Overview

DC centrifugal blowers are essential devices that harness centrifugal force to manage air or gas flow efficiently across a range of applications, including electronics cooling, HVAC systems, and medical equipment. Their significance is underscored by key specifications such as:

- Airflow rate

- Static pressure

- Energy efficiency

These specifications are critical for selecting the appropriate blower to meet specific industrial requirements. This focus on efficiency is increasingly relevant due to the rising market demand propelled by energy-saving regulations and technological advancements.

To address the growing need for effective airflow management, understanding these specifications becomes imperative. Airflow rate determines the volume of air moved, static pressure impacts the blower’s ability to overcome resistance in the system, and energy efficiency reflects operational cost-effectiveness. By evaluating these factors, industries can make informed decisions that align with both performance and sustainability goals.

In conclusion, as the landscape of industrial applications evolves, the role of DC centrifugal blowers becomes more pronounced. The integration of advanced technologies and adherence to energy regulations not only enhances performance but also contributes to environmental responsibility. Therefore, selecting the right blower is not merely a technical choice; it is a strategic decision that can significantly influence operational success.

Introduction

DC centrifugal blowers are critical components in a variety of applications, harnessing the power of centrifugal force to efficiently manage air and gas flow. Understanding their operational principles, specifications, and versatile uses can unlock significant benefits for industries ranging from electronics to HVAC. However, as the demand for energy-efficient solutions rises, engineers and decision-makers face a pressing challenge: how can they select the right blower to meet both performance and sustainability goals? This question is paramount in an era where efficiency is not just desired but required.

To address this, it is essential to delve into the operational principles of DC centrifugal blowers. These devices utilize centrifugal force to propel air and gases, making them ideal for numerous applications. Their specifications vary widely, catering to different needs and environments. By examining these specifications, industries can identify the most suitable blower for their unique requirements, ensuring optimal performance.

Moreover, the versatility of DC centrifugal blowers is noteworthy. They find applications across various sectors, including electronics, HVAC, and beyond. This adaptability not only highlights their importance but also underscores the need for careful selection based on specific operational demands.

In conclusion, as the landscape of energy efficiency evolves, the choice of the right DC centrifugal blower becomes crucial. Engineers and decision-makers must leverage their understanding of operational principles and specifications to make informed decisions that align with both performance and sustainability objectives.

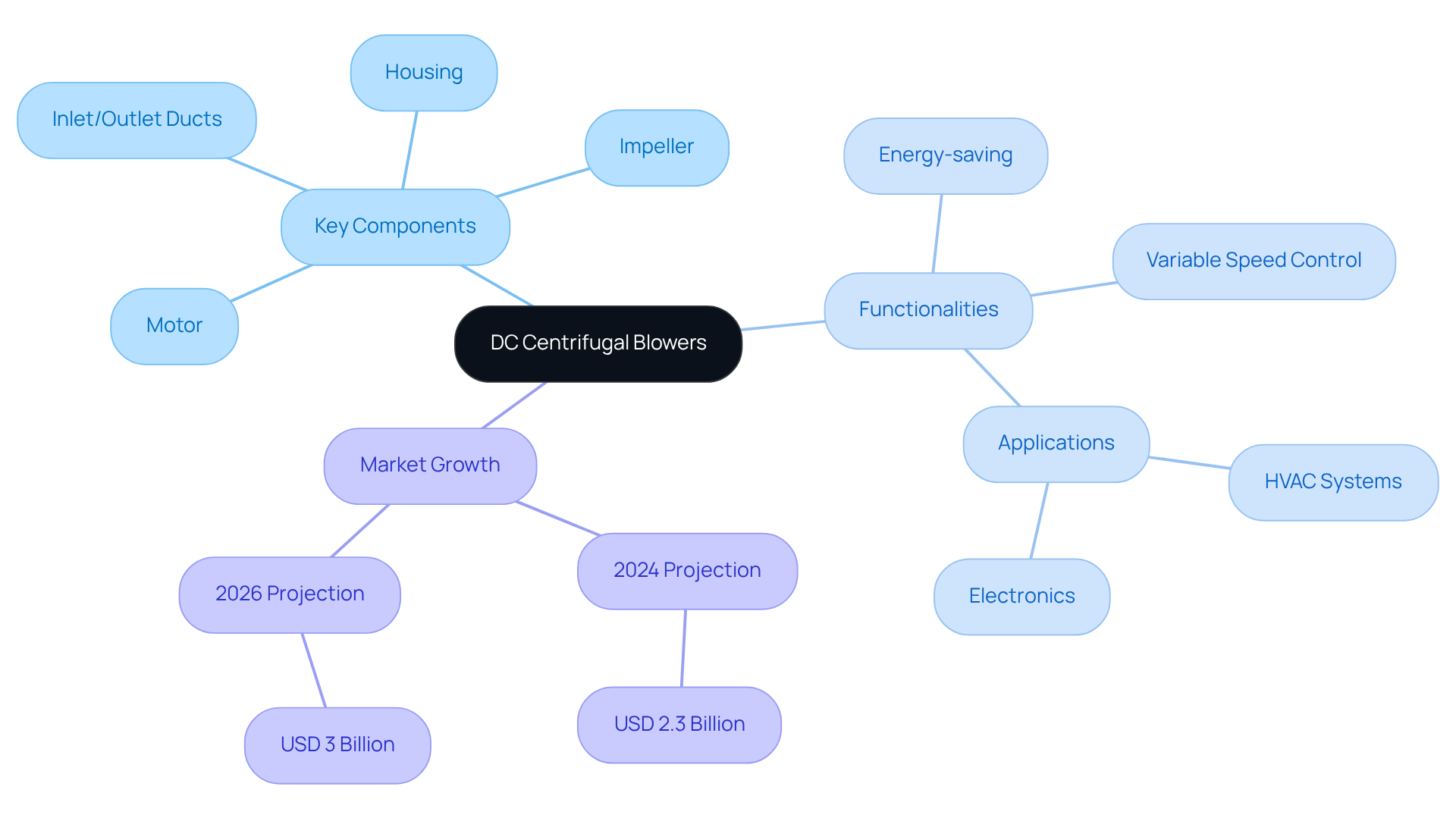

Explore the Fundamentals of DC Centrifugal Blowers

DC centrifugal blowers are indispensable devices that use a rotating impeller to direct air or gas flow. Operating on the principle of centrifugal force, these devices create a low-pressure zone as the impeller rotates, drawing air in through the inlet and expelling it through the outlet. Key components include:

- Motor

- Impeller

- Housing

- Inlet/outlet ducts

Each component plays a vital role in the device’s functionality. A comprehensive understanding of these components is essential for effective use and maintenance, as emphasized by industry experts who underscore that engineering focuses on achieving function while preventing failure.

Gagner-Toomey Associates stands out as the world’s largest producer of standard and custom air-movers, offering an extensive product range of DC centrifugal blowers that vary in size from 15 to 225mm, with IP protection available upon request. These devices are particularly valued for their energy-saving capabilities and ease of management, making them ideal for diverse applications in electronics and HVAC systems. Their ability for variable speed control facilitates precise airflow management, which is critical in sensitive electronic environments. Data indicates that the adoption of DC centrifugal blowers is expected to grow significantly, with forecasts projecting an increase from USD 2.3 billion in 2024 to USD 3 billion by 2026, driven by rising energy-saving regulations and advancements in intelligent automation technologies. This trend underscores the growing importance of these devices in contemporary engineering solutions, where the integration of technology and efficiency is paramount.

Furthermore, Gagner-Toomey’s innovative cooling solutions, which include an extensive range of thermal management products such as extruded aluminum heatsinks and integrated cooling solutions, exemplify their commitment to optimizing performance and energy consumption in electronics. Case studies on the efficiency of centrifugal fans in electronics further reinforce the necessity of understanding their components and operational principles.

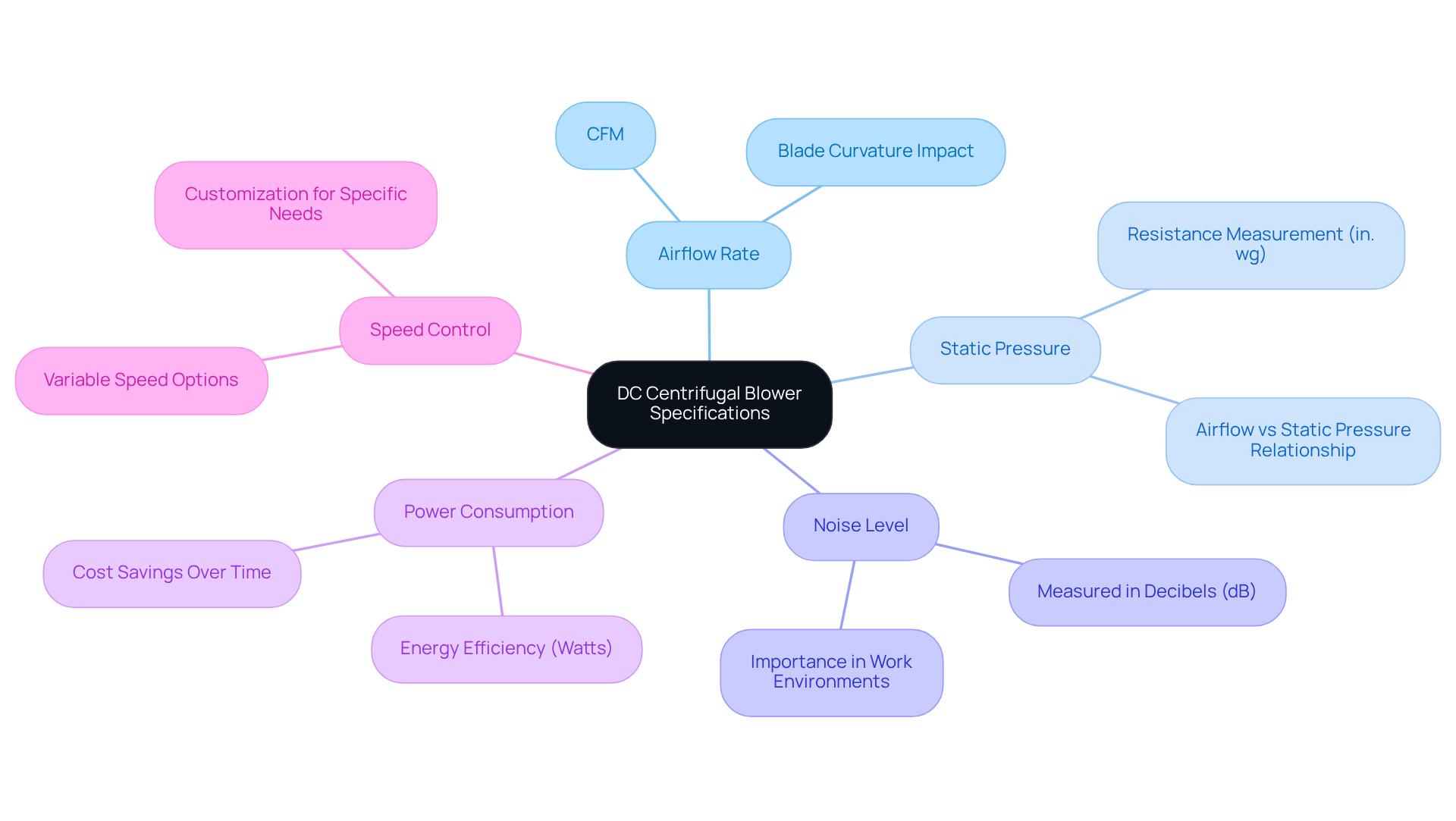

Analyze Technical Specifications and Features

When evaluating DC centrifugal blowers, several essential specifications must be taken into account:

-

Airflow Rate: Expressed in cubic feet per minute (CFM), this metric indicates the volume of air the blower can move. For applications that require significant air movement, a dc centrifugal blower with elevated CFM ratings is essential. Notably, fans with improved blade curvature can boost airflow effectiveness, leading to enhanced performance in HVAC systems and various applications. According to AMETEK® Lamb Electric, their dc centrifugal blower devices are meticulously engineered with state-of-the-art technology and premium-quality materials to ensure superior performance and energy efficiency.

-

Static Pressure: This specification measures the resistance the fan can overcome, typically indicated in inches of water gauge (in. wg). A comprehensive grasp of static pressure is essential, as it directly affects the efficiency of the dc centrifugal blower in various settings. Case studies, such as ‘Understanding Air Flow vs Static Pressure,’ have demonstrated that as static pressure rises, airflow may diminish, emphasizing the significance of choosing a fan that balances both metrics.

-

Noise Level: Measured in decibels (dB), this specification reflects the operational sound of the fan. In environments where noise is a concern, selecting a dc centrifugal blower with lower noise levels is preferable, ensuring a more comfortable working atmosphere.

-

Power Consumption: Indicated in watts, this metric reveals the energy efficiency of the device. Selecting a dc centrifugal blower with optimal power consumption not only supports sustainability efforts but also leads to considerable cost savings over time.

-

Speed Control: Many DC fans offer variable speed options, enabling users to modify airflow based on specific needs. This adaptability improves both productivity and performance, simplifying the customization of the device’s operation for the task at hand.

By thoroughly grasping these specifications, users can make informed choices when selecting the most appropriate device, such as a dc centrifugal blower, for their specific uses.

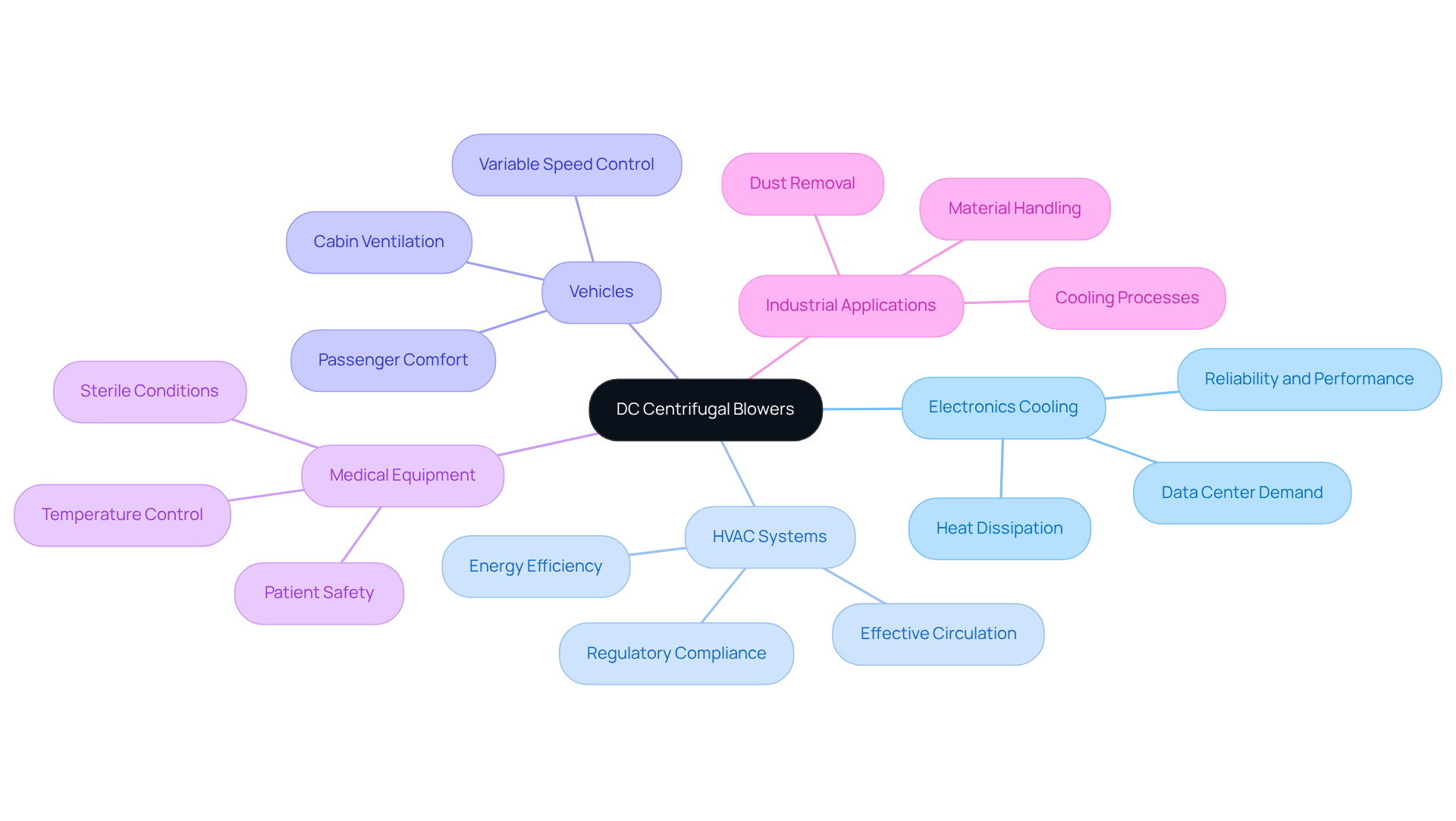

Identify Practical Applications Across Industries

DC centrifugal blowers are essential components across multiple industries, as they play a pivotal role in enhancing efficiency and performance. Their applications include:

-

Electronics Cooling: In electronic devices, maintaining optimal temperatures is crucial. DC fans effectively dissipate heat from components, ensuring reliability and performance. The swift expansion of data centers highlights the rising need for effective cooling solutions, with DC fans being essential to avoiding overheating in compact electronic devices.

-

HVAC Systems: These fans are integral to heating, ventilation, and air conditioning setups, delivering effective circulation and temperature regulation in residential and commercial structures. The global HVAC market is projected to grow significantly, driven by the demand for energy-efficient solutions. According to the U.S. Department of Energy, the HVAC sector is expected to expand at a CAGR of 5.6% from 2026 to 2033. DC fans improve airflow regulation, sustaining preferred temperatures while lowering energy usage, in accordance with changing regulatory requirements. As noted by Mike Wolf, PE, the 2023-2024 president of AMCA International, “Fortunately, federal grants are available to help offset the cost of implementing energy-efficient systems.”

In vehicles, the use of a DC centrifugal blower is essential for cabin ventilation and cooling systems, enhancing passenger comfort and safety. Their ability to provide variable speed control makes them ideal for adapting to changing conditions within the vehicle.

-

Medical Equipment: In medical devices, fans assist in preserving sterile conditions and controlling temperatures, ensuring patient safety and equipment performance. The importance of reliable airflow in medical applications cannot be overstated, as it directly impacts operational effectiveness.

-

Industrial Applications: In manufacturing, DC fans are utilized for dust removal, material handling, and cooling processes, contributing to operational efficiency. Consistent upkeep of these devices is crucial for peak performance and durability, with efficient methods resulting in substantial energy savings. A case study on “Energy Efficiency Considerations in Fan Blower Design” highlights that prioritizing energy-efficient designs not only reduces operational costs but also improves indoor air quality, contributing to sustainability initiatives within the electronics sector.

Understanding these applications allows engineers to appreciate the importance of selecting the right DC centrifugal blower for their specific needs, which ensures optimal performance and compliance with industry standards.

Conclusion

DC centrifugal blowers play a pivotal role in various industries by efficiently managing airflow and temperature. Their fundamental operation, specifications, and practical applications underscore their significance, highlighting the necessity for careful selection based on specific requirements.

This article has delved into the essential components of DC centrifugal blowers, including the motor, impeller, and housing. It has also detailed key specifications such as airflow rate, static pressure, noise levels, power consumption, and speed control. These insights are crucial for users aiming to optimize performance and enhance energy efficiency across applications ranging from electronics cooling to HVAC systems and medical equipment.

Given the increasing focus on energy efficiency and advanced automation, the rising adoption of DC centrifugal blowers marks a transformative shift in engineering solutions. By prioritizing the right blower for specific tasks, industries can elevate operational effectiveness, reduce costs, and contribute to sustainability efforts. Embracing these technologies not only meets regulatory demands but also paves the way for innovative practices that drive future advancements in airflow management.

Frequently Asked Questions

What are DC centrifugal blowers?

DC centrifugal blowers are devices that use a rotating impeller to direct air or gas flow, operating on the principle of centrifugal force to create a low-pressure zone.

What are the key components of a DC centrifugal blower?

The key components include the motor, impeller, housing, and inlet/outlet ducts, each playing a vital role in the blower’s functionality.

Why is it important to understand the components of DC centrifugal blowers?

A comprehensive understanding of the components is essential for effective use and maintenance, as it helps achieve function while preventing failure.

Who is a leading manufacturer of DC centrifugal blowers?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a wide range of DC centrifugal blowers.

What sizes do DC centrifugal blowers come in?

DC centrifugal blowers from Gagner-Toomey Associates vary in size from 15 to 225mm.

What are the advantages of using DC centrifugal blowers?

They are valued for their energy-saving capabilities, ease of management, and ability for variable speed control, making them ideal for applications in electronics and HVAC systems.

What is the projected market growth for DC centrifugal blowers?

The market for DC centrifugal blowers is expected to grow from USD 2.3 billion in 2024 to USD 3 billion by 2026, driven by rising energy-saving regulations and advancements in intelligent automation technologies.

What other products does Gagner-Toomey offer related to thermal management?

Gagner-Toomey offers an extensive range of thermal management products, including extruded aluminum heatsinks and integrated cooling solutions.

How do case studies support the use of centrifugal fans in electronics?

Case studies demonstrate the efficiency of centrifugal fans in electronics, reinforcing the necessity of understanding their components and operational principles for optimal performance.