Overview

This article delves into the operation, benefits, and selection criteria for electrically commutated motors (ECMs), underscoring their efficiency and increasing significance in HVAC systems.

- Attention: In an era where energy efficiency is paramount, ECMs stand out as a solution to rising operational costs.

- Interest: These motors provide substantial energy savings, extended lifespan, and quieter operation, making them an exceptional choice for contemporary applications. Market growth projections indicate a robust demand for ECMs, further supported by case studies that illustrate their effectiveness in minimizing operational expenses.

- Desire: By integrating ECMs into HVAC systems, businesses can not only enhance performance but also contribute to sustainability efforts. The longevity of these motors reduces the frequency of replacements, leading to lower maintenance costs over time.

- Action: For those considering upgrades or new installations, selecting ECMs is a strategic move that aligns with both economic and environmental goals. Embrace the future of HVAC technology by opting for ECMs, ensuring efficiency and reliability in your systems.

Introduction

The evolution of electric machinery marks a pivotal moment with the rise of electronically commutated motors (ECMs), revolutionizing energy efficiency and operational effectiveness. By leveraging electronic controls to replace traditional mechanical brushes, these advanced motors deliver significant advantages, especially in HVAC systems, where energy savings can reach an impressive 90%. As the demand for sustainable solutions intensifies, engineers and decision-makers face the challenge of navigating the complexities of selecting the right ECM for their specific applications.

This article explores the operation, benefits, and strategic selection of electrically commutated motors, offering a comprehensive guide for those eager to optimize performance while embracing eco-friendly technologies. With a clear understanding of ECMs, professionals can make informed decisions that align with their sustainability goals.

Define Electronically Commutated Motors (ECMs)

Electronically Commutated Devices (ECDs), which include electrically commutated motors, represent a significant advancement in electric machinery technology. By utilizing electronic controls to manage the commutation process, electrically commutated motors eliminate the need for mechanical brushes found in traditional brushed machines. This brushless design, which features an electrically commutated motor, not only enhances efficiency but also extends the lifespan of the devices, making them particularly advantageous in various applications, especially within HVAC systems.

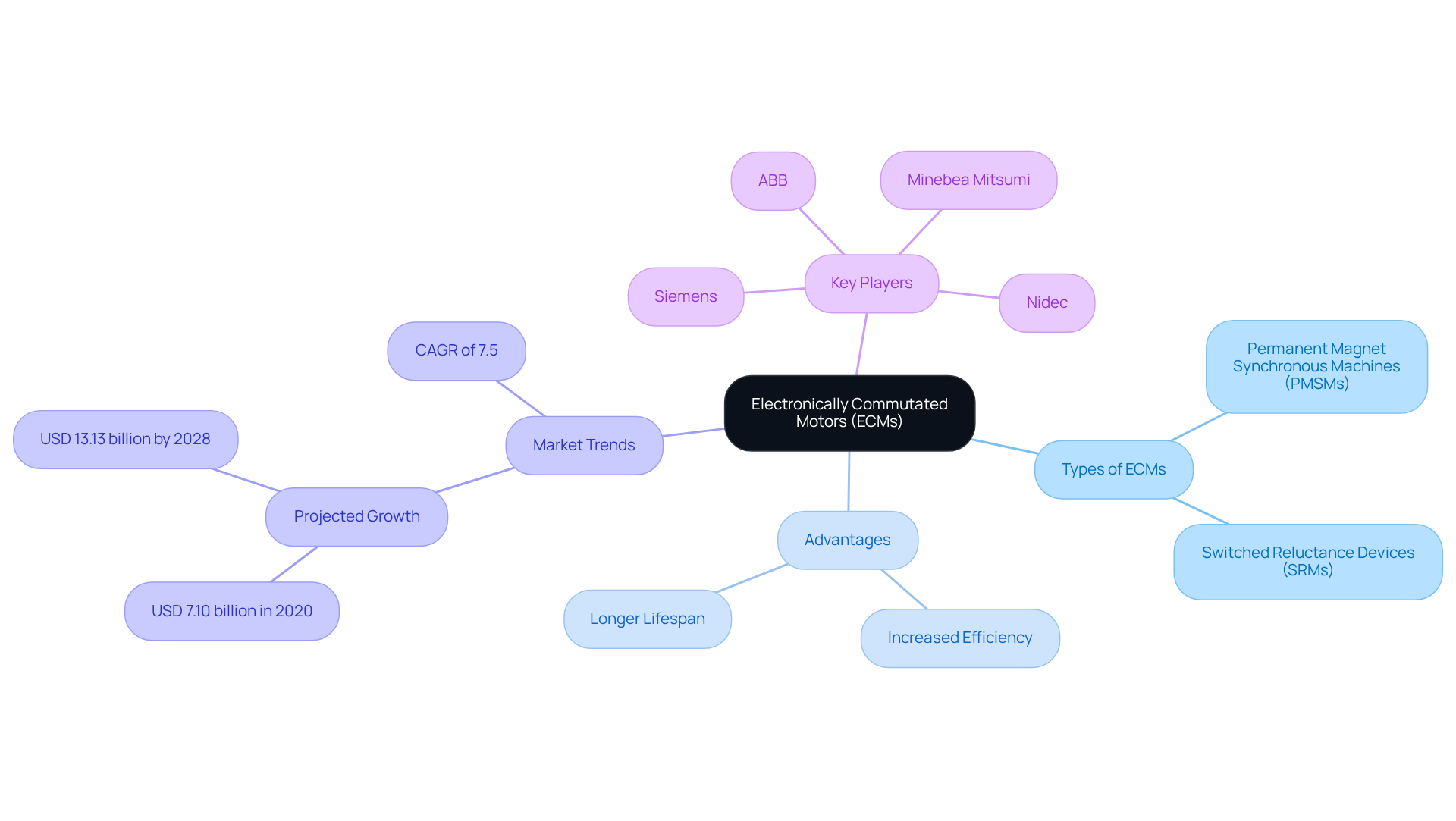

ECDs are primarily categorized into two types:

- Permanent magnet synchronous machines (PMSMs)

- Switched reluctance devices (SRMs)

Each type presents distinct operational advantages, such as improved energy efficiency and precise speed control. The rising demand for energy-efficient solutions has driven a marked increase in the adoption of electrically commutated motors, with the HVAC sector emerging as the largest end-use market.

In fact, the market for electrically commutated motors in HVAC systems is projected to grow from USD 7.10 billion in 2020 to USD 13.13 billion by 2028, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth trajectory is further bolstered by the U.S. Department of Energy’s updated furnace efficiency rating standards, which mandate the incorporation of energy-efficient electrically commutated motors in new furnaces.

Moreover, substantial investments in mergers and acquisitions within the ECD market underscore a robust competitive landscape, with key players such as ABB, Siemens, and Nidec at the forefront of innovation and market expansion for electrically commutated motors. This trend highlights the critical role of electronic control mechanisms in achieving power consumption savings and enhancing performance in modern setups.

Explain How ECMs Operate in HVAC Systems

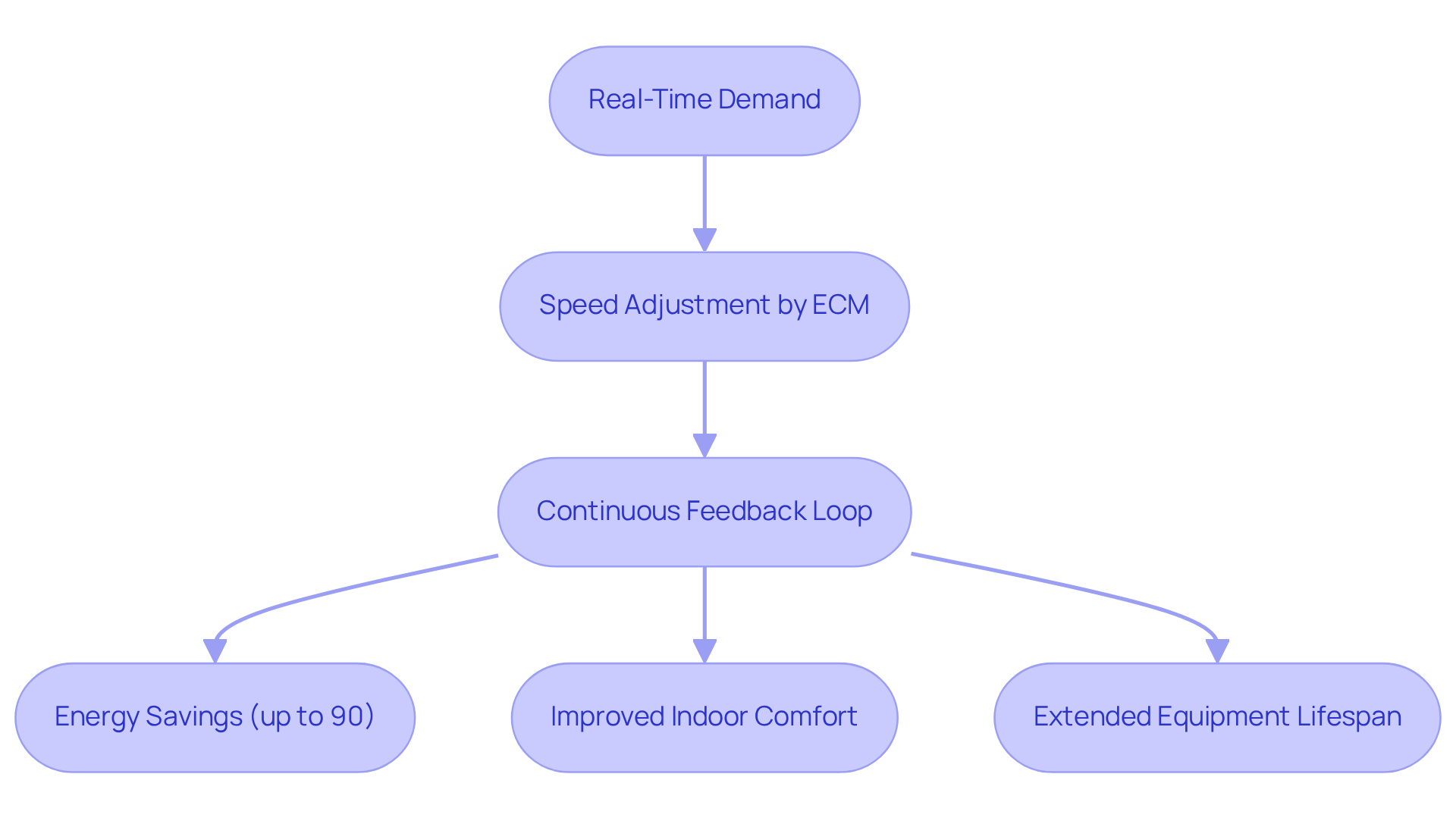

In HVAC setups, electrically commutated motors dynamically adjust their speed based on real-time demand, leveraging integrated sensors and advanced control mechanisms. This innovative capability allows electronic control modules to fine-tune their speed using an electrically commutated motor to meet specific heating or cooling needs, resulting in energy savings of up to 90% compared to traditional fixed-speed devices, which typically operate at an efficiency of around 60-70%.

The operation of an electrically commutated motor relies on a continuous feedback loop, where the motor monitors its performance and adjusts output accordingly. This responsiveness not only enhances indoor comfort by maintaining stable temperatures but also minimizes wear and tear on the electrically commutated motor, which significantly extends the equipment’s lifespan. A well-maintained HVAC unit can generally serve a home for 15 to 20 years.

Moreover, electrically commutated motors operate quietly, making them an ideal choice for environments, both residential and commercial, where noise reduction is crucial. Their ability to provide precise control over airflow not only improves indoor air quality but also boosts overall system performance, solidifying their role as essential components in modern HVAC systems that feature electrically commutated motors.

As highlighted in a case study, “the effective functioning of ECM devices can greatly reduce homeowners’ utility costs, aiding in overall savings.” This underscores the importance of considering electrically commutated motors in HVAC design and upgrades, as they signify a major advancement in energy efficiency and operational effectiveness.

Discuss Advantages of ECM Technology

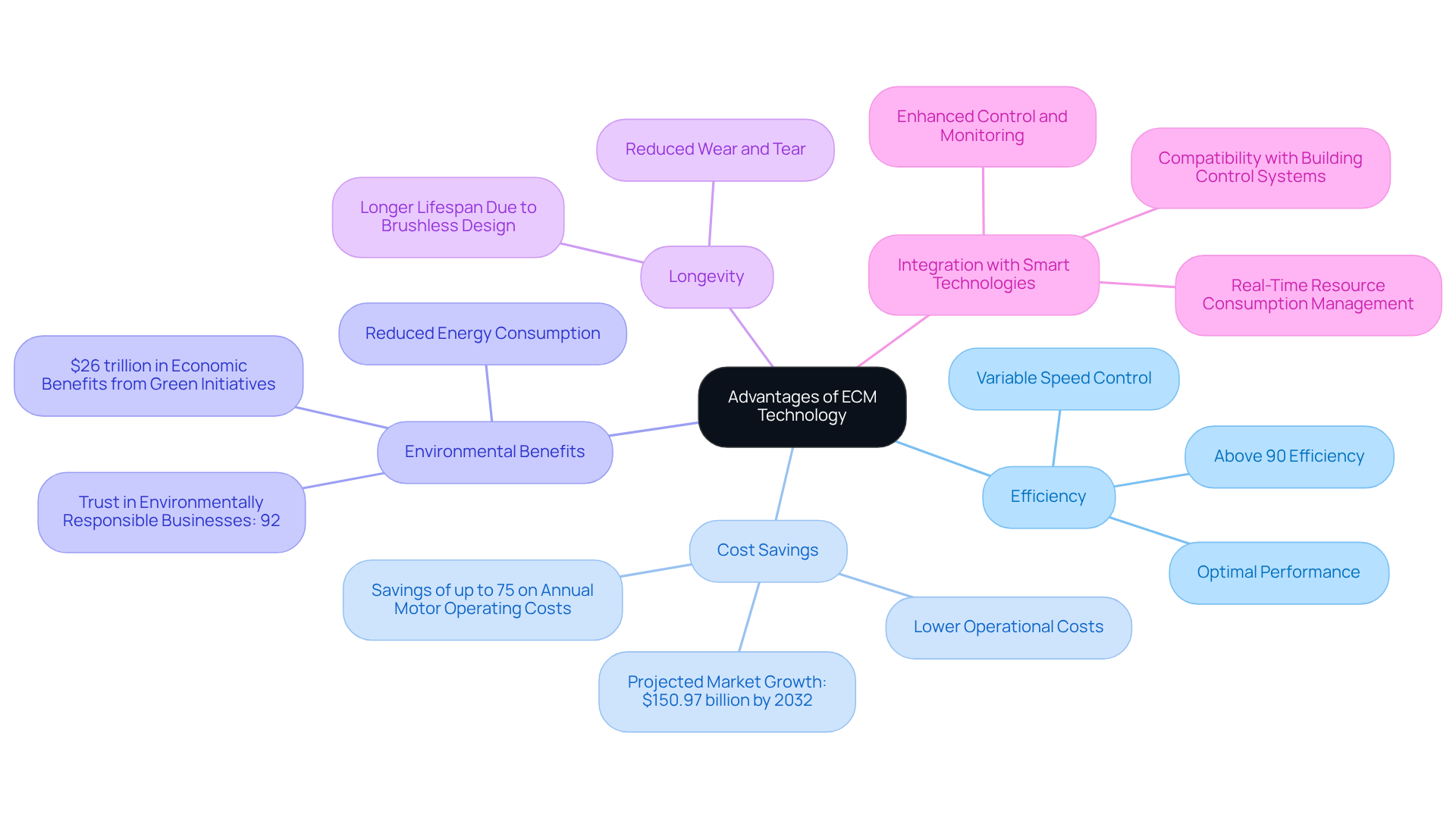

The benefits of electrically commutated motor technology are substantial and extensive. These systems are recognized for their outstanding efficiency, often achieving ratings above 90%. This high efficiency translates directly into lower operational costs for users. Their ability to modulate speed according to demand not only reduces energy consumption but also positions electrically commutated motors as environmentally friendly alternatives to traditional motors. Furthermore, brushless motors boast a longer lifespan due to their design, which eliminates the wear associated with brushes. This durability, combined with quieter operation and reduced vibration, significantly enhances overall user comfort.

Integrating electronic content management systems with smart building technologies amplifies these benefits. This compatibility enables advanced control and monitoring functionalities, enhancing resource consumption in real-time. For instance, in commercial HVAC setups, electrically commutated motors can adjust their speed based on fluctuating cooling requirements, leading to significant power savings. Research indicates that the use of electrically commutated motors (ECMs) can reduce total kilowatt hours consumed by HVAC units, contributing to a more sustainable environment.

As the market for ECM technology continues to expand, projected to reach $150.97 billion by 2032 with a compound annual growth rate (CAGR) of 17%, the focus on energy efficiency and environmental responsibility remains paramount. Companies collectively stand to gain $26 trillion in economic advantages by adopting green initiatives, underscoring the broader impact of sustainability efforts.

Guide on Choosing the Right ECM for Applications

Choosing the appropriate electrically commutated motor for your application is essential for optimizing performance and efficiency. Here are several key considerations to guide your decision:

-

Application Requirements: Start by assessing the specific demands of your framework, including load characteristics and operational conditions. For example, a mid-sized office in Texas saw a remarkable 28% decrease in yearly cooling expenses after upgrading to a 16 SEER2 smart setup. This case underscores the importance of aligning the capabilities of the electrically commutated motor with operational requirements.

-

Efficiency Ratings: Prioritize electrically commutated motors (ECMs) that have high efficiency ratings to maximize energy savings. By 2025, units rated 16 SEER2 or higher are expected to deliver substantial cost savings, often recouping their expenses within five years through reduced utility bills. As Dr. Emily Carson notes, “High-SEER units often cover their costs within three to five years via reduced utility bills.”

-

Control Compatibility: Ensure that the ECM can seamlessly integrate with existing control frameworks or smart technologies. Smart HVAC systems can enhance efficiency by up to 15%, making it essential to integrate these systems with building management systems for optimal performance.

-

Size and Form Factor: Consider the physical dimensions and mounting options to ensure compatibility with your installation space. Electrically commutated motors designed for specific applications can significantly improve airflow and resource utilization, particularly in constrained environments. Notably, a 20% reduction in fan speed can lead to nearly 50% savings in fan power consumption, highlighting the importance of selecting the right size and form factor.

-

Cost vs. Benefit: Evaluate the initial investment against potential long-term savings in power and maintenance. While electrically commutated motors may come with a higher upfront cost, they often lead to a lower total cost of ownership due to reduced maintenance needs and energy consumption.

By carefully weighing these factors, engineers can select the most suitable electrically commutated motor that aligns with both performance objectives and budgetary constraints. This thoughtful approach ultimately enhances system efficiency and sustainability.

Conclusion

The exploration of electrically commutated motors (ECMs) underscores their pivotal role in modern electric machinery, especially within HVAC systems. By utilizing electronic controls for commutation, these brushless motors not only enhance efficiency but also significantly extend the lifespan of devices. As the demand for energy-efficient solutions escalates, grasping the operational mechanics and selection criteria for ECMs becomes essential for optimizing performance across various applications.

Key insights from this discussion reveal the substantial energy savings and operational advantages that ECMs offer. With the capability to modulate speed based on real-time demand, these motors can achieve energy savings of up to 90% compared to traditional systems. Moreover, the integration of ECMs with smart technologies further boosts their efficiency, establishing them as a cornerstone in the pursuit of sustainable and cost-effective HVAC solutions. The projected growth of the ECM market highlights the increasing acknowledgment of their benefits, ranging from reduced operational costs to improved indoor comfort.

In light of these advancements, it is imperative for engineers and decision-makers to prioritize the selection of the appropriate ECM for their specific applications. By evaluating factors such as efficiency ratings, control compatibility, and comprehensive cost-benefit analysis, stakeholders can ensure optimal performance and sustainability in their systems. Embracing the potential of electrically commutated motors not only yields immediate operational benefits but also aligns with broader environmental objectives, making the investment in ECM technology a strategic choice for the future.

Frequently Asked Questions

What are Electronically Commutated Motors (ECMs)?

Electronically Commutated Motors (ECMs), also known as Electrically Commutated Devices (ECDs), are advanced electric machinery that utilize electronic controls to manage the commutation process, eliminating the need for mechanical brushes found in traditional motors.

What are the advantages of ECMs over traditional brushed motors?

ECMs feature a brushless design that enhances efficiency and extends the lifespan of the devices, making them particularly beneficial in various applications, especially in HVAC systems.

What types of Electrically Commutated Devices exist?

ECDs are primarily categorized into two types: Permanent Magnet Synchronous Machines (PMSMs) and Switched Reluctance Devices (SRMs), each offering distinct operational advantages like improved energy efficiency and precise speed control.

Why is there a growing demand for ECMs?

The rising demand for energy-efficient solutions has led to increased adoption of ECMs, particularly in the HVAC sector, which is the largest end-use market for these motors.

What is the projected market growth for ECMs in HVAC systems?

The market for electrically commutated motors in HVAC systems is projected to grow from USD 7.10 billion in 2020 to USD 13.13 billion by 2028, reflecting a compound annual growth rate (CAGR) of 7.5%.

What factors are contributing to the growth of ECMs in the HVAC market?

The growth is supported by the U.S. Department of Energy’s updated furnace efficiency rating standards, which require the integration of energy-efficient ECMs in new furnaces.

Who are the key players in the ECM market?

Key players in the ECM market include ABB, Siemens, and Nidec, which are at the forefront of innovation and market expansion for electrically commutated motors.

How do electronic control mechanisms benefit ECMs?

Electronic control mechanisms in ECMs contribute to power consumption savings and enhance performance in modern setups, highlighting their critical role in energy efficiency.