Overview

This article delves into the critical understanding of auto fan mechanisms, outlining their operational principles and essential troubleshooting techniques vital for effective vehicle temperature management. It underscores the necessity of distinguishing between mechanical and electric fans, while also highlighting recent technological advancements. Furthermore, practical troubleshooting steps are provided, equipping automotive engineers with the essential knowledge required to enhance fan performance and reliability.

Introduction

In the intricate realm of automotive engineering, the efficiency of cooling systems is profoundly influenced by the operation of auto fan mechanisms. These systems, encompassing both mechanical and electric fans, play a critical role in regulating engine temperature and ensuring optimal performance.

As vehicles continue to evolve, so too do the technologies underpinning these fans, with advancements that promise enhanced energy efficiency and responsiveness. This article explores the fundamental concepts, components, and troubleshooting techniques associated with auto fan systems, while also spotlighting the latest innovations from industry leaders such as Gagner-Toomey Associates.

By examining these elements, engineers and automotive enthusiasts can gain invaluable insights into enhancing vehicle reliability and performance through effective cooling solutions.

Explore Auto Fan Mechanisms: Fundamental Concepts

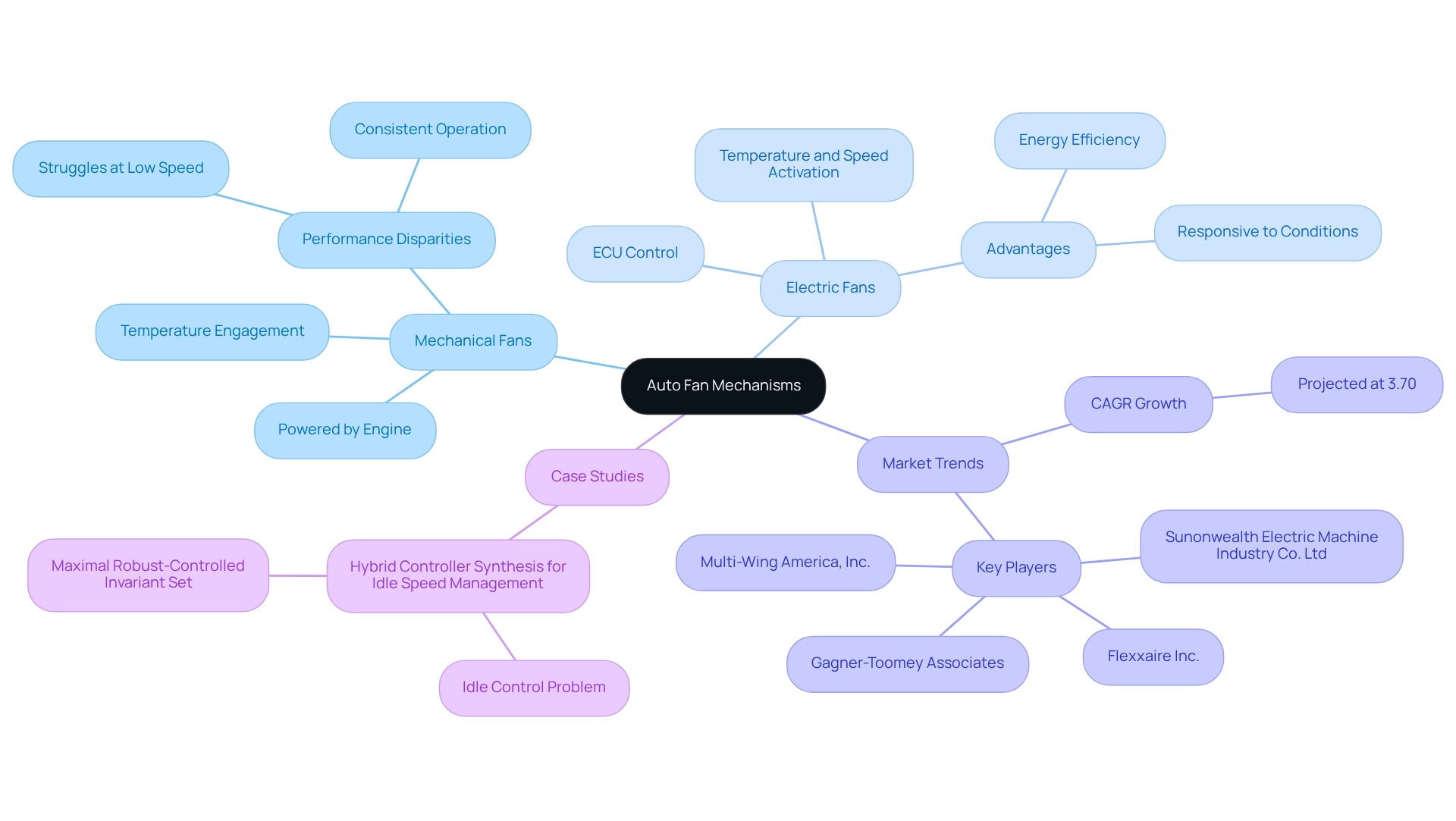

The auto fan mechanisms are integral to a vehicle’s cooling system, primarily responsible for regulating engine temperature by optimizing airflow through the radiator. These devices fall into two categories: mechanical and electric. Mechanical blowers are directly powered by the engine’s serpentine belt, ensuring consistent operation in sync with engine speed. Conversely, electric blowers utilize the automobile’s electrical system and are governed by the engine control unit (ECU), allowing for more precise airflow management based on real-time conditions.

Understanding the functionality of these devices is essential for efficient diagnostics and performance enhancement. Mechanical blowers typically engage when the engine reaches a specific temperature, while electric units can activate based on both temperature and vehicle speed, providing versatility in temperature management. Critical components like the fan clutch, which connects or disconnects the fan according to temperature, are vital for diagnosing temperature-related issues.

Recent advancements in , particularly from leading manufacturers such as Gagner-Toomey Associates, have resulted in enhanced performance and efficiency. Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a diverse range of DC input tube axial devices from 15 to 280mm and centrifugal blowers from 15 to 225mm, essential for automotive applications. The radiator fan segment is projected to grow at a compound annual growth rate (CAGR) exceeding 3.70% in the coming years, reflecting the increasing demand for efficient cooling solutions in modern vehicles. By 2025, it is anticipated that approximately 60% of vehicles will incorporate electric cooling systems, marking a significant shift from traditional mechanical systems.

Real-world examples illustrate the performance disparities between mechanical and electric devices. Research indicates that electric devices can provide superior cooling efficiency under varying load conditions, whereas mechanical units may struggle to maintain optimal airflow during low-speed operations. Insights from automotive engineers emphasize the advantages of electric cooling systems in terms of energy efficiency and responsiveness, making them a preferred choice in contemporary design. For instance, engineers have observed that electric fans can adapt more swiftly to fluctuations in engine temperature, thereby enhancing overall vehicle performance.

Moreover, findings from the case study titled “Hybrid Controller Synthesis for Idle Speed Management of an Automotive Engine” reveal how fan mechanisms are integrated into broader automotive engineering challenges. This research addresses the idle control dilemma for automotive engines, striving to maintain crankshaft speed within a specified range despite load variations, underscoring the importance of efficient thermal management in engine oversight.

Key players in the automotive ventilation fan market, including Gagner-Toomey Associates, Flexxaire Inc., Sunonwealth Electric Machine Industry Co. Ltd, and Multi-Wing America, Inc., are spearheading innovations that further advance fan technology. Their contributions are crucial for engineers aiming to stay abreast of the latest developments in temperature regulation solutions.

In conclusion, a thorough understanding of auto fan mechanisms, which includes their operational principles and recent innovations, is vital for engineers aiming to effectively troubleshoot and improve automobile temperature management.

Analyze Components and Functions of Auto Fan Systems

Auto fans play a pivotal role in the thermal management of automobiles, comprising several essential components: the fan motor, relay, and temperature sensors. The fan motor, which may be a high-efficiency DC motor for electric fans or a mechanical drive for belt-driven systems, is tasked with driving the fan blades. Gagner-Toomey Associates, the world’s largest manufacturer of both standard and custom air-movers, provides a diverse range of high-efficiency DC motors that not only minimize energy consumption but also enhance overall performance, significantly contributing to improved vehicle efficiency. This is particularly critical as data indicates that these motors can yield substantial energy savings in automotive applications.

The relay functions as a switch, regulating the power supply to the fan based on engine temperature. Upon reaching a predetermined temperature, the relay activates the fan, ensuring optimal temperature regulation. Additionally, temperature sensors play a vital role by continuously monitoring engine heat, delivering real-time data that informs the relay’s operation.

A fan shroud may also be incorporated, directing airflow and enhancing thermal efficiency. Understanding the interplay between these components is essential for diagnosing issues such as auto fan failure or insufficient cooling performance. For instance, a case analysis on HVAC technologies in passenger transport highlighted the importance of collecting and pre-processing Time-To-Failure (TTF) data, which revealed common failure modes and facilitated efficient resource allocation in reliability improvement initiatives. Furthermore, the application of Reliability Block Diagrams (RBD) is widely recognized for reliability modeling, helping to identify critical subsystems and potential failure modes within auto fan configurations. Moreover, statistics indicate that certain components within auto fan setups exhibit specific failure rates, highlighting the necessity for condition-based monitoring solutions to preemptively address potential failures. This proactive approach can significantly enhance the reliability of automotive temperature control systems, ensuring that vehicles operate efficiently under varying conditions. Additionally, comprehending the average lifespan of fan motors in automotive contexts is crucial for maintenance planning and sustaining optimal performance over time. Gagner-Toomey Associates’ extensive portfolio of and centrifugal blowers, available in sizes ranging from 15 to 280mm, offers engineers innovative solutions tailored to . Most models also provide IP protection upon request, guaranteeing durability and reliability across diverse applications.

Implement Troubleshooting Techniques for Optimal Fan Performance

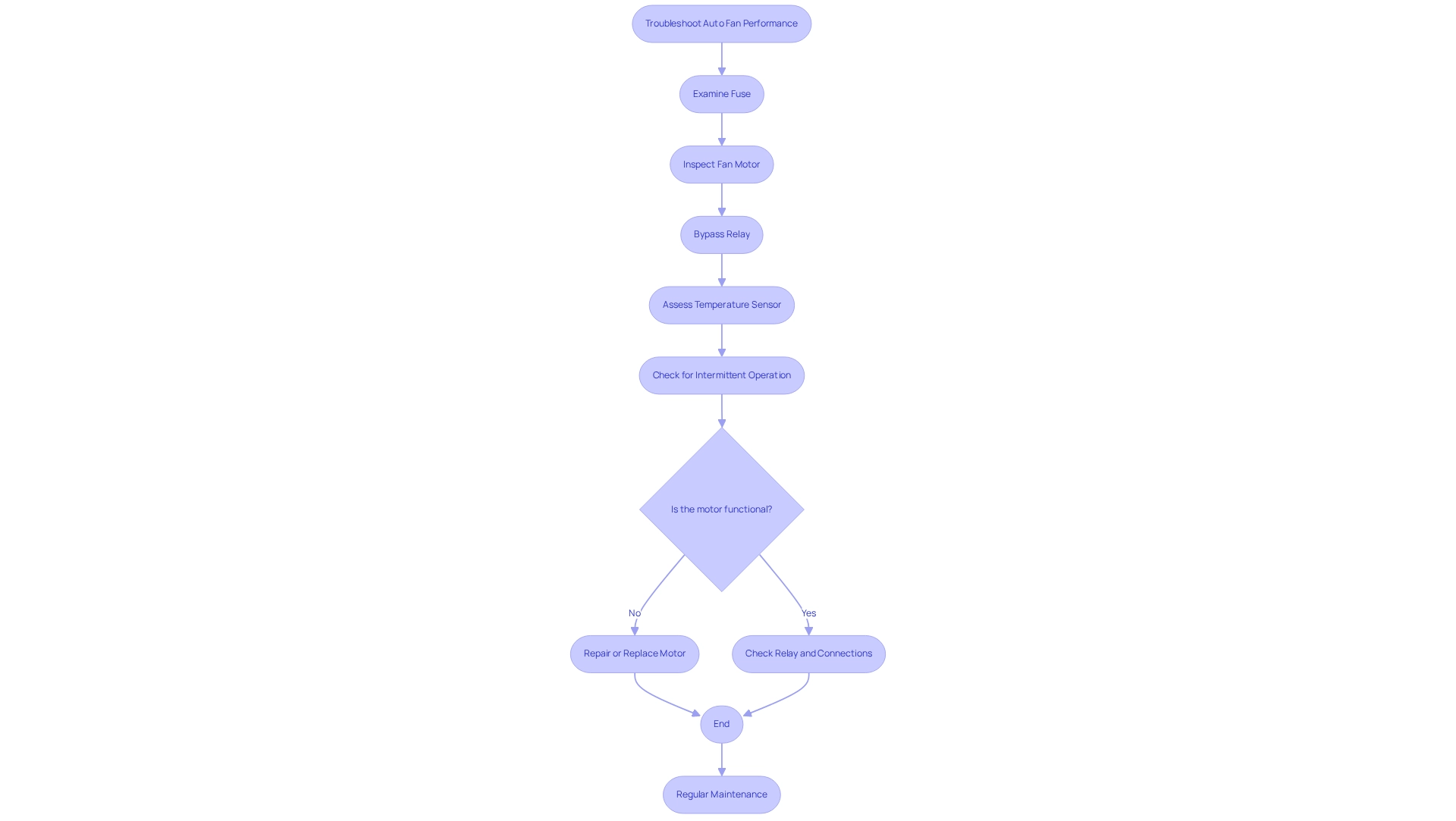

To effectively troubleshoot auto fan performance, begin by examining the fuse associated with the fan circuit, since blown fuses account for a significant percentage of failures. Next, inspect the fan motor for any signs of wear or damage. If the fan fails to operate, bypass the relay using a fused jumper wire to determine if the motor is functional. Additionally, assess the temperature sensor to ensure it accurately reflects engine temperature. Intermittent fan operation may indicate a faulty relay or poor electrical connections.

Regular maintenance of the auto fan, including cleaning the fan blades and verifying proper wiring, can significantly enhance both performance and longevity. Automotive specialists recommend inspecting your auto fan at least every six months to identify potential problems early. For instance, a thorough system inspection prior to returning a vehicle to the client can verify that all components, including the ECT sensor, thermostat, and fan units, are functioning properly, thereby ensuring customer satisfaction and vehicle dependability.

As FoxWellRussell, an automotive repair specialist, states, “Here’s how to identify fan issues before they leave you stranded.” Furthermore, automotive repair specialists emphasize the importance of early identification of fan issues to prevent malfunctions, underscoring the necessity for regular inspections every six months. This proactive approach is exemplified in the case study titled ‘,’ where the technician conducts a comprehensive inspection of the entire refrigeration setup to confirm that all parts are operational, ultimately enhancing the reliability of the automobile.

Integrate Auto Fan Mechanisms: Best Practices and Advanced Considerations

To effectively integrate the auto fan mechanisms, it is crucial to adhere to the following best practices:

- Ensure proper alignment and balance of the fan blades to minimize vibration and noise, which can significantly impact the auto fan’s performance.

- Employ that dynamically adjust fan speed based on real-time temperature data, thereby enhancing energy efficiency and cooling effectiveness.

- Notably, the average value of the PWM signal was highest for the PI controller, indicating its effectiveness in optimizing fan performance.

- Prioritize high-performance blowers from Gagner-Toomey Associates, as they provide superior airflow while consuming less power, contributing to overall vehicle efficiency.

- Their comprehensive portfolio includes DC input tube axial auto fans ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm, optimized for performance and low noise, making them ideal for automotive applications.

- For instance, advanced controllers utilizing fuzzy logic have demonstrated enhancements in energy efficiency and temperature stability across multiple applications, underscoring the potential of such setups in automotive cooling.

- Frequent examinations and upkeep are vital; look for debris that may block airflow, as this can result in overheating and diminished performance.

- Additionally, some EC fans from Gagner-Toomey Associates are rated up to 150℃, highlighting their capability to operate effectively in harsh conditions.

- Implementing these strategies not only optimizes the cooling performance of the auto fan but also prolongs the lifespan of the auto fan system, ultimately supporting the vehicle’s operational reliability.

- Furthermore, consider using products that meet stringent standards such as UL, CE, and TUV certifications, as endorsed by Gagner-Toomey Associates, to ensure high performance and reliability.

Conclusion

The exploration of auto fan mechanisms underscores their essential role in maintaining optimal engine temperatures and enhancing vehicle performance. It is crucial for automotive engineers and enthusiasts to understand the distinctions between mechanical and electric fans, along with their respective components. The advancements in fan technology, particularly from leading manufacturers such as Gagner-Toomey Associates, illustrate the shift towards more efficient electric fan systems, which are projected to dominate the market in the coming years.

By analyzing the components and functions of auto fan systems, it becomes evident that effective cooling relies on the integration of various elements, including fan motors, relays, and temperature sensors. The emphasis on proactive troubleshooting techniques further highlights the importance of regular maintenance and early detection of potential issues to avert vehicle breakdowns. Implementing best practices in fan integration and utilizing advanced control systems can significantly enhance energy efficiency and cooling performance.

As the automotive industry continues to evolve, remaining informed about the latest innovations and technologies in auto fan mechanisms is vital for improving vehicle reliability and performance. By prioritizing effective cooling solutions, engineers can contribute to the development of more efficient, responsive, and durable automotive systems, ultimately leading to a superior driving experience.

Frequently Asked Questions

What are the primary functions of auto fan mechanisms in vehicles?

Auto fan mechanisms are integral to a vehicle’s cooling system, primarily responsible for regulating engine temperature by optimizing airflow through the radiator.

What are the two categories of auto fan mechanisms?

The two categories of auto fan mechanisms are mechanical and electric fans.

How do mechanical fans operate?

Mechanical fans are directly powered by the engine’s serpentine belt, ensuring consistent operation in sync with engine speed.

How do electric fans operate?

Electric fans utilize the automobile’s electrical system and are governed by the engine control unit (ECU), allowing for more precise airflow management based on real-time conditions.

When do mechanical fans typically engage?

Mechanical fans typically engage when the engine reaches a specific temperature.

How do electric fans activate?

Electric fans can activate based on both temperature and vehicle speed, providing versatility in temperature management.

What is the function of the fan clutch in auto fan mechanisms?

The fan clutch connects or disconnects the fan according to temperature, which is vital for diagnosing temperature-related issues.

What advancements have been made in automotive fan technology?

Recent advancements in automotive fan technology have resulted in enhanced performance and efficiency, particularly from manufacturers like Gagner-Toomey Associates.

What is the projected growth for the radiator fan segment?

The radiator fan segment is projected to grow at a compound annual growth rate (CAGR) exceeding 3.70% in the coming years.

What shift is expected in vehicle cooling systems by 2025?

By 2025, it is anticipated that approximately 60% of vehicles will incorporate electric cooling systems, marking a significant shift from traditional mechanical systems.

What are the performance differences between mechanical and electric fans?

Electric fans can provide superior cooling efficiency under varying load conditions, whereas mechanical fans may struggle to maintain optimal airflow during low-speed operations.

Why are electric cooling systems preferred in contemporary vehicle design?

Electric cooling systems are preferred due to their energy efficiency and responsiveness, allowing them to adapt quickly to fluctuations in engine temperature.

What does the case study “Hybrid Controller Synthesis for Idle Speed Management of an Automotive Engine” address?

The case study addresses the idle control dilemma for automotive engines, focusing on maintaining crankshaft speed within a specified range despite load variations, highlighting the importance of efficient thermal management.

Who are the key players in the automotive ventilation fan market?

Key players include Gagner-Toomey Associates, Flexxaire Inc., Sunonwealth Electric Machine Industry Co. Ltd, and Multi-Wing America, Inc.

Why is understanding auto fan mechanisms important for engineers?

A thorough understanding of auto fan mechanisms is vital for engineers aiming to effectively troubleshoot and improve automobile temperature management.