Overview

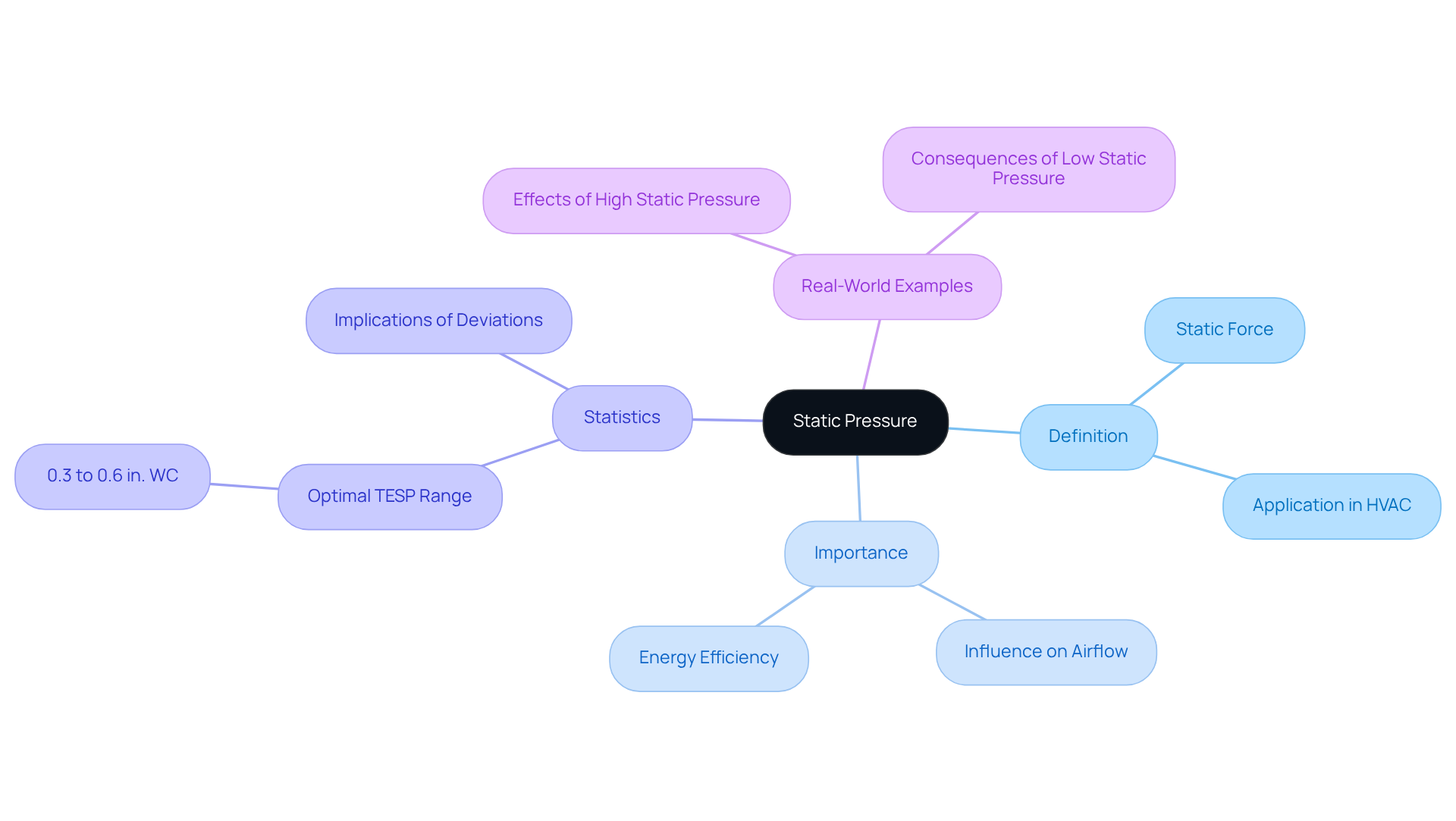

Static pressure is defined as the pressure exerted by a fluid at rest, a critical factor in the performance of HVAC systems that significantly influences airflow and energy efficiency. Understanding and measuring static pressure using appropriate techniques and tools is essential for engineers. This knowledge allows them to optimize system performance and address issues such as reduced airflow and increased operational costs effectively.

Introduction

Understanding static pressure is crucial for engineers, particularly in the realm of HVAC systems, where the force exerted by a fluid at rest can significantly influence performance and efficiency. This guide delves into the following aspects:

- Definition of static pressure

- Measurement techniques

- Implications of static pressure

The guide offers engineers essential insights into optimizing airflow and energy consumption. However, with many systems operating outside the ideal pressure range, engineers face the challenge of effectively troubleshooting and maintaining static pressure. This is vital to prevent costly inefficiencies and ensure optimal system operation.

Understand Static Pressure: Definition and Importance

To define static pressure, one must understand that static force denotes the force applied by a fluid at rest, which plays a crucial role in various engineering applications, particularly in HVAC setups. To understand this force, we need to define static pressure, which is the pressure that air exerts on the walls of ducts and other components when airflow is absent. Understanding how to define static pressure is essential because it directly influences airflow, energy efficiency, and the overall performance of the system. Engineers must define static pressure when considering fixed force in their designs to ensure optimal operation and mitigate issues such as reduced airflow or increased energy consumption. For instance, maintaining appropriate fixed force levels in climate control systems is essential to define static pressure, which can enhance comfort and significantly lower energy costs.

Statistics indicate that the optimal total external static pressure (TESP) for most residential heating and cooling units is approximately 0.5 inches of water column (in. WC), with a normal range of 0.3 to 0.6 in. WC. Deviations from this range can result in inefficiencies and elevated operational costs. As noted by industry specialists, to define static pressure is to understand that fixed resistance is a critical metric of opposition to airflow within air distribution ducts, underscoring its importance in engineering applications. Real-world examples demonstrate that elevated fixed force can lead to noisy heating and cooling operations, as well as increased energy expenses, highlighting the necessity for routine maintenance and appropriate duct dimensions to optimize performance.

Measure Static Pressure: Techniques and Tools

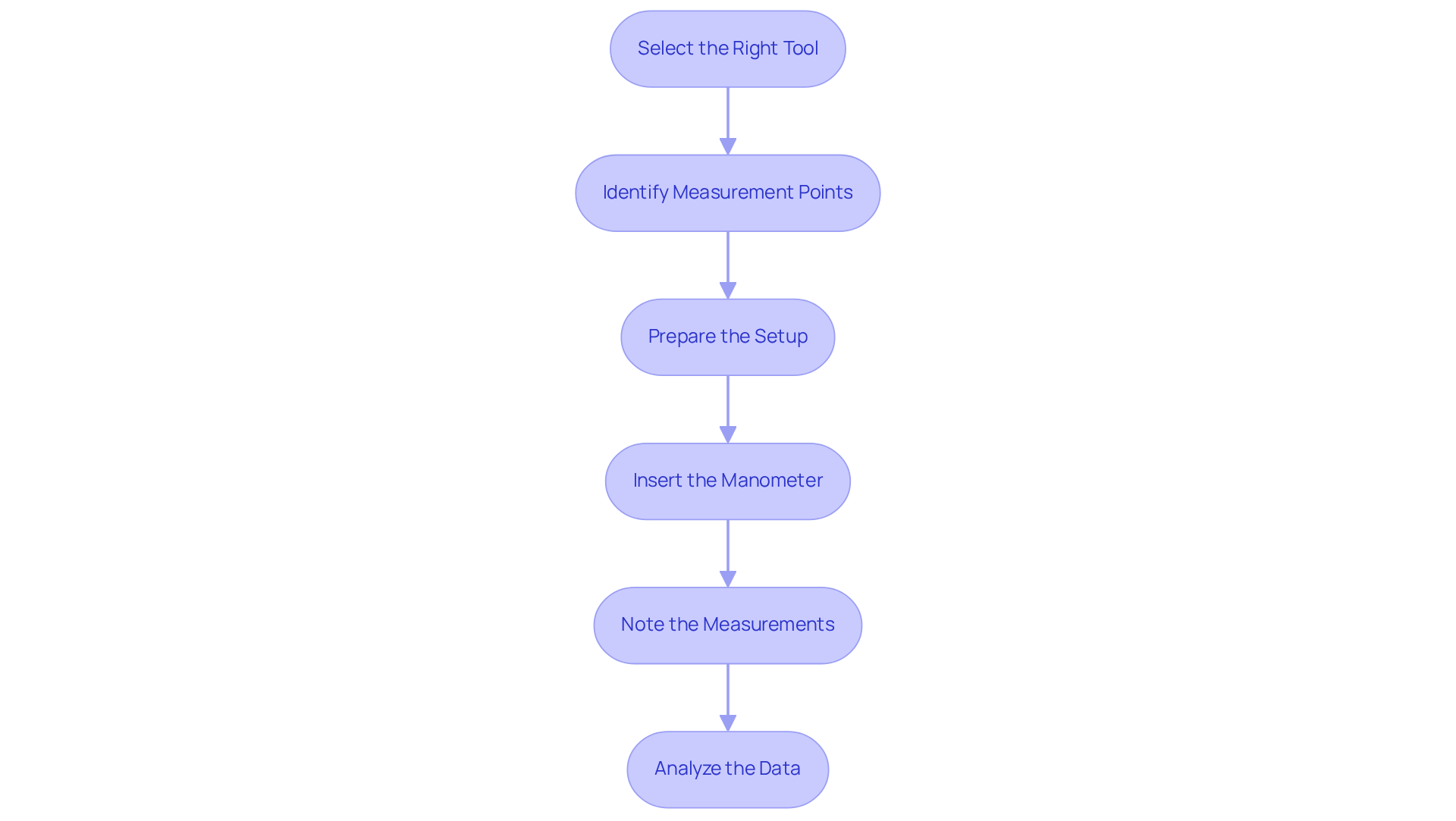

A precise assessment of non-dynamic force is essential for engineers engaged in HVAC systems. Utilizing various instruments, such as manometers and barometers, can yield effective results. Below is a step-by-step guide to measuring static pressure:

- Select the Right Tool: Choose either a digital manometer or a water column manometer, both of which are commonly employed for static pressure measurements in heating, ventilation, and air conditioning applications.

- Identify Measurement Points: Pinpoint the appropriate locations within the ductwork for measurement, generally on both the supply and return sides of the system.

- Prepare the Setup: Prior to taking measurements, ensure the HVAC unit is turned off and all dampers are closed to prevent airflow interference.

- Insert the Manometer: Carefully position the manometer probes into the designated measurement taps, ensuring they are oriented correctly to capture accurate readings.

- Note the Measurements: Reactivate the system and record the fixed readings from both the supply and return sides. Compare these values to verify if the setup operates within the recommended pressure range, ideally between 0.4 and 0.6 inches of water column. It is important to note that if the Total External Static Pressure (TESP) exceeds 0.50 inches, the fan will struggle to move the required 400 CFM per ton, which can significantly impact performance.

- Analyze the Data: Use the recorded data to evaluate performance and identify any potential static pressure-related issues.

By utilizing the appropriate tools and adhering to these steps, you can markedly enhance the effectiveness and reliability of heating and cooling units, ensuring optimal performance and comfort. As Rob ‘Doc’ Falke states, “Proper equipment selection is your responsibility, not the manufacturer’s or distributors.” This underscores the critical importance of precise measurement in achieving efficient heating and cooling solutions.

Analyze Static Pressure: Impact on System Performance

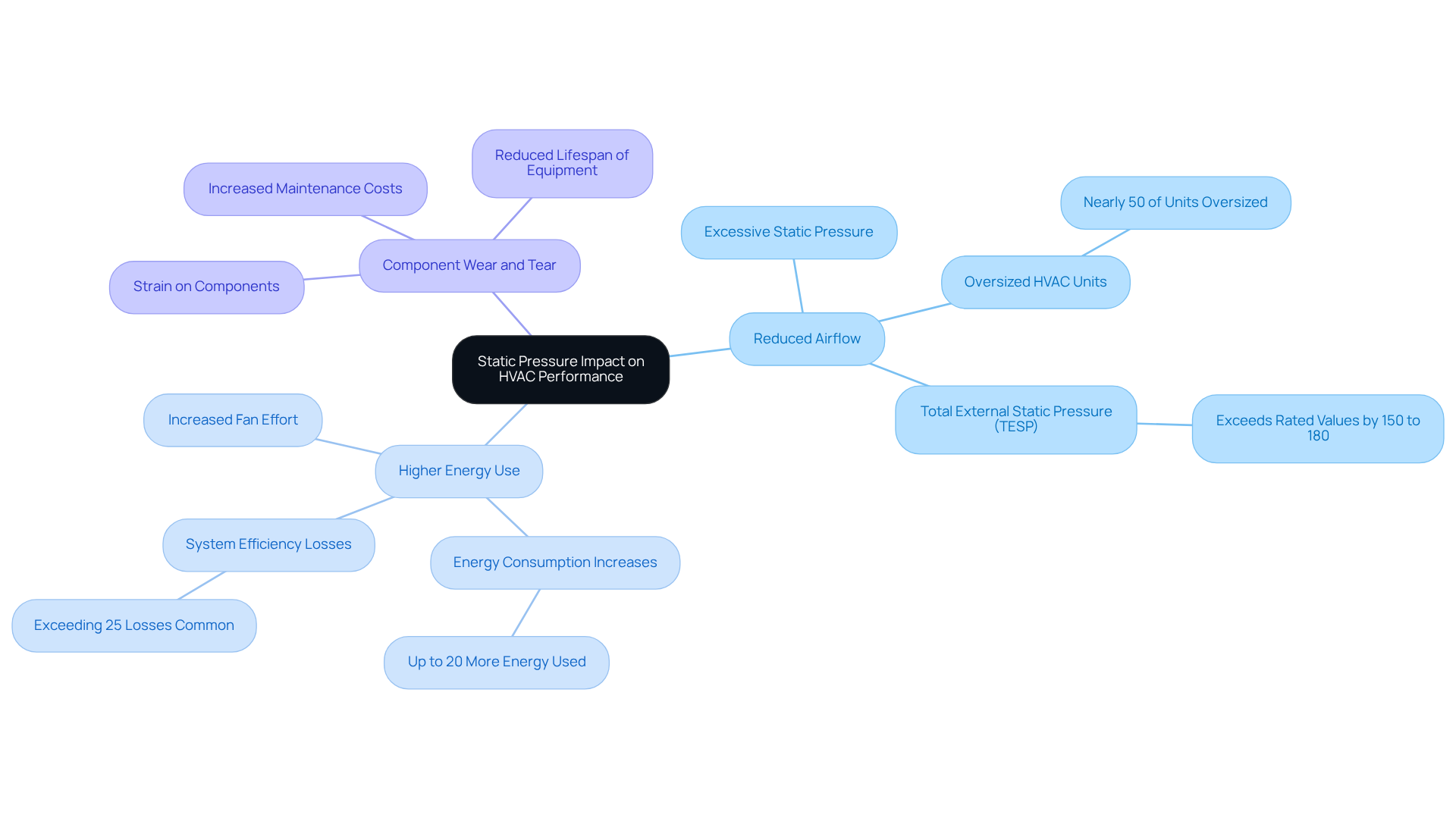

Examining fixed force is essential for understanding its impact on climate control performance. High static pressure can lead to several significant issues:

-

Reduced Airflow: Excessive static pressure restricts airflow, making it challenging for HVAC systems to deliver conditioned air effectively. This limitation can result in inconsistent temperatures and discomfort in living areas, especially given that nearly 50% of HVAC units are oversized, which exacerbates airflow problems. Furthermore, typical total external resistance (TESR) often exceeds rated equipment values by 150% to 180%, complicating airflow dynamics even further.

-

Higher Energy Use: When ambient resistance is elevated, the system’s fans must exert more effort to push air through the ducts, leading to energy consumption increases of up to 20%. Systems contending with elevated levels can consume up to 20% more energy, significantly impacting utility expenses. As Rob ‘Doc’ Falke observes, “System efficiency losses over 25% are frequent due to excessive resistance,” underscoring the financial implications of neglecting this issue.

-

Component Wear and Tear: Over time, elevated loads place excessive strain on components, potentially resulting in early breakdowns and costly repairs. The pressure on the infrastructure can lead to higher maintenance expenses and a reduced lifespan of heating and cooling equipment.

To mitigate these concerns, engineers should consistently monitor fixed airflow measurements and define static pressure while making necessary modifications to duct dimensions, filter types, and configurations. Routine expert maintenance is crucial for maintaining optimal force levels and ensuring the longevity and effectiveness of HVAC systems.

Troubleshoot Static Pressure Issues: Common Problems and Solutions

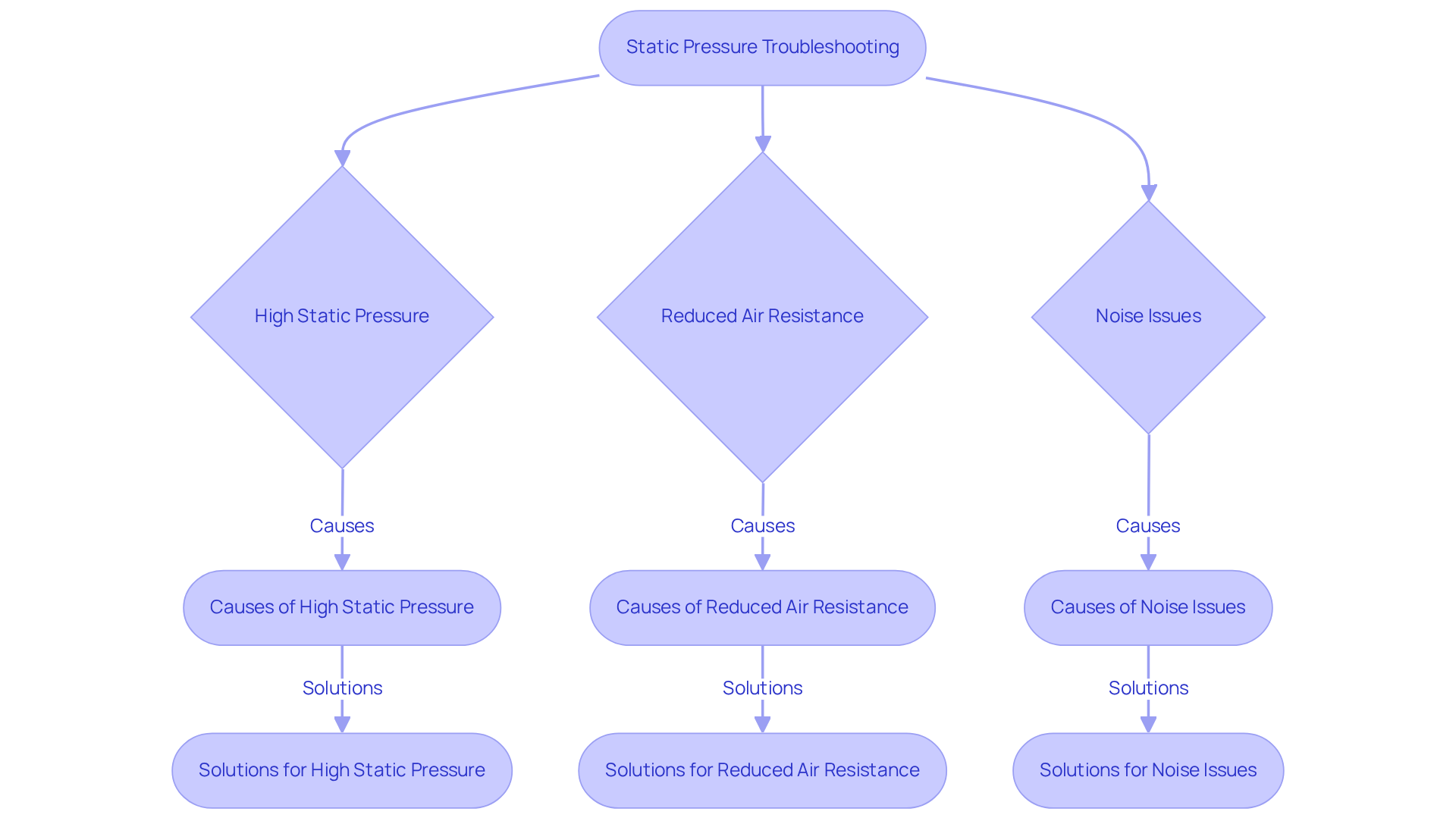

Diagnosing fixed resistance challenges necessitates a methodical strategy to recognize frequent issues and execute efficient remedies. Here are some prevalent issues along with their remedies:

-

High Static Pressure: Elevated static pressure readings often stem from clogged filters, dirty coils, or undersized ductwork. To mitigate these issues, regularly replace filters, clean coils, and resize ducts as necessary. Elevated airflow resistance can cause greater energy usage, as units exert more effort to move air through limited routes, leading to increased utility costs and possible equipment deterioration. According to BEST Air Conditioning Plumbing Repair, “Elevated resistance can lead to a limitation in the ductwork, decreasing the volume of air that can circulate through the system,” which further highlights the necessity for prompt action. Furthermore, a case analysis on the effect of elevated fixed conditions emphasizes that overlooking these concerns can result in higher energy consumption and deterioration of parts.

-

Reduced Air Resistance: Low air resistance may suggest leaks in the duct system or inadequate airflow. Inspect ducts for any leaks and ensure that all vents are open and unobstructed. Sealing leaks and modifying airflow can assist in returning appropriate equilibrium levels. Tackling low air resistance is essential, as it can result in inconsistent heating or cooling and unease within the area. Regular upkeep is crucial to avoid these problems, as it guarantees that the setup functions efficiently.

-

Noise Issues: Excessive sound from the HVAC equipment is often a sign of elevated resistance. Examine the setup for obstructions and confirm that fans are functioning properly. Adjusting fan speeds or modifying duct configurations can alleviate noise problems. In situations where elevated fixed force leads to loud mechanical sounds, it may suggest a requirement for upkeep or enhancement of airflow.

By tackling these frequent fixed force challenges, engineers can guarantee effective operation and prolong the durability of climate control equipment. It’s important to note that average commercial HVAC systems deliver just 48% of their specified cooling capacity to the occupied space, which underscores the significance of how we define static pressure levels.

Conclusion

Understanding static pressure is vital for engineers, particularly in HVAC systems, as it directly affects airflow, energy efficiency, and overall system performance. By accurately defining static pressure, engineers can design systems that operate optimally, ensuring comfort while minimizing energy costs. The insights provided in this article underline the importance of maintaining appropriate static pressure levels to prevent inefficiencies and potential system failures.

Key techniques for measuring and analyzing static pressure have been detailed, emphasizing the necessity of using the right tools and methods. From selecting suitable measurement instruments to troubleshooting common issues, engineers are equipped with practical knowledge to enhance HVAC performance. Neglecting static pressure can lead to reduced airflow, increased energy consumption, and premature wear on system components, all of which significantly impact operational costs and comfort levels.

Ultimately, addressing static pressure concerns transcends technical necessity; it is a crucial aspect of engineering that influences the efficiency and longevity of HVAC systems. Engineers are encouraged to adopt a proactive approach in monitoring and adjusting static pressure, ensuring their designs foster optimal performance. By prioritizing static pressure management, significant improvements in energy efficiency and system reliability can be achieved, benefiting both users and the environment.

Frequently Asked Questions

What is static pressure?

Static pressure is the pressure that air exerts on the walls of ducts and other components when airflow is absent. It represents the force applied by a fluid at rest.

Why is understanding static pressure important?

Understanding static pressure is essential because it directly influences airflow, energy efficiency, and the overall performance of HVAC systems. It helps engineers ensure optimal operation and mitigate issues like reduced airflow or increased energy consumption.

What is the optimal total external static pressure (TESP) for residential heating and cooling units?

The optimal total external static pressure (TESP) for most residential heating and cooling units is approximately 0.5 inches of water column (in. WC), with a normal range of 0.3 to 0.6 in. WC.

What can happen if static pressure deviates from the optimal range?

Deviations from the optimal static pressure range can lead to inefficiencies, increased operational costs, noisy heating and cooling operations, and decreased overall system performance.

How does fixed resistance relate to static pressure?

Fixed resistance is a critical metric that indicates the opposition to airflow within air distribution ducts, making it an important factor in defining static pressure in engineering applications.

What maintenance practices can help optimize static pressure performance?

Routine maintenance and ensuring appropriate duct dimensions are necessary practices to optimize static pressure performance and enhance comfort while lowering energy costs.