Overview

This article delves into the mastery of fan blade design, emphasizing the critical factors of airflow efficiency. It highlights the significance of cutting-edge shape, pitch, and material selection. By detailing specific design choices—such as airfoil edges and optimal pitch angles—it demonstrates how these elements can substantially enhance airflow performance and energy savings. Ultimately, these insights lead to the development of more effective and sustainable fan systems.

Introduction

The intricate dance between fan blade design and airflow efficiency represents a critical aspect of modern engineering that is frequently overlooked. With the growing demand for energy-efficient cooling solutions, it is essential to grasp the fundamental principles underlying fan blade design. This article explores the key elements that influence airflow dynamics, including:

- The shape of the cutting edge

- The pitch

- The selection of materials for the blades

However, a pressing question endures: how can engineers effectively balance performance and energy consumption to achieve optimal efficiency in fan systems?

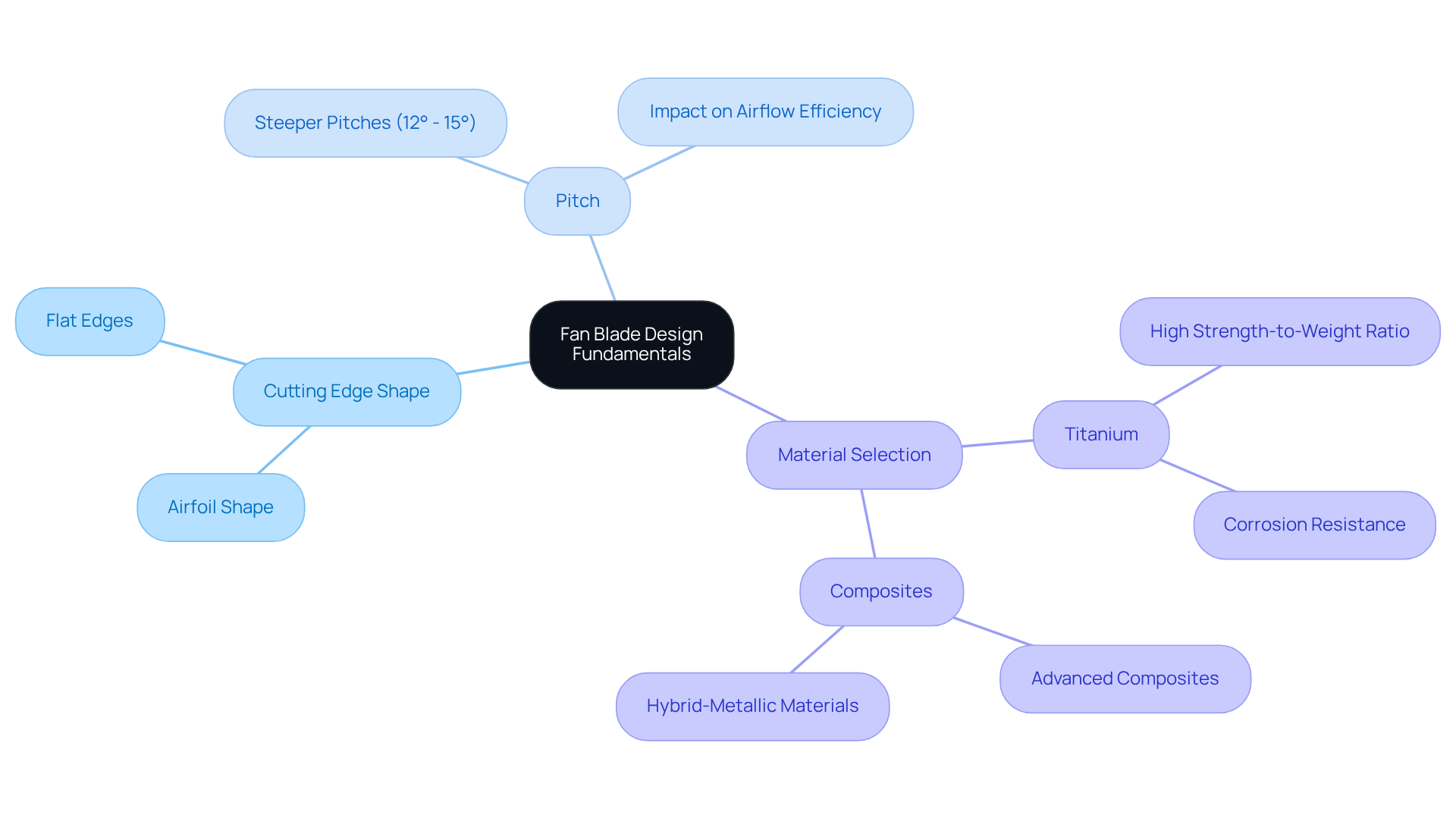

Explore the Fundamentals of Fan Blade Design

The design of fan blades significantly influences airflow, as it is fundamentally rooted in aerodynamics, dictating the interaction between air and the rotating elements. Key factors include:

- Cutting edge shape

- Pitch

- Material selection

The fan blade design airflow is significantly impacted by the form of the cutting edge; for instance, airfoil-shaped edges are recognized for their exceptional performance compared to flat edges, as they effectively minimize drag and turbulence. The fan blade design airflow is crucially affected by the pitch of the rotor, or the angle at which the rotors are positioned, with steeper pitches, typically between 12° and 15°, being particularly effective for enhancing air movement.

Material choice also influences performance, with lightweight yet durable options like titanium, known for its high strength-to-weight ratio and corrosion resistance, and advanced composites being favored. Current trends in fan propeller design focus on enhancing these components to achieve greater performance and reduced noise levels. For example, the integration of hybrid-metallic materials combines the benefits of traditional metals and composites, improving structural integrity while reducing weight.

Understanding these fundamentals enables engineers to design components that enhance air movement and optimize fan blade design airflow while also reducing energy consumption, leading to more sustainable and . Moreover, optimizing fan design can yield up to 20% energy savings, underscoring the importance of these considerations in modern engineering.

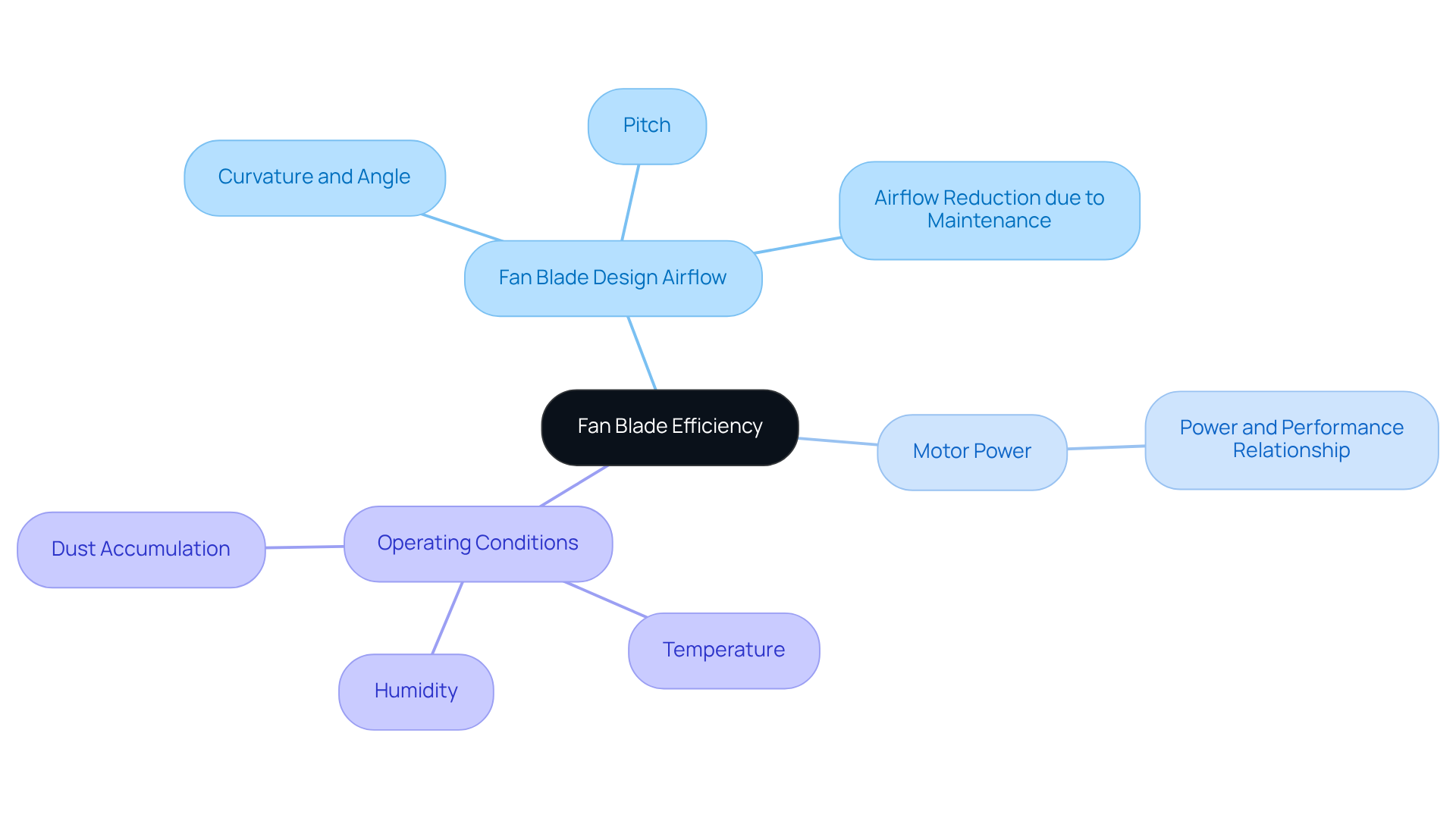

Analyze Factors Influencing Fan Blade Efficiency

The efficiency of fan propellers is influenced by several critical factors, including:

- Fan blade design airflow

- Motor power

- Operating conditions

The curvature and angle of the cutting edges are pivotal in determining . For instance, propellers with a higher pitch typically move more air, quantified in cubic feet per minute (CFM); however, achieving optimal performance often necessitates a more powerful motor. Research indicates that a shallow angle of the propeller may lead to weak circulation, while a steep angle can result in increased power consumption.

Environmental factors, such as temperature and humidity, significantly impact air density, which in turn affects the efficiency of air movement. For example, plastic edges may begin to deform at temperatures exceeding 176°F (80°C), thereby diminishing their effectiveness. Routine maintenance is essential, as dust accumulation on the edges can reduce airflow by as much as 30%, consequently elevating energy consumption.

Real-world applications underscore the importance of curvature and edge angle. Airfoil components, which emulate the shape of aircraft wings, are recognized as the gold standard for commercial and industrial applications due to their energy-saving attributes and ability to minimize drag while enhancing air movement. By comprehensively understanding these factors, engineers can devise improved design and operational strategies that substantially enhance fan efficiency and performance.

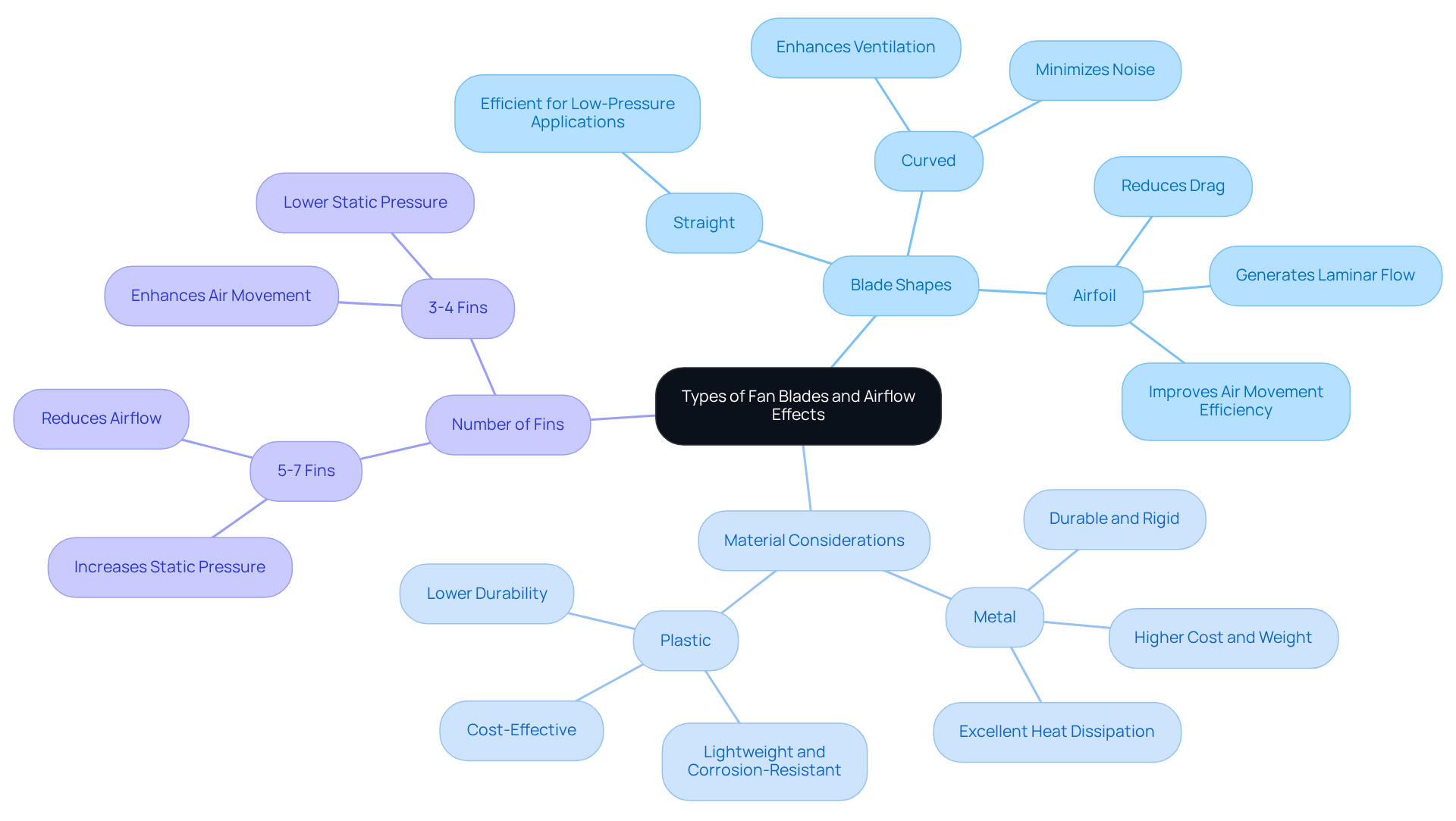

Examine Types of Fan Blades and Their Airflow Effects

The classification of fan components into straight, curved, and airfoil types is essential for understanding fan blade design airflow, as each type serves unique functions in air movement management.

- Straight edges are efficient for low-pressure applications.

- Curved edges enhance ventilation and minimize noise.

- Airfoil components, commonly found in high-performance ventilators, are specifically designed to enhance fan blade design airflow by reducing drag and improving air movement efficiency.

Each type possesses unique airflow characteristics related to fan blade design airflow; for instance, airfoil structures can generate a more laminar flow, reducing turbulence and enhancing overall performance.

When considering (CFE), efficient fans can achieve a CFE of 1.72 at high speeds, whereas less efficient fans may only reach a CFE of 0.63. This statistic underscores the importance of selecting the appropriate type of cutting tool for optimal performance.

Furthermore, material considerations are critical in fan component design.

- Metal edges offer durability and excellent heat dissipation but come with higher costs and weight, potentially impacting energy consumption and circulation.

- Conversely, plastic components are lightweight and corrosion-resistant, yet may lack the durability of their metal counterparts.

The number of fins also influences cooling performance; configurations with three or four fins can lower static pressure, enhancing air movement, while five to seven fins increase static pressure at the cost of airflow. Additionally, backward curved fans are noted for their efficiency and reduced noise levels, making them suitable for various applications. Selecting the right cutting tool is essential for achieving desired air movement rates and energy efficiency in specific applications.

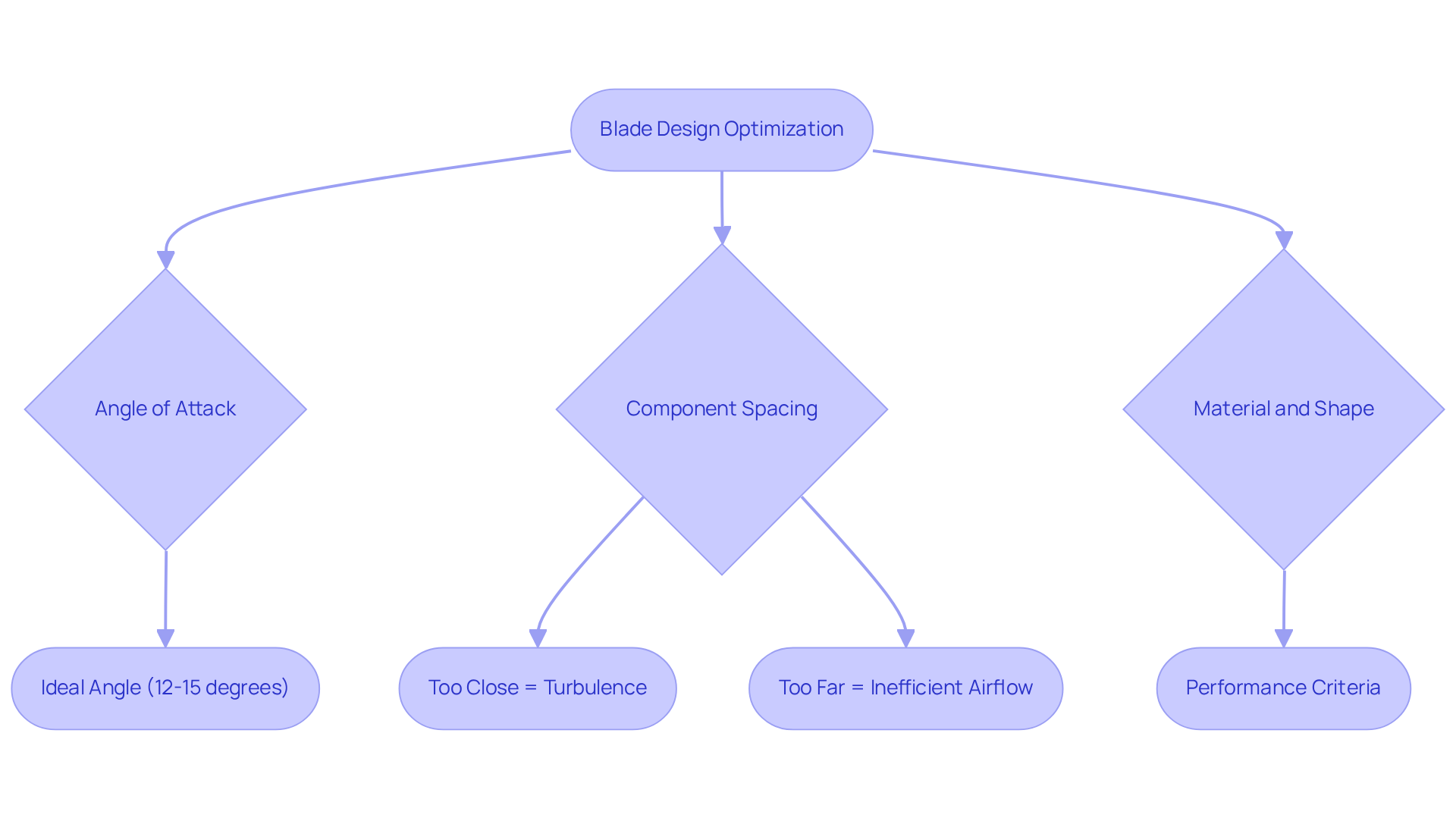

Understand the Relationship Between Blade Design and Airflow Mechanics

The interaction between cutting-edge design and air movement mechanics is fundamentally rooted in the principles of fluid dynamics. As edges rotate, they create a pressure differential that drives air movement. The angle of attack—the angle between the rotor and the oncoming air—is crucial in assessing the effectiveness of air movement. Optimizing this angle is essential for enhancing ventilation while minimizing energy loss. Engineers frequently discover that a component set at an ideal angle of 12 to 15 degrees can significantly enhance performance, as it permits smoother air movement and decreased turbulence.

Real-world applications underscore the importance of this optimization. For instance, in ceiling fan design, a pitch angle between 12 to 15 degrees is typically deemed ideal for maximizing air movement and energy efficiency. Conversely, excessive angles can lead to flow separation, resulting in turbulence and diminished performance. Furthermore, the distance between the elements is vital; components placed too closely can generate turbulence, while those set too far apart may not efficiently capture airflow.

Understanding these is vital for engineers striving to achieve optimal fan blade design airflow that operates efficiently across various conditions. By thoughtfully evaluating the angle of attack and the spacing of the components, engineers can develop fan blade design airflow systems that not only satisfy performance criteria but also promote energy conservation and improved operational effectiveness. As noted by industry experts:

- “The efficiency of a fan blade is directly impacted by a couple of forces, which include the shape of the blade, the material in use, and the angle of the fan blade.”

Incorporating these insights into practices for fan blade design airflow can lead to more effective and efficient fan systems.

Conclusion

The intricate relationship between fan blade design and airflow efficiency is pivotal in achieving optimal performance in modern engineering. Understanding the fundamentals—such as cutting edge shape, pitch, and material selection—enables engineers to create fan systems that not only enhance air movement but also promote energy conservation. This balance is essential in a landscape increasingly focused on sustainability and efficiency.

Key insights emphasize the importance of factors like the curvature and angle of the blades, as well as the materials used. Airfoil designs, for instance, are notable for their ability to minimize drag and turbulence, while the pitch angle significantly affects airflow dynamics. Furthermore, the choice among different blade types—straight, curved, or airfoil—further influences performance, underscoring the need for careful consideration in design choices.

Ultimately, mastering fan blade design transcends mere airflow improvement; it involves creating systems that align with the growing demand for energy efficiency and sustainability. As the industry progresses, embracing these principles will be crucial for engineers striving to innovate and optimize cooling solutions that address contemporary challenges. By applying this knowledge, the potential for enhanced performance and reduced energy consumption in fan systems becomes a tangible reality.

Frequently Asked Questions

What factors influence fan blade design and airflow?

Key factors influencing fan blade design and airflow include cutting edge shape, pitch, and material selection.

How does the shape of the cutting edge affect fan blade performance?

The shape of the cutting edge significantly affects performance; airfoil-shaped edges are known for their superior performance as they minimize drag and turbulence compared to flat edges.

What role does pitch play in fan blade design?

The pitch, or angle at which the rotors are positioned, is crucial for airflow. Steeper pitches, typically between 12° and 15°, are particularly effective for enhancing air movement.

What materials are commonly used in fan blade design?

Lightweight yet durable materials such as titanium and advanced composites are commonly used due to their high strength-to-weight ratio and corrosion resistance.

What are current trends in fan propeller design?

Current trends focus on enhancing performance and reducing noise levels, including the integration of hybrid-metallic materials that combine the benefits of traditional metals and composites.

How does optimizing fan design contribute to energy savings?

Optimizing fan design can lead to up to 20% energy savings, making it an important consideration for sustainable and efficient cooling solutions in modern engineering.