Introduction

Understanding airflow measurement is essential in various engineering applications, from optimizing HVAC systems to ensuring the reliability of electronic devices. This guide delves into the fundamentals of airflow measurement, detailing key concepts such as velocity and pressure, along with the technologies used to assess air movement effectively.

However, with numerous measurement techniques available, how can engineers determine the most accurate and efficient methods for their specific needs? This article explores the intricacies of airflow measurement, offering a step-by-step approach to enhance system performance and reliability. By examining these techniques, engineers can make informed decisions that lead to improved outcomes in their projects.

Understand Airflow Measurement Fundamentals

Airflow assessment quantifies the volume of air moving through a specific area over time, which raises the question of how airflow is measured, typically expressed in cubic feet per minute (CFM). Understanding airflow is essential for various applications, and key concepts include:

-

Velocity: This refers to the speed of air moving in a specific direction, measured in feet per minute (FPM). Precise velocity measurement is crucial, as it directly impacts the performance of HVAC units and other engineering applications. The volume flow rate, which explains how airflow is measured, is the total volume of air passing through a section per unit time, calculated as the product of velocity and cross-sectional area. Grasping this relationship is vital for enhancing design configurations and ensuring proper ventilation.

-

Pressure: Airflow is influenced by pressure differences, driving air movement from areas of high pressure to low pressure. Engineers must consider these variations to maintain operational efficiency.

The significance of airflow assessment extends beyond theoretical concepts; it plays a critical role in the electronics sector. Accurate air circulation measurement is essential in cooling mechanisms for electronic components, where insufficient air movement can lead to overheating and equipment failures. Advanced pump technologies, such as solenoid and rotary boost pumps from Gagner-Toomey Associates, are engineered to improve air management by providing precise control and efficient operation. These pumps can function up to 16 Bar and operate with low noise, ensuring optimal performance in cooling applications and preventing overheating in sensitive electronic devices.

Practical applications include the development of air intake mechanisms in automotive engines and the enhancement of HVAC systems in commercial buildings, where maintaining adequate circulation can significantly reduce energy consumption.

As industry specialists emphasize, understanding how airflow is measured, including velocity and volume flow rate, is essential for engineers to ensure that systems operate efficiently and meet design specifications. This knowledge not only enhances performance but also contributes to the longevity and reliability of electronic systems.

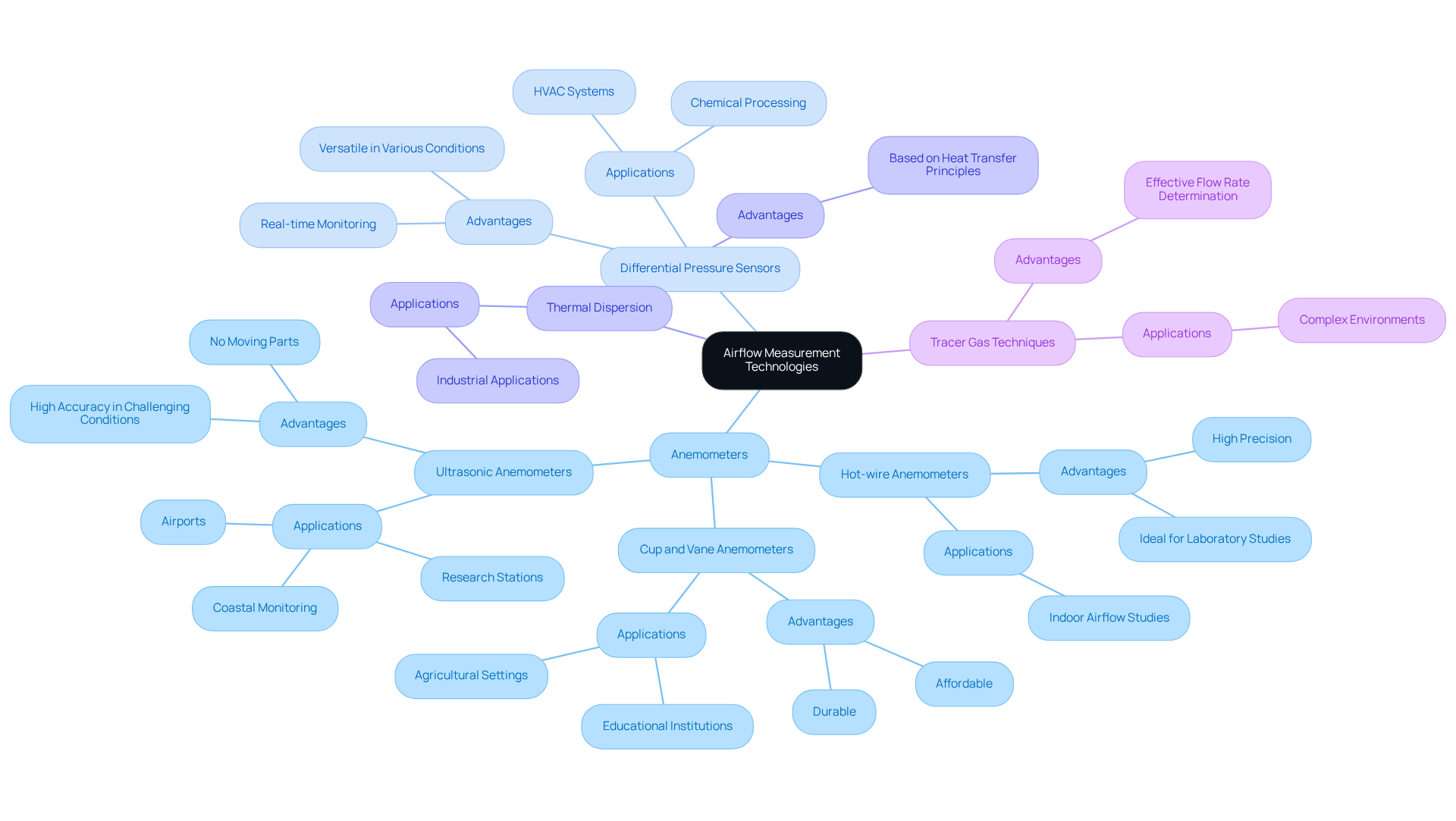

Explore Airflow Measurement Technologies

Airflow measurement technologies play a pivotal role for engineers across various applications, each presenting distinct advantages and limitations. Understanding how airflow is measured is essential for effective airflow assessment, ensuring safety and efficiency in diverse environments. The primary methods include:

-

Anemometers: These devices directly measure air velocity and come in several types:

- Hot-wire Anemometers: Renowned for their precision, these instruments detect airflow by measuring temperature changes in a heated wire, making them ideal for laboratory and indoor studies.

- Cup and Vane Anemometers: Utilizing spinning cups to gauge wind speed and a vane for direction, these are favored for their affordability and durability, commonly found in educational institutions and agricultural settings.

- Ultrasonic Anemometers: Operating without moving parts, they employ sound signals to measure wind speed and direction, delivering high accuracy even in challenging conditions.

-

Differential Pressure Sensors: These sensors measure the pressure difference across a known area, facilitating calculations of air movement, particularly in duct systems. They are vital in HVAC applications, where maintaining optimal air movement is crucial for energy efficiency and comfort. The sensing element converts diaphragm movement into an electrical signal, enabling real-time monitoring and control. These sensors are versatile, adapting to various operating conditions, including high temperatures and corrosive environments.

-

Thermal Dispersion: This method employs temperature sensors to evaluate air movement based on heat transfer principles, making it suitable for a range of industrial applications.

-

Tracer Gas Techniques: By releasing a tracer gas into the airflow and measuring its concentration at different points, this method effectively determines flow rates, often utilized in complex environments.

Each technology serves distinct purposes, and engineers must carefully evaluate how airflow is measured to select the most appropriate method for their specific project requirements. As industry leaders emphasize, reliable equipment is essential for effective airflow assessment. Regular calibration and maintenance of these tools are vital for accurate readings over time, and the proper placement of anemometers significantly impacts measurement accuracy. Furthermore, the integration of IoT technology in differential pressure sensors is transforming their application, enabling enhanced monitoring and data analysis.

Utilize Key Measurement Devices

Key devices for measuring airflow include:

-

Anemometers: Essential for measuring air velocity at specific points, anemometers come in various forms, including handheld models for spot checks and fixed installations for continuous monitoring. They typically offer an accuracy range of 1 to 5 percent, with higher precision models recommended for professional use. For instance, the Sauermann Si-VH3 hotwire thermo-anemometer provides precise readings of air movement, air speed, and temperature, making it a versatile choice for engineers. Additionally, anemometer batteries may last for approximately 300 hours of continuous use, a practical consideration for users.

-

Flow Hoods: These devices are crucial for understanding how airflow is measured at vents and diffusers, providing direct readings of air volume in cubic feet per minute (CFM). However, it’s important to recognize that commercially available flow hoods can exhibit significant accuracy errors, often around 20%, which is unacceptably high for most applications. Active flow hoods with responsive flow monitoring devices outperform conventional models, ensuring more reliable results. Research has shown that active flow hoods excel in demonstrating how airflow is measured in residential HVAC setups, underscoring the necessity for precise air assessments to guarantee comfort and efficiency. Moreover, using appropriately sized cones for airflow assessment is vital to encompass the entire opening of the vent.

-

Pitot Tubes: Frequently utilized in duct networks, these instruments assess total pressure and determine flow based on velocity pressure. They are particularly effective in environments where accurate air movement measurements are critical.

-

Duct Blowers: Employed for assessing how airflow is measured in HVAC systems, duct blowers are especially beneficial for balancing air distribution. They help ensure that each component of the HVAC system operates within its designed parameters, contributing to overall system efficiency.

When selecting a device, consider factors such as range, accuracy, and ease of use. Understanding the specific needs of your application will assist you in choosing the most effective airflow assessment tool.

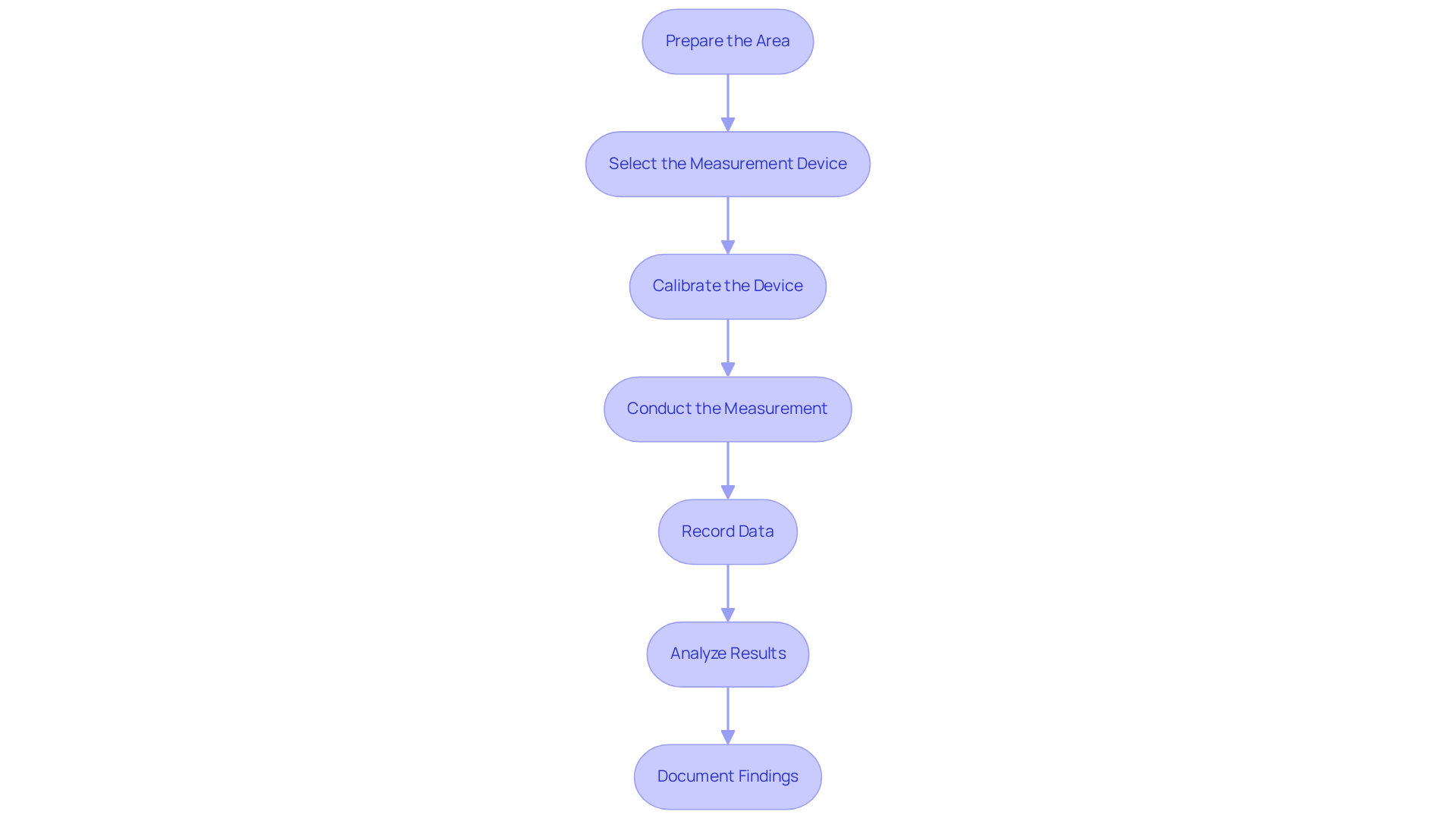

Implement Step-by-Step Airflow Measurement Procedures

To measure airflow effectively, it’s crucial to follow these steps:

- Prepare the Area: Ensure the testing site is free of obstacles that could influence air movement. This initial step is vital for obtaining accurate measurements.

- Select the Measurement Device: Choose a suitable device based on the air characteristics and assessment requirements. The right tool is essential for reliable data.

- Calibrate the Device: Follow the manufacturer’s instructions to calibrate the device for accurate readings. Proper calibration is key to ensuring precision in your measurements.

- Conduct the Measurement: Position the device at the designated measurement point, ensuring it is aligned correctly with the direction of the flow. Correct positioning is critical for valid results.

- Record Data: Take multiple readings to ensure accuracy and calculate the average air movement. This practice helps in mitigating any anomalies in the data.

- Analyze Results: Compare the measured air movement against design specifications to identify any discrepancies. This analysis is essential for evaluating system performance.

- Document Findings: Maintain thorough logs of readings for future reference and system modifications. Comprehensive documentation supports ongoing improvements and adjustments.

By adhering to these procedures, engineers can ensure reliable and accurate airflow measurements, which leads to the important question of how is airflow measured, ultimately enhancing system efficiency and performance.

Conclusion

Understanding how airflow is measured is a fundamental aspect of engineering that directly impacts system efficiency and performance. This article has explored the essential principles and technologies involved in airflow measurement, emphasizing the importance of accurate assessment in various applications, from HVAC systems to electronic cooling mechanisms.

Key points covered include:

- The critical roles of velocity and pressure in airflow dynamics.

- The various measurement technologies available such as anemometers and differential pressure sensors.

- The step-by-step procedures necessary for conducting accurate airflow assessments.

Each method and device has its unique advantages, and selecting the appropriate tools is vital for achieving reliable measurements that meet design specifications.

Ultimately, mastering airflow measurement techniques not only enhances engineering practices but also contributes to the longevity and reliability of systems across industries. Engineers are encouraged to stay informed about the latest technologies and best practices in airflow measurement to ensure optimal performance in their projects. By doing so, they foster innovation and efficiency in engineering solutions, paving the way for advancements that benefit the entire field.

Frequently Asked Questions

What is airflow measurement?

Airflow measurement quantifies the volume of air moving through a specific area over time, typically expressed in cubic feet per minute (CFM).

What are the key concepts involved in understanding airflow?

The key concepts include velocity, which is the speed of air measured in feet per minute (FPM), and pressure, which influences airflow by creating differences that drive air movement.

How is airflow measured?

Airflow is measured as the volume flow rate, which is the total volume of air passing through a section per unit time, calculated as the product of velocity and cross-sectional area.

Why is precise velocity measurement important?

Precise velocity measurement is crucial as it directly impacts the performance of HVAC units and other engineering applications.

How does pressure affect airflow?

Pressure differences drive air movement from areas of high pressure to low pressure, and engineers must consider these variations to maintain operational efficiency.

What role does airflow assessment play in the electronics sector?

Accurate air circulation measurement is essential in cooling mechanisms for electronic components, as insufficient air movement can lead to overheating and equipment failures.

What types of pumps are used to improve air management?

Advanced pump technologies, such as solenoid and rotary boost pumps, are engineered to improve air management by providing precise control and efficient operation.

What are the practical applications of airflow measurement?

Practical applications include developing air intake mechanisms in automotive engines and enhancing HVAC systems in commercial buildings to reduce energy consumption.

Why is understanding airflow measurement important for engineers?

Understanding how airflow is measured helps engineers ensure that systems operate efficiently, meet design specifications, enhance performance, and contribute to the longevity and reliability of electronic systems.