Overview

This article delves into the fundamental concepts and practical applications of fan innovation, underscoring the critical nature of understanding airflow dynamics, types of blowers, and fan laws to optimize performance across various applications. It highlights significant technological advancements, including smart fans and noise reduction technologies, which not only enhance efficiency but also promote sustainability. These innovations empower engineers to seamlessly integrate fan technology into electronic systems, ensuring compliance with industry standards while effectively addressing prevalent challenges.

Introduction

Mastering fan innovation transcends merely understanding how these devices move air; it encompasses leveraging their potential to enhance efficiency and performance across diverse applications. As industries increasingly prioritize energy conservation and optimal thermal management, the demand for advanced fan technologies is surging. Engineers face significant challenges in integrating these innovations, and it is crucial for them to ensure compliance while maximizing functionality. This article delves into the key concepts of fan technology, exploring practical applications and the latest advancements that promise to redefine cooling systems in electronic environments.

Explore the Fundamentals of Fan Innovation

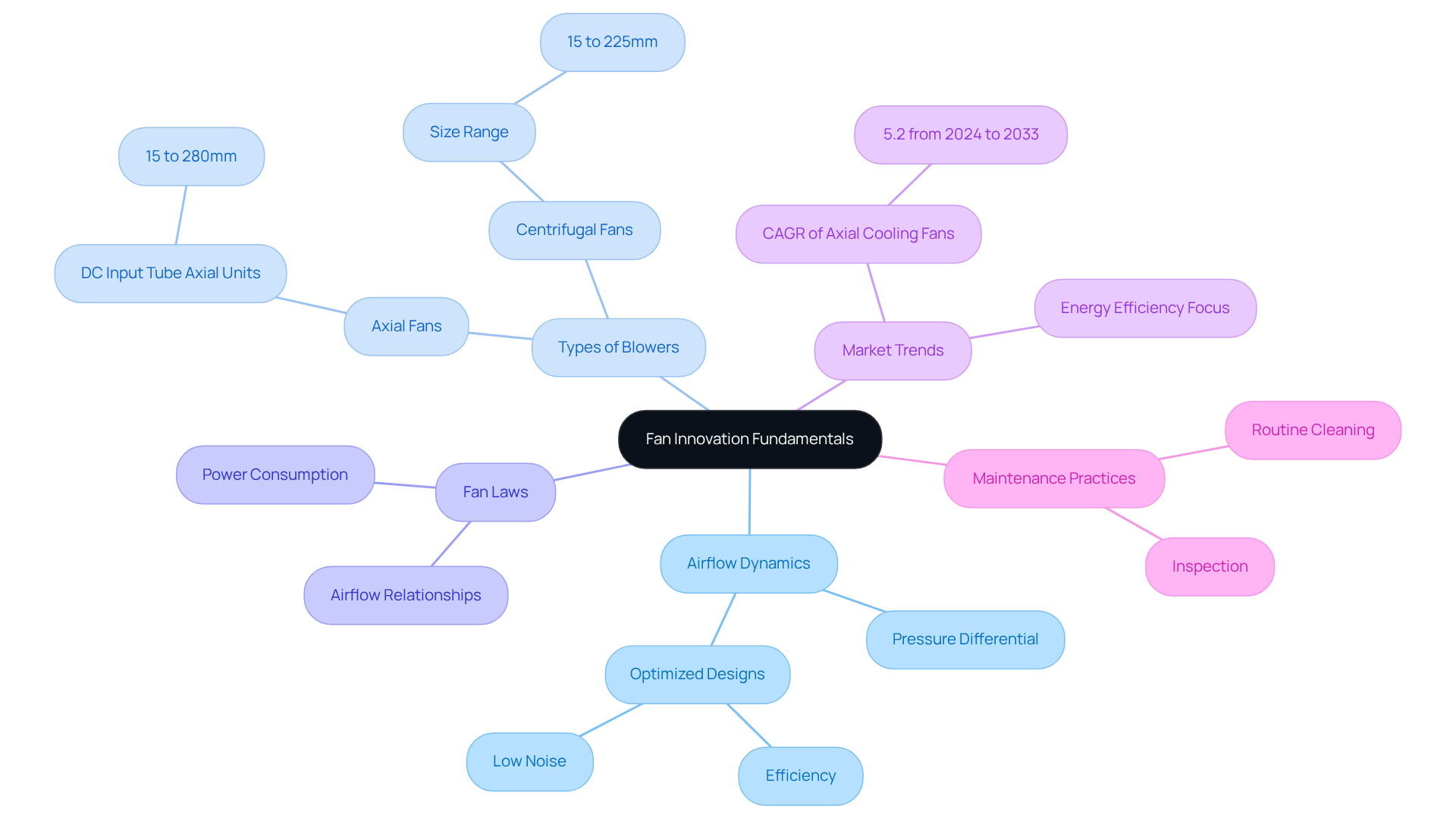

Innovation among enthusiasts is grounded in a comprehensive understanding of their operation. At their core, supporters function as devices designed to move air, generating airflow that is crucial for cooling and ventilation across various applications. Key concepts include:

- Airflow Dynamics: Fans create a pressure differential that facilitates air movement from high-pressure zones to low-pressure zones. This principle is fundamental for optimizing fan performance in diverse environments, particularly in Gagner-Toomey’s optimized designs for efficiency and low noise.

- Types of Blowers: It is essential to distinguish between different types of blowers, notably axial and centrifugal varieties. Gagner-Toomey’s extensive product range features DC input tube axial units, varying from 15 to 280mm, and centrifugal blowers, from 15 to 225mm, making them ideal for applications in data centers, HVAC setups, and automotive environments.

- Fan Laws: The three fundamental fan laws describe the interrelationship between airflow, pressure, and power consumption. These laws are critical for predicting how variations in one parameter can influence the others, enabling engineers to design more efficient cooling systems, especially when considering Gagner-Toomey’s advanced thermal management solutions.

As the axial cooling fans market is projected to grow at a CAGR of 5.2% from 2024 to 2033, energy efficiency has emerged as a significant driver in fan design. Industries increasingly prioritize consumption awareness, prompting engineers to incorporate these factors into their designs, particularly when utilizing Gagner-Toomey’s innovative cooling solutions.

Moreover, efficient maintenance practices, such as routine cleaning and inspection of fan setups, are essential for ensuring optimal performance and energy conservation. By mastering these fundamentals, engineers can enhance their approach to fan innovation and application in electronic systems, leveraging the cutting-edge technology offered by Gagner-Toomey Associates.

Examine Technological Advancements in Fan Design

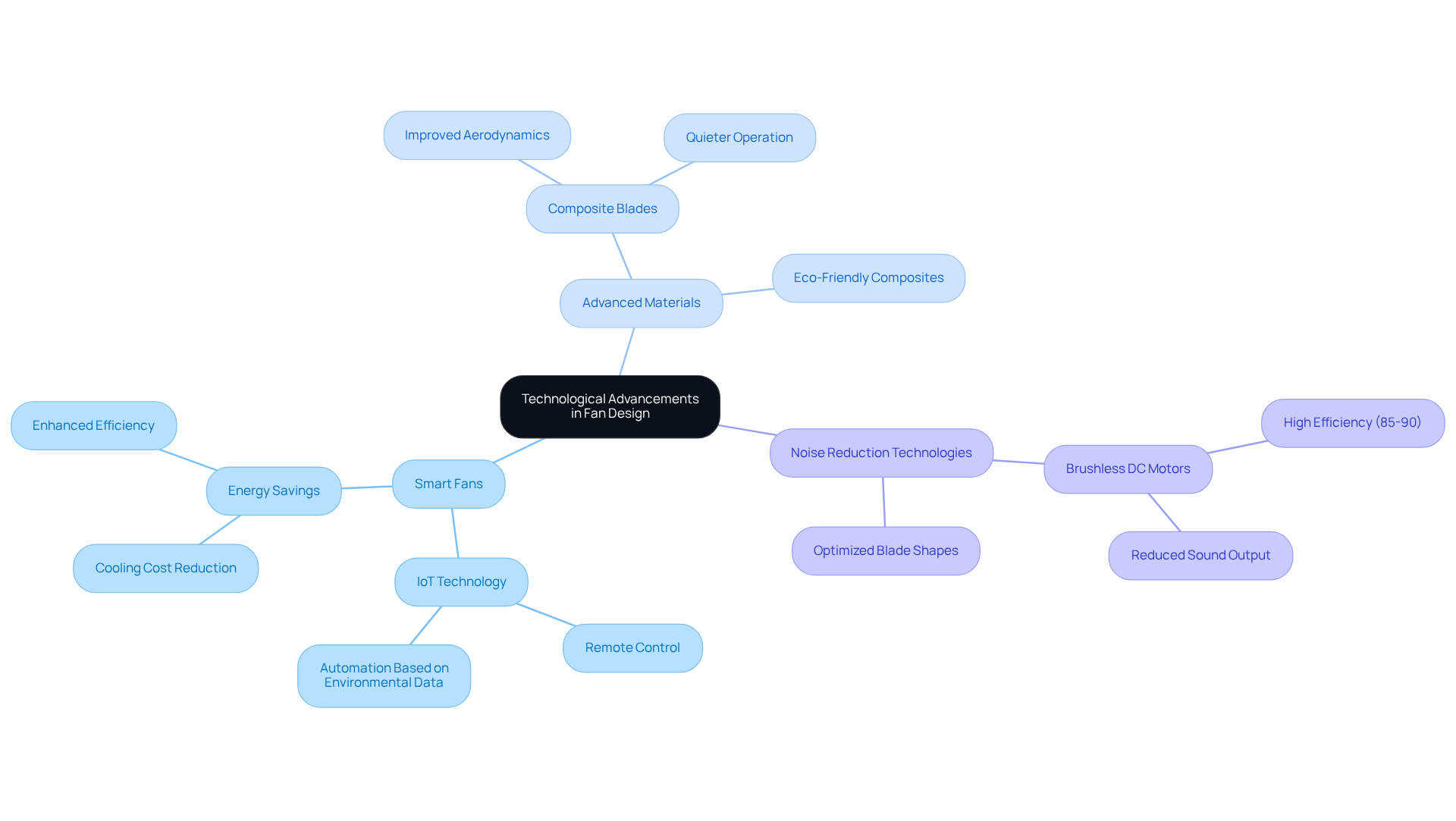

Recent advancements in fan innovation have significantly improved performance and productivity across various applications. Key innovations include:

-

Smart Fans: These fans leverage IoT technology, enabling remote control and automation based on real-time environmental data. By dynamically adjusting speed and operation with fan innovation, they enhance efficiency, contributing to substantial savings in both residential and commercial settings. For instance, intelligent ceiling fans can lower cooling expenses by as much as 15% when thermostat settings are raised by only 4 degrees, emphasizing their capability for resource conservation.

-

Advanced Materials: The incorporation of lightweight and durable materials in fan construction has proven to lower energy consumption while extending the lifespan of the products. Fan innovation, such as composite blades, not only improves aerodynamic performance but also leads to quieter operation, making them ideal for sensitive environments like data centers. The use of materials like high-quality metals and eco-friendly composites is becoming increasingly common, reflecting a shift towards sustainability in design.

-

Noise Reduction Technologies: Modern fans are engineered with advanced motor designs and optimized blade shapes to minimize operational noise. This is particularly important in environments where noise levels must be controlled, such as offices and healthcare facilities. The integration of brushless DC motors exemplifies fan innovation, achieving efficiencies of 85-90% while further enhancing performance and reducing sound output.

By remaining updated on these technological developments, engineers can choose and apply the most efficient fan solutions customized for their particular applications, ensuring optimal performance and energy conservation.

Implement Fan Technology in Electronic Systems

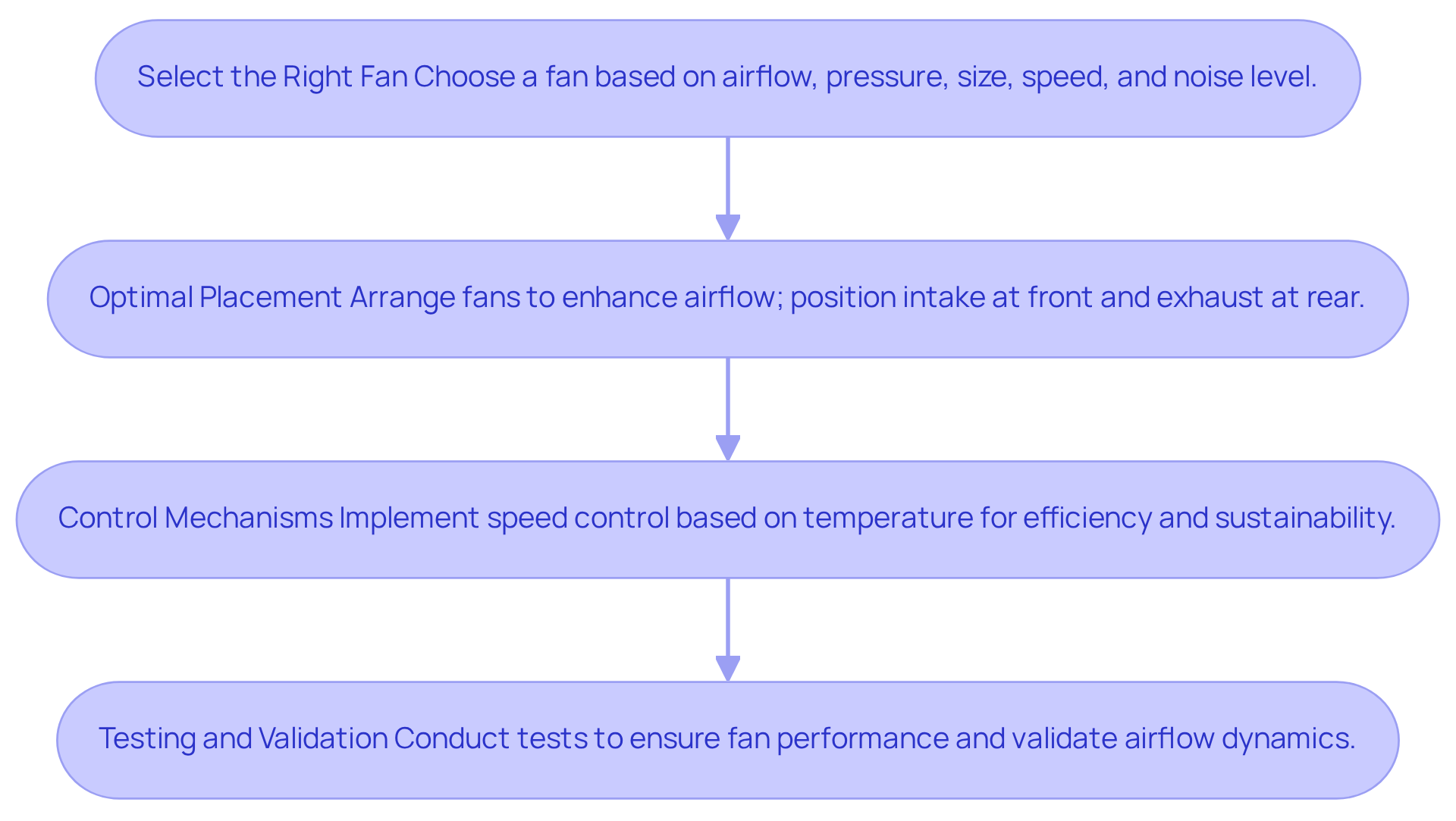

Integrating fan technology into electronic systems involves several key steps:

-

Selecting the Right Fan: It is essential to choose a fan that meets the specific airflow and pressure requirements of your application. Factors such as size, speed, and noise level must be considered. For instance, dual ball bearing blowers are ideal for high-speed applications due to their durability and effectiveness.

-

Optimal Placement: Strategically arranging ventilators enhances airflow and cooling efficiency. Positioning intake vents at the front and exhaust vents at the rear of a setup establishes efficient airflow routes. Research indicates that optimal fan placement can significantly improve thermal management, ensuring that critical components receive adequate cooling. Strategies include minimizing obstructions and selecting forward or backward curved fans based on application needs.

-

Control Mechanisms: Implementing control mechanisms that adjust fan speed based on temperature readings not only improves cooling performance but also reduces power usage, promoting sustainability. EC devices, which combine AC input with DC motor control, exemplify this approach by providing high efficiency and adaptable speed modulation. These fans are particularly advantageous in applications prioritizing energy conservation.

-

Testing and Validation: Following installation, comprehensive testing is crucial to confirm that the fan operates as expected within the setup. Monitoring temperature and airflow validates performance. Effective testing reveals insights into airflow dynamics and refines fan placement strategies for optimal results. Understanding static pressure traits is vital for assessing fan performance, as it directly impacts the cooling effectiveness of the setup.

By adhering to these steps, engineers can effectively utilize fan innovation to enhance the reliability and performance of electronic setups, ensuring they meet contemporary application demands. As Sam Pelonis noted, “The first step in the cooling fan selection process is performing a thermal analysis,” underscoring the importance of understanding airflow requirements in the design process.

Address Challenges in Fan Integration and Compliance

Integrating fans into electronic systems presents several challenges that engineers must navigate to ensure optimal performance and compliance.

-

Compliance with Standards: Fan systems must adhere to industry standards for energy efficiency and safety. Engineers should familiarize themselves with regulations established by the Department of Energy (DOE) and the Air Movement and Control Association (AMCA) to ensure compliance. Recent changes in energy efficiency metrics, such as the new SEER2 and HSPF2 standards for residential air conditioners and heat pumps, highlight the evolving regulatory landscape that engineers must consider.

-

Thermal Management: Effective thermal management is critical to preventing overheating in electronic systems. Engineers must evaluate the thermal load and choose devices capable of dissipating heat efficiently. For instance, utilizing devices with higher airflow rates can significantly enhance heat dissipation, thereby maintaining optimal operating temperatures. According to the DOE, establishing new energy conservation standards for air circulating devices (ACDs) could save an estimated 4.5 quads of energy, underscoring the importance of effective thermal management.

-

Vibration and Noise Control: The inclusion of blowers can create vibrations and noise, potentially affecting the performance of the setup. To mitigate these issues, engineers should implement vibration isolation techniques and select low-noise fan models. This approach not only enhances user experience but also boosts the reliability of the entire framework. Michael Wolf, PE, emphasizes that fan-efficiency regulation is enduring, indicating the necessity of choosing devices that meet stringent performance criteria.

-

Maintenance and Reliability: Regular upkeep is essential for ensuring the longevity and performance of fan units. Establishing a maintenance schedule that includes routine cleaning and inspection of fan components can prevent failures and extend operational life. The DOE’s analysis found that maintenance and repair costs for ACFs do not significantly increase with efficiency improvements, suggesting that investing in higher efficiency fans can be economically beneficial in the long run.

By proactively addressing these challenges and incorporating insights from industry experts and relevant statistics, engineers can achieve successful fan innovation and compliance within their electronic systems, ultimately leading to enhanced performance and reliability.

Conclusion

Mastering fan innovation necessitates a profound understanding of airflow dynamics, efficient design principles, and the latest technological advancements. By concentrating on these foundational elements, engineers can significantly enhance the performance and energy efficiency of cooling systems across diverse applications. The focus on smart technologies and sustainable materials not only optimizes fan functionality but also meets the increasing demand for environmentally responsible solutions.

Key insights from this exploration underscore the necessity of:

- Selecting the appropriate fan type for specific applications.

- Grasping the fan laws that dictate performance.

- Implementing effective maintenance practices.

Moreover, the integration of advanced materials and noise reduction technologies exemplifies the industry’s dedication to enhancing user experience while adhering to evolving standards.

Ultimately, the journey of fan innovation is continuous, urging engineers to remain informed about emerging trends and technologies. By embracing these advancements and tackling challenges such as compliance and thermal management, professionals can ensure that their designs not only satisfy current demands but also pave the way for future innovations in cooling solutions. Engaging with the latest developments in fan technology will be crucial for achieving enhanced efficiency and reliability in electronic systems.

Frequently Asked Questions

What is the primary function of fans?

Fans are devices designed to move air, generating airflow that is crucial for cooling and ventilation across various applications.

How do fans create airflow?

Fans create a pressure differential that facilitates air movement from high-pressure zones to low-pressure zones, which is fundamental for optimizing fan performance.

What are the different types of blowers mentioned in the article?

The article distinguishes between two main types of blowers: axial and centrifugal. Gagner-Toomey offers a range of DC input tube axial units and centrifugal blowers suitable for various applications.

What are the sizes of blowers available from Gagner-Toomey?

Gagner-Toomey’s product range includes DC input tube axial units varying from 15 to 280mm and centrifugal blowers from 15 to 225mm.

What are the fan laws and why are they important?

The three fundamental fan laws describe the relationship between airflow, pressure, and power consumption. They are critical for predicting how changes in one parameter can influence the others, helping engineers design more efficient cooling systems.

What is the projected growth rate of the axial cooling fans market?

The axial cooling fans market is projected to grow at a CAGR of 5.2% from 2024 to 2033.

What is driving the focus on energy efficiency in fan design?

Energy efficiency has emerged as a significant driver in fan design due to increasing consumption awareness among industries, prompting engineers to incorporate these factors into their designs.

What maintenance practices are essential for optimal fan performance?

Efficient maintenance practices, such as routine cleaning and inspection of fan setups, are essential for ensuring optimal performance and energy conservation.

How can engineers enhance their approach to fan innovation?

By mastering the fundamentals of fan operation and leveraging cutting-edge technology, engineers can enhance their approach to fan innovation and application in electronic systems.