Overview

The article provides an in-depth examination of axial exhaust fans, emphasizing their applications, configurations, common issues, and comparisons with centrifugal fans. Axial exhaust fans are predominantly utilized in industrial ventilation, HVAC systems, and for cooling electronic equipment, owing to their efficiency in moving substantial volumes of air at low pressure. Furthermore, the article outlines how to optimize their configurations to meet specific requirements and underscores the necessity of regular maintenance to avert operational challenges. This comprehensive overview not only informs the reader about the critical role of axial exhaust fans but also encourages proactive management of these systems to ensure optimal performance.

Introduction

Axial exhaust fans serve a crucial function across various industries, from improving air quality in HVAC systems to cooling delicate electronic devices. Their distinctive design facilitates efficient airflow management, rendering them essential in environments that require substantial air movement.

Nevertheless, the extensive application of these fans brings forth the challenge of comprehending their configurations and potential issues. What strategies can be employed to optimize their performance and avert common pitfalls associated with these vital devices?

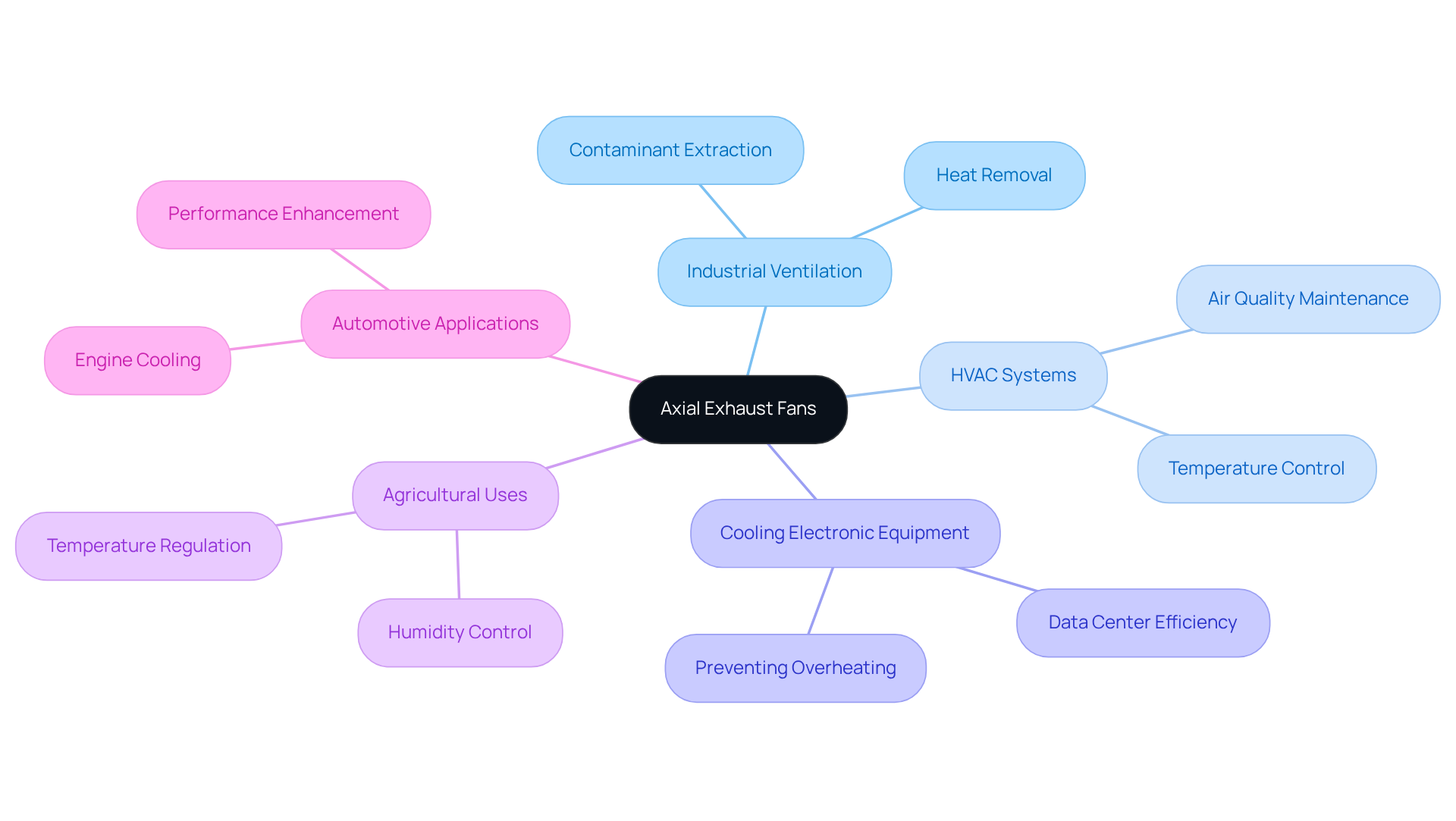

Define Axial Exhaust Fans and Their Applications

Axial exhaust fans are sophisticated mechanical devices engineered to move air parallel to the axis of the apparatus. Characterized by their blades that rotate around a central shaft, these units generate a steady airflow in a linear direction. Their applications are extensive and include:

- Industrial Ventilation: Crucial for the removal of heat and contaminants from manufacturing environments.

- HVAC Systems: Integral for maintaining air quality and temperature control in buildings, often utilizing axial exhaust fans.

- Cooling Electronic Equipment: Axial exhaust fans are essential for preventing overheating in data centers and electronic devices.

- Agricultural Uses: Axial exhaust fans are used in greenhouses and livestock facilities to effectively regulate temperature and humidity.

- Automotive Applications: Axial exhaust fans are utilized in vehicle cooling systems to enhance engine performance.

These devices exhibit remarkable efficiency in scenarios requiring high airflow at low pressure, making them suitable for a variety of environments.

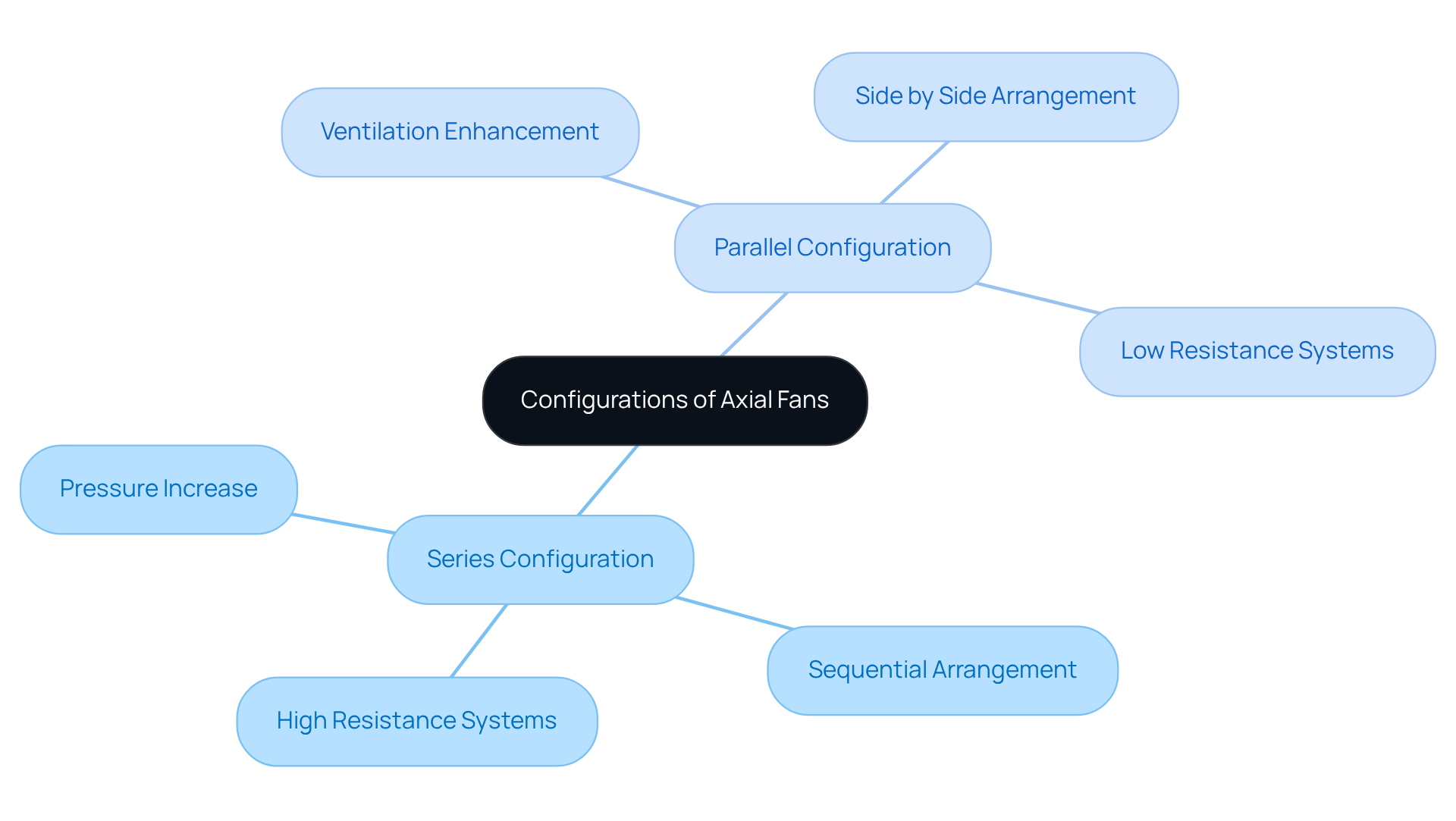

Explore Series and Parallel Configurations of Axial Fans

Axial blowers can be arranged in two primary configurations: series and parallel.

-

Series Configuration: In this arrangement, air circulators are organized sequentially, effectively raising the overall pressure while preserving the same flow rate. This setup is particularly beneficial in systems with high resistance, where additional pressure is essential to overcome obstacles.

-

Parallel Configuration: Conversely, in this arrangement, fans are placed side by side, enhancing the overall ventilation while maintaining the same pressure. This configuration is ideal for low-resistance systems that require large volumes of air.

Choosing the appropriate configuration hinges on the specific needs of the application, including ventilation requirements and system resistance. By understanding these configurations, one can make informed decisions that optimize system performance.

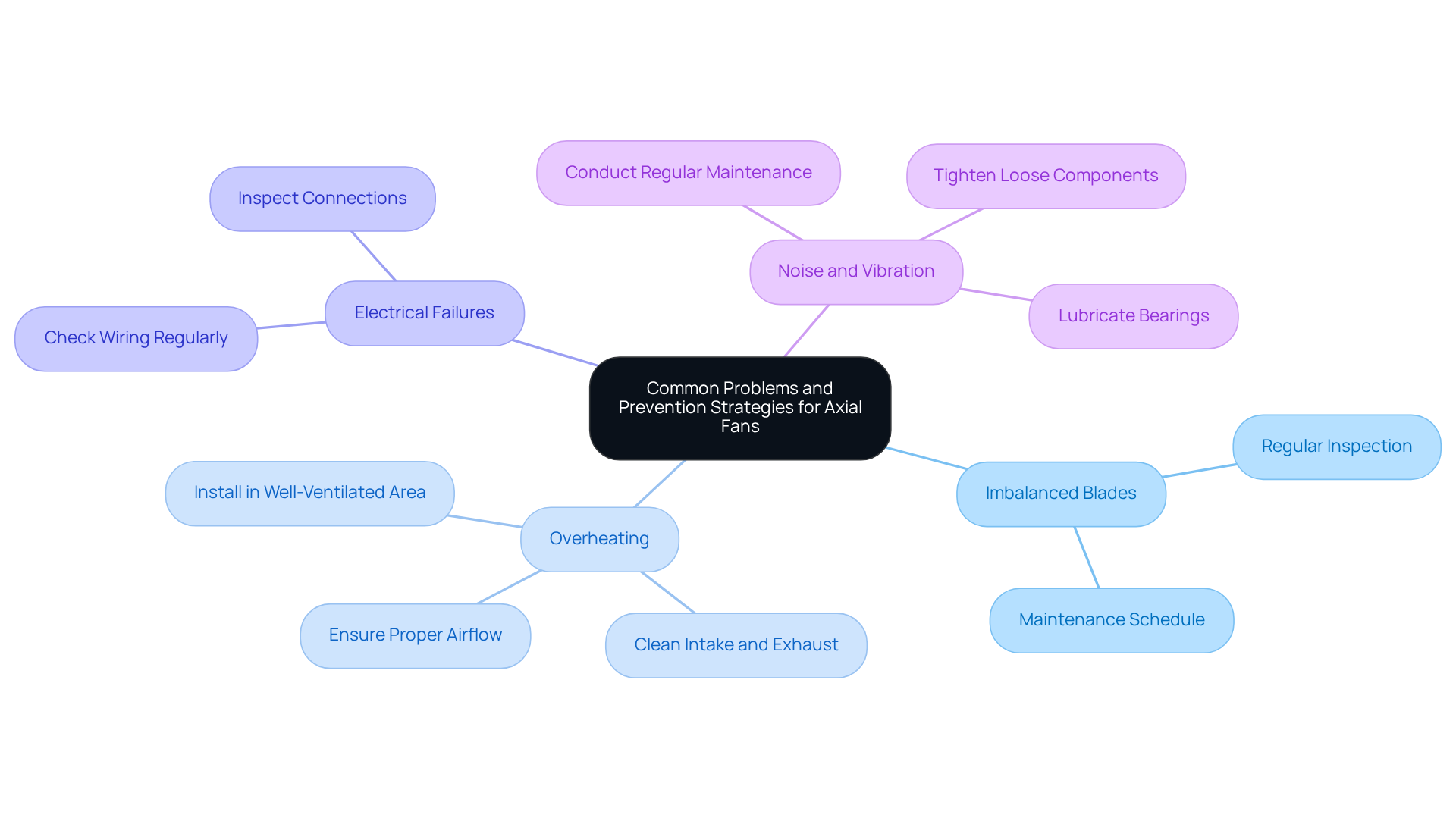

Identify Common Problems and Prevention Strategies for Axial Fans

Common problems associated with axial fans include the following:

- Imbalanced Blades: This issue can lead to excessive vibration and noise. Regular inspection and maintenance are essential to prevent this problem.

- Overheating: Often caused by insufficient airflow or blocked vents, it is crucial to ensure that the fan is installed in a well-ventilated area. Additionally, regularly cleaning the intake and exhaust will help mitigate this risk.

- Electrical Failures: To prevent power issues, check wiring and connections on a regular basis.

- Noise and Vibration: These are frequently due to loose components or worn bearings. Conducting regular maintenance, including lubrication and tightening of screws, can significantly reduce these concerns.

Implementing a routine maintenance schedule can substantially decrease the likelihood of these issues, ensuring that the fan operates efficiently.

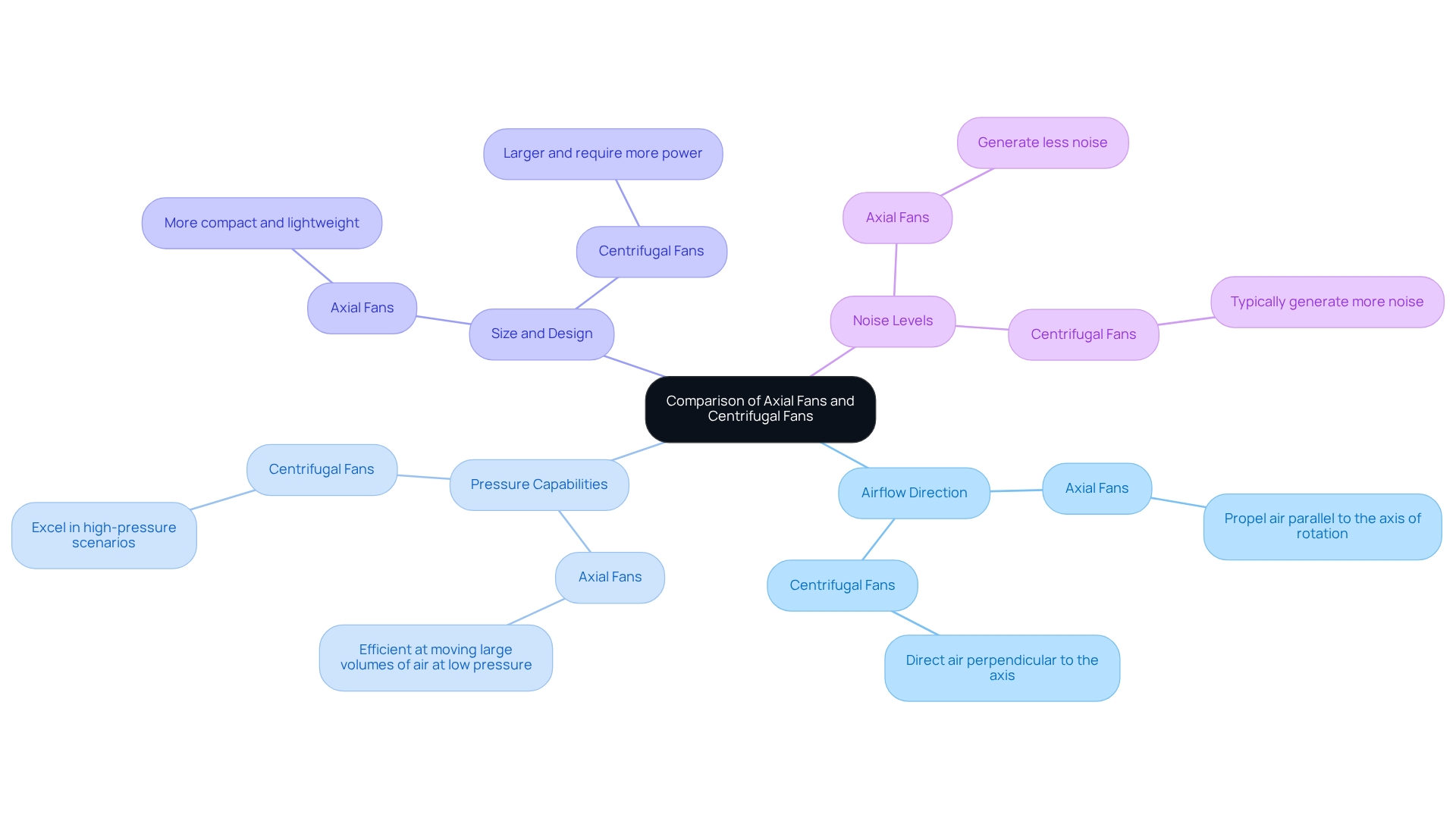

Compare Axial Fans with Centrifugal Fans: Key Differences

Axial fans and centrifugal fans fulfill similar functions but operate on distinct principles.

Airflow Direction: Axial fans propel air parallel to the axis of rotation, whereas centrifugal fans direct air perpendicular to the axis.

Pressure Capabilities: Axial exhaust fans are notably efficient at moving large volumes of air at low pressure, making them ideal for general ventilation applications. In contrast, centrifugal blowers excel in high-pressure scenarios, such as those found in ducted systems, where their design maximizes air pressure output.

Size and Design: Generally, axial exhaust fans are more compact and lightweight, which facilitates installation in confined spaces. Conversely, centrifugal blowers tend to be larger and require more power to operate effectively.

Noise Levels: Typically, axial exhaust fans generate less noise compared to their centrifugal counterparts, which is a crucial consideration in noise-sensitive environments.

By comprehending these distinctions, engineers can make informed decisions when selecting the appropriate fan type tailored to specific application requirements.

Conclusion

Axial exhaust fans are pivotal in a myriad of applications, showcasing their versatility and efficiency in moving air parallel to their axis. Their importance transcends multiple industries, encompassing industrial ventilation, HVAC systems, agricultural settings, and automotive cooling. A comprehensive understanding of their configurations—such as series and parallel arrangements—enables optimized performance tailored to specific requirements, thereby enhancing air quality and operational efficiency.

This article examines prevalent issues associated with axial fans, including:

- Imbalanced blades

- Overheating

It highlights the crucial role of regular maintenance in addressing these challenges. Furthermore, a comparison with centrifugal fans underscores the distinctive advantages of axial fans, notably their compact design, reduced noise levels, and effectiveness in low-pressure environments.

In conclusion, mastering the applications, configurations, and maintenance of axial exhaust fans is essential for maximizing their benefits. By implementing preventive strategies and making informed choices between axial and centrifugal fans, industries can ensure optimal airflow management and operational reliability. Embracing these insights not only enhances system performance but also contributes to a safer and more efficient working environment.

Frequently Asked Questions

What are axial exhaust fans?

Axial exhaust fans are mechanical devices designed to move air parallel to the axis of the fan. They feature blades that rotate around a central shaft to generate a steady airflow in a linear direction.

What are the main applications of axial exhaust fans?

Axial exhaust fans are used in various applications, including industrial ventilation, HVAC systems, cooling electronic equipment, agricultural uses, and automotive applications.

How do axial exhaust fans contribute to industrial ventilation?

In industrial settings, axial exhaust fans are crucial for removing heat and contaminants from manufacturing environments.

What role do axial exhaust fans play in HVAC systems?

Axial exhaust fans are integral to HVAC systems as they help maintain air quality and temperature control in buildings.

Why are axial exhaust fans important for cooling electronic equipment?

They are essential for preventing overheating in data centers and electronic devices by ensuring adequate airflow.

How are axial exhaust fans utilized in agriculture?

In agriculture, axial exhaust fans are used in greenhouses and livestock facilities to effectively regulate temperature and humidity.

What is the significance of axial exhaust fans in automotive applications?

Axial exhaust fans enhance engine performance by being utilized in vehicle cooling systems.

What efficiency characteristics do axial exhaust fans exhibit?

Axial exhaust fans are remarkably efficient in scenarios that require high airflow at low pressure, making them suitable for various environments.