Overview

Mechanical and electric cooling fans exhibit significant differences in operation and efficiency.

- Mechanical fans, being belt-driven, rely on engine RPM.

- Electric fans operate independently based on temperature needs.

This distinction is crucial for understanding their respective advantages.

- Electric fans enhance fuel efficiency and adapt to varying thermal demands, making them more suited for modern vehicles.

- In contrast, mechanical fans are recognized for their reliability in older models, yet they suffer from inefficiencies at low speeds.

Thus, while mechanical fans have their merits, the adaptability and efficiency of electric fans position them as the superior choice in contemporary automotive design.

Introduction

In the realm of automotive cooling, the decision between mechanical and electric fans plays a pivotal role in influencing vehicle performance and efficiency.

- Mechanical fans are often lauded for their reliability and straightforward design; however, they draw power directly from the engine, which can result in inefficiencies under specific driving conditions.

- Conversely, electric fans present a modern solution, functioning independently of engine speed and optimizing cooling based on real-time temperature readings.

This article investigates the fundamental differences between these two types of cooling fans, examining their respective advantages and disadvantages, application suitability, and cost considerations.

As technology progresses and vehicle designs evolve, grasping these distinctions becomes essential for vehicle owners and engineers alike, facilitating informed decisions that enhance both performance and longevity.

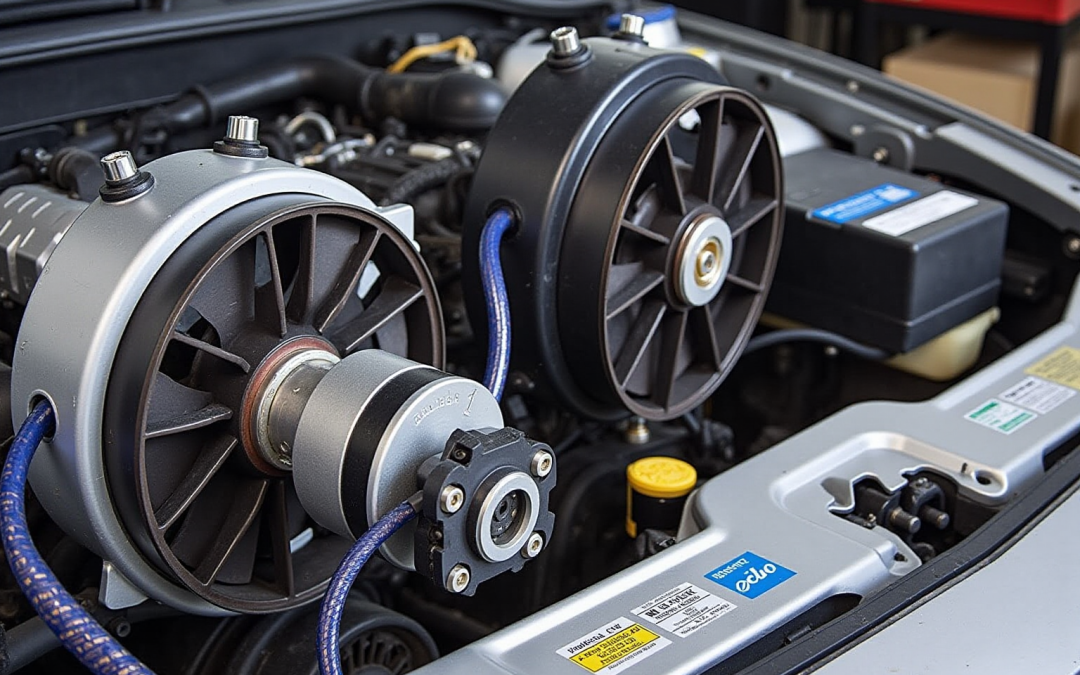

Understanding Mechanical and Electric Cooling Fans

Understanding mechanical and electric cooling fans is crucial, as mechanical cooling fans, commonly referred to as belt-driven fans, serve as a type of cooling fan for cars that is directly linked to the engine via a belt system. Their operation is fundamentally tied to the motor’s RPM, resulting in a constant power draw irrespective of the actual thermal demand. This can lead to inefficiencies, particularly during idle or low-speed conditions, where the fan may operate at full capacity without necessity. In contrast, electric ventilation devices utilize the vehicle’s electrical system, operating independently of motor speed. Regulated by the control module (ECM), these units engage according to current temperature measurements, enabling enhanced cooling exactly when necessary.

This operational distinction is pivotal in evaluating the advantages and disadvantages of each fan type. Electric ventilators, such as those provided by Gagner-Toomey Associates, can significantly improve fuel efficiency by minimizing parasitic drag on the engine, especially in contemporary vehicles where engine load management is vital. Gagner-Toomey is recognized as the globe’s largest producer of standard and custom air-movers, offering a wide range of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise. Their offerings include sizes ranging from 15 to 280mm for tube axial devices and 15 to 225mm for centrifugal blowers, with IP protection available upon request. Recent advancements in electric fan technology have further enhanced their performance, making the cooling fan for cars a popular choice in contemporary automotive design. On the other hand, mechanical devices are frequently commended for their dependability and straightforwardness, especially in older automobiles where electrical systems might not accommodate high-demand temperature control solutions. For instance, the standard radiator in the 1970 HG Holden Kingswood is a 2 core radiator, which demonstrates the temperature management needs of older vehicles that mechanical fans can effectively handle under high-load conditions. However, they may not adapt as effectively to varying thermal demands as their powered counterparts.

Pros and Cons of Mechanical vs. Electric Cooling Fans:

- Mechanical Fans:

- Pros: Reliable, simple design, effective in older vehicles.

- Cons: Continuous power draw, less efficient at low speeds.

- Electric Fans:

- Pros: Optimized cooling based on demand, improved fuel efficiency, available in various sizes with IP protection.

- Cons: Requires proper wiring and control setups for effective operation.

Real-world examples demonstrate that while mechanical devices can offer strong cooling, the efficiency of powered ventilators is frequently emphasized in discussions. As pointed out by registered user matt69olds, ‘If powered ventilators were better than mechanical ones, then they would be utilized on heavy-duty trucks,’ suggesting an opposing perspective on their efficiency in high-demand applications.

Furthermore, user experiences presented in the case study titled ‘Electric Fan Wiring and Control’ highlight the significance of proper wiring and control configurations for fans, which are considered essential for efficient operation. Users recommend using quality wiring kits and ensuring that the electrical system can handle the power requirements of a cooling fan for cars. In summary, understanding the basic distinctions in function between mechanical and electric ventilation systems is crucial for making informed choices in automotive applications, especially as innovations continue to influence the realm of vehicle temperature regulation technologies, including the use of a cooling fan for cars. ‘Gagner-Toomey Associates’ extensive range of temperature regulation solutions, including both standard and custom designs, provides engineers with the necessary tools to navigate these choices effectively.

Pros and Cons of Mechanical vs. Electric Cooling Fans

Mechanical devices are renowned for their simplicity and reliability, typically delivering higher airflow (CFM) at elevated RPMs, which is essential during high-load scenarios such as towing. However, their efficiency diminishes at rest, as they consume power even when cooling is not necessary. In contrast, powered ventilators present several advantages: they operate solely when needed, leading to improved fuel efficiency and reduced motor load. Their capacity to maintain consistent airflow, regardless of engine speed, renders them particularly effective in stop-and-go traffic. Notable air circulators, including the Mark VIII models and Taurus dual cooling arrangements, exemplify the effectiveness of a cooling fan for car in contemporary vehicles.

Despite these benefits, powered ventilators can introduce complexity, requiring additional components such as relays and sensors that may become failure points. Furthermore, while high-quality powered ventilators generally entail a higher initial investment compared to mechanical models, their long-term benefits in fuel savings and performance may justify the expense. Recent discussions within the automotive community, such as Glenn Bearup’s inquiry regarding fan options for his inherited 1970 Holden Kingswood, underscore the ongoing relevance of these considerations in vehicle upgrades.

Additionally, case studies on temperature regulation system modifications for classic vehicles highlight the importance of evaluating modern powered devices against traditional mechanical alternatives, emphasizing the need for effective temperature management solutions tailored to specific driving conditions. As noted by Cole Quinnell, ‘the fan would be a cooling fan for car vehicles that usually operate at low vehicle speeds with low motor rpm.’ This insight reinforces the suitability of a cooling fan for car in particular driving scenarios.

Ultimately, the choice of fan type can profoundly impact performance and longevity, making it a pivotal decision for vehicle owners.

Application Suitability: When to Use Mechanical or Electric Fans

Mechanical blowers are predominantly favored in conventional vehicles and high-performance applications where optimal airflow is critical, particularly at elevated RPMs. They excel in vehicles that rarely idle or operate at low speeds, such as trucks utilized for towing. Conversely, powered ventilators are gaining traction in modern vehicles, especially those equipped with stop-start technology or hybrid systems, where efficiency and reduced motor load are paramount. These devices demonstrate exceptional performance in urban driving scenarios characterized by frequent stops and starts, delivering necessary airflow without the continuous power consumption associated with mechanical systems. Additionally, electric fans offer advantages in compact spaces, enhancing installation versatility.

The automotive engine temperature regulation fan market is anticipated to witness substantial growth, projected to achieve a CAGR of 5.2% from 2025 to 2030. This growth is driven by the increasing demand for advanced temperature management technologies that resonate with the industry’s commitment to lowering vehicular emissions. Such trends emphasize the necessity for a comprehensive understanding of the application suitability of both fan types to optimize vehicle temperature management. As underscored by MAHLE GmbH, a leading supplier of automotive temperature regulation solutions, “high-performance products and extensive expertise in thermal management are crucial for meeting the evolving demands of the automotive industry.”

Furthermore, the case study titled “Market Customization Opportunities” highlights the flexibility in report customization, enabling stakeholders to gain insights tailored to their specific needs, thereby enhancing decision-making within the automotive fan market. This dynamic competitive landscape underscores the continuous evolution of sophisticated temperature control technologies, reinforcing the imperative for engineers to stay informed about the latest trends and innovations.

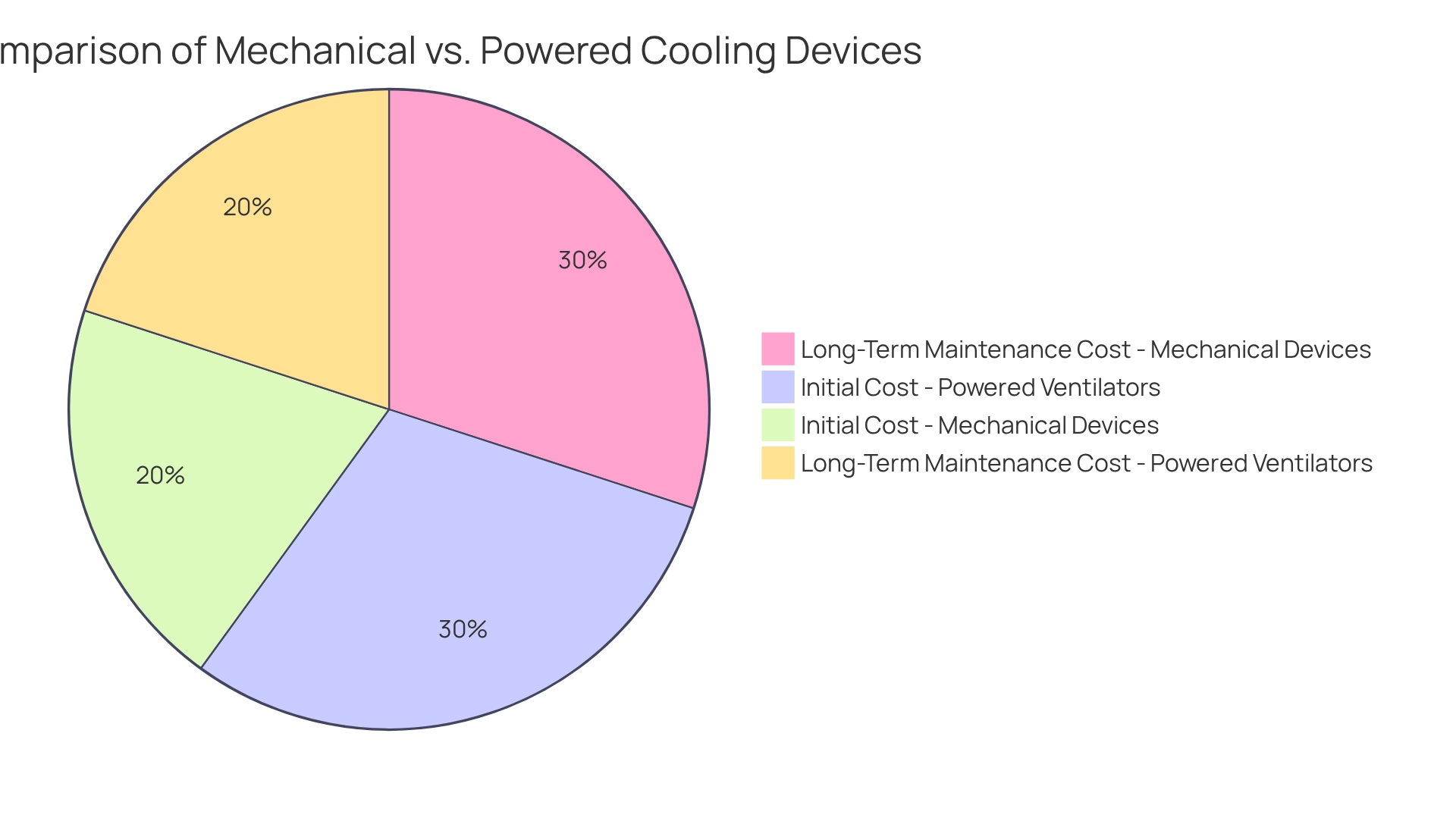

Cost Considerations and Maintenance

Mechanical cooling devices typically present a lower initial investment, appealing to budget-conscious consumers. However, they often incur higher long-term maintenance costs due to the wear and tear on mechanical components such as bearings and belts. In contrast, powered ventilators, although initially more expensive, can yield significant savings in fuel efficiency and reduced engine wear, potentially offsetting their upfront costs over time. Additionally, cooling devices generally require less frequent maintenance because they have fewer moving parts, making them less prone to mechanical failures.

Despite these advantages, the complexity of such systems may result in increased repair costs if electrical components fail. A case study titled ‘Mechanical vs. Electric Blade Efficiency’ illustrates how powered devices can be fine-tuned for optimal performance at specific speeds, leading to superior overall efficiency compared to mechanical models that may become less effective at non-ideal RPMs. This aspect is particularly crucial in automotive applications, which often demand devices capable of moving several thousand CFM to effectively manage engine temperatures.

When evaluating the choice between mechanical and powered units, it is vital to consider both the initial purchase price and the long-term maintenance implications. Practical examples indicate that while mechanical devices may seem cost-effective at first glance, the cumulative maintenance expenses can make powered alternatives a more economical choice over time. Data suggests that fans can lead to a reduction in maintenance frequency, further enhancing their appeal for those looking to minimize long-term costs. As noted by a FABO Gold Member, combining a clutch fan with an electric fan can provide a practical solution, especially in vehicles like the 1970 Holden Kingswood, which may encounter temperature regulation challenges. This underscores the evolving landscape of automotive cooling solutions and the critical importance of selecting the appropriate fan system for specific applications.

Conclusion

The comparison between mechanical and electric cooling fans reveals key differences that significantly affect vehicle performance and efficiency.

Mechanical fans are reliable, providing high airflow in demanding situations, making them suitable for traditional vehicles. However, they continuously draw power from the engine, leading to inefficiencies during idle or low-speed driving.

In contrast, electric fans optimize cooling based on real-time temperature, enhancing fuel efficiency and reducing engine load, particularly in modern vehicles that frequently encounter stop-and-go traffic.

Understanding the application suitability of each type is crucial. Mechanical fans excel in high-performance applications, while electric fans are increasingly favored in vehicles equipped with stop-start systems or hybrids. The growth of the automotive cooling fan market reflects a shift towards advanced technologies that align with environmental goals.

Cost considerations are also paramount. Although mechanical fans have a lower initial cost, they may incur higher long-term maintenance due to component wear. Electric fans, while more expensive upfront, can yield savings through improved fuel efficiency and reduced maintenance frequency.

In conclusion, choosing between mechanical and electric cooling fans necessitates a thorough evaluation of vehicle requirements, driving conditions, and long-term costs. By understanding the strengths and weaknesses of each option, vehicle owners and engineers can make informed decisions that enhance performance and efficiency, ensuring their cooling systems meet the demands of modern automotive design.

Frequently Asked Questions

What is the main difference between mechanical and electric cooling fans in cars?

Mechanical cooling fans are belt-driven and linked directly to the engine, operating based on the motor’s RPM, which can lead to inefficiencies. Electric cooling fans operate independently of the engine speed and are regulated by the control module (ECM), engaging based on current temperature measurements.

What are the advantages of electric cooling fans?

Electric cooling fans provide optimized cooling based on demand, improve fuel efficiency by reducing parasitic drag on the engine, and are available in various sizes with IP protection options.

What are the disadvantages of electric cooling fans?

Electric fans require proper wiring and control setups for effective operation, which can complicate their installation and use.

What are the pros of mechanical cooling fans?

Mechanical fans are known for their reliability, simple design, and effectiveness in older vehicles where electrical systems may not support high-demand temperature control solutions.

What are the cons of mechanical cooling fans?

Mechanical fans have a continuous power draw and are less efficient at low speeds, which can lead to unnecessary energy consumption.

How do mechanical fans perform in high-load conditions?

Mechanical fans can effectively handle temperature management needs in high-load conditions, especially in older vehicles, but may not adapt as well to varying thermal demands compared to electric fans.

What is the significance of proper wiring and control configurations for electric fans?

Proper wiring and control configurations are essential for the efficient operation of electric fans, as inadequate setups can hinder their performance.

Who is Gagner-Toomey Associates and what do they provide?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a wide range of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise.

What recent advancements have been made in electric fan technology?

Recent advancements in electric fan technology have enhanced their performance, making them a popular choice in contemporary automotive design.

What user experiences highlight the efficiency of electric fans?

User experiences, such as those discussed in the case study ‘Electric Fan Wiring and Control,’ emphasize the importance of quality wiring and ensuring the electrical system can handle the power requirements for effective operation of electric cooling fans.