Overview

The article presents a comprehensive comparison of leading fan manufacturers, emphasizing their unique features and performance metrics that are particularly relevant to engineers. It underscores the critical importance of energy efficiency, smart controls, and durability in the selection of fans for various applications. These factors are not merely preferences; they are essential criteria that engineers must consider, as they significantly influence the future landscape of the fan industry. By addressing these key elements, the article aims to equip engineers with the knowledge necessary to make informed decisions in an evolving market.

Introduction

In an industry poised for significant growth, the fan manufacturing sector is rapidly evolving, driven by innovation and an increasing demand for energy efficiency. Engineers seeking optimal cooling solutions will discover a wealth of options among leading manufacturers, each offering unique features and technologies tailored to diverse applications.

However, with so many choices available, navigating the complexities of performance metrics becomes essential. How can one select the right fan that not only meets immediate needs but also adapts to future demands? This question underscores the importance of informed decision-making in a landscape characterized by rapid advancements and diverse offerings.

Overview of Leading Fan Manufacturers

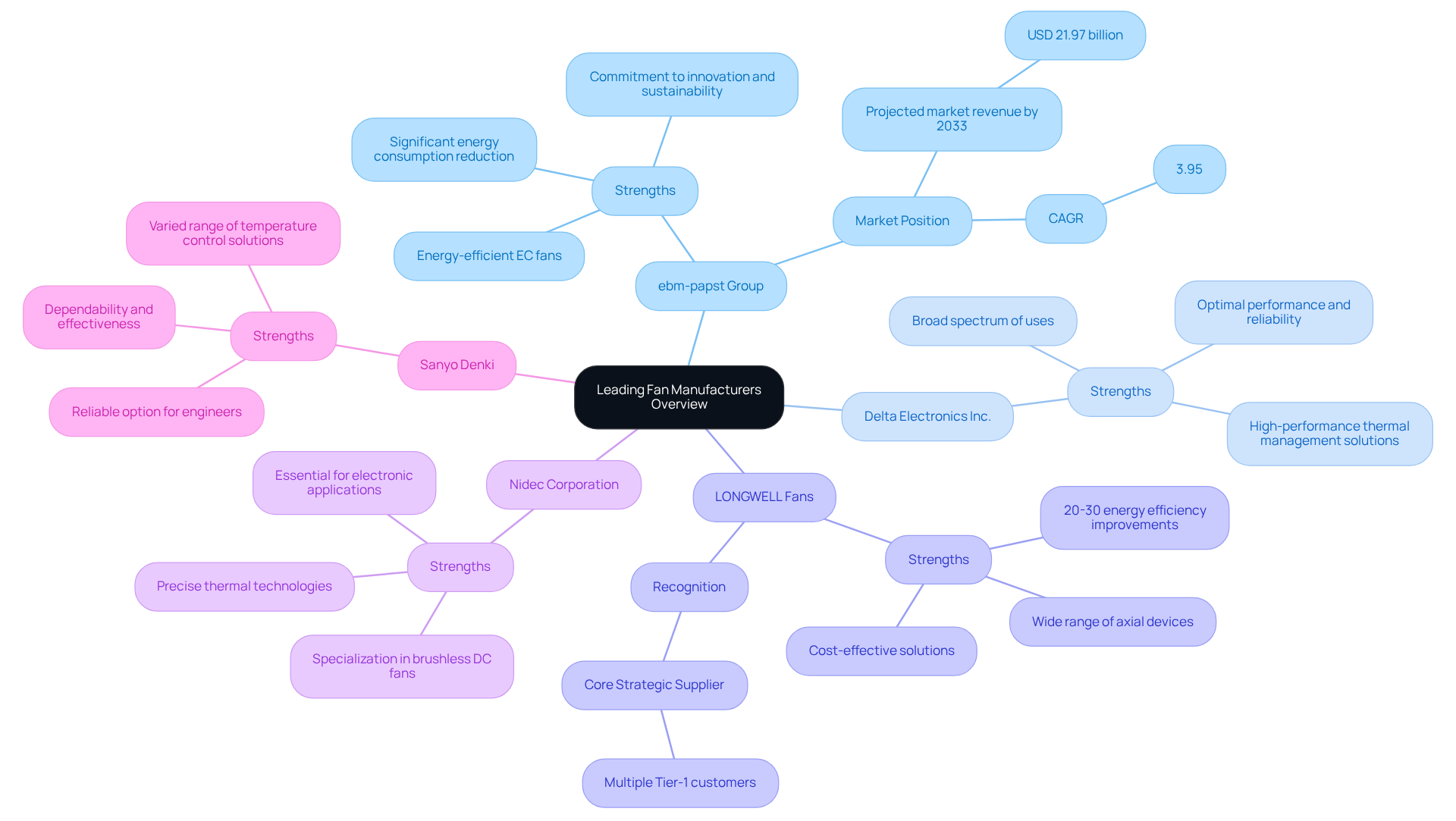

In 2025, several manufacturers distinguish themselves in the fan industry, each recognized for their unique strengths and product offerings:

-

ebm-papst Group (Germany): A leader in energy-efficient EC fans, ebm-papst is celebrated for its commitment to innovation and sustainability. They have made significant strides in reducing energy consumption across applications. Their technology is crucial as the fan market is anticipated to reach approximately USD 21.97 billion by 2033, with a CAGR of 3.95%.

-

Delta Electronics Inc. (Taiwan): Renowned for high-performance thermal management solutions, Delta Electronics excels in delivering devices that serve a broad spectrum of uses, ensuring optimal performance and reliability.

-

LONGWELL Fans (China): Known for cost-effective solutions, LONGWELL provides a wide range of axial devices designed to meet both industrial and commercial needs. They achieve notable energy efficiency improvements of 20-30% through advanced technology and have been recognized as a ‘Core Strategic Supplier’ by multiple Tier-1 customers.

-

Nidec Corporation (Japan): Specializing in brushless DC fans, Nidec distinguishes itself with its precise thermal technologies, which are essential for various electronic applications, ensuring effective thermal management.

-

Sanyo Denki (Japan): With a varied range of temperature control solutions, Sanyo Denki emphasizes dependability and effectiveness, particularly in the electronics industry, establishing itself as a reliable option for engineers.

These manufacturers, as a fans company, play a crucial role in shaping the fan market and provide engineers with a variety of options tailored to specific cooling needs. As noted by industry leaders, advancements in energy efficiency and customization capabilities are critical factors driving the market forward.

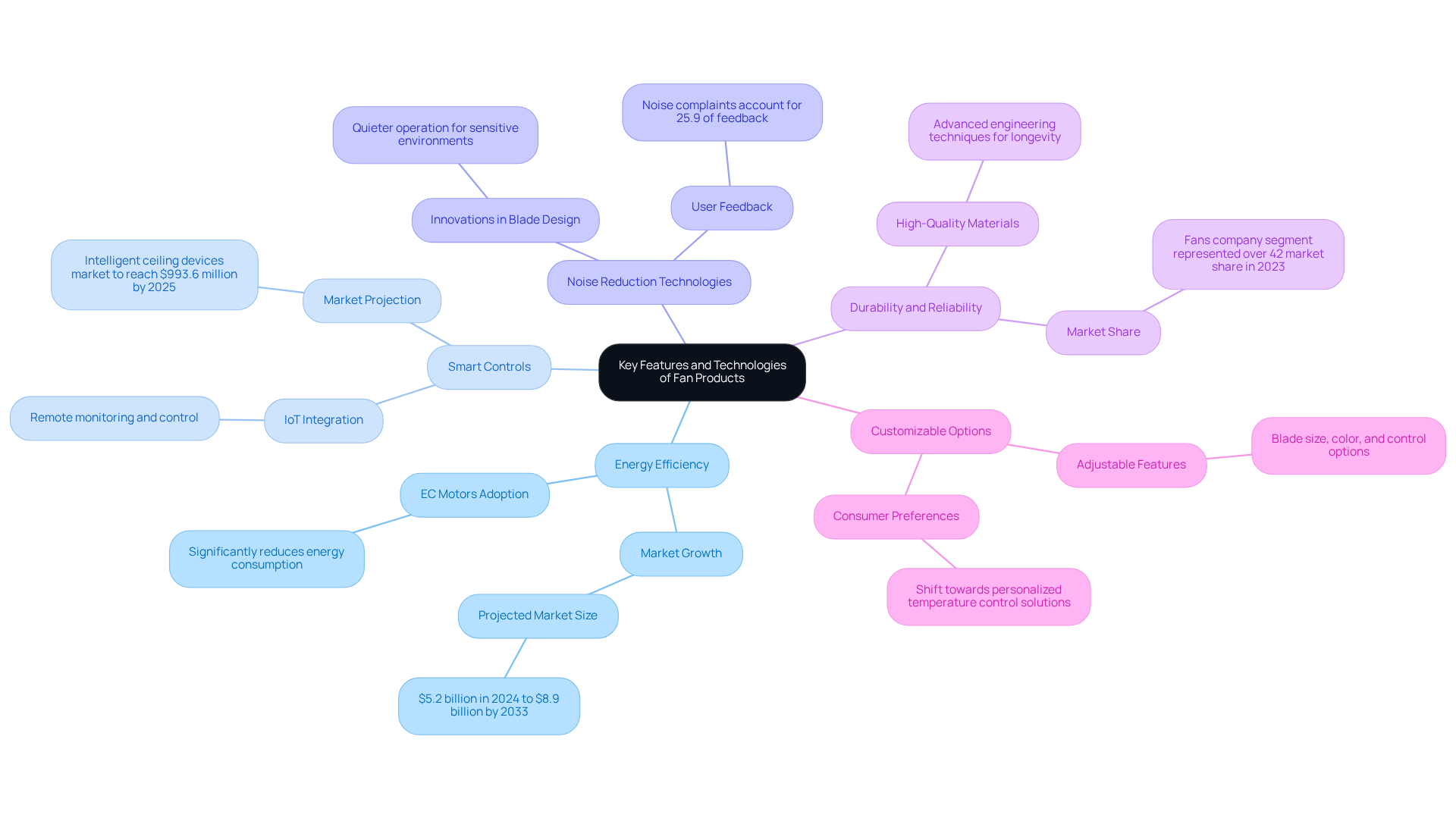

Key Features and Technologies of Fan Products

Prominent fans company producers are progressively incorporating cutting-edge technologies and features into their products to enhance functionality and efficiency. This evolution in the industry is marked by several key innovations from the fans company that address the growing demand for sustainable solutions.

-

Energy Efficiency stands at the forefront of these advancements. The fans company has significantly reduced energy consumption through the widespread adoption of EC (electronically commutated) motors compared to traditional AC motors. This shift is projected to propel the fans company market from $5.2 billion in 2024 to $8.9 billion by 2033, driven by an increasing demand for energy-efficient solutions.

-

Smart Controls have also transformed fan functionality. The integration of IoT systems facilitates remote monitoring and control, allowing users to optimize fan performance based on real-time data. The market for intelligent ceiling devices, including those from fans company, is anticipated to reach $993.6 million by 2025, reflecting the rising consumer interest in energy efficiency and smart home technology.

-

Another critical area is Noise Reduction Technologies. Innovations in blade design and motor technology have resulted in quieter operation, which is essential for applications in sensitive environments. Notably, noise complaints account for 25.9% of feedback regarding ceiling devices, underscoring the importance of these advancements in ensuring user satisfaction and comfort.

-

Durability and Reliability are paramount in the fan industry. Manufacturers, including fans company, are increasingly utilizing high-quality materials and advanced engineering techniques to guarantee long-lasting performance, even under demanding conditions. This focus on durability is particularly crucial, as the fans company segment of fan mechanisms represented over 42% of the market share in 2023.

-

Lastly, Customizable Options are gaining traction. Numerous companies now offer devices with adjustable features, including blade size, color, and control options, enabling engineers to tailor solutions for specific applications. This flexibility is becoming increasingly significant as consumer preferences shift towards personalized and efficient temperature control solutions.

These innovations not only elevate the functionality of fans but also align with the rising demand for sustainable and efficient temperature regulation technologies, reflecting a substantial trend within the fans company.

Performance Metrics and Application Suitability

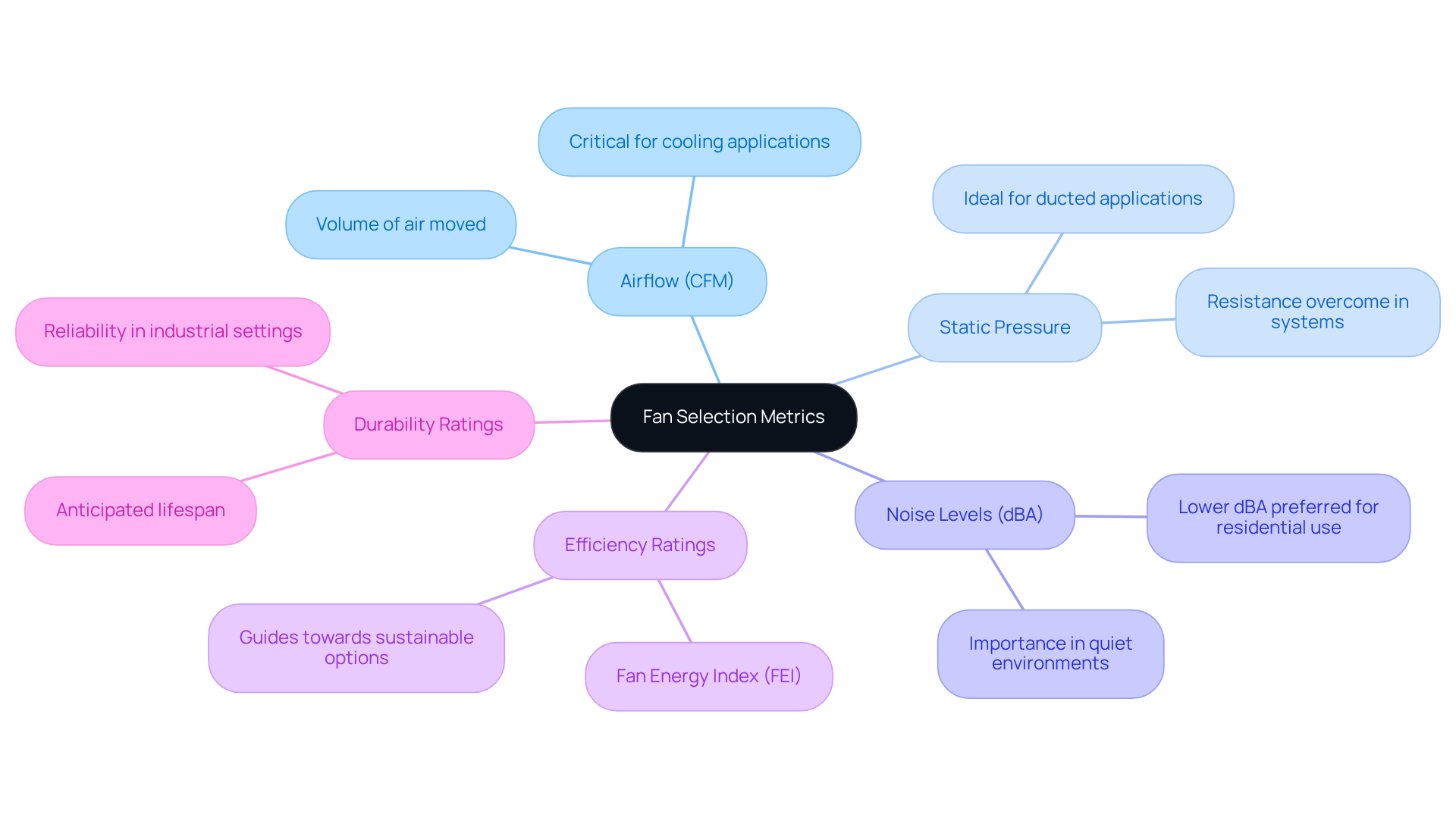

When selecting a fan from a fans company, engineers must consider several performance metrics that directly impact application suitability.

-

Airflow (CFM) is measured in cubic feet per minute (CFM) and indicates the volume of air a fan can move. Greater CFM ratings are crucial for cooling larger areas or high-heat applications.

-

Static Pressure measures the resistance a fan can overcome in a system. Fans designed for high static pressure are ideal for ducted applications where airflow is restricted.

-

Noise Levels (dBA) are critical in environments where noise reduction is a priority. Fans with lower dBA ratings are preferable for residential or office settings, ensuring a quieter atmosphere.

-

Efficiency Ratings such as the Fan Energy Index (FEI) assist engineers in evaluating the energy efficiency of ventilators, guiding them toward more sustainable options.

-

Durability Ratings are essential for understanding the anticipated lifespan and reliability of a fan, particularly in industrial settings where downtime can be costly.

By examining these metrics, engineers can select products from the fans company that not only meet their requirements but also align with their project objectives.

Conclusion: Selecting the Right Fan for Your Electronics Needs

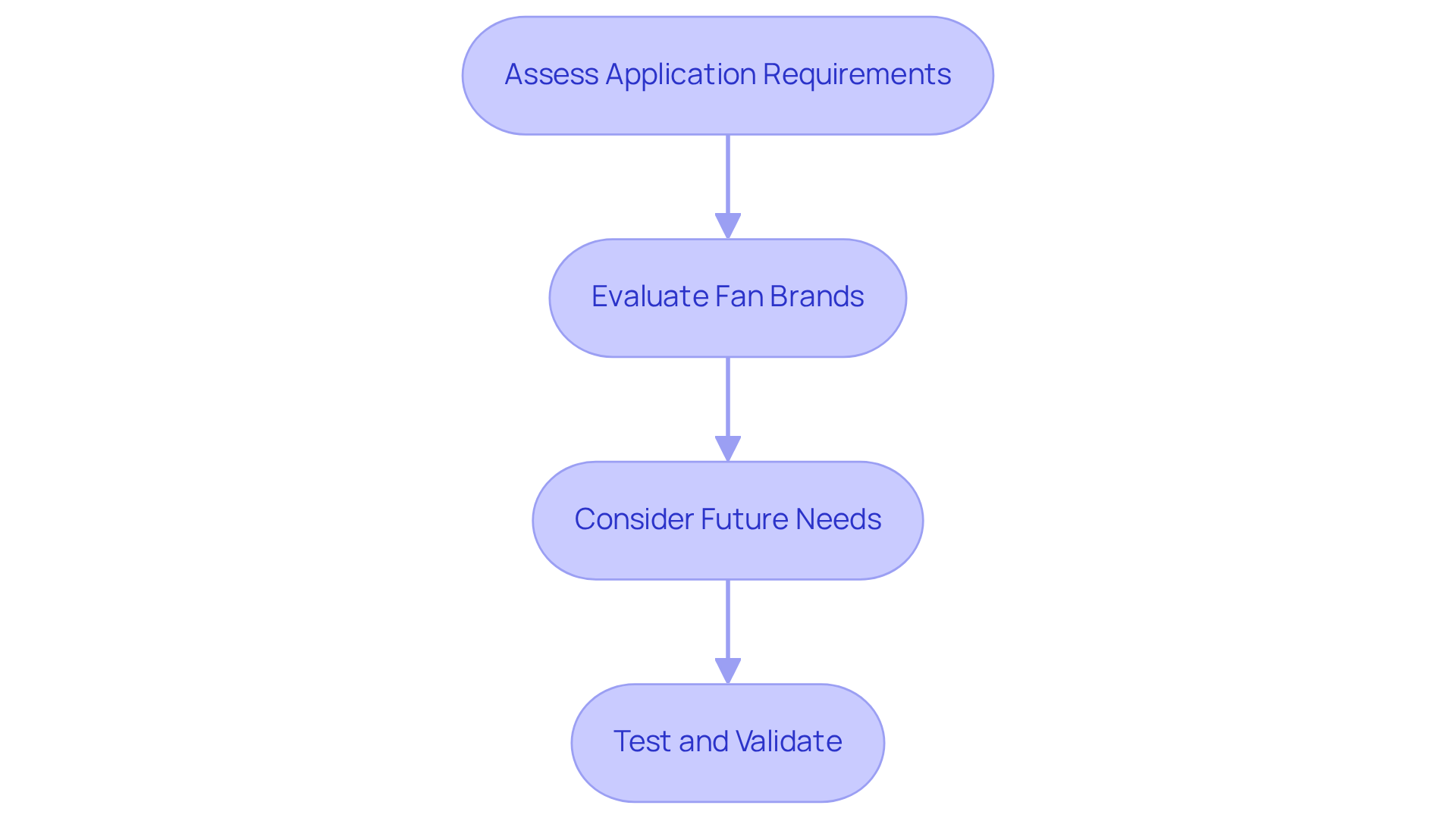

Selecting the right fan for electronics applications necessitates a thorough evaluation of features, technologies, and performance metrics. Engineers must navigate several key steps to ensure optimal outcomes:

-

Assess Application Requirements: Begin by identifying specific cooling needs, with a focus on airflow (measured in CFM), static pressure (mmH2O), and acceptable noise levels (dBA). For example, high static pressure devices are critical for CPU heatsinks and liquid cooler radiators, where airflow must be directed effectively through tight spaces. Static pressure becomes especially vital in scenarios with limited ventilation, such as densely packed electronic enclosures.

-

Assessing the reputation of a fans company is imperative to choose products recognized for their quality and innovation. Brands such as Crompton Greaves and the fans company, Hunter Fan Company, have demonstrated reliability, holding market shares of 18-22% and 8-10%, respectively. Their commitment to energy efficiency and performance can significantly influence project outcomes.

-

Consider Future Needs: Opt for devices that incorporate smart technologies and energy-efficient designs, capable of adapting to evolving requirements. The rise of IoT integration in temperature management solutions facilitates real-time monitoring and control, thereby enhancing operational efficiency. Industry experts emphasize that the incorporation of IoT with ventilation systems is gaining traction, enabling intelligent control and real-time monitoring.

-

Test and Validate: Performance tests should be conducted in real-world conditions whenever feasible. Ongoing assessments with temperature sensors can ensure that the selected devices maintain optimal efficiency and meet temperature requirements over time. Notably, improper mounting can lead to a 30% increase in installation-related failures, highlighting the necessity for thorough testing and validation processes.

By adhering to these guidelines, engineers can confidently select fans that not only meet immediate cooling demands but also contribute to the long-term success and reliability of their electronic projects.

Conclusion

Selecting the appropriate fan for electronic applications is a critical process that necessitates a thorough evaluation of various features, technologies, and performance metrics. Insights from leading fan manufacturers underscore the significance of energy efficiency, advanced control systems, and durability in addressing the diverse cooling demands faced by engineers. By grasping these essential elements, engineers can make informed decisions that not only satisfy immediate requirements but also align with future technological advancements.

This comparative analysis presents key arguments that highlight the strengths of various manufacturers, including ebm-papst, Delta Electronics, LONGWELL, Nidec, and Sanyo Denki. Each company contributes unique innovations, ranging from energy-efficient solutions to customizable options tailored for specific applications. The focus on performance metrics—such as airflow, static pressure, noise levels, and efficiency ratings—empowers engineers to select fans that optimize their projects effectively.

Ultimately, the importance of thorough evaluation and testing cannot be overstated. Engineers are urged to adopt best practices when selecting fans, ensuring that their choices not only meet current specifications but also adapt to the evolving demands of a rapidly changing industry. By prioritizing energy efficiency and leveraging advanced technologies, the right fan selection can enhance performance and reliability, paving the way for successful electronic applications.

Frequently Asked Questions

Which manufacturers are leading in the fan industry as of 2025?

The leading manufacturers in the fan industry as of 2025 include ebm-papst Group (Germany), Delta Electronics Inc. (Taiwan), LONGWELL Fans (China), Nidec Corporation (Japan), and Sanyo Denki (Japan).

What is ebm-papst Group known for?

ebm-papst Group is recognized for its energy-efficient EC fans and its commitment to innovation and sustainability, significantly reducing energy consumption across various applications.

What strengths does Delta Electronics Inc. offer in the fan market?

Delta Electronics Inc. is renowned for its high-performance thermal management solutions, delivering devices that ensure optimal performance and reliability across a broad spectrum of uses.

What distinguishes LONGWELL Fans in the fan industry?

LONGWELL Fans is known for providing cost-effective solutions with a wide range of axial devices that meet industrial and commercial needs, achieving energy efficiency improvements of 20-30%.

What is the specialty of Nidec Corporation?

Nidec Corporation specializes in brushless DC fans and is distinguished by its precise thermal technologies, which are essential for effective thermal management in various electronic applications.

How does Sanyo Denki position itself in the market?

Sanyo Denki emphasizes dependability and effectiveness with a varied range of temperature control solutions, particularly catering to the electronics industry and establishing itself as a reliable option for engineers.

What are the key factors driving the fan market forward?

Advancements in energy efficiency and customization capabilities are critical factors driving the fan market forward, as noted by industry leaders.