Overview

The article titled “Master Electric Mini Fans: A Step-by-Step Guide for Engineers” serves as an essential resource for engineers, offering them comprehensive knowledge and practical steps necessary for the effective selection, evaluation, and integration of electric mini fans into their projects. It meticulously details the key specifications to consider and outlines a systematic evaluation process. Furthermore, it emphasizes best practices for installation, thereby empowering engineers to significantly enhance cooling solutions across various applications.

Introduction

Electric mini fans have emerged as indispensable tools within the engineering landscape, providing compact yet powerful solutions for effective airflow management across a variety of applications. This guide explores the intricate workings of these devices, detailing their specifications, benefits, and integration strategies that can significantly enhance project outcomes.

As engineers navigate the extensive array of options available, a critical question arises: how can they ensure the selection of the right fan that balances performance, efficiency, and user comfort?

Understand the Basics of Electric Mini Fans

Electric mini fans represent a sophisticated solution for generating airflow through a compact design powered by a small electric motor. These devices typically comprise a motor, blades, and a housing that effectively directs airflow. The motor drives the blades, enabling them to rotate and create a steady current of air. Electric mini fans can be powered by batteries or USB connections, providing versatility for various applications, including personal cooling and the cooling of electronic components.

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive range of DC input tube axial devices and centrifugal blowers that are optimized for performance, efficiency, and low noise. Their diverse portfolio features sizes ranging from 15mm to 910mm, catering to a wide array of applications across industries such as electronics, automotive, and telecommunications. Most models are designed with IP protection, ensuring their durability in various environments.

Understanding the fundamental operation of these devices is crucial for engineers who aim to integrate them effectively into their designs. This comprehension is particularly important when evaluating Gagner-Toomey’s innovative temperature management solutions, which incorporate integrated systems combining airflow devices, heat pipes, and radiators. By recognizing the capabilities and applications of electric mini fans, professionals can make informed decisions that enhance their engineering projects.

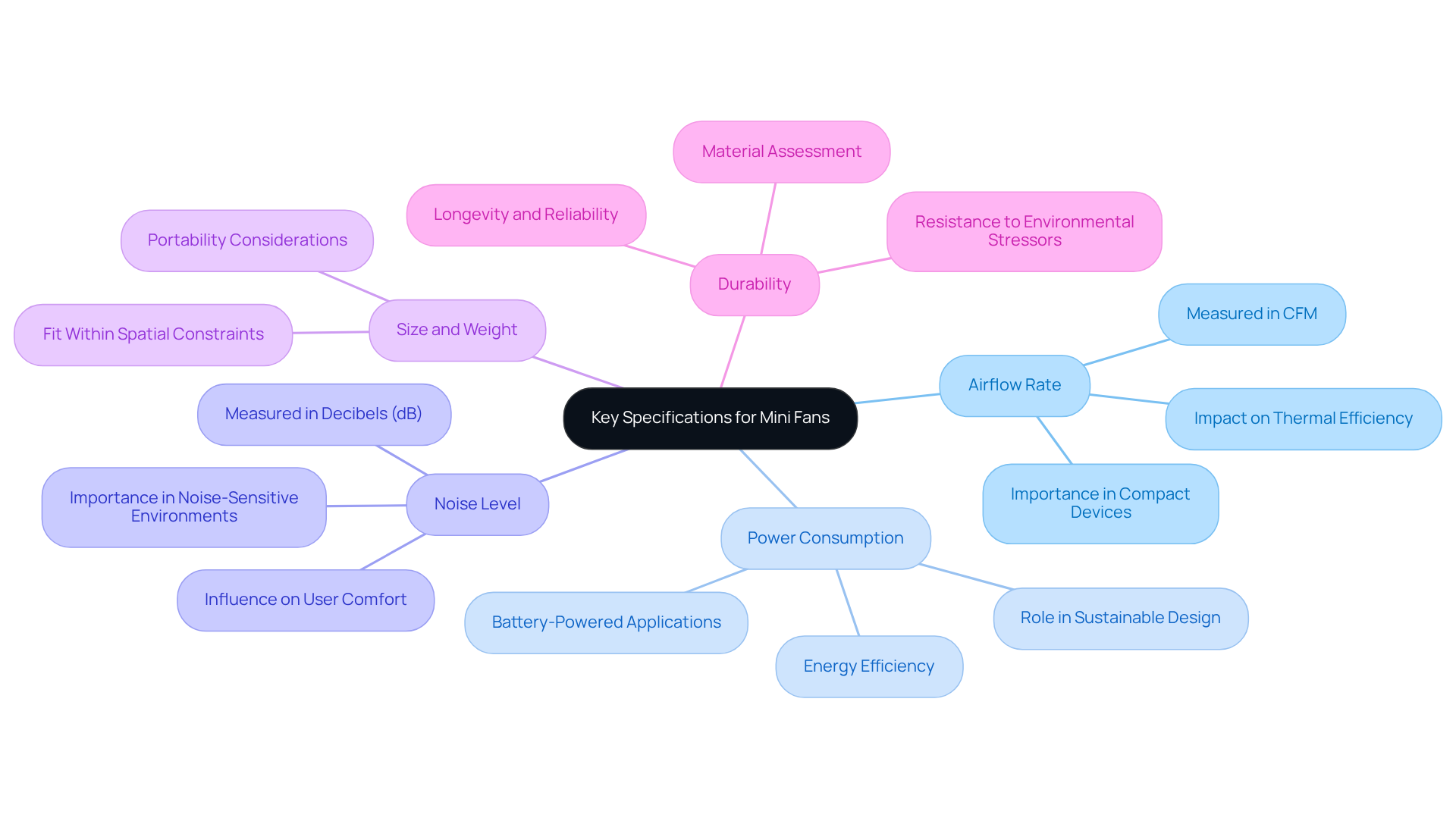

Identify Key Specifications for Your Project

When selecting a mini fan for your project, it is essential to prioritize several key specifications:

-

Airflow Rate: Measured in cubic feet per minute (CFM), this specification indicates the volume of air the fan can move. Selecting a fan with an appropriate ventilation rate is crucial for efficiently satisfying your temperature regulation needs. For instance, fans with higher CFM ratings significantly enhance thermal efficiency in compact electronic devices. Industry leaders emphasize that air circulation rates have a direct impact on the effectiveness of cooling solutions in electronic applications.

-

Power Consumption: Opt for devices that deliver efficient airflow while minimizing energy consumption. This consideration is particularly vital in battery-powered applications, where energy efficiency can extend operational life. Although specific statistics on power consumption were not provided, it is widely acknowledged that energy-efficient devices like the electric mini fan play a crucial role in sustainable design.

-

Noise Level: The noise level, measured in decibels (dB), can greatly influence user comfort, particularly in noise-sensitive environments. Choosing a fan that operates quietly ensures an enhanced user experience without compromising performance.

-

Size and Weight: It is important to verify that the fan fits within the spatial constraints of your project. A lightweight design is beneficial for portability, especially in scenarios where space is limited.

-

Durability: Assess the materials used in the fan’s construction, especially if it will be subjected to harsh conditions. Durable fans are capable of withstanding environmental stressors, thereby ensuring longevity and reliability across various applications.

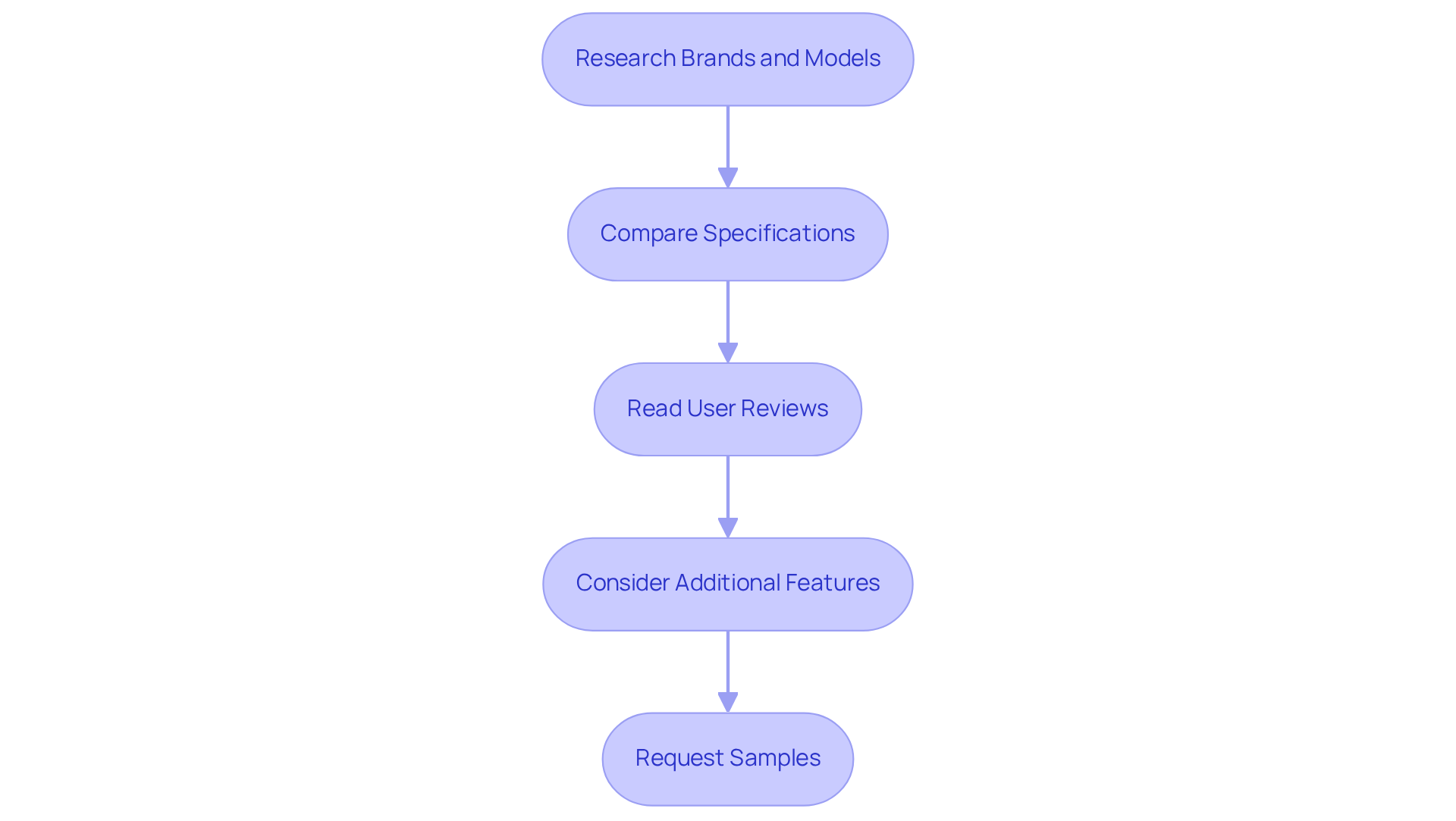

Evaluate Available Mini Fan Options

To evaluate available mini fan options, follow these steps:

- Research Brands and Models: Begin by investigating reputable brands known for producing high-quality mini appliances. Focus on models, particularly the electric mini fan, that have garnered positive reviews and demonstrated proven performance.

- Compare Specifications: Develop a comparison chart detailing various models, emphasizing key specifications such as airflow rate, power consumption, noise level, and size.

- Read User Reviews: Examine user reviews and ratings on platforms like Amazon or specialized electronics forums to gain valuable insights into real-world performance and reliability.

- Consider additional features of an electric mini fan: some devices offer extra attributes, including adjustable speed settings, built-in lights, or rechargeable batteries. Identify which features are essential for your specific project.

- Request Samples: If feasible, request samples from manufacturers to test the fans in your intended application prior to making a bulk purchase.

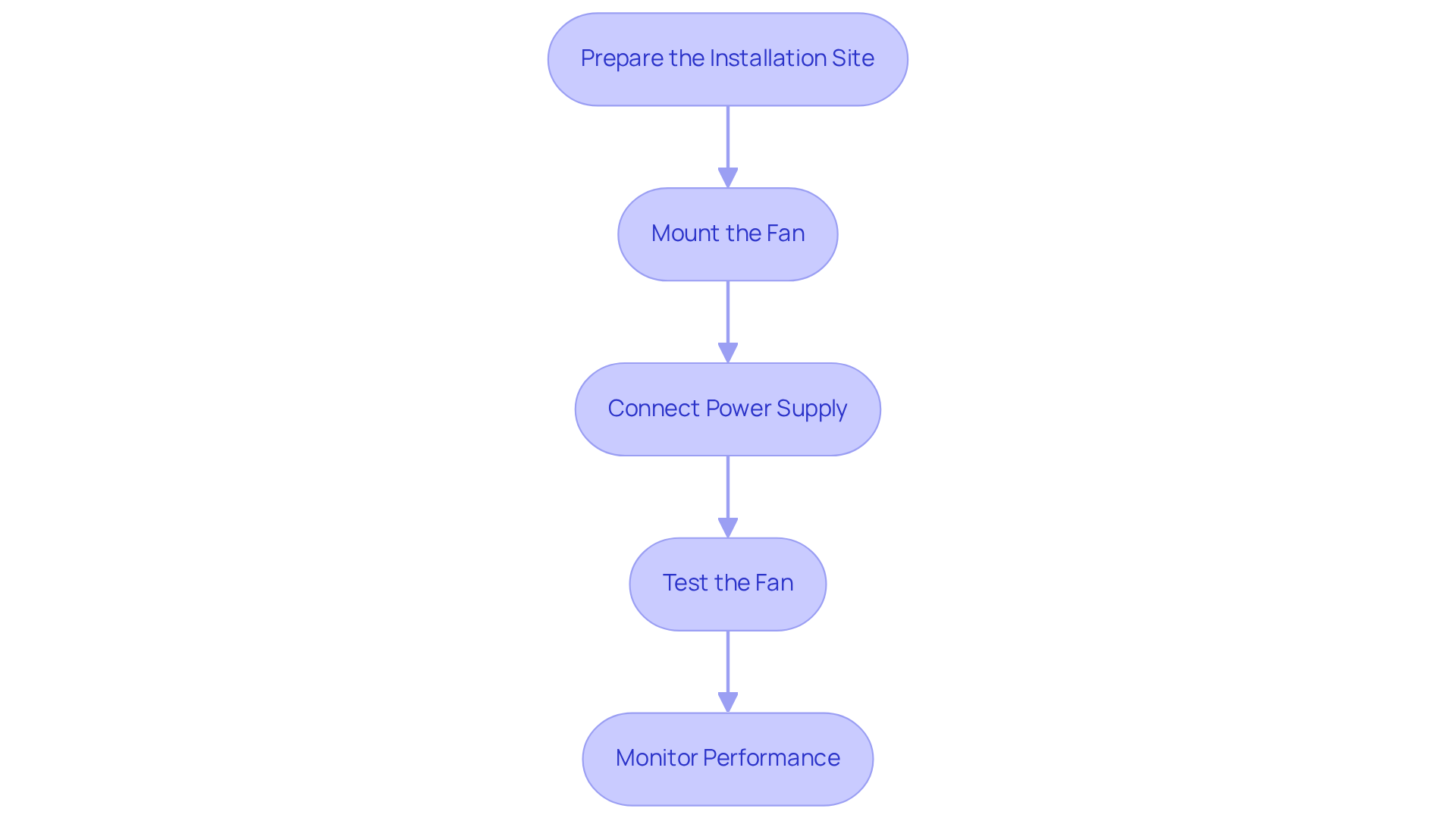

Install and Integrate Your Mini Fan Effectively

To effectively install and integrate your mini fan, follow these essential steps:

- Prepare the Installation Site: Ensure the area is clean and free of obstructions. Consider the direction of air movement and proximity to heat sources to maximize cooling efficiency.

- Mount the Fan: Utilize appropriate mounting methods such as screws, brackets, or adhesive to secure the fan. Ensure stability and optimal positioning for air circulation.

- Connect Power Supply: For battery-powered fans, confirm a full charge. For USB-powered models, connect to a suitable power source, ensuring that voltage and current ratings align with the fan’s specifications.

- Test the Fan: After installation, power on the fan and listen for unusual noises or vibrations that may indicate improper installation. This step is crucial for ensuring functionality.

- Monitor Performance: Continuously monitor the fan’s performance to ensure efficient operation. Make necessary modifications to enhance ventilation and temperature regulation.

Common issues during mini fan integration include improper mounting leading to vibrations and inadequate airflow due to obstructions. Statistics indicate that nearly 30% of installation problems stem from misalignment or incorrect power connections, underscoring the importance of meticulous installation practices.

In engineering projects, successful mini fan integration has been demonstrated in various applications, such as automotive ventilation systems and electronic temperature regulation solutions. Engineers emphasize the importance of thorough testing and monitoring, with one stating, “The difference between the impossible and the possible lies in a person’s determination.” By adhering to these best practices, you can significantly enhance the effectiveness of your cooling solutions.

Conclusion

In conclusion, electric mini fans are invaluable assets in engineering, delivering efficient airflow solutions across diverse applications. This guide has thoroughly examined the critical elements involved in selecting, evaluating, and integrating these compact devices into engineering projects. By grasping their fundamental operation and specifications, engineers are empowered to make informed decisions that significantly enhance performance and reliability in their designs.

The discussion highlighted key considerations such as:

- Airflow rate

- Power consumption

- Noise levels

- Size

- Durability

These are essential when choosing the appropriate mini fan for specific requirements. Evaluating available options through brand research, user reviews, and direct testing ensures that the selected fan aligns seamlessly with project needs. Moreover, effective installation practices are vital for optimizing the performance of electric mini fans; even minor misalignments can result in substantial operational challenges.

Integrating electric mini fans into engineering projects not only bolsters thermal management but also promotes energy efficiency and user comfort. By embracing these devices, engineers can unlock innovative solutions in sectors like electronics and automotive design. It is imperative for engineers to apply the insights from this guide to fully harness the potential of electric mini fans, ultimately driving advancements in their respective fields.

Frequently Asked Questions

What are electric mini fans and how do they work?

Electric mini fans are compact devices that generate airflow using a small electric motor. They consist of a motor, blades, and a housing that directs airflow. The motor drives the blades to rotate, creating a steady current of air.

What power sources do electric mini fans use?

Electric mini fans can be powered by batteries or USB connections, providing versatility for various applications.

What are some common applications of electric mini fans?

Electric mini fans are commonly used for personal cooling and cooling electronic components.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers. They offer a wide range of DC input tube axial devices and centrifugal blowers optimized for performance, efficiency, and low noise.

What sizes do Gagner-Toomey’s fans come in?

Gagner-Toomey’s fans range in size from 15mm to 910mm, catering to various applications across different industries.

In which industries are electric mini fans used?

Electric mini fans are used in industries such as electronics, automotive, and telecommunications.

What is the importance of understanding electric mini fans for engineers?

Understanding the operation of electric mini fans is crucial for engineers to integrate them effectively into their designs and make informed decisions that enhance their engineering projects.

What features do most models of Gagner-Toomey fans have?

Most models are designed with IP protection, ensuring their durability in various environments.

What innovative solutions does Gagner-Toomey provide?

Gagner-Toomey provides innovative temperature management solutions that incorporate integrated systems combining airflow devices, heat pipes, and radiators.