Introduction

The evolution of electric fan technology has progressed from a basic two-blade design to advanced systems that significantly improve energy efficiency and performance. Today, engineers can harness innovations like brushless DC motors and Pulse Width Modulation to enhance cooling systems while simultaneously lowering operational costs and minimizing environmental impact. As the demand for smarter, more efficient solutions continues to rise, the pressing question remains: how can engineers effectively integrate these cutting-edge features into their projects to maximize both performance and sustainability?

Trace the Evolution of Electric Fan Technology

Since its inception in the late 19th century, the innovation of electric fan technology has undergone significant transformations. The first electric fan, invented by Schuyler Wheeler in 1882, featured a basic two-blade design powered by an electric motor. Over the decades, the innovation of electric fan technology has dramatically improved fan performance and versatility through advancements in materials and motor technology. Notably, the innovation of electric fan technology, particularly through the introduction of brushless DC motors, has revolutionized fan efficiency, achieving energy savings of up to 70% compared to conventional AC motors. The innovation of electric fan not only enhances power effectiveness but also reduces operational noise, resulting in quieter and more efficient contemporary devices.

Key milestones in the innovation of electric fan development include the evolution of impeller designs, which have seen performance levels rise from 25-45% a decade ago to approximately 60% today. Furthermore, the innovation of electric fan technologies has enabled features such as variable speed control and remote operation, allowing for customized airflow management across various applications. As engineers explore these advancements, they can leverage the capabilities of modern devices to enhance output, promote energy conservation, and support sustainable practices in their projects.

Gagner-Toomey Associates stands out as the world’s largest producer of standard and custom air-movers, offering an extensive range of DC input tube axial units and centrifugal blowers, all optimized for performance, efficiency, and low noise. Their product lineup includes sizes ranging from 15 to 280mm for tube axial units and 15 to 225mm for centrifugal blowers, catering to diverse industries such as electronics, automotive, and telecommunications. Understanding this historical context equips engineers with the insight to appreciate the intricate designs and functionalities of modern electric devices, particularly those provided by Gagner-Toomey.

Leverage Innovative Features of Modern Electric Fans

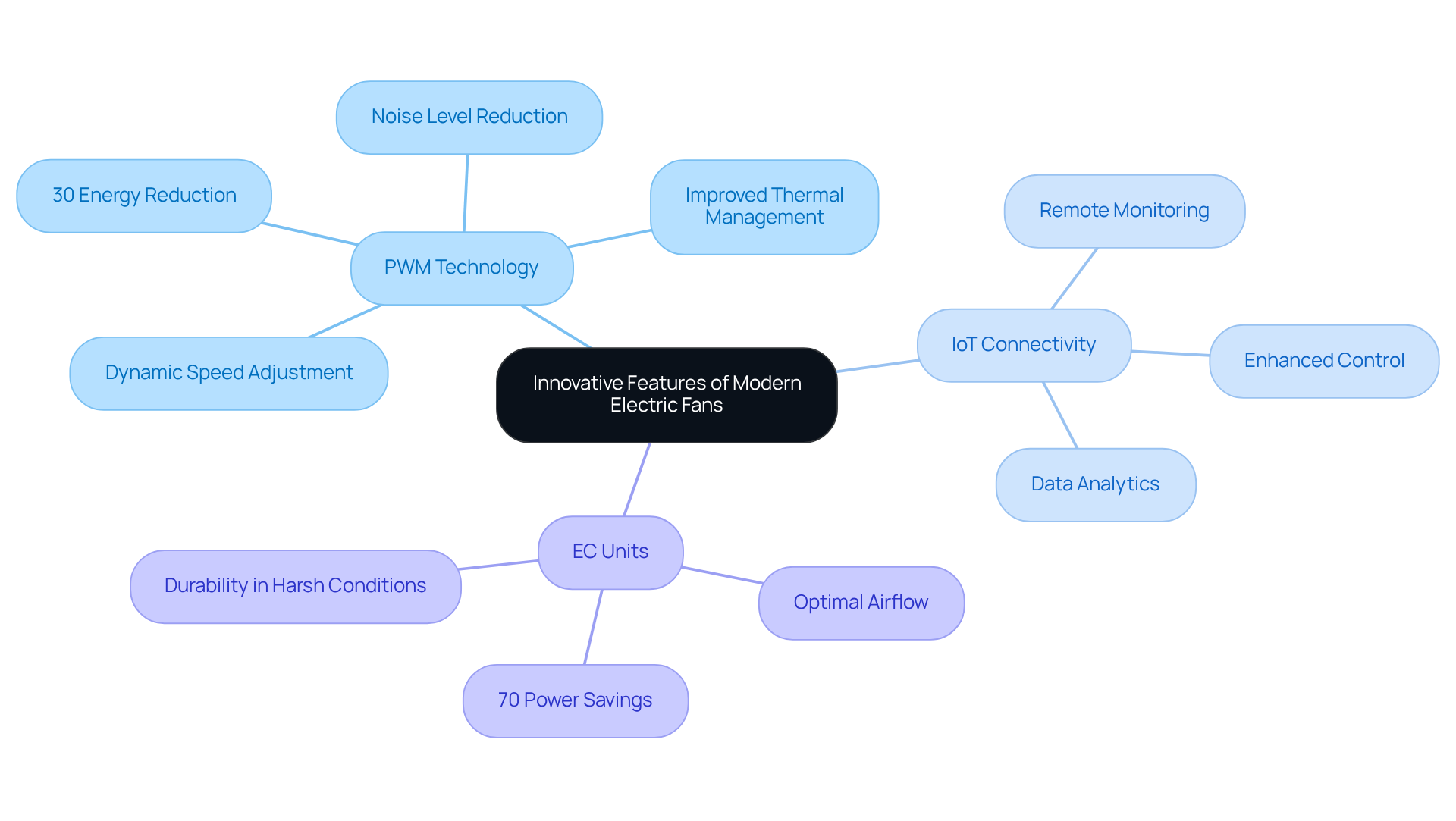

Contemporary electric devices face the challenge of energy inefficiency, but advanced features are transforming their functionality and efficiency. One such innovation is Pulse Width Modulation (PWM) technology, which allows devices to dynamically adjust their speed according to real-time cooling needs. This capability can lead to energy consumption reductions of up to 30%, making PWM devices a preferred choice across various applications.

Moreover, the integration of IoT connectivity enhances these devices further by enabling remote monitoring and control, which is essential for optimizing smart environments. For instance, Electronically Commutated (EC) units in HVAC systems have demonstrated significant power savings while ensuring optimal airflow. Notably, DC cooling units consume up to 70% less power than their AC counterparts for the same airflow output.

Data reveals that over 70% of electronics engineers utilizing PWM devices report substantial improvements in thermal management and power performance. These advancements empower engineers to design systems that not only meet cooling requirements effectively but also promote overall energy efficiency. By adopting these technologies, stakeholders can significantly reduce operational expenses while enhancing performance.

Implement Effective Strategies for Integration in Engineering Projects

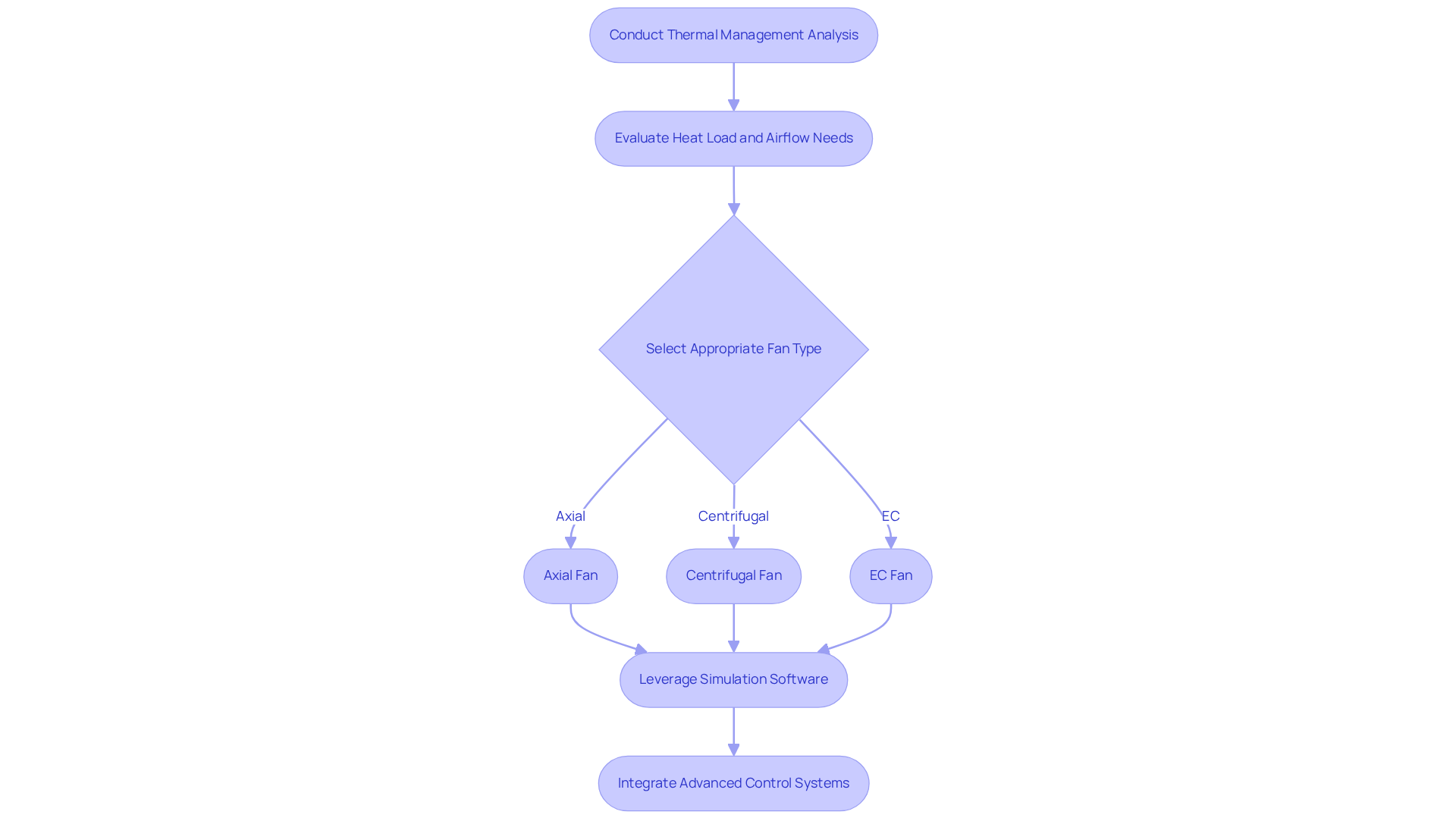

To effectively integrate the innovation of electric fan into engineering projects, engineers must adopt several key strategies. The first step involves conducting a thorough analysis of the thermal management requirements. This critical assessment includes evaluating the heat load and airflow needs of the system.

Next, selecting the appropriate fan type – whether axial, centrifugal, or EC fans – based on the specific application is crucial. Engineers should leverage simulation software to model airflow and thermal performance, allowing for optimization before physical implementation.

Furthermore, integrating advanced control systems, such as variable speed drives, can significantly enhance fan performance and responsiveness to varying conditions. Practical examples, like the incorporation of large ceiling devices in industrial environments, illustrate how these strategies can lead to substantial power savings and improved operational performance.

By following these strategies, engineers can ensure that the innovation of electric fan designs is not only effectively integrated but also optimized for maximum efficiency.

Highlight the Benefits of Electric Fan Technology in Engineering

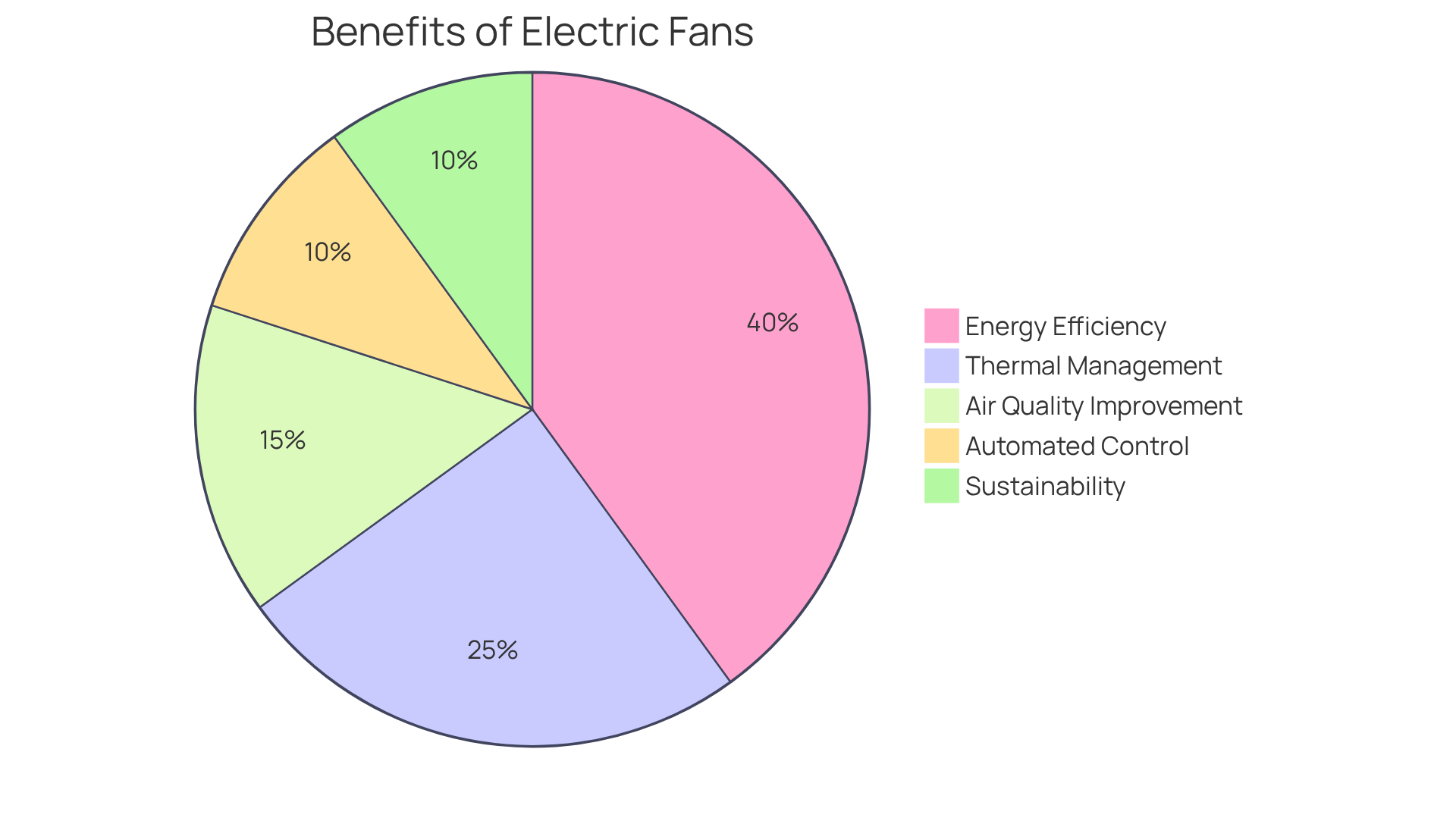

Electric fan technology offers numerous advantages that can significantly enhance engineering projects. One of the most compelling benefits is energy efficiency; modern brushless units can consume up to 70% less power than traditional brushed devices, leading to substantial operational cost savings. These fans are essential for improving thermal management, effectively preventing overheating in electronic components. Moreover, they enhance air quality by promoting better circulation and reducing humidity levels.

The integration of advanced technologies, such as Pulse Width Modulation (PWM), enables automated control that optimizes performance based on real-time conditions. PWM devices are particularly versatile, capable of lowering noise levels, making them ideal for sensitive environments. This not only enhances system reliability but also supports sustainability goals by reducing the overall carbon footprint of engineering initiatives.

Case studies reveal that adopting brushless fan technology can result in energy savings of up to 80%. This statistic underscores the financial and environmental advantages brought about by the innovation of electric fans across various applications. By embracing the innovation of electric fan, engineers can enhance efficiency and sustainability in their projects.

Conclusion

The evolution of electric fan technology marks a significant journey of innovation that has fundamentally transformed engineering practices. From the early designs of the 19th century to today’s sophisticated, energy-efficient models, advancements in this field underscore the critical importance of integrating modern technologies into engineering projects. Embracing these innovations not only enhances performance and efficiency but also aligns with sustainability goals, establishing electric fans as essential components in contemporary engineering solutions.

Key insights reveal the substantial benefits of modern electric fans, including:

- Improved energy efficiency

- Enhanced thermal management

- Advanced control features such as Pulse Width Modulation and IoT connectivity

These advancements empower engineers to optimize airflow, reduce operational costs, and promote environmentally friendly practices. Case studies illustrate how adopting brushless fan technology can lead to remarkable energy savings, further emphasizing the value these innovations bring to various industries.

Ultimately, integrating electric fan technology into engineering projects is not merely a technical choice; it is a strategic decision that drives sustainability and enhances overall system performance. As the industry continues to evolve, engineers are encouraged to stay updated on the latest advancements and best practices in electric fan technology. By doing so, they can harness the full potential of these innovations to create more efficient, reliable, and environmentally responsible engineering solutions.

Frequently Asked Questions

When was the first electric fan invented and who created it?

The first electric fan was invented by Schuyler Wheeler in 1882.

What was the design of the first electric fan?

The first electric fan featured a basic two-blade design powered by an electric motor.

How has electric fan technology improved over the years?

Electric fan technology has improved dramatically in performance and versatility due to advancements in materials and motor technology.

What role do brushless DC motors play in electric fan technology?

Brushless DC motors have revolutionized fan efficiency, achieving energy savings of up to 70% compared to conventional AC motors, while also reducing operational noise.

What advancements have been made in impeller designs for electric fans?

The performance levels of impeller designs have increased from 25-45% a decade ago to approximately 60% today.

What features have been enabled by advancements in electric fan technology?

Advancements have enabled features such as variable speed control and remote operation, allowing for customized airflow management.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a range of DC input tube axial units and centrifugal blowers optimized for performance, efficiency, and low noise.

What sizes do Gagner-Toomey’s products come in?

Their product lineup includes sizes ranging from 15 to 280mm for tube axial units and 15 to 225mm for centrifugal blowers.

Which industries benefit from Gagner-Toomey’s electric fan technology?

Industries such as electronics, automotive, and telecommunications benefit from Gagner-Toomey’s electric fan technology.

Why is understanding the historical context of electric fan technology important for engineers?

Understanding the historical context equips engineers with insights to appreciate the intricate designs and functionalities of modern electric devices.