Overview

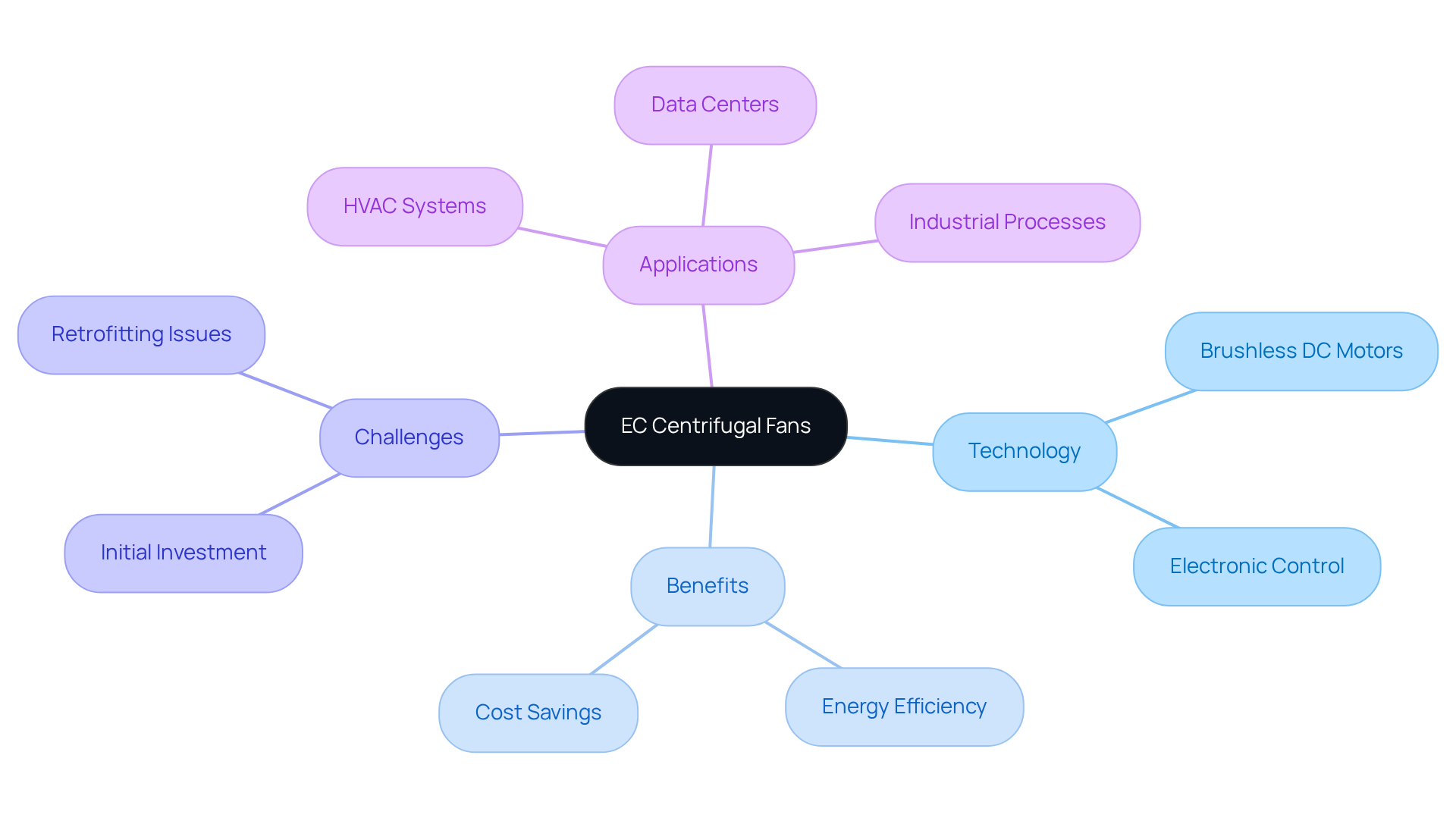

EC centrifugal fans, or Electronically Commutated centrifugal blowers, represent a significant advancement in air-moving technology. These devices leverage brushless DC motors to achieve enhanced energy efficiency and precise speed control, resulting in up to 50% less energy consumption compared to traditional AC fans. This remarkable efficiency not only lowers operational costs but also addresses the growing demand for sustainable engineering solutions.

The importance of EC centrifugal fans extends across various applications, including HVAC systems and data centers. Their long lifespan, reduced operational noise, and adaptability to varying airflow demands position them as a superior choice in modern engineering practices. Despite their higher initial costs, the long-term benefits—such as lower energy bills and improved system performance—make them a compelling option for those seeking to optimize their operations.

In conclusion, the adoption of EC centrifugal fans is a strategic move for organizations aiming to enhance energy efficiency and operational effectiveness. By investing in these advanced air-moving devices, companies can not only reduce their environmental footprint but also ensure reliable performance in demanding applications.

Introduction

EC centrifugal fans are transforming the air-moving technology landscape, seamlessly integrating advanced engineering with energy efficiency. By utilizing brushless DC motors and sophisticated control systems, these fans not only enhance performance but also promise substantial energy savings—up to 50% less than traditional AC units.

However, despite these clear advantages, the higher initial investment and integration complexities present challenges that may deter some industries from transitioning. Therefore, what factors should engineers consider when evaluating the shift to EC centrifugal fans? More importantly, how can these devices ultimately reshape operational efficiency across various sectors?

Define EC Centrifugal Fans and Their Importance in Engineering

EC centrifugal fans, which are also referred to as Electronically Commutated centrifugal blowers, represent a significant advancement in air-moving technology. Utilizing brushless DC motors in conjunction with sophisticated electronic control mechanisms, this innovative design facilitates precise speed adjustments and enhances energy efficiency, achieving reductions in energy consumption of up to 50% compared to conventional AC units. This level of effectiveness is crucial in engineering applications, particularly within HVAC systems, data centers, and various industrial processes, where operational costs and system reliability are of utmost importance.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive array of EC centrifugal fans. These blowers are meticulously optimized for performance, efficiency, and low noise, with sizes ranging from 15 to 225mm. The integration of these devices not only leads to lower energy costs but also aligns with global sustainability initiatives, making them indispensable in modern engineering practices.

However, it is essential to acknowledge that the initial investment for EC units may exceed that of traditional AC units, potentially discouraging some industries from embracing this technology. Additionally, retrofitting existing HVAC systems with EC units can present technical challenges, necessitating modifications to current infrastructure. As industries increasingly emphasize energy-efficient solutions, the significance of the EC centrifugal fan continues to grow, propelling advancements in both performance and operational efficiency.

According to the U.S. Department of Energy, efficient motors akin to those found in EC devices could yield substantial savings—potentially billions of dollars annually—across the industrial sector.

Explain the Operating Principles of EC Centrifugal Fans

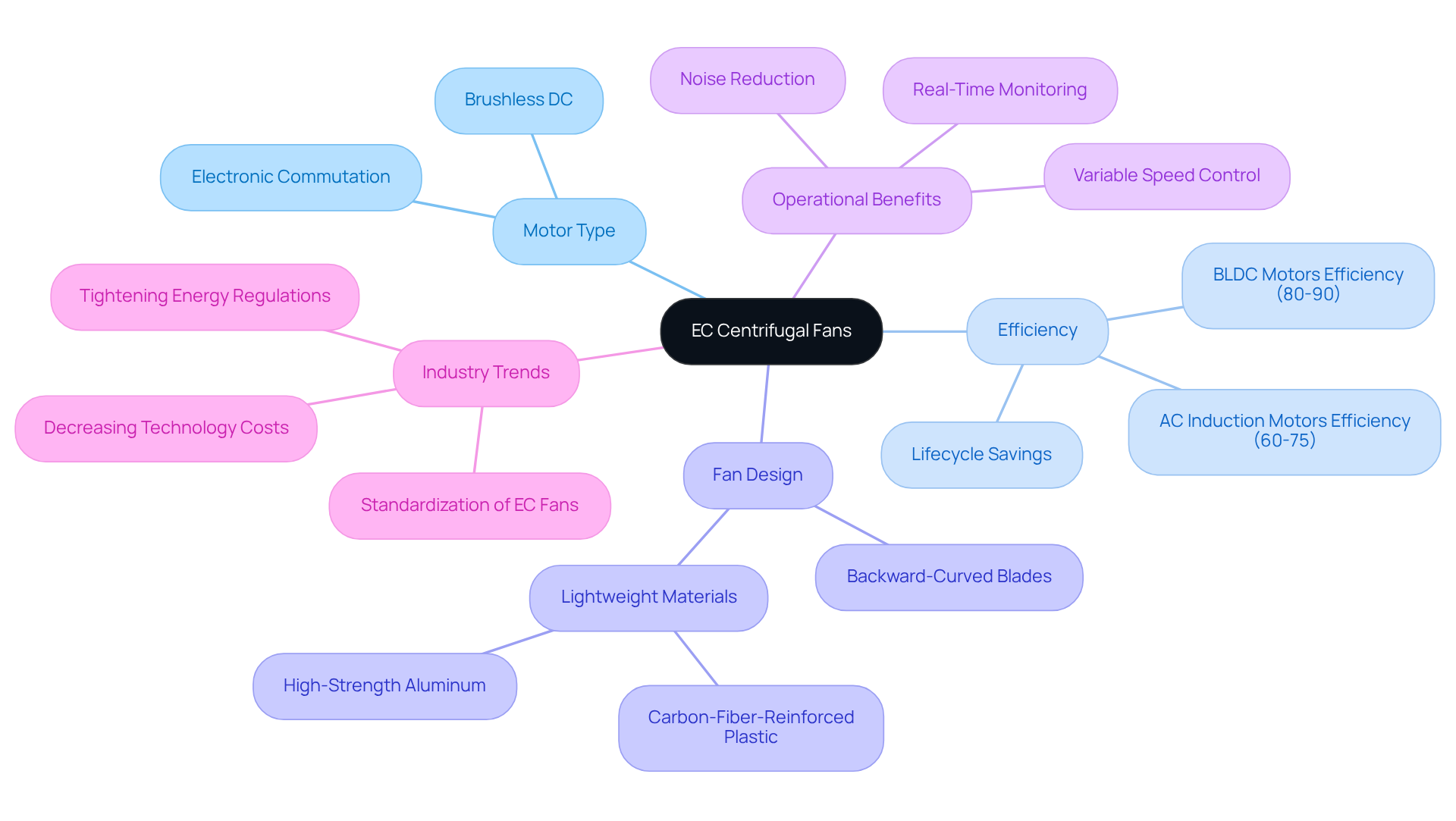

The principle behind EC centrifugal fans is to convert electrical power into mechanical power using a brushless DC motor. This motor’s electronic commutation enables variable speed control, allowing the fan’s performance to adapt to system demands. BLDC motors achieve an impressive efficiency of 80-90%, compared to 60-75% for AC induction motors, making them a superior choice for resource conservation.

The fan impeller, designed with backward-curved blades, draws air in through the center and expels it at a 90-degree angle, resulting in high-pressure airflow. This design enhances efficiency while simultaneously reducing noise levels, rendering EC centrifugal units suitable for sensitive environments such as data centers and laboratories.

Additionally, the integration of onboard electronics facilitates real-time monitoring and adjustments, optimizing performance and enhancing operational flexibility. Although the initial investment may be higher, BLDC EC units offer significant lifecycle savings in energy and maintenance, underscoring their value in industrial applications.

Industry trends indicate that as energy regulations tighten and technology costs decrease, the use of EC centrifugal fans powered by BLDC technology is poised to become standard in air movement technology. Furthermore, the incorporation of lightweight materials in fan design is critical for improving operational efficiency and performance.

Compare EC Fans with Traditional AC Fans: Advantages and Applications

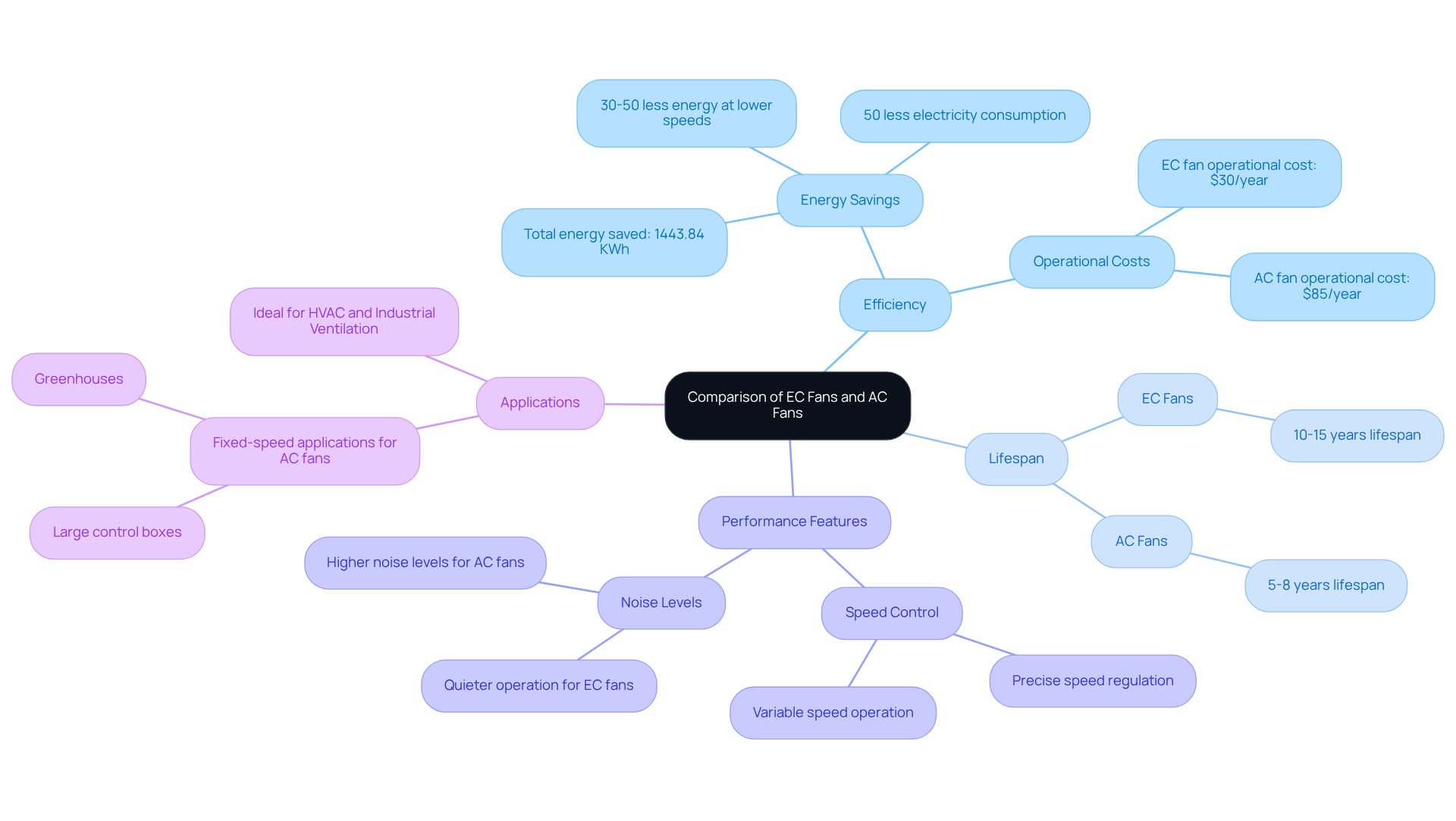

When comparing the efficiency of EC centrifugal fans to conventional AC units, several significant advantages become evident. The EC centrifugal fan can achieve power savings of 30-50%, particularly at lower speeds, making it ideal for applications that require variable airflow. This efficiency is crucial in settings such as HVAC systems and industrial ventilation, where the implementation of an EC centrifugal fan can lead to resource savings that directly impact operational expenses. Notably, EC centrifugal fans consume approximately 50% less electricity than AC motors, underscoring the energy savings. Furthermore, EC devices typically have longer lifespans, lasting between 10 to 15 years, compared to the 5 to 8 years of AC units. This longevity is attributed to reduced wear and tear on motor components, as EC units generate less heat during operation.

Moreover, an EC centrifugal fan offers precise speed regulation, allowing for enhanced adaptability to varying system requirements. This feature optimizes performance, especially in applications where airflow demands can shift rapidly. In contrast, AC units generally operate at constant speeds, which can lead to inefficiencies and increased power usage, particularly in dynamic environments.

While conventional AC units remain popular for basic, fixed-speed applications, such as in large control boxes and greenhouses, the growing emphasis on efficiency and performance enhancement positions the EC centrifugal fan as a superior choice for modern industrial applications. Their ability to integrate with intelligent control systems, designed to work effectively with EC devices, further enhances their appeal, providing a pathway to substantial power savings and reduced operational costs. For instance, a case study demonstrated that EC units saved $42,000 in energy costs and reduced repair expenses by 70% over eight years, highlighting their financial advantages. Overall, EC models consume less power, last longer, and require less maintenance than AC models, rendering them a more cost-effective solution.

Explore Common Applications of EC Centrifugal Fans in Industry

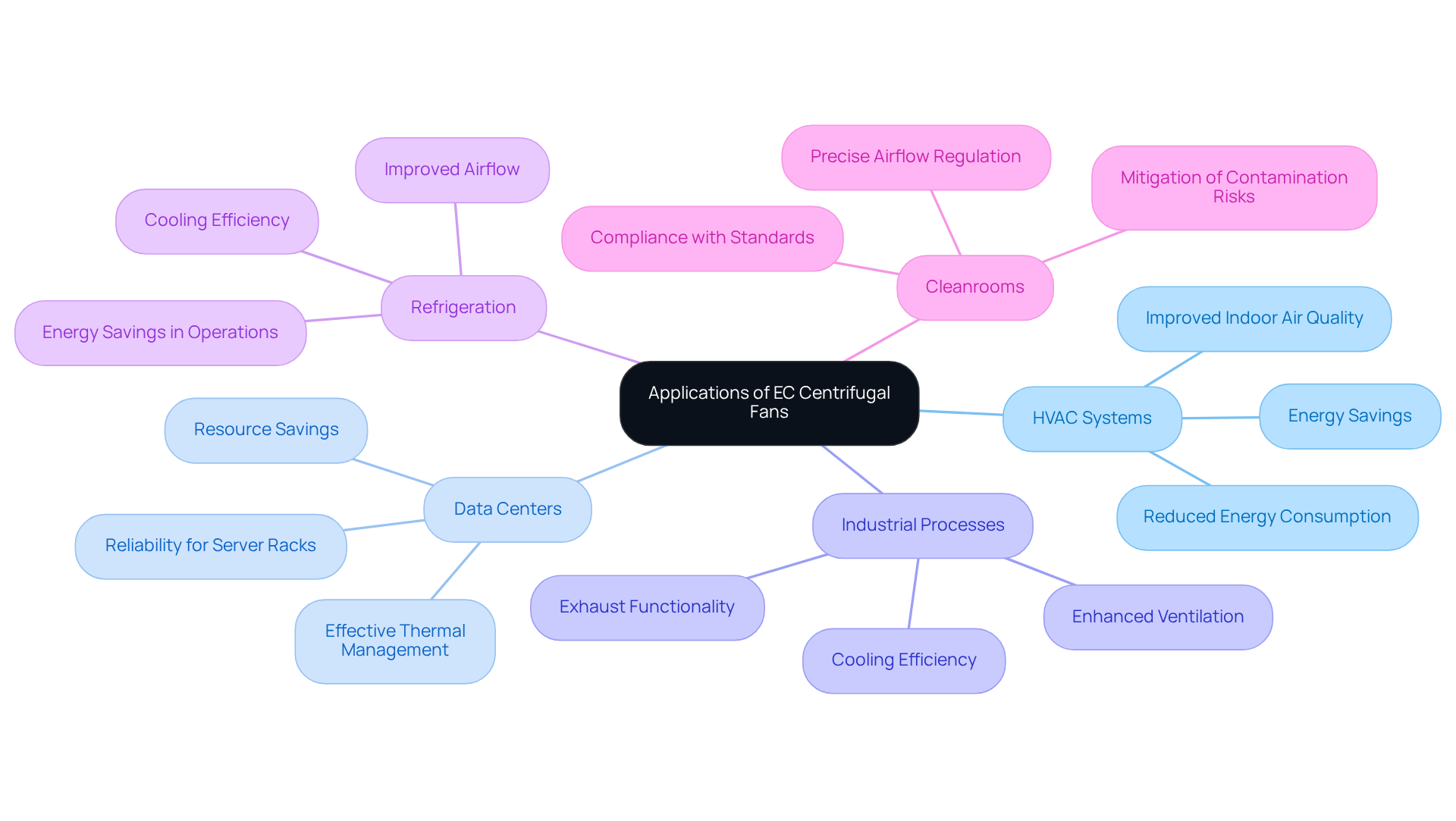

EC centrifugal fans are indispensable across various sectors, renowned for their efficiency and versatility. Their key applications include:

- HVAC Systems: Within heating, ventilation, and air conditioning, EC fans optimize indoor air quality while significantly reducing energy consumption, which accounts for 40-50% of total energy use in these systems.

- Data Centers: These cooling devices are critical for maintaining server racks, ensuring effective thermal management and reliability. Their implementation can yield substantial resource savings, with projections indicating that the global market for EC centrifugal fans is expected to expand at a CAGR of 6.9% from 2025 to 2033, reaching a market value of USD 5.27 billion by 2030, driven by the growing demand for efficient cooling solutions.

- Industrial Processes: In manufacturing and processing facilities, EC blowers enhance ventilation, cooling, and exhaust functions, thereby contributing to overall performance and productivity.

- Refrigeration: In commercial refrigeration systems, EC motors improve airflow and cooling efficiency, further promoting energy savings in operations.

- Cleanrooms: In environments where air quality control is paramount, EC units provide precise airflow regulation, mitigating contamination risks and ensuring compliance with stringent standards.

These applications highlight the effectiveness and adaptability of EC centrifugal fans in addressing the complex challenges faced by modern engineering. However, it is crucial to acknowledge that challenges such as higher initial costs and integration complexities may deter some users from embracing these advanced solutions. As one expert noted, ‘EC centrifugal fans provide higher energy efficiency, reduced operational noise, intelligent speed control, an extended operational life, and simpler integration with smart building management systems.

Conclusion

EC centrifugal fans signify a crucial advancement in air-moving technology, underscoring their essential role in improving energy efficiency across a range of engineering applications. By utilizing electronically commutated designs, these fans not only achieve substantial reductions in energy consumption but also offer adaptable performance tailored to specific operational requirements. Their significance is paramount, especially as industries strive for sustainable solutions to comply with escalating energy regulations and operational efficiency targets.

Key insights have emerged regarding the operating principles of EC centrifugal fans, their advantages over traditional AC units, and their diverse applications in sectors such as HVAC, data centers, and industrial processes. The incorporation of brushless DC motors facilitates remarkable energy savings, enhanced longevity, and diminished maintenance needs, establishing them as a compelling solution for contemporary engineering challenges. Moreover, despite their higher initial costs, the long-term benefits and lifecycle savings associated with EC fans accentuate their value in today’s energy-conscious landscape.

The transition to EC centrifugal fans is not simply a trend; it represents a necessary evolution in air movement technology. Industries are urged to recognize the long-term economic and environmental benefits of adopting these advanced solutions. By embracing EC centrifugal fans, businesses can significantly enhance their operational efficiency while contributing to wider sustainability initiatives, ultimately fostering a more energy-efficient future.

Frequently Asked Questions

What are EC centrifugal fans?

EC centrifugal fans, or Electronically Commutated centrifugal blowers, are advanced air-moving technology that use brushless DC motors and electronic control mechanisms for precise speed adjustments and enhanced energy efficiency.

How do EC centrifugal fans improve energy efficiency?

They can achieve reductions in energy consumption of up to 50% compared to conventional AC units, which is crucial for reducing operational costs in engineering applications.

In which applications are EC centrifugal fans commonly used?

They are commonly used in HVAC systems, data centers, and various industrial processes where operational costs and system reliability are important.

Who produces EC centrifugal fans and what is their range?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering EC centrifugal fans in sizes ranging from 15 to 225mm.

What are the benefits of integrating EC centrifugal fans into systems?

Integrating these fans leads to lower energy costs, improved performance, efficiency, and reduced noise, while also aligning with global sustainability initiatives.

What are the potential drawbacks of EC centrifugal fans?

The initial investment for EC units may be higher than traditional AC units, which could discourage some industries from adopting this technology. Additionally, retrofitting existing HVAC systems can present technical challenges.

What is the potential economic impact of using efficient motors like those in EC devices?

According to the U.S. Department of Energy, efficient motors similar to those in EC devices could save the industrial sector billions of dollars annually.