Overview

This article delves into the setup, troubleshooting, and optimization of Master fan PWM technology, emphasizing its critical role in enhancing cooling systems through precise speed regulation. It presents a compelling case for PWM technology by detailing its advantages over traditional fans, including:

- Energy efficiency

- Noise reduction

- Improved temperature control

Furthermore, the article provides practical steps for installation and troubleshooting, ensuring optimal performance and empowering readers to implement these solutions effectively.

Introduction

Pulse Width Modulation (PWM) technology is transforming the operation of cooling systems, providing a sophisticated approach to regulating fan speeds and enhancing energy efficiency. As electronic devices become increasingly powerful, the demand for effective thermal management intensifies, and PWM fans meet this challenge by dynamically adjusting their performance in response to real-time thermal requirements.

Nevertheless, the numerous advantages of PWM technology are accompanied by complexities in setup and optimization, leaving many engineers questioning how to achieve optimal results. To harness the full potential of PWM fans, it is essential to explore steps that ensure effective cooling while minimizing noise and energy consumption.

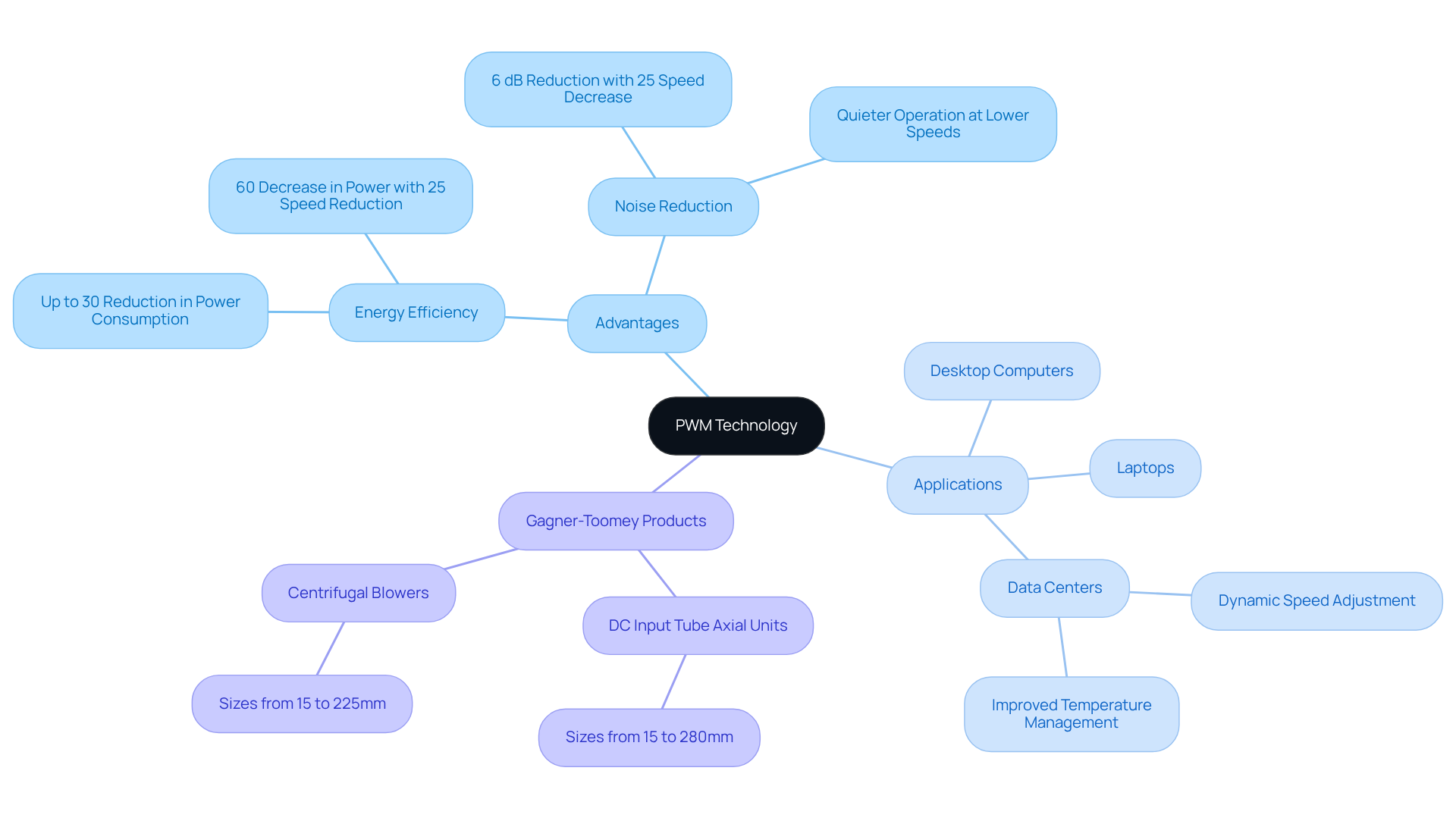

Define PWM Technology and Its Role in Cooling Systems

Pulse Width Modulation (PWM) is a sophisticated technique utilized for regulating the power supplied to electrical devices, particularly within cooling systems. By adjusting the width of the pulses in a signal, fan PWM facilitates precise regulation of fan speeds, which is crucial for maintaining optimal temperatures in electronic components. This adaptability allows fans, including those from Gagner-Toomey Associates, to dynamically alter their rates based on real-time thermal demands, significantly enhancing energy efficiency and reducing noise levels compared to traditional fan control methods. Notably, a 25% reduction in fan speed can result in an impressive 60% decrease in power consumption, underscoring PWM’s effectiveness in optimizing energy use.

In practical applications, the fan PWM technology is integral to the cooling systems of contemporary devices, such as desktop computers, laptops, and data centers. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers an extensive product range of DC input Tube Axial units varying from 15 to 280mm and Centrifugal Blowers from 15 to 225mm, all enhanced for performance and efficiency. This ensures that devices operate solely at the necessary velocities required to maintain preferred temperatures, thereby preventing excessive heat and extending the lifespan of critical components. Recent advancements in fan PWM technology, including improved control algorithms and refined designs, have further elevated efficiency and performance in Gagner-Toomey’s offerings. As a result, PWM devices are increasingly favored in high-performance computing environments, where they contribute to superior thermal management and reduced operational costs.

Explore Advantages of PWM Fans Compared to Traditional Fans

Fan PWM technology offers distinct advantages over traditional fans, particularly when compared to DC fans, establishing itself as a preferred choice in modern electronics cooling systems.

-

Energy Efficiency: PWM units dynamically adjust their operating rate based on cooling requirements, achieving energy usage reductions of up to 30% compared to conventional DC models that operate at a fixed rate. This adaptability not only lowers energy costs but also minimizes heat generation, which is essential for a sustainable operation that utilizes fan PWM.

-

Noise Reduction: By operating at reduced rates during lighter tasks, PWM devices significantly decrease noise levels. Research indicates that a 25% reduction in airflow can lead to a noise decrease of approximately 6 dB, making PWM devices particularly suitable for noise-sensitive environments.

Improved temperature control is facilitated by fan PWM technology, which allows for superior temperature regulation as fans can swiftly adjust their rates in response to real-time thermal conditions. This capability ensures that electronic components remain within safe operating temperatures, thereby reducing the risk of overheating.

-

Extended Lifespan: Operating at optimal speeds minimizes wear and tear on fan components, potentially extending their operational lifespan. This longevity is vital for maintaining system reliability, especially in high-performance applications.

-

Enhanced Performance: PWM devices excel in providing superior airflow and cooling efficiency, particularly in high-demand scenarios. Their ability to adapt to varying thermal loads ensures effective heat dissipation, which is essential for the longevity and stability of critical electronic components.

-

Considerations: While PWM devices deliver significant benefits, they tend to be more complex and costly than conventional DC models. Engineers must carefully weigh these factors against the advantages when selecting cooling solutions.

In conclusion, the integration of fan PWM ventilators into electronic systems not only enhances energy efficiency and noise management but also significantly boosts overall performance and reliability. Case studies have demonstrated that employing PWM technology can lead to substantial energy savings and improved reliability, underscoring the importance of these devices in contemporary applications.

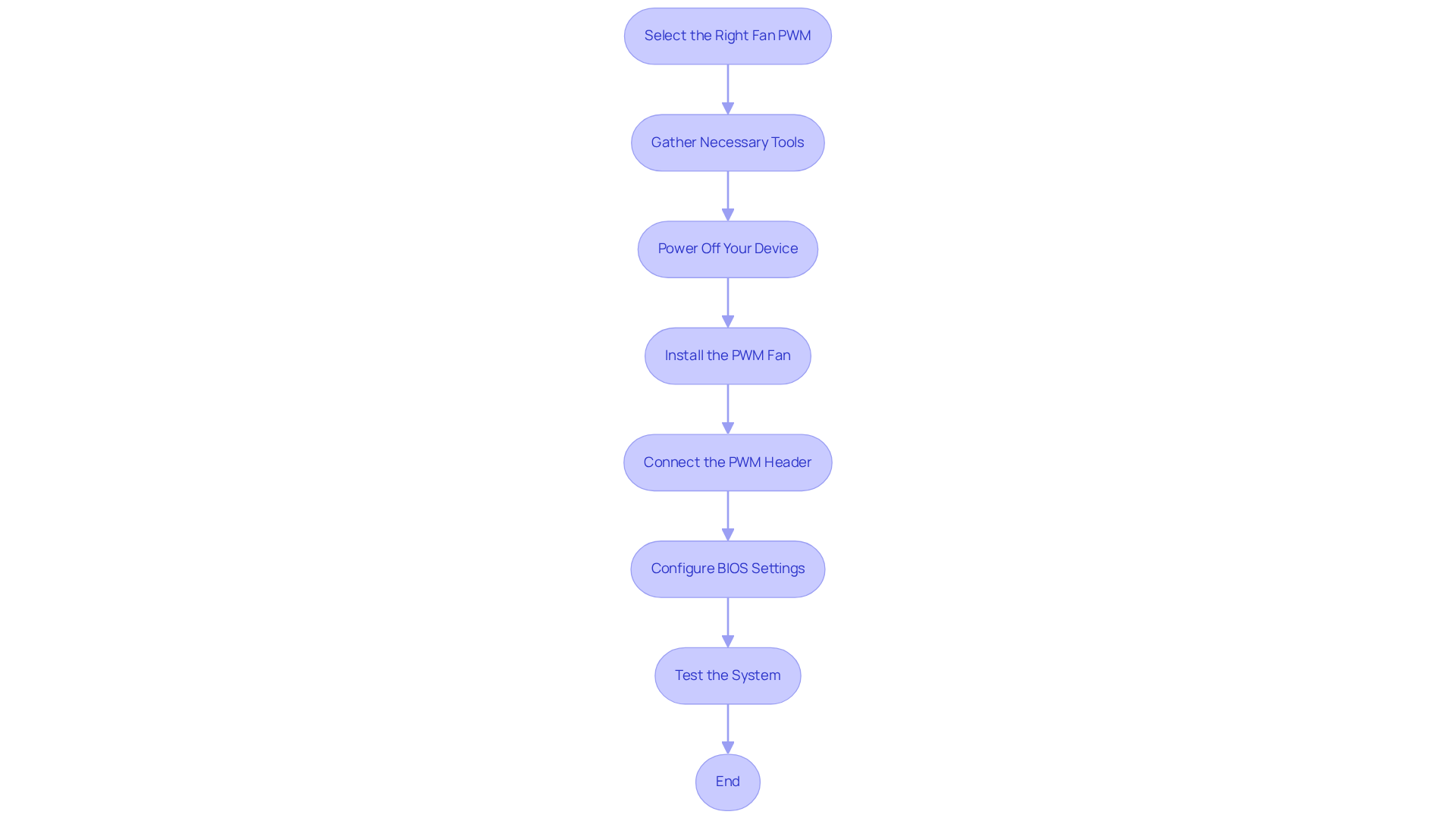

Implement PWM Fans: Setup and Configuration Steps

To effectively implement PWM fans in your cooling system, adhere to these essential steps:

- Select the right fan PWM: Choose a fan PWM that meets your cooling requirements and is compatible with your specifications. PWM units typically have a longer lifespan than their DC counterparts, making them a reliable choice for sustained performance.

- Gather Necessary Tools: Ensure you possess the required tools, such as screwdrivers, thermal paste (if applicable), and any necessary connectors for installation.

- Power Off Your Device: For safety, power down your device and unplug it before commencing the installation process.

- Install the PWM Fan: Secure the fan in the designated area, ensuring the airflow direction is correct. Fasten it using screws or clips as needed. Note that fan PWM uses a four-pin connector, whereas DC fans employ a three-pin connector, which is critical for compatibility.

- Connect the PWM Header: Identify the PWM fan header on your motherboard or fan controller. Connect the fan’s PWM cable to this header, ensuring a firm connection.

- Configure BIOS Settings: Power on your device and access the BIOS setup. Navigate to the fan control settings to verify that the PWM fan is recognized. Adjust the fan curve settings to optimize performance based on your cooling needs. As Daren Perez observes, ‘Fan PWM is a tool that allows engineers to balance these variables according to the demands placed on their setup at any given time.’

- Test the System: Following configuration, monitor the fan’s operation during system use to ensure it responds appropriately to temperature variations, thereby maintaining efficient cooling performance. Case studies have demonstrated that reducing the fan rate during standard operation can significantly decrease airflow, noise, and power consumption, illustrating the effectiveness of PWM technology in modern cooling solutions.

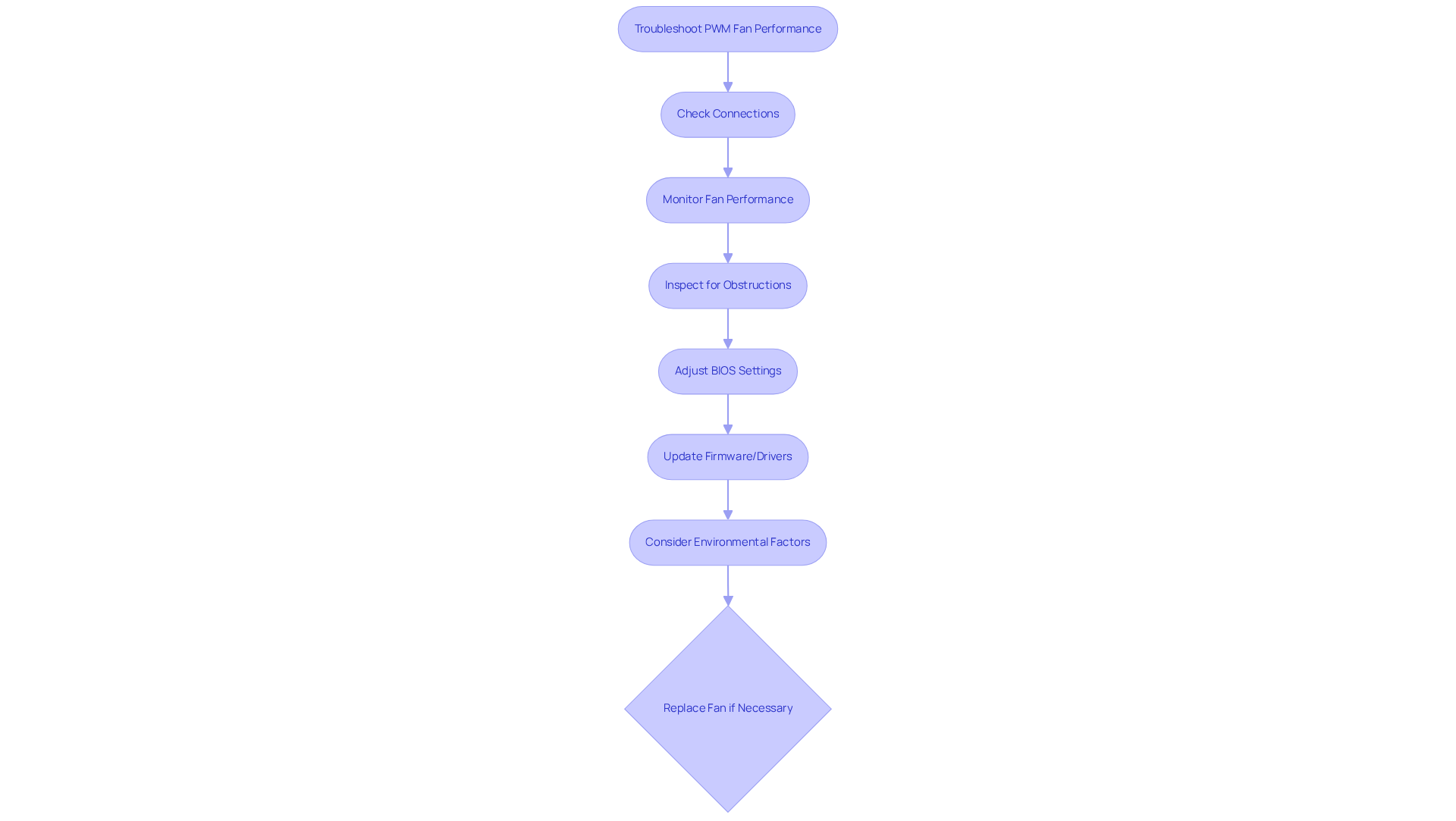

Troubleshoot and Optimize PWM Fan Performance

To troubleshoot and optimize PWM fan performance effectively, adhere to the following essential steps:

- Check Connections: Begin by verifying that the PWM fan is securely connected to the motherboard or fan controller. Loose connections can lead to erratic fan behavior, negatively impacting performance.

- Monitor Fan Performance: Utilize software tools such as HWMonitor or SpeedFan to track fan activity, ensuring it operates within expected parameters. These tools are recognized for their comprehensive monitoring capabilities. If the fan fails to respond to temperature changes, further investigation is warranted.

- Inspect for Obstructions: Ensure that no physical obstructions are blocking the fan blades, as this can significantly hinder airflow and overall performance.

- Adjust BIOS Settings: Revisit the BIOS fan control settings to confirm they are configured correctly. Adjust the fan curve to optimize performance according to your thermal profile, enhancing cooling efficiency. Notably, fan PWM controllers significantly reduce noise levels by dynamically adjusting the fan speed in response to thermal loads.

- Update Firmware/Drivers: Regularly maintain your motherboard’s firmware and appropriate drivers, as updates can enhance fan control functionality and overall performance.

- Consider Environmental Factors: Assess the ambient temperature and airflow within the case. Enhancing case ventilation can lead to improved cooling performance and stability of the setup. Engineers recognize that fan PWM can enable fans to operate at speeds as low as 10% of peak speed, which is beneficial in low-load conditions.

- If a fan consistently underperforms or produces unusual noises, consider replacing it with a new fan PWM to maintain system efficiency and reliability. As SANYO DENKI emphasizes, every custom fan undergoes rigorous quality checks to meet the highest standards.

By implementing these strategies, engineers can ensure optimal fan PWM operation, thereby enhancing the cooling performance and extending the lifespan of critical components.

Conclusion

The significance of Pulse Width Modulation (PWM) technology in cooling systems is paramount. By enabling precise control over fan speeds, PWM not only enhances energy efficiency but also reduces noise and optimizes thermal management in electronic devices. This sophisticated approach ensures that components remain within safe operating temperatures, contributing to the longevity and reliability of these systems.

Throughout this discussion, the various advantages of PWM fans over traditional DC fans have been thoroughly examined. These advantages encompass substantial energy savings, quieter operation, improved temperature control, and extended lifespans. Furthermore, the comprehensive setup and troubleshooting guidelines provided equip users with the necessary tools to implement and optimize PWM technology effectively in their cooling systems.

As technology continues to advance, the integration of PWM fans will play a crucial role in enhancing the performance and efficiency of electronic devices. Embracing this innovative cooling solution is essential for engineers and enthusiasts alike, ensuring systems operate at peak performance while minimizing energy consumption and noise levels. The transition to PWM technology is not merely a trend; it represents a significant step towards sustainable and efficient cooling solutions in modern electronics.

Frequently Asked Questions

What is Pulse Width Modulation (PWM) technology?

Pulse Width Modulation (PWM) is a technique used to regulate the power supplied to electrical devices by adjusting the width of the pulses in a signal. It is particularly important in cooling systems for controlling fan speeds.

How does PWM technology benefit cooling systems?

PWM technology allows for precise regulation of fan speeds based on real-time thermal demands, enhancing energy efficiency and reducing noise levels compared to traditional fan control methods.

What impact does reducing fan speed have on power consumption?

A 25% reduction in fan speed can lead to a significant 60% decrease in power consumption, demonstrating PWM’s effectiveness in optimizing energy use.

In what types of devices is PWM technology commonly used?

PWM technology is integral to the cooling systems of contemporary devices such as desktop computers, laptops, and data centers.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a wide range of DC input Tube Axial units and Centrifugal Blowers designed for performance and efficiency.

How does PWM technology extend the lifespan of electronic components?

By ensuring that fans operate only at the necessary speeds required to maintain preferred temperatures, PWM technology helps prevent excessive heat, which can extend the lifespan of critical components.

What advancements have been made in PWM technology recently?

Recent advancements include improved control algorithms and refined designs, which have further enhanced the efficiency and performance of PWM devices, making them increasingly favored in high-performance computing environments.