Overview

The article emphasizes the measurement techniques and specifications of fans utilized in electronics, underscoring their pivotal role in cooling applications across diverse industries. It elucidates critical metrics such as airflow (CFM), static pressure, and rotational speed (RPM), demonstrating how a comprehensive understanding of these measurements is vital for optimizing fan selection and enhancing energy efficiency in electronic systems.

Introduction

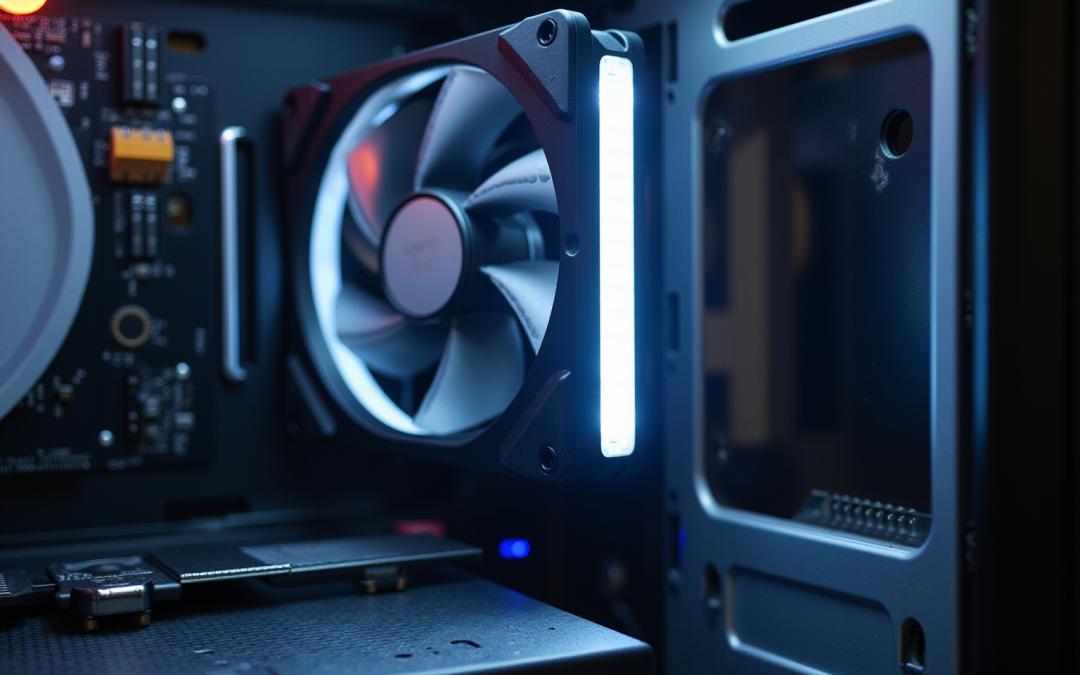

In the realm of electronics, fans are not merely accessories; they are critical components that ensure the efficient operation and longevity of devices. As technology continues to advance, the demand for effective cooling solutions has surged, prompting innovations that enhance performance while minimizing noise and energy consumption.

The evolution of fan technology—from the basic electric fans of the 19th century to today’s sophisticated smart fans equipped with brushless DC motors—reflects a commitment to meeting the cooling needs of increasingly powerful electronic systems.

Understanding the intricate specifications and performance metrics of these fans is essential for engineers and designers aiming to optimize thermal management strategies and prevent costly failures in various applications, including:

- Computers

- HVAC systems

- Industrial machinery

This exploration delves into the purpose, measurement techniques, key characteristics, and historical advancements of fans, illuminating their indispensable role in modern electronics.

Define Fans in Electronics: Purpose and Importance

In the realm of electronics, ventilators serve as to generate airflow, primarily for cooling purposes. , recognized as the world’s largest manufacturer of , provides an extensive range of meticulously designed for effectiveness, efficiency, and minimal noise.

These devices play a , including:

- Computers

- HVAC systems

- Industrial machinery

They proficiently dissipate heat produced by electronic components. By facilitating , Gagner-Toomey’s devices help maintain optimal operating temperatures, thereby enhancing performance and extending the lifespan of equipment.

The significance of cooling devices is underscored by the reality that overheating can lead to system failures and diminished performance; thus, they constitute an indispensable element in electronic design and . Industry experts recognize that the growing reliance on devices is essential for achieving , further solidifying their importance as crucial instruments in electronics design.

A comprehensive analysis of the North American reveals that understanding how fans are measured, along with specifications and efficiency metrics, is vital for companies aiming to elevate their thermal management strategies and prevent costly failures. Furthermore, the case study titled ‘Regional Analysis of North America Cooling Fan Market’ illustrates how organizations can pinpoint leading regions and strategize for market expansion based on regional findings, emphasizing the critical role of fans in thermal regulation.

Explore Measurement Techniques for Fan Performance

is critically evaluated through several essential metrics, including:

- Volume flow (measured in cubic feet per minute, or CFM)

- (measured in inches of water gauge)

- Rotational speed (measured in RPM)

Airflow quantifies the volume of air a fan can move, while static pressure reflects the fan’s capability to overcome system resistance. Notably, a 10% drop in RPM can induce a significant 27% decline in horsepower, which underscores the importance of understanding ; the movement of air can be assessed using an anemometer or by determining the pressure difference across the fan. are often created to illustrate the interplay between these metrics, providing valuable insights into fan efficiency across different operating conditions.

Chris, with extensive experience in ventilation control systems, emphasizes that a thorough understanding of these metrics is crucial for across various applications. He notes that utilizing FEI values, depicted as contour areas within performance curves, facilitates the visualization of operating regions and enhances .

Furthermore, for electronic devices typically range from 30 to 150 CFM, depending on their size and design. Implementing is essential for engineers to understand how fans are measured to ensure that the selected fan meets the specific requirements of their projects, ultimately leading to enhanced performance and improved energy efficiency.

Identify Key Characteristics and Specifications of Fans

When assessing devices, several essential traits and specifications must be considered. These include:

- Size, typically measured in millimeters

- Airflow capacity (CFM)

- Static pressure rating

- Power consumption (watts)

Gagner-Toomey Associates offers a wide range of , varying from 15 to 280mm, alongside a comprehensive collection of DC input , sized from 15 to 225mm. The type of fan—axial or centrifugal—significantly influences performance. Axial units are recognized for their ability to provide , making them ideal for general cooling applications, whereas centrifugal units are engineered for , delivering effective airflow in more challenging environments.

Key specifications also encompass , such as sleeve, ball, or fluid dynamic, which can affect both durability and noise levels. For instance, devices with ball bearings typically exhibit a longer lifespan and reduced noise output compared to those with sleeve bearings. Understanding these traits is crucial for engineers and designers to select blowers that align with the specific cooling requirements of their systems.

Noise levels vary among different types of blowers, with average decibel ratings ranging from 20 dB for quiet models to over 40 dB for high-performance units. This variance can significantly influence in electronics, where noise sensitivity is often a critical concern. For example, while five Arctic P12 units may be priced similarly or lower than one Mobius 120P ARGB unit, the choice between them may hinge on the desired balance between ventilation and sound.

Moreover, Robinson noted that the cost of integrating additional particulate collection apparatus prior to the current heavy industrial process units and APC devices, along with the increased pressure drop of this equipment, will offset any effectiveness advantages. This underscores the importance of considering . Additionally, manufacturers may be required to conduct simulations or provide analyses of previous simulations upon request by the Department, highlighting the necessity for regulatory compliance in the selection process.

Recent discussions surrounding fan definitions, such as the not to adopt a specific term for ‘exclusively embedded fan,’ illustrate the evolving regulatory landscape that engineers must navigate. This simplification facilitates understanding of fan classifications and their applications, ultimately guiding better decision-making in fan selection.

Trace the Evolution of Fan Technology in Electronics

The evolution of fan technology in electronics has undergone remarkable transformations since the introduction of the electric fan in the late 19th century. Initially designed for basic ventilation, the growing power and compactness of electronic components have necessitated . The advent of has significantly enhanced fan efficiency, enabling quieter operation and improved performance. Notably, the automotive industry constitutes the majority of the brushless DC motors market share, underscoring their critical role in advancing technology-driven solutions across various sectors. Furthermore, have optimized airflow and reduced , contributing to these improvements.

Recent innovations include the development of intelligent ventilators that dynamically adjust their speed based on real-time temperature readings. This capability facilitates accurate , addressing the increasing demand for within the electronics sector. The adoption rates of brushless DC motors in cooling devices have surged, reflecting their importance in contemporary applications.

At , we are committed to empowering engineers with and power management technologies. Our portfolio of exceptional manufacturers offers a broad array of electronics solutions that cater to the evolving needs of the industry. Case studies, such as “,” illustrate the integration of advanced fan technology in settings like offices and schools. These innovations are linked to improved air quality and comfort, which, in turn, enhance productivity and concentration. As Jackson Murphy, a seasoned author in the consumer electronics industry, observes, the ongoing evolution of fan technology underscores the essential function fans serve in modern technology, driving the continuous pursuit of better performance and energy efficiency. This evolution also highlights the , which is crucial for engineers in optimizing cooling solutions.

Conclusion

The exploration of fan technology in electronics highlights their critical role in maintaining optimal operating conditions across diverse applications. From basic airflow generation to advanced smart fans equipped with brushless DC motors, the evolution of fan technology has been propelled by the demand for enhanced performance, energy efficiency, and reduced noise levels. For engineers and designers aiming to optimize thermal management strategies and avert costly system failures, understanding the purpose and significance of fans is essential.

Measurement techniques are pivotal in assessing fan performance, with metrics such as airflow, static pressure, and rotational speed being crucial in fan selection. By employing precise measurement methods, engineers can ensure that the selected fans meet the specific cooling requirements of their systems, ultimately leading to improved efficiency and reliability. Furthermore, recognizing the key characteristics and specifications of fans—such as size, noise levels, and power consumption—enables informed decision-making in the design and implementation of effective cooling solutions.

As technology continues to advance, the importance of fans in electronics remains paramount. Their evolution underscores a commitment to enhancing the performance and longevity of electronic devices while addressing the increasing demand for energy-efficient solutions. The ongoing innovations in fan technology not only emphasize their indispensable role in modern electronics but also highlight the necessity for engineers to remain informed about the latest advancements and specifications to optimize system performance effectively.

Frequently Asked Questions

What are ventilators in the context of electronics?

Ventilators are mechanical devices designed to generate airflow, primarily for cooling purposes in electronic applications.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest manufacturer of standard and custom air movers, providing a wide range of cooling solutions that are effective, efficient, and operate with minimal noise.

What applications do ventilators serve?

Ventilators play a critical role in various applications, including computers, HVAC systems, and industrial machinery.

How do Gagner-Toomey’s devices help maintain optimal operating temperatures?

Their devices dissipate heat produced by electronic components by facilitating air circulation over these components, which enhances performance and extends the lifespan of equipment.

Why are cooling devices important in electronic design and thermal management?

Cooling devices are essential because overheating can lead to system failures and reduced performance, making them indispensable for effective thermal management.

What is the significance of PWM (Pulse Width Modulation) devices in cooling?

The growing reliance on PWM devices is crucial for achieving energy efficiency, highlighting their importance in electronics design.

Why is it important to understand how fans are measured and their specifications?

Understanding fan measurements and specifications is vital for companies looking to improve their thermal management strategies and prevent costly failures.

What does the case study titled ‘Regional Analysis of North America Cooling Fan Market’ address?

The case study illustrates how organizations can identify leading regions for market expansion based on regional findings, emphasizing the critical role of fans in thermal regulation.