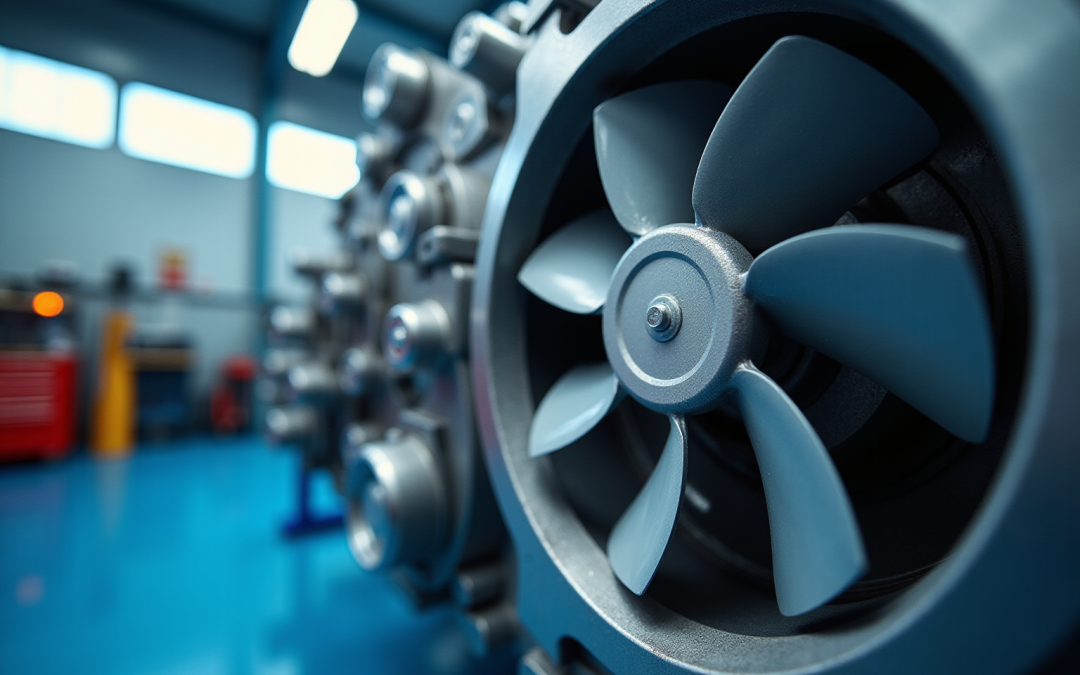

In the realm of motor systems, cooling fans are indispensable for maintaining optimal performance by regulating temperature and dissipating heat generated during operation. As technology advances, a diverse array of cooling fan types, including axial and centrifugal fans, presents tailored solutions for various applications, spanning from automotive to electronics. The potential of these fans to enhance motor longevity and efficiency underscores the necessity of understanding the intricacies of cooling fan design and performance. This article explores the different types of cooling fans, evaluates leading brands, and highlights key considerations for selecting the appropriate fan, ensuring reliability and effectiveness in motor systems.

Understanding Cooling Fans for Motors

A cooling fan for motor systems is an essential component that plays a pivotal role in temperature regulation by dissipating heat generated during operation. These devices act as a cooling fan for motor, generating a current of air that efficiently eliminates surplus heat, ensuring motors operate within ideal temperature limits. Gagner-Toomey Associates, the globe’s largest producer of standard and custom air-movers, provides an extensive range of DC input tube axial devices and centrifugal blowers, optimized for performance, efficiency, and low noise. This makes them perfect for various applications in electronics and automotive industries.

Different varieties of ventilation devices, including axial and centrifugal types, exhibit unique air movement characteristics tailored for specific applications. For instance, axial fans excel in situations requiring high airflow at low pressure, making them suitable for ventilating larger spaces. In contrast, centrifugal fans are designed for high-pressure applications, delivering concentrated airflow in restricted areas. Gagner-Toomey’s centrifugal blowers, ranging in size from 15 to 225mm, are particularly efficient in these high-pressure scenarios.

Recent research underscores the importance of efficient temperature regulation techniques in preventing material aging, demagnetization, and deformation in electric motors. Operating a vehicle with an overheating engine not only poses safety risks due to potential breakdowns but also accelerates wear and tear on engine components, resulting in more frequent repairs and a diminished lifespan. This highlights the critical need for effective operation of a cooling fan for motor. A comparative analysis of turbulence models for flow rate predictions identified the k - ω SST model as the most accurate, emphasizing the importance of precise airflow dynamics in optimizing the cooling fan for motor operations. The model’s precision directly influences real-world applications, ensuring that temperature control systems are designed to meet the specific thermal demands of various motors.

As advancements in fan technology continue to emerge, understanding the specific temperature requirements of different motors becomes increasingly crucial. Debasish Biswas confirmed that no flow separation occurred for the movement along the blade surfaces, further validating the importance of effective fan design. Recent data indicate that contemporary ventilation devices, including those from Gagner-Toomey Associates, can achieve efficiencies exceeding 90%, making a cooling fan for motor indispensable for enhancing motor functionality. Moreover, many models offer IP protection upon request, ensuring durability and reliability across various environments. This foundational knowledge will pave the way for a deeper exploration of specific fan models and their performance metrics in subsequent sections.

Pros and Cons of Cooling Fan Types:

- Axial Fans:

- Pros: High airflow at low pressure, suitable for larger areas.

- Cons: Less effective in high-pressure applications.

- Centrifugal Fans:

- Pros: High-pressure capabilities, focused airflow in confined spaces.

- Cons: Typically lower airflow at low pressure compared to axial fans.

In summary, while axial fans are advantageous for high airflow needs, centrifugal fans provide superior pressure capabilities. Assessing the advantages and disadvantages of each type will assist engineers in selecting the most appropriate thermal solution, such as a cooling fan for motor applications, particularly when considering the advanced offerings from Gagner-Toomey Associates.

Key Performance Features of Leading Brands

In the competitive fan market, brands such as SANYO DENKI, SPAL, and Flex-a-Lite distinguish themselves by providing unique functionalities tailored to various applications. SANYO DENKI’s 9RA series devices exemplify high efficiency and low noise operation, making them particularly suitable for sensitive environments where sound levels are critical. These devices have established a new performance standard, as noted in the case study titled ‘Establishing a New Performance Benchmark,’ which underscores their adaptability across various frame sizes and voltages to meet different cooling requirements.

Conversely, SPAL supporters are celebrated for their robust construction and exceptional airflow capabilities, making them ideal for automotive applications. Their design ensures reliability under demanding conditions, which is crucial for maintaining optimal engine temperatures. Expert opinions highlight SPAL’s commitment to quality, with a representative stating, “This guarantees the quality of every step in the design and manufacturing process and continues to advance technologies that help keep our cars and trucks cool, even in the most demanding situations.”

Flex-a-Lite specializes in electric fans that significantly enhance horsepower by reducing parasitic drag, a vital feature for high-performance vehicles. Their innovative designs not only improve engine efficiency but also contribute to overall vehicle performance.

Key features across these brands include:

- Variable speed control

- Durability

- Ease of installation

These are all critical factors influencing their suitability as a cooling fan for motor applications. Additionally, customers can contact representatives or distributors for quotes and project discussions, ensuring they find the right solutions for their needs. This comparative analysis highlights the strengths and weaknesses of each brand, offering valuable insights for consumers as they explore their choices in the fan market.

As the sector progresses, events like ECTC 2025, taking place from May 27 to May 30, 2025, in Dallas, Texas, will highlight innovations in temperature management technologies, further educating engineers about the latest advancements in the field.

Comparative Analysis of Top Cooling Fan Brands

When evaluating leading brands of cooling fan for motor, several critical factors must be considered: ventilation efficiency, noise levels, energy consumption, and durability. SANYO DENKI supporters distinguish themselves with exceptional airflow efficiency, typically exceeding 100 CFM (cubic feet per minute), while operating at an impressively low noise level of around 30 dBA. This combination renders them suitable for applications that demand both performance and discretion. Conversely, SPAL supporters are specifically engineered for high-temperature environments, capable of continuous operation at temperatures exceeding 200°F, making them particularly advantageous for automotive applications where effective heat management is essential.

Flex-a-Lite units are optimized for high RPM usage, delivering substantial horsepower gains by minimizing the drag associated with traditional belt-driven systems. Energy consumption is another vital consideration, with various models incorporating a cooling fan for motor that significantly reduces overall power usage. Notably, SANYO DENKI is committed to manufacturing ventilation devices characterized by low power consumption and extended service life, thereby promoting a low-carbon society.

Real-world examples further underscore these distinctions; for instance, Krenz & Co., Inc. has effectively implemented transformer ventilation systems that maintain optimal operating temperatures across diverse energy sectors, demonstrating the importance of efficient temperature regulation solutions. Additionally, Molveno Oem Service S.r.l. supplies over 15 million products annually, underscoring the scale of temperature control device production and market presence.

The healthcare sector, as highlighted by Future Market Report, necessitates advanced temperature management solutions for medical devices and equipment, further emphasizing the critical role of such devices in various applications. Moreover, HVLS fans serve as a cooling fan for motor by providing steady air circulation that cools a room more efficiently than high-velocity fans, which is a crucial factor in selecting the appropriate fan type. By understanding these essential metrics and comparisons, engineers can make informed decisions when selecting the most suitable fan for their projects.

Selecting the Right Cooling Fan: Practical Considerations

Choosing the suitable cooling fan for motor is critical, as it directly impacts the performance of the motor. The primary consideration is ensuring that the size of the cooling fan for motor aligns with the motor’s ventilation requirements. A fan that is too small may not facilitate adequate airflow, while an oversized fan can lead to increased noise and energy consumption. Research demonstrates that the size of a cooling fan for motor plays a significant role in cooling efficiency, as optimal sizing enhances airflow and minimizes thermal resistance. Notably, evaluating thermal performance deterioration through thermal cycling from -40 to 125°C underscores the importance of selecting devices capable of maintaining efficiency across varying temperatures.

Moreover, the type of motor and its operational environment are essential factors in fan selection. Motors exposed to high temperatures necessitate a cooling fan for motor made from materials that withstand elevated thermal conditions. Noise levels also warrant consideration, particularly in applications where quiet operation is paramount; excessive noise can be detrimental in such contexts. Therefore, implementing structural design measures that mitigate fluid noise in large-capacity open motors becomes a vital consideration.

Energy efficiency is another pivotal aspect; opting for fans with higher efficiency ratings can lead to substantial reductions in operational costs over time. By meticulously evaluating these components, engineers can select a cooling fan for motor systems that not only fulfills immediate temperature regulation needs but also enhances the overall effectiveness and reliability of motor systems. A case study analyzing the impact of underfill materials on BGA thermal behavior reveals the importance of thermal management, showing a 10-30% reduction in thermal resistance for underfilled components. This finding emphasizes the necessity of effective cooling solutions, particularly a cooling fan for motor, in sustaining component reliability, which is intrinsically linked to the choice of appropriate cooling fans.

As D. Lampard articulates, ‘Due to the close proximity of the end winding to the rotor, the end winding porosity has a significant effect on the flow generated by the rotor, the overall flow field and the ventilation losses.’ This statement further exemplifies the intricate relationship between fan design and motor performance.

Conclusion

Understanding the nuances of cooling fans is crucial for optimizing motor performance across various applications. This article has explored the essential roles of axial and centrifugal fans, emphasizing their unique characteristics and the specific scenarios in which each type excels. While axial fans are ideal for high airflow needs, centrifugal fans excel in high-pressure environments, underscoring the importance of selecting the right fan type for the intended application.

The evaluation of leading brands such as SANYO DENKI, SPAL, and Flex-a-Lite reveals a competitive landscape where each brand offers distinct advantages.

- SANYO DENKI is recognized for its high efficiency and low noise operation.

- SPAL boasts robust construction suited for demanding automotive conditions.

- Flex-a-Lite provides horsepower-enhancing designs.

Understanding these strengths enables engineers and consumers alike to make informed decisions tailored to their specific cooling requirements.

Selecting the appropriate cooling fan involves careful consideration of various factors, including fan size, noise levels, energy efficiency, and the operational environment of the motor. By prioritizing these considerations, engineers can ensure that their cooling solutions not only meet immediate cooling needs but also contribute to the long-term reliability and efficiency of motor systems.

In conclusion, integrating advanced cooling fan technology is vital for enhancing motor longevity and performance. As the industry evolves, staying informed about the latest innovations and understanding the critical role of cooling fans will empower engineers and manufacturers to make choices that drive efficiency and reliability in their motor systems.

Frequently Asked Questions

What is the role of a cooling fan in motor systems?

A cooling fan is essential for temperature regulation in motor systems, dissipating heat generated during operation to ensure motors operate within ideal temperature limits.

What types of cooling fans does Gagner-Toomey Associates produce?

Gagner-Toomey Associates produces a range of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise, suitable for various applications in electronics and automotive industries.

What are the differences between axial and centrifugal fans?

Axial fans excel in high airflow at low pressure, making them suitable for ventilating larger spaces, while centrifugal fans are designed for high-pressure applications, delivering concentrated airflow in restricted areas.

What sizes do Gagner-Toomey’s centrifugal blowers come in?

Gagner-Toomey’s centrifugal blowers range in size from 15 to 225mm.

Why is efficient temperature regulation important for electric motors?

Efficient temperature regulation prevents material aging, demagnetization, and deformation in electric motors, reducing the risk of overheating, breakdowns, and wear on engine components, which can lead to more frequent repairs and a diminished lifespan.

What is the significance of the k - ω SST turbulence model in cooling fan operations?

The k - ω SST model has been identified as the most accurate for flow rate predictions, emphasizing the importance of precise airflow dynamics in optimizing cooling fan operations.

How efficient are contemporary ventilation devices from Gagner-Toomey Associates?

Contemporary ventilation devices from Gagner-Toomey Associates can achieve efficiencies exceeding 90%.

What are the pros and cons of axial fans?

Pros: High airflow at low pressure, suitable for larger areas. Cons: Less effective in high-pressure applications.

What are the pros and cons of centrifugal fans?

Pros: High-pressure capabilities and focused airflow in confined spaces. Cons: Typically lower airflow at low pressure compared to axial fans.

How can engineers select the most appropriate fan for motor applications?

Engineers can assess the advantages and disadvantages of axial and centrifugal fans to determine the best thermal solution for specific motor applications, considering the advanced offerings from Gagner-Toomey Associates.