Overview

The article provides a comprehensive comparison of four fan manufacturing companies, highlighting their unique features and innovations. It focuses on their strengths and weaknesses in relation to engineering needs. Understanding these distinctions—such as energy efficiency, noise reduction, and sustainability practices—is crucial for engineers. This knowledge enables them to make informed decisions that align with project requirements.

Introduction

The fan manufacturing industry is undergoing a significant transformation, with companies vigorously pursuing innovation and enhancement of their product offerings. As engineers strive for optimal solutions in their projects, it becomes imperative to grasp the distinctive features and technologies offered by leading manufacturers. Yet, with an abundance of choices at one’s disposal, how does one determine which company aligns best with specific needs and sustainability objectives? This article embarks on a comparative analysis of four prominent fan manufacturers, examining their strengths, weaknesses, and the innovations that distinguish them within a competitive landscape.

Overview of Fan Manufacturing Companies: Key Features

In the fan manufacturing companies, several firms distinguish themselves through their unique features and capabilities, warranting attention from engineers. Gagner-Toomey Associates showcases a portfolio of outstanding manufacturers that focus on innovative cooling solutions, power management systems, and robust interconnect technologies.

- Entity A specializes in high-efficiency devices designed specifically for power management applications.

- Entity B offers advanced cooling solutions tailored for the RF sector.

- Firm C is recognized for its cutting-edge interconnect technologies, which enhance the performance of their fans within complex electronic systems.

- Firm D prioritizes sustainability, providing eco-friendly fan options that do not compromise performance.

Understanding the key characteristics of each fan manufacturing company is crucial for assessing their suitability for various engineering applications. Engineers must grasp these distinctions to make informed decisions that align with their specific needs.

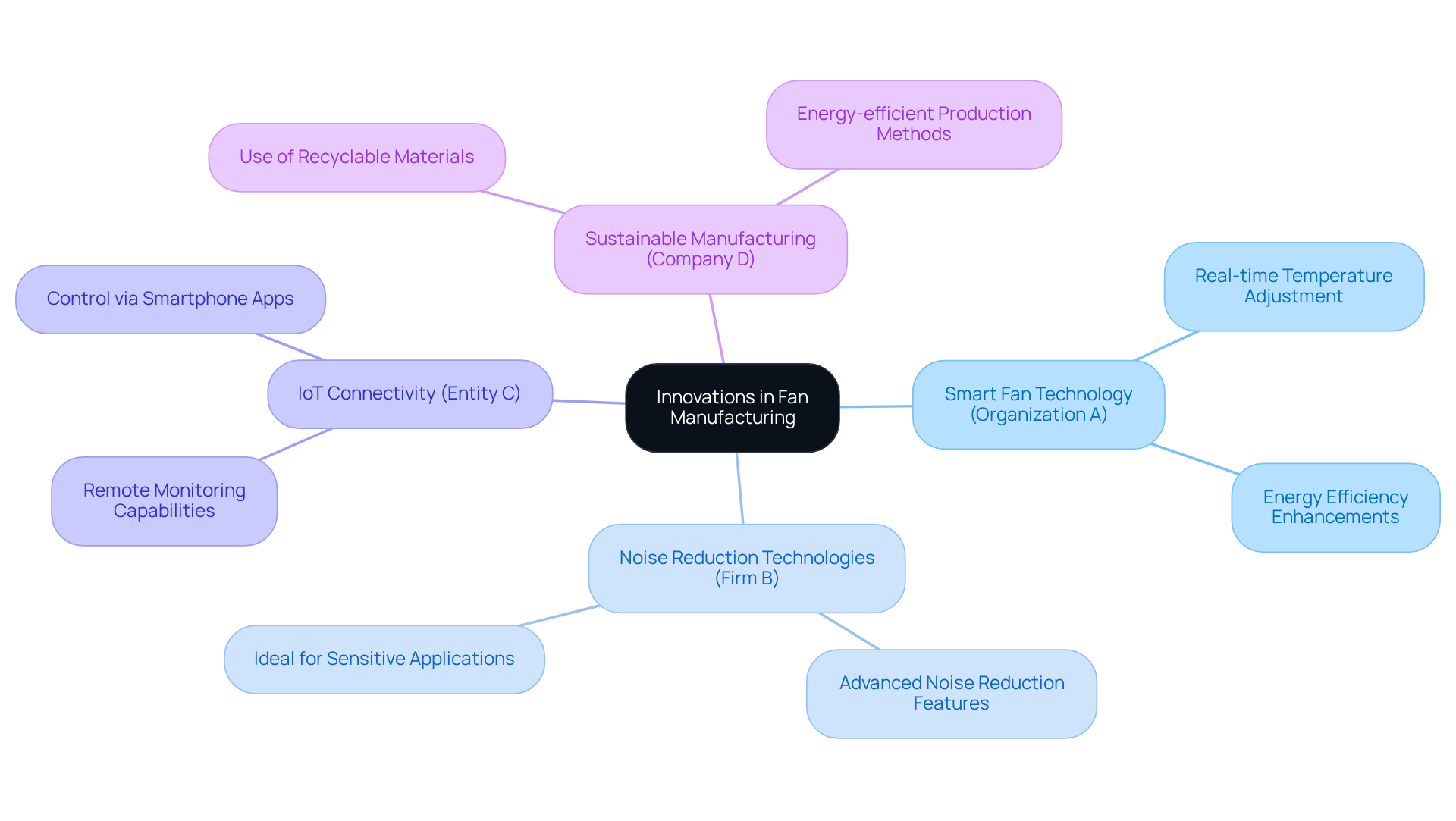

Innovations in Fan Manufacturing: Enhancements and Technologies

Innovation serves as a pivotal force within the fan manufacturing companies sector.

- Organization A has introduced smart fan technology that adjusts speed based on real-time temperature data, significantly enhancing energy efficiency.

- Firm B has developed fans featuring advanced noise reduction technologies, making them ideal for sensitive applications.

- Entity C is at the forefront of integrating IoT connectivity into their fan systems, enabling remote monitoring and control capabilities.

- Concurrently, Company D prioritizes sustainable manufacturing processes by utilizing recyclable materials and energy-efficient production methods.

These innovations not only improve performance but also address the increasing demand for environmentally responsible solutions in fan manufacturing companies within the electronics industry.

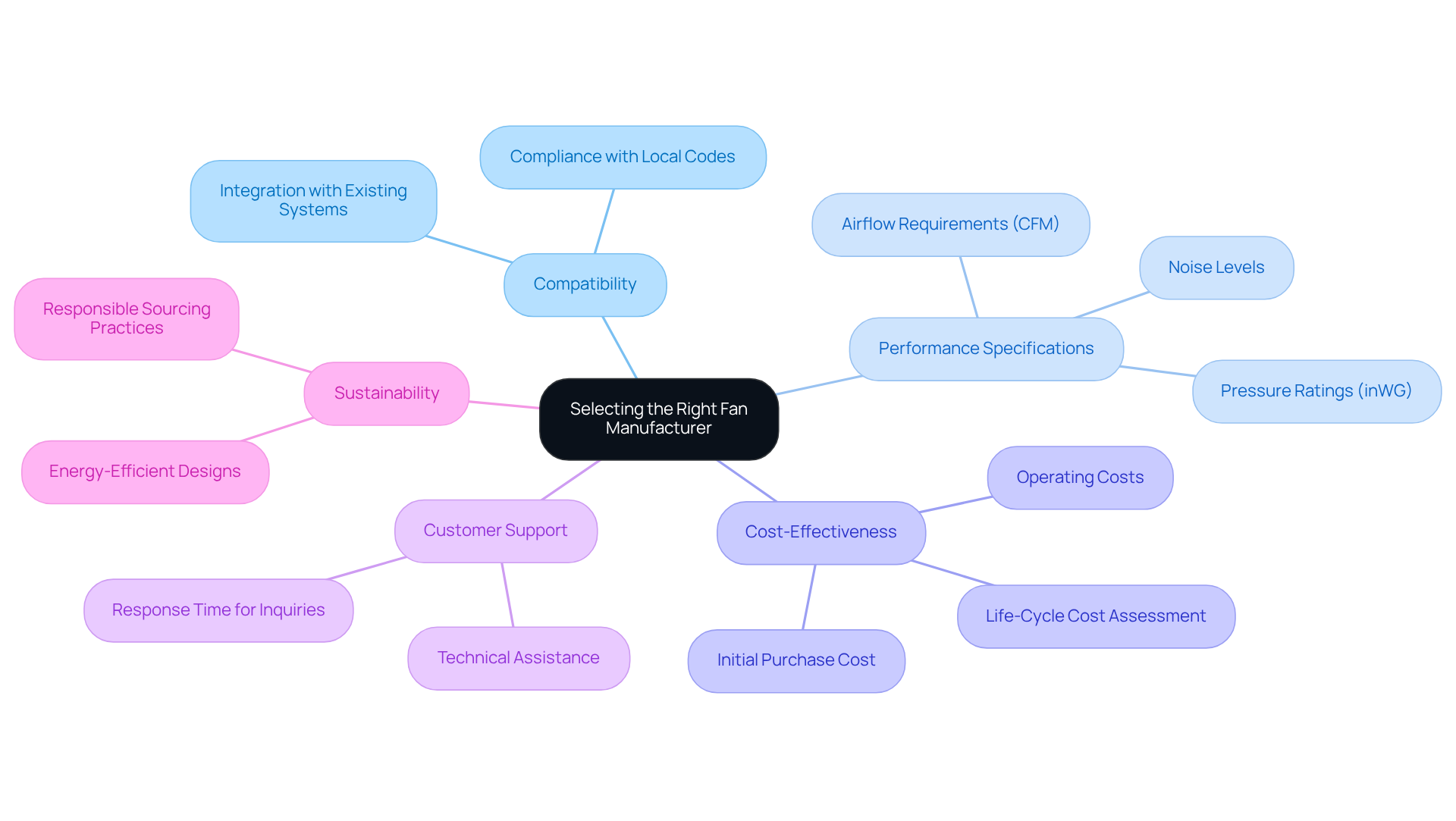

Selecting the Right Fan Manufacturer: Considerations for Engineers

When selecting fan manufacturing companies, engineers face the critical task of evaluating several essential factors to ensure optimal integration and performance.

- Compatibility with existing systems is paramount; the chosen fan must seamlessly integrate with other components to prevent operational inefficiencies.

- Furthermore, performance specifications—including airflow, pressure ratings, and noise levels—must align with project requirements to guarantee effective functionality.

- Cost-effectiveness stands as another significant consideration, as budget constraints often play a pivotal role in decision-making.

- Additionally, the quality of customer support and technical assistance provided by the producer can greatly influence project outcomes, particularly in complex applications.

- In today’s landscape, sustainability practices are increasingly vital, with engineers leaning towards producers that minimize environmental impact through energy-efficient designs and responsible sourcing.

By meticulously weighing these factors, engineers can select a provider that not only meets their technical needs but also aligns with their broader project goals.

Comparative Analysis of Leading Fan Manufacturers: Strengths and Weaknesses

In comparing the strengths and weaknesses of the leading fan manufacturing companies, several aspects emerge that warrant attention.

- Ebm-papst excels in energy efficiency, offering a wide range of products tailored for power management. However, its higher price point may deter budget-conscious engineers, presenting a challenge for those with limited resources.

- NMB is renowned for its ultra-quiet operation and innovative cooling solutions, making it ideal for delicate applications. Yet, it may lack the variety of options available from other firms, which could limit its appeal in certain markets.

- Manufacturer C distinguishes itself with its IoT-enabled fans, providing advanced monitoring capabilities that enhance operational efficiency. Nevertheless, its products may require more complex integration, posing potential hurdles for implementation.

- Lastly, SUNON’s commitment to sustainability is commendable, reflecting a growing trend in the industry. However, its product range may not meet the high-performance demands of all applications, necessitating careful consideration by engineers.

This comparative analysis underscores the importance of aligning the strengths of fan manufacturing companies with project requirements, guiding informed decision-making in fan selection.

Conclusion

The landscape of fan manufacturing companies is characterized by a diverse array of features and innovations, each meticulously tailored to meet the specific demands of engineers and their projects. A thorough examination of the strengths and unique offerings of each manufacturer reveals that making informed choices is essential for achieving optimal performance and efficiency across various applications.

Key insights from the comparative analysis indicate that manufacturers like Ebm-papst and NMB excel in energy efficiency and quiet operation, respectively. In contrast, others, such as Manufacturer C, prioritize IoT integration for advanced monitoring capabilities. Moreover, sustainability practices are gaining prominence, exemplified by firms like SUNON. Each company presents distinct advantages and potential challenges, underscoring the necessity for engineers to align their selections with project requirements and budget constraints.

Ultimately, the significance of selecting the right fan manufacturer cannot be overstated. As the industry evolves with rapid technological advancements and an increasing emphasis on sustainability, engineers are encouraged to consider compatibility, performance specifications, and customer support when making their decisions. By embracing these considerations, the optimal integration of fan systems can be realized, leading to enhanced operational efficiency and a reduced environmental impact in the long run.

Frequently Asked Questions

What are the main features of fan manufacturing companies?

Fan manufacturing companies distinguish themselves through innovative cooling solutions, power management systems, and robust interconnect technologies.

What does Entity A specialize in?

Entity A specializes in high-efficiency devices designed specifically for power management applications.

What type of solutions does Entity B offer?

Entity B offers advanced cooling solutions tailored for the RF (radio frequency) sector.

What is Firm C recognized for?

Firm C is recognized for its cutting-edge interconnect technologies, which enhance the performance of their fans within complex electronic systems.

What does Firm D prioritize in its products?

Firm D prioritizes sustainability by providing eco-friendly fan options that do not compromise performance.

Why is it important for engineers to understand the key characteristics of fan manufacturing companies?

Understanding the key characteristics of each fan manufacturing company is crucial for assessing their suitability for various engineering applications, allowing engineers to make informed decisions that align with their specific needs.