Overview

The article delivers critical insights for electronics engineers regarding the advantages and specifications of DC fans in comparison to AC fans. It asserts that DC fans are not only more energy-efficient but also operate more quietly and provide enhanced speed control. These features are essential for optimizing cooling solutions across various electronic applications. As energy efficiency becomes increasingly prioritized within the industry, the significance of DC fans continues to grow, underscoring their vital role in contemporary electronic design.

Introduction

In the realm of cooling solutions, the debate between AC and DC fans has taken center stage, revealing critical distinctions that impact efficiency, performance, and application suitability.

- AC fans, recognized for their robust power capabilities, are frequently the preferred choice for larger installations.

- In contrast, DC fans excel in energy efficiency, consuming significantly less power and operating quietly—making them ideal for sensitive electronic environments.

- As industries increasingly prioritize sustainability, understanding the advantages and specifications of these fan types becomes essential for engineers tasked with optimizing cooling systems.

This article delves into the nuances of AC versus DC fans, exploring their benefits, specifications, and best practices to ensure effective thermal management across various applications.

AC vs. DC Fans: Key Differences

AC devices operate on alternating current and are commonly utilized in larger applications due to their robust power capabilities. Conversely, DC fans, which function on direct current, are recognized for their energy efficiency, consuming up to 70% less power than their AC counterparts.

Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, offers an extensive selection of DC input units optimized for performance and low noise, ideal for sensitive electronic applications. Although the initial cost of DC ceiling units is generally higher than that of AC ceiling units, the significant reduction in energy consumption proves particularly advantageous for battery-operated devices, where efficiency is paramount.

Furthermore, DC fans excel in speed regulation and operate with greater quietness, enhancing their applicability across various settings. While AC units are often preferred for their lower upfront costs and diverse control options—such as wall control, pull cord, or remote—case studies indicate that AC motor ceiling devices continue to be a favored choice due to their affordability and user-friendly design.

As the demand for energy-efficient solutions escalates, it is crucial for engineers to comprehend these essential distinctions when seeking optimal cooling solutions in their designs. Gagner-Toomey Associates is committed to providing comprehensive support and expertise in selecting the appropriate fan type tailored to specific needs.

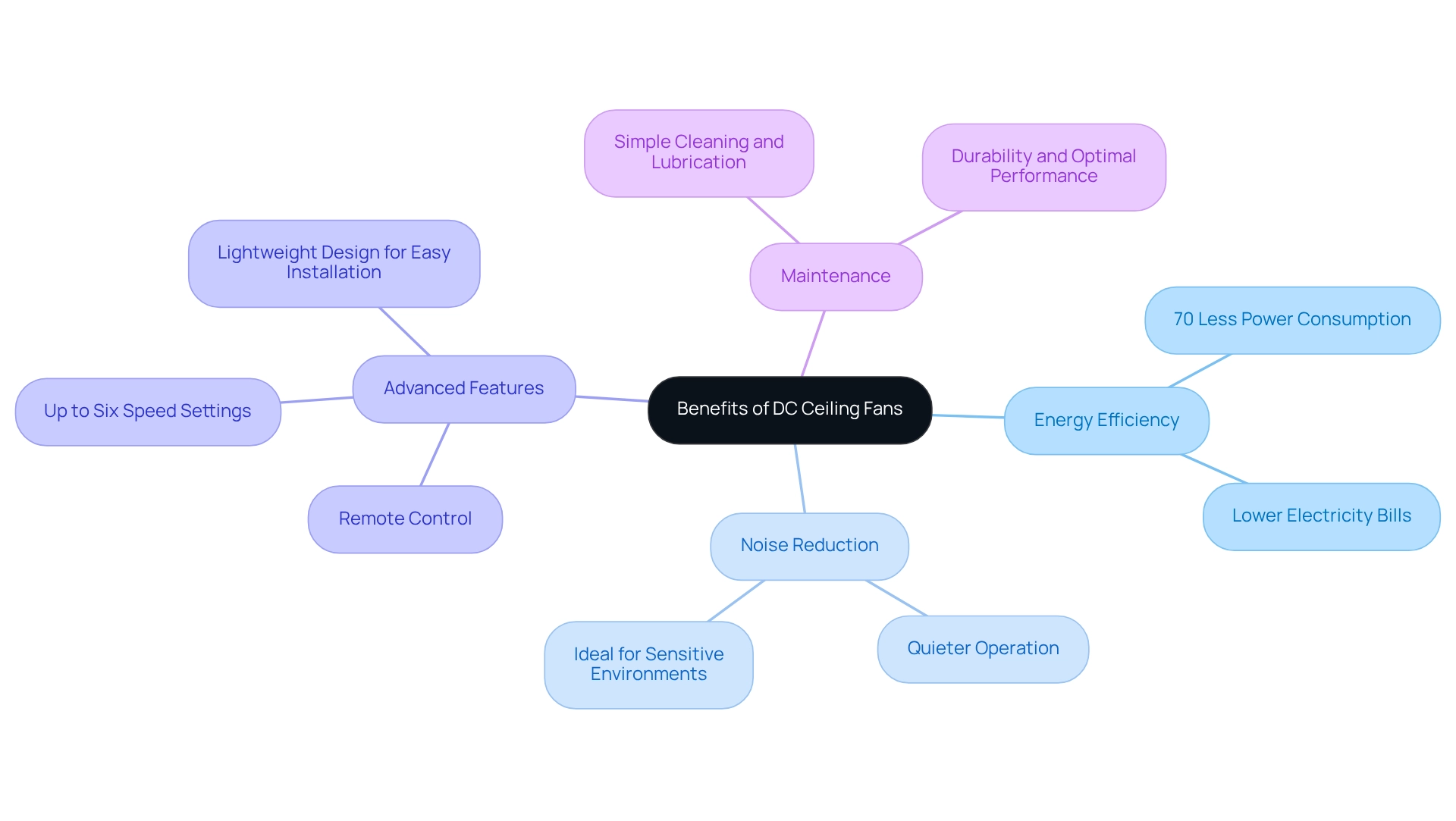

Benefits of DC Ceiling Fans

DC ceiling models stand out for their exceptional energy efficiency, consuming up to 70% less power than conventional AC units. This substantial reduction in energy consumption leads to lower electricity bills, making them an appealing choice for both residential and commercial environments. Furthermore, DC devices operate at a quieter level, a critical advantage in settings where noise reduction is essential, such as offices or homes.

Equipped with advanced features, including remote control and multiple speed settings—often reaching up to six compared to the three or four speeds typical of AC units—DC models enhance user convenience and adaptability. Their lightweight design facilitates installation, allowing for seamless integration into various environments.

Real-world examples demonstrate the effectiveness of DC units in minimizing noise levels while maintaining optimal airflow, further solidifying their reputation as a superior option for modern cooling solutions. Conversely, maintenance for air conditioning units is generally straightforward, focusing on routine cleaning and lubrication to prevent performance issues. By ensuring AC motors are maintained through simple cleaning and lubrication, users can guarantee durability and optimal performance while reducing the difficulty of identifying potential problems.

Popular AC motor ceiling devices, such as Claro Whisper and Airborne Bulimba, serve as benchmarks for comparison, highlighting the advantages of DC motors in terms of energy conservation and noise reduction. As energy efficiency continues to be a pressing concern, the benefits of DC ceiling devices are increasingly recognized, making them a prudent investment for individuals seeking to balance performance with sustainability. Both DC and AC ceiling devices are available in a variety of styles and price points, providing consumers with a wide range of choices.

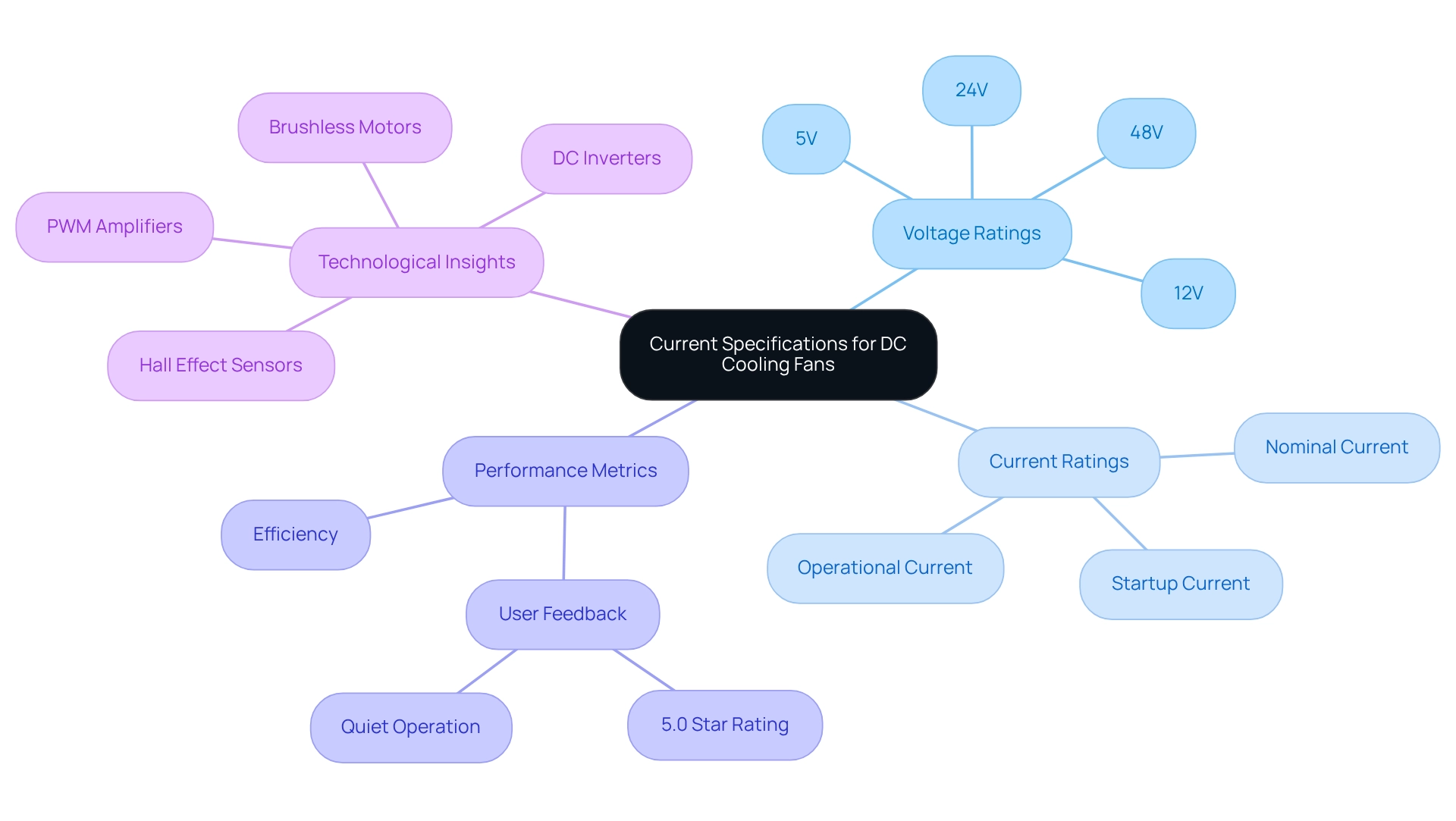

Current Specifications for DC Cooling Fans

DC ventilation devices from Gagner-Toomey Associates are meticulously designed to operate across multiple voltages, including 5V, 12V, 24V, and 48V, tailored for specific applications. The nominal rated current is crucial for ensuring optimal fan performance, preventing overheating, and extending longevity. For instance, a standard 12V fan may have a current rating of 0.2A, resulting in an energy consumption of 2.4 watts. This comprehension of voltage and current ratings is vital for engineers when selecting fans that fulfill their cooling requirements while maximizing system efficiency.

As we look to 2025, the current specifications for DC cooling fans have advanced, with numerous models now necessitating a total current of 6A upon reaching full speed. This highlights the importance of considering both startup and operational currents when designing supply systems. A case study focusing on power supply considerations illustrates that the nominal current rating is predicated on full-speed operation under open-air conditions, and engineers must account for startup current to ensure dependable performance.

User feedback from real-world applications further emphasizes the importance of these specifications. A customer rated a Gagner-Toomey fan 5.0 out of 5 stars on April 18, 2024, commending its quiet operation and efficiency in maintaining a Motorola radio. Such insights reflect the growing acknowledgment of products that not only meet technical specifications but also deliver exceptional performance in practical applications. Moreover, expert analysis indicates that brushless motors in chassis ventilation systems utilize PWM amplifiers, DC inverters, and hall effect sensors to maintain optimal performance. This technology ensures that the magnetic fields of the stator and rotor remain aligned, enhancing efficiency and heat dissipation. As engineers navigate the complexities of selecting DC airflow devices, grasping these specifications and their implications is essential for achieving optimal temperature management solutions in electronic systems. To implement these insights effectively, engineers should thoroughly evaluate both the startup and operational current ratings when selecting DC fans to guarantee compatibility with their power supply systems.

Best Practices for DC Motor Control

To maximize the performance of DC motors, engineers must adopt best practices, prominently including the implementation of pulse width modulation (PWM) for speed control. This technique facilitates precise modifications to fan speed, significantly reducing energy consumption while enhancing operational performance.

A recent case study, ‘Optimizing PWM Control And Sensor Modifications For Custom Cooling Fans,’ underscores advancements in PWM control and sensor modifications, showcasing improved thermal management and energy performance in electronic systems.

Furthermore, maintaining effective thermal management and conducting regular maintenance are vital for preventing overheating and prolonging the motor’s lifespan, as demonstrated by the outcomes of the case study. The incorporation of feedback systems to continuously monitor performance and dynamically adjust control parameters is also advisable.

As noted by Sahithi Priya Alloju from the Kakatiya Institute of Technology & Science, “The micro controller keeps on tracking the determined speed by varying duty cycle in a closed loop control system.”

Effective PWM strategies can lead to substantial enhancements in DC motor performance, establishing it as an essential practice for engineers in the electronics sector. For practical implementation, engineers should consider integrating PWM controllers that allow for real-time adjustments based on thermal feedback, ensuring optimal performance in their designs.

Understanding PWM Control in DC Fans

Pulse Width Modulation (PWM) represents a sophisticated method for controlling the speed of DC motors by adjusting the pulse width in the power supply. By meticulously fine-tuning the duty cycle, engineers can attain precise speed control, which significantly enhances temperature regulation while minimizing noise levels. This capability allows devices to operate at reduced speeds without the risk of stalling, rendering PWM particularly advantageous for applications necessitating variable airflow.

Moreover, PWM control facilitates substantial energy savings, as cooling devices can dynamically adjust their speeds according to real-time cooling requirements. For instance, PWM cooling devices can function at lower speeds during lighter tasks, resulting not only in reduced operational costs but also in quieter operation. The absence of brushes in DC motors further bolsters reliability and performance, diminishing the likelihood of mechanical failure.

Case studies underscore the pivotal role of PWM in modern thermal management systems, showcasing how these devices integrate efficiency, adaptability, and reliability to meet evolving heat management challenges. Notably, the case study titled “Speed Control Mechanisms” illustrates that while certain DC devices can accommodate voltage-regulated speeds, they lack the flexibility and precision inherent in PWM units, rendering them less effective in responding to fluctuating cooling demands. Additionally, the Lawrence Berkeley National Laboratory reports that transitioning to state-of-the-art PWM mode can yield approximately a 20% reduction in total energy consumption, highlighting the significant energy savings associated with PWM technology.

With their global compatibility and customizable options, PWM-controlled DC devices are poised as future-proof solutions, adept at addressing the dynamic needs of the electronics industry.

Power Supply Requirements for DC Fans

Selecting the appropriate energy source for direct current blowers is essential for achieving peak efficiency and durability. It is crucial to align the voltage and current ratings with the fan’s specifications. For instance, a 12V DC fan requires a power supply that can deliver at least the nominal current rating specified by the manufacturer. Engineers must prioritize the effectiveness and reliability of the energy source; underpowered fans may struggle to start consistently or operate effectively, potentially leading to overheating and a significantly reduced lifespan.

Statistics reveal that around 20% of energy is typically lost as heat, highlighting the importance of choosing a supply that minimizes energy dissipation. This underscores the necessity for high-quality energy sources that not only meet the required specifications but also enhance overall system efficiency. As a Keysight Account Manager noted, “Clients approach us and purchase used items because they receive premium KS quality at a reduced cost, and we dispatch within 2 weeks,” emphasizing the critical role of quality in supply selection.

Furthermore, evaluating the total cost of ownership when selecting a supply can aid engineers in balancing initial expenditures with long-term performance and maintenance costs. This strategy ensures that the chosen energy source optimizes performance and cost-effectiveness across various projects. The case study titled “Total Cost of Ownership in Supply Selection” demonstrates that reconciling the initial cost of a supply with its long-term value necessitates consideration of durability, effectiveness, and maintenance expenses.

Practical examples illustrate the importance of aligning supply ratings with the specifications of DC fans. For example, employing a supply with a higher efficiency rating not only enhances the fan’s performance but also contributes to overall system reliability. Additionally, engineers should consider UL-listed and UL-recognized products, acknowledged as the gold standard for safety certification, ensuring that selected supplies comply with industry safety standards.

As the sector evolves in 2025, staying informed about the latest energy supply technologies and their compatibility with direct current cooling devices will be vital for engineers aiming to implement efficient cooling strategies. Bravo Electro’s team of experts is ready to assist with power supply inquiries and selections, offering valuable resources for engineers seeking guidance.

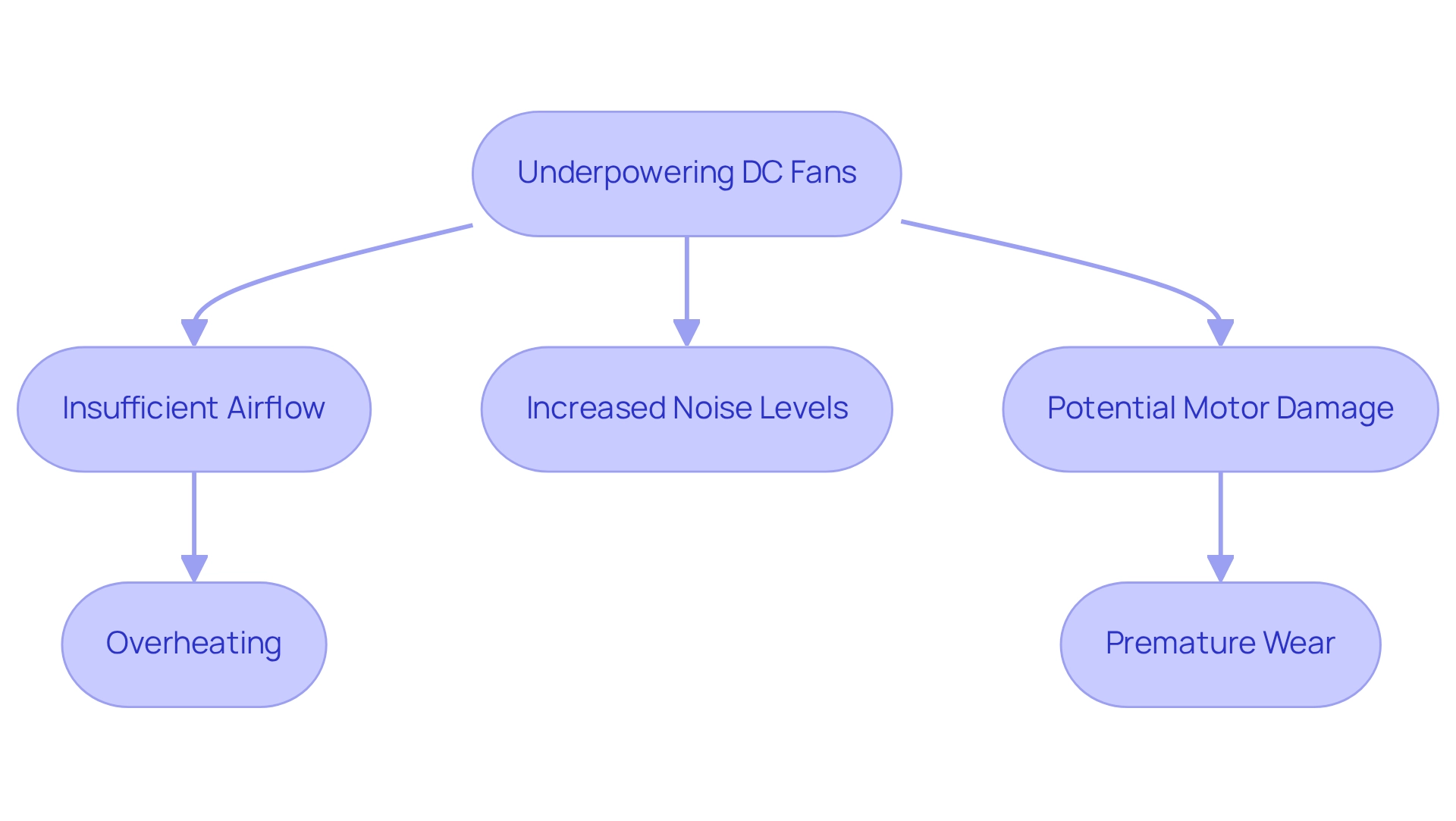

Risks of Underpowering DC Fans

Underpowering DC blowers can result in a range of serious issues, including insufficient airflow, increased noise levels, and potential motor damage. When a fan does not receive the requisite voltage or current, it may either fail to start or operate inefficiently, leading to overheating in the systems it is designed to cool. This inefficiency is particularly concerning, as studies indicate that PWM devices can reduce their speed by as much as 40% of their rated capacity, exacerbating cooling problems if not sufficiently powered.

Prolonged operation under these suboptimal conditions can lead to premature wear and eventual failure of the fan motor. A case study on PWM devices illustrates how these units, equipped with an additional wire for PWM control, can adjust their speed based on temperature, thereby enhancing efficiency. However, if the energy supply is inadequate, the benefits of this technology are rendered ineffective, resulting in increased failure rates. The benefits of employing PWM fans in cooling applications encompass precise speed control and the capability to operate at lower speeds, making them particularly suitable for CPU cooling.

Real-world examples underscore the ramifications of underperformance; documented instances of motor damage due to insufficient energy supply highlight the critical importance of adhering to manufacturer specifications. Engineers must ensure that their power supply not only meets but exceeds the fan’s requirements to mitigate these risks and sustain optimal performance. To facilitate the effective implementation of PWM or DC fans, engineers can explore the PCB Design and Analysis tools from Cadence, which offer a free trial for their design and analysis solutions. As noted by Bravo Electro, “Our blog is also jam-packed with technical articles exploring topics in the world of electrical components,” emphasizing the necessity of comprehending these components to ensure reliable fan operation.

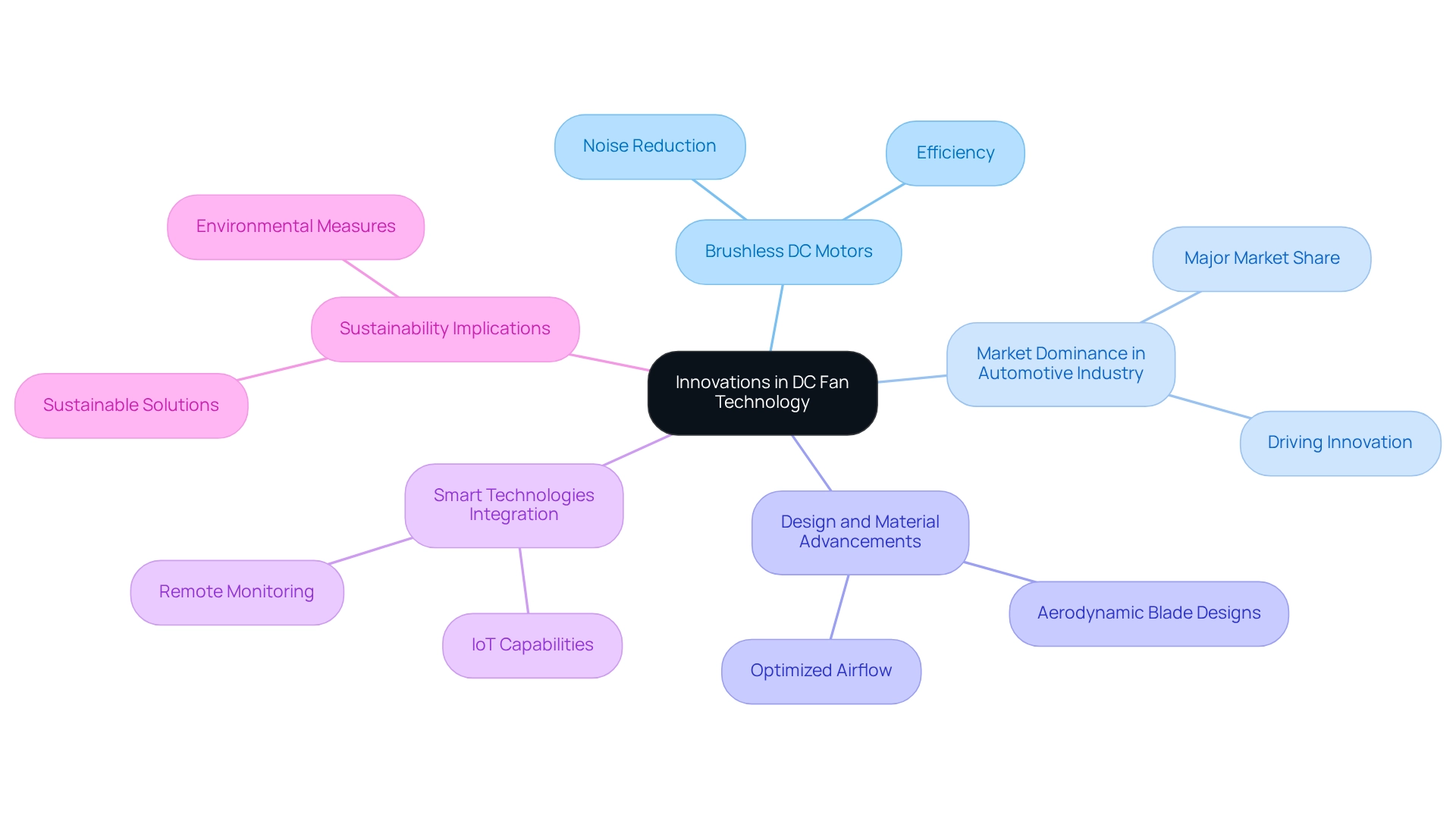

Innovations in DC Fan Technology

Recent advancements in DC fan technology have significantly transformed temperature regulation methods, particularly with the rise of brushless DC fans. These motors are recognized for their superior efficiency and lower noise levels compared to traditional brushed motors, making them exceptionally suited for a variety of applications. Notably, the automotive industry dominates the brushless DC motors market share, reflecting a robust demand that propels innovation within this sector.

Furthermore, enhancements in materials and aerodynamic blade designs have optimized airflow and static pressure performance, leading to more effective temperature regulation. Insights from the case study titled ‘Technological Advancements in DC Fans’ reveal that innovations in digital and manufacturing technologies are shaping the DC fan market, resulting in heightened product innovation and profitability for manufacturers.

The integration of smart fan technologies, which encompass IoT capabilities, facilitates remote monitoring and control. This empowers engineers to refine temperature regulation performance based on real-time data, ensuring adaptability in dynamic environments. As the market for brushless DC motors continues to expand, driven by increasing demand across industries such as automotive and electronics, these innovations are establishing new benchmarks for efficiency and performance in thermal management solutions. Moreover, the adoption of brushless DC motors may contribute to the development of more sustainable temperature regulation solutions, aligning with the growing emphasis on environmental measures in contemporary engineering practices.

Applications of DC Fans in Electronics

DC enthusiasts play a crucial role in a wide array of electronic applications, encompassing computers, servers, telecommunications equipment, and medical devices. Their compact design and energy efficiency render them particularly effective for cooling sensitive components in confined spaces.

In HVAC systems, DC motors are indispensable for regulating temperature and enhancing air circulation, which contributes to overall energy savings. Notably, the market for DC fans is projected to experience significant growth in the electronic cooling sector, with a market size expected to reach USD 3.2 billion by 2033, up from USD 1.5 billion in 2024. This reflects a compound annual growth rate (CAGR) of 9.2% from 2026 to 2033, according to Verified Market Reports.

This growth is driven by the increasing demand for energy-efficient solutions, particularly in the Asia Pacific region, where manufacturers such as Delta Fan, Ebmpapst, and Sanyo Denki are focusing on emerging market opportunities. Furthermore, the silent operation of DC units makes them a preferred choice for applications requiring dependable thermal control without intrusive noise.

Real-world examples underscore their effectiveness in medical devices, where maintaining optimal temperatures is critical for patient safety and device performance. For instance, in the telecommunications sector, DC cooling devices are employed to maintain equipment within safe operating temperatures, thereby enhancing reliability and performance.

Overall, the adaptability of DC devices positions them as essential components in contemporary electronic systems.

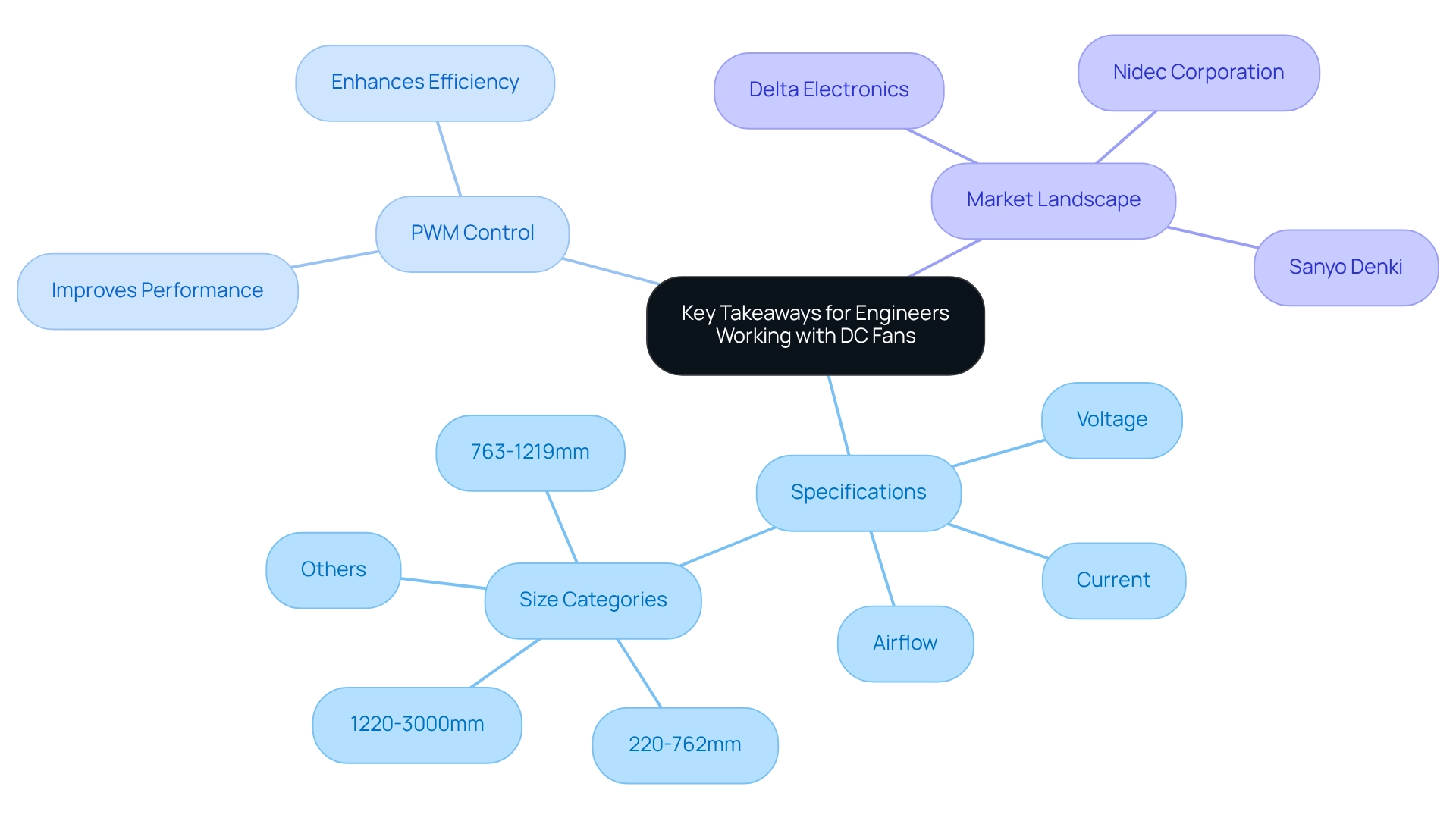

Key Takeaways for Engineers Working with DC Fans

Selecting the appropriate DC fans is essential for engineers, as these components directly impact application performance. Key factors to consider include voltage, current, and airflow specifications, all of which are crucial for ensuring optimal functionality. The market for DC fans is diverse, with sizes categorized by diameter:

- 220-762mm

- 763-1219mm

- 1220-3000mm

- Others

A thorough understanding of these specifications empowers engineers to make informed decisions based on the specific requirements of their applications.

Applying Pulse Width Modulation (PWM) control can greatly enhance fan performance and energy efficiency, allowing for precise adjustments according to real-time temperature needs. It is vital to ensure that power supplies align with fan specifications to prevent underpowering, which can lead to reduced efficiency and potential system failures. Staying updated on advancements in DC fan technology is essential for engineers aiming to enhance designs and temperature control solutions.

The competitive landscape of the DC fan market features key players such as Delta Electronics, Nidec Corporation, and Sanyo Denki, who are committed to product innovation and strategic partnerships to meet the evolving needs of end-users. Practical examples demonstrate that improving fan performance through PWM control not only boosts efficiency but also contributes to overall energy savings. As Elon Musk wisely stated, “Constantly think about how you could be doing things better.” By concentrating on these critical aspects, engineers can make informed decisions that lead to superior cooling solutions in their projects.

Conclusion

The comparison between AC and DC fans reveals significant differences that are essential for engineers pursuing effective cooling solutions. AC fans, commonly employed in larger applications due to their robust power capabilities, typically exhibit lower energy efficiency when compared to their DC counterparts. In contrast, DC fans are distinguished by their energy-saving features, consuming up to 70% less power and operating quietly, making them particularly suitable for sensitive electronic applications. This shift toward energy efficiency is increasingly pertinent as industries prioritize sustainability in their designs.

Understanding the technical specifications and operational advantages of both fan types is crucial for optimizing performance across various applications. Engineers must take into account factors such as voltage, current ratings, and the implementation of technologies like Pulse Width Modulation (PWM) to enhance efficiency and control. The expanding market for DC fans reflects a broader trend toward sustainable practices, driven by innovations such as brushless motors and IoT capabilities that facilitate real-time monitoring and adjustments.

In conclusion, selecting the appropriate fan type transcends mere preference; it constitutes a strategic decision that influences energy consumption, operational efficiency, and overall system reliability. As the demand for energy-efficient solutions continues to escalate, engineers are presented with the opportunity to harness the advantages of DC fans, ensuring that their cooling systems align with modern performance standards while contributing to sustainability goals. Staying abreast of advancements in fan technology will empower engineers to make informed choices that harmonize operational needs with environmental considerations, paving the way for more efficient and responsible cooling solutions in the future.

Frequently Asked Questions

What is the difference between AC and DC devices in terms of power consumption?

AC devices operate on alternating current and are commonly used in larger applications, while DC fans operate on direct current and are recognized for their energy efficiency, consuming up to 70% less power than AC fans.

What advantages do DC fans offer for sensitive electronic applications?

DC fans are optimized for performance and low noise, making them ideal for sensitive electronic applications. They also excel in speed regulation and operate more quietly than AC units.

Why is the initial cost of DC ceiling units generally higher than AC ceiling units?

The initial cost of DC ceiling units is higher due to their advanced technology and energy efficiency. However, the significant reduction in energy consumption can lead to lower electricity bills, particularly beneficial for battery-operated devices.

What features do DC ceiling models typically have?

DC ceiling models often include advanced features such as remote control, multiple speed settings (up to six speeds), and a lightweight design that facilitates installation.

How does the maintenance of AC units compare to DC units?

Maintenance for AC units is generally straightforward, focusing on routine cleaning and lubrication to prevent performance issues. This helps ensure durability and optimal performance.

What are some examples of popular AC motor ceiling devices?

Popular AC motor ceiling devices include Claro Whisper and Airborne Bulimba, which serve as benchmarks for comparison against the advantages of DC motors in terms of energy conservation and noise reduction.

What voltage options are available for DC ventilation devices from Gagner-Toomey Associates?

DC ventilation devices from Gagner-Toomey Associates operate across multiple voltages, including 5V, 12V, 24V, and 48V, tailored for specific applications.

Why is understanding current ratings important for engineers selecting fans?

Understanding current ratings is crucial for ensuring optimal fan performance, preventing overheating, and extending the longevity of the device. Engineers must consider both startup and operational currents when designing supply systems.

What technology is used in brushless motors for chassis ventilation systems?

Brushless motors in chassis ventilation systems utilize PWM amplifiers, DC inverters, and hall effect sensors to maintain optimal performance, ensuring that the magnetic fields of the stator and rotor remain aligned for enhanced efficiency and heat dissipation.