Introduction

Mastering the complexities of high CFM (Cubic Feet per Minute) 12V DC fans is essential for engineers focused on developing efficient cooling systems. These fans are critical in maintaining optimal temperatures, particularly in high-density electronic environments where excessive heat can lead to component failure. The challenge, however, extends beyond merely selecting the right fan; it involves a deep understanding of how factors such as airflow, static pressure, and fan placement can significantly impact system performance.

To ensure these fans operate at peak efficiency and reliability, engineers must adopt best practices that consider these variables. By doing so, they can enhance the effectiveness of their cooling solutions and prevent potential failures in their applications.

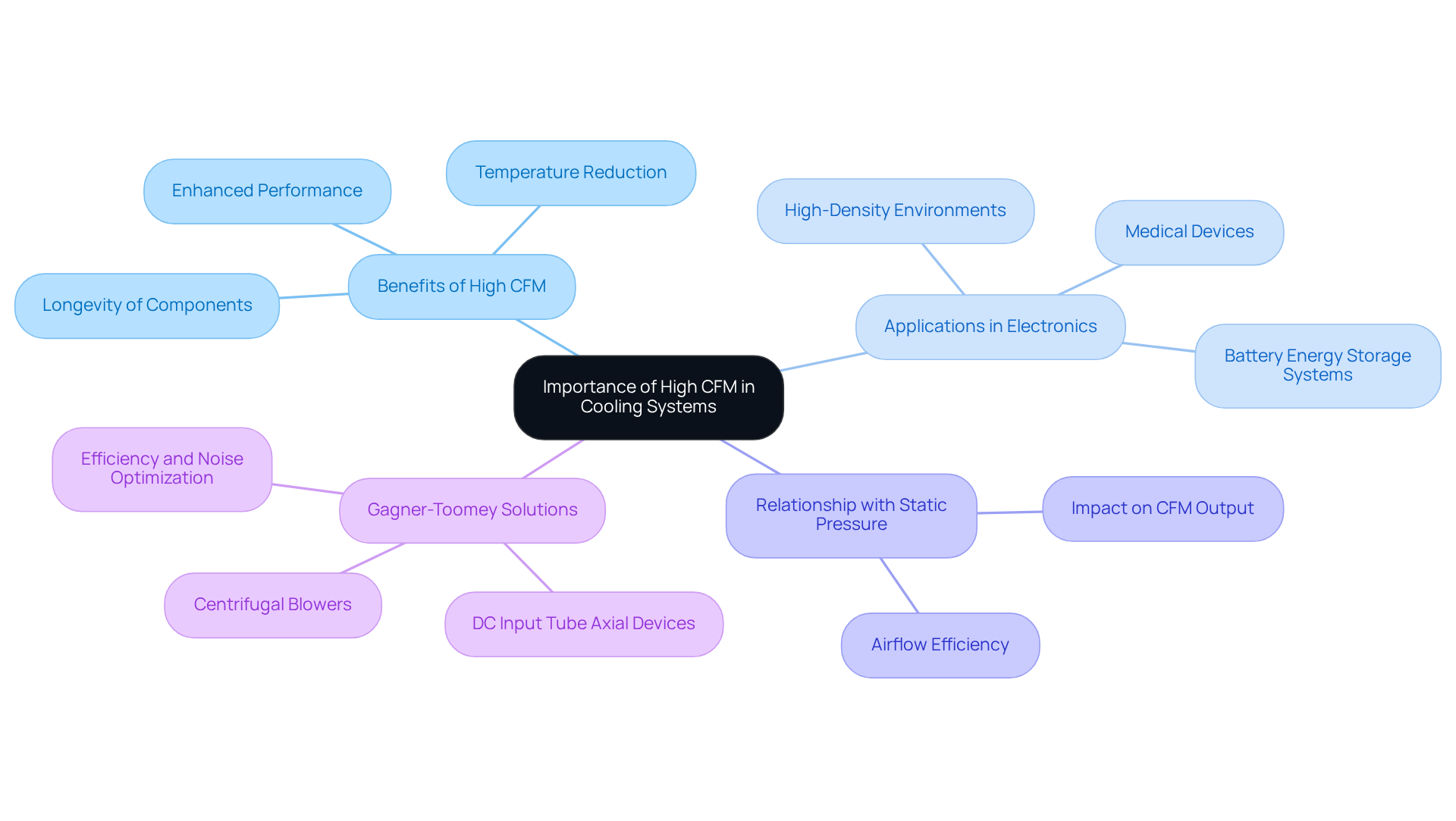

Understand the Importance of High CFM in Cooling Systems

In temperature control systems, a 12v dc fan high cfm is essential, as high CFM ratings dictate the volume of air that can be moved to effectively dissipate heat. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers a comprehensive range of DC input Tube Axial devices and Centrifugal Blowers, optimized for efficiency and minimal noise. In electronic applications, maintaining optimal temperatures is critical to prevent component failure and extend lifespan.

For example, a well-designed temperature regulation system utilizing a 12v dc fan high cfm from Gagner-Toomey can reduce the temperature of sensitive components by several degrees, significantly enhancing performance and reliability. Engineers must prioritize using a 12v dc fan high cfm when designing temperature control solutions, especially in high-density electronic environments where heat accumulation poses a substantial risk.

Moreover, understanding the relationship between CFM and static pressure is vital, as it directly influences airflow efficiency and overall effectiveness. By ensuring adequate CFM with Gagner-Toomey’s innovative cooling solutions, engineers can enhance the longevity of electronic components and improve system reliability.

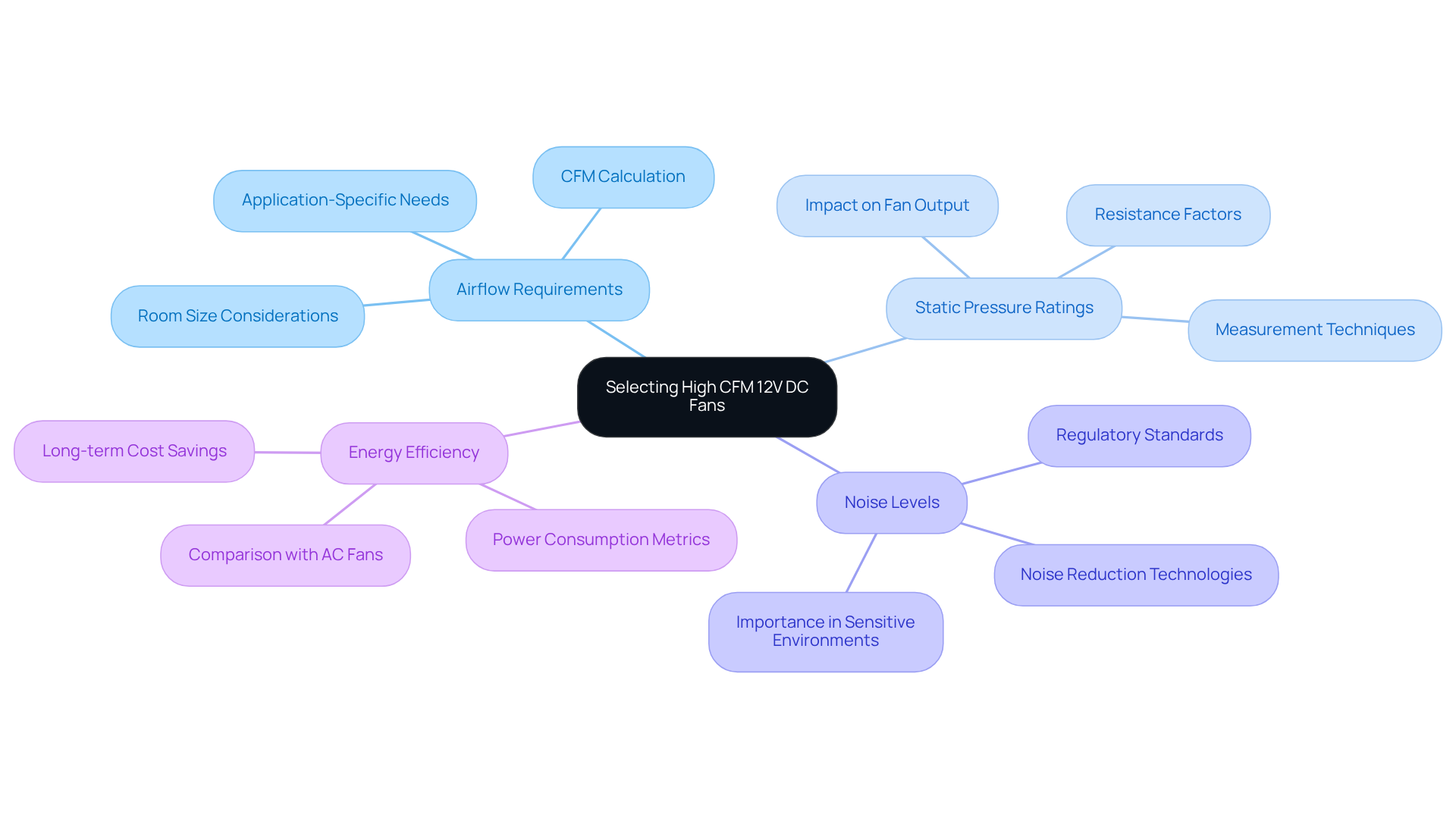

Select the Right High CFM 12V DC Fans for Your Application

When selecting 12V DC fans high CFM, engineers face critical decisions that can significantly impact performance. Key factors to consider include:

- Airflow requirements

- Static pressure ratings

- Noise levels

- Energy efficiency

Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, offers a comprehensive range of DC input Tube Axial fans, with sizes ranging from 15 to 280mm, and Centrifugal Blowers, from 15 to 225mm, all designed for optimal efficiency and minimal noise.

A fan may boast a high CFM rating, but if it lacks sufficient static pressure, its effectiveness in restrictive environments will be severely compromised. For example, inadequate static pressure can diminish fan output by 30-50%, potentially leading to equipment failure in critical applications. Engineers must carefully assess the specific temperature regulation needs of their applications, considering factors such as enclosure size and the heat load generated by components.

Moreover, features like variable speed control enhance adaptability and efficiency, enabling devices to adjust their operation according to current thermal conditions. Most models also offer IP protection upon request, providing an additional layer of reliability. Real-world applications, such as the deployment of 12V DC fan high CFM blowers in data centers, demonstrate how thoughtful selection can yield substantial energy savings and improved temperature management.

By aligning airflow requirements with static pressure ratings, engineers can optimize their cooling solutions, ensuring the reliability and longevity of critical systems.

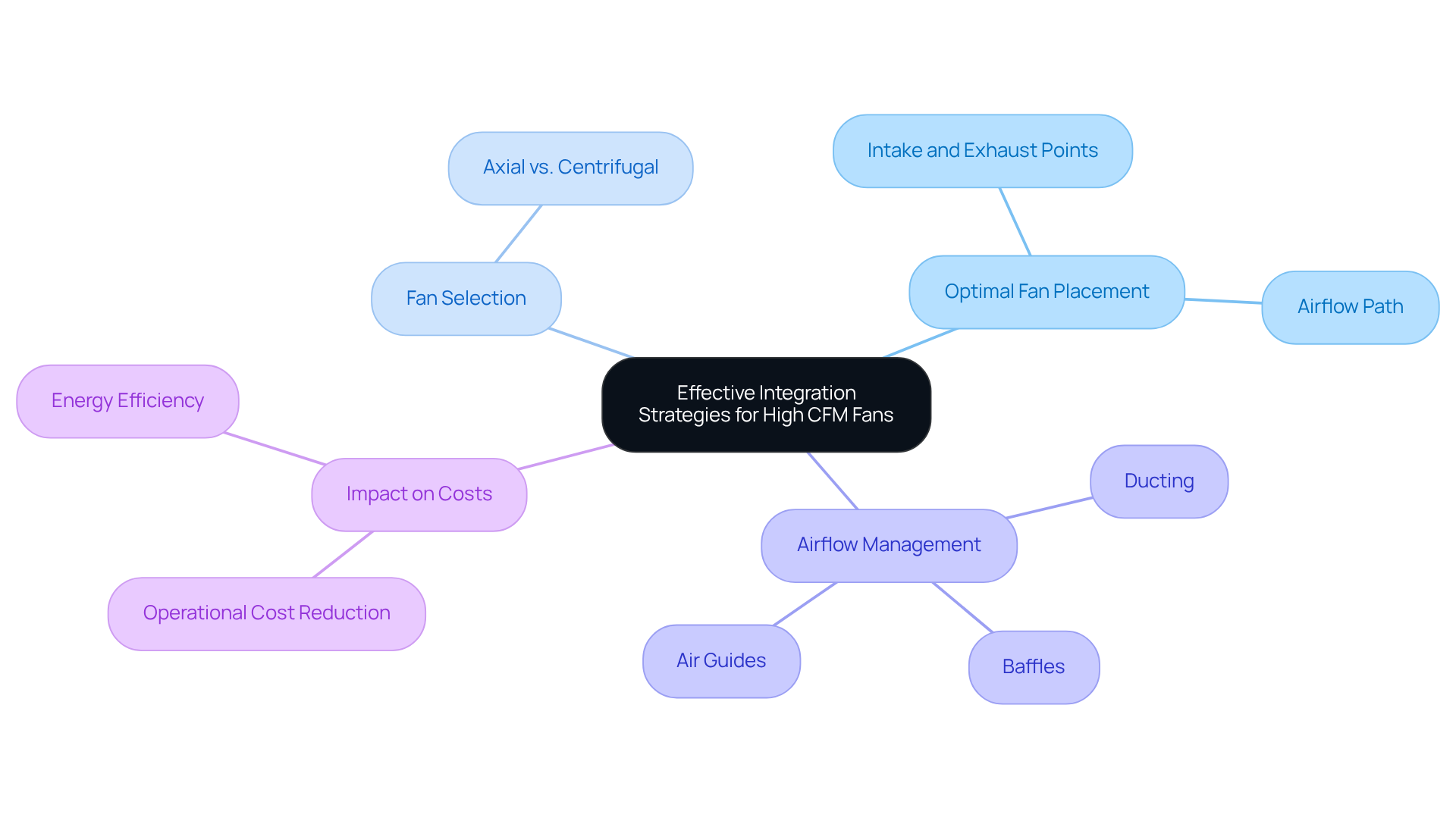

Implement Effective Integration Strategies for High CFM Fans

To enhance the effectiveness of systems, engineers must prioritize the strategic integration of 12v dc fan high cfm blowers. Optimal fan placement is crucial; positioning fans at both the intake and exhaust points of an enclosure establishes a more effective airflow path, significantly reducing hotspots.

As highlighted by BENCOR, “Selecting between an axial and a centrifugal fan, and subsequently strategically incorporating it into an electronic enclosure, is a crucial engineering choice that directly impacts product reliability, functionality, and lifespan.” This decision is not merely technical; it is foundational to the system’s overall performance.

Furthermore, the application of ducting can guide air precisely where it is needed, improving temperature regulation efficiency. Utilizing baffles or air guides enhances airflow directionality and minimizes turbulence, leading to superior thermal management. These methods not only improve temperature regulation but also contribute to lowering energy usage.

Consider the impact: case studies have shown that optimized fan integration can lower operational costs by up to 20% while improving system reliability. This highlights the critical role of effective airflow management in electronic cooling systems, especially when utilizing a 12v dc fan high cfm. Engineers must act decisively to implement these strategies, ensuring their systems operate at peak efficiency.

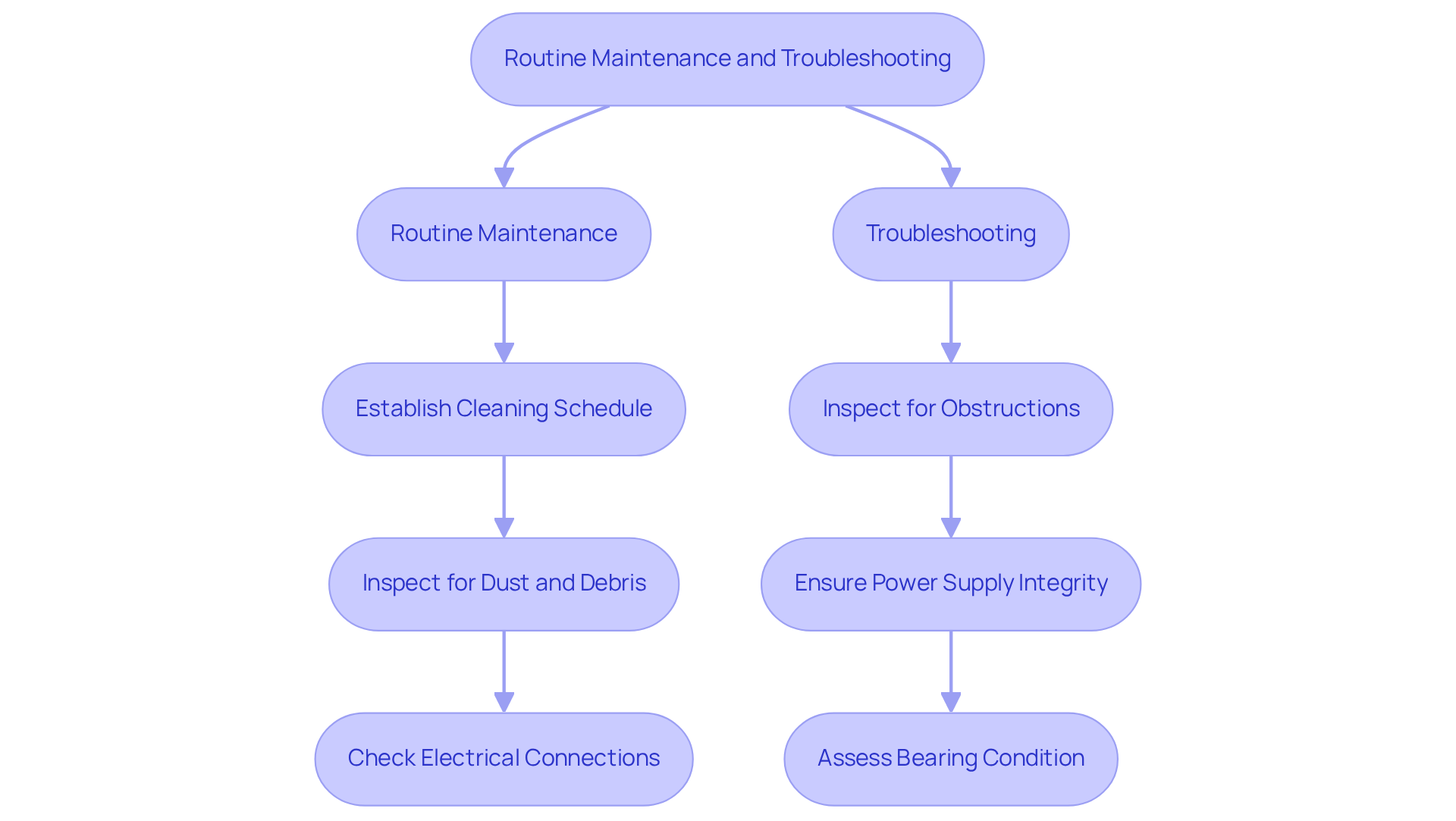

Maintain and Troubleshoot High CFM Fans for Optimal Performance

Routine upkeep of the 12v dc fan high cfm units is essential for optimizing their efficiency and longevity. Engineers must establish a routine cleaning schedule to eliminate dust and debris from fan blades and housings. Even minor accumulations can lead to significant reductions in airflow efficiency. For instance, dust buildup can restrict airflow, forcing the fan to operate harder, which increases energy consumption and can lead to premature failure. Additionally, confirming that electrical connections are secure and that fans operate within their specified voltage range is crucial to avoid operational issues.

Troubleshooting common problems, such as unusual noises or diminished airflow, requires a systematic approach. Engineers should:

- Inspect the fan for obstructions

- Ensure the integrity of the power supply

- Assess the condition of the bearings

A 10% increase in airflow can necessitate a 33% increase in horsepower, and it’s important to note that a 10% increase in CFM results in a 21% increase in static pressure. This underscores the importance of maintaining optimal performance for the 12v dc fan high cfm. Furthermore, annual maintenance can save an estimated average of 5% to 15% in energy costs, providing a clear financial incentive for regular upkeep.

By adhering to these maintenance and troubleshooting best practices, engineers can significantly enhance the reliability of their cooling systems, reduce the risk of costly downtime, and ensure efficient operation in demanding environments.

Conclusion

Understanding the complexities of high CFM 12V DC fans is crucial for engineers aiming to boost cooling efficiency and system reliability. By focusing on high CFM ratings in their designs, engineers can greatly enhance thermal management, extending the lifespan of sensitive electronic components and ensuring optimal performance in challenging environments.

This article shared essential insights on selecting the right fans based on airflow requirements, static pressure ratings, and noise levels. The significance of strategic integration – such as optimal fan placement and the use of ducting – was underscored as a method to maximize airflow efficiency. Furthermore, regular maintenance and effective troubleshooting practices were highlighted as vital for sustaining fan performance and reliability.

Ultimately, the effective use of high CFM 12V DC fans relies on a thorough understanding of their role in cooling systems. Engineers are urged to embrace these best practices and incorporate innovative solutions to not only meet but surpass the thermal management demands of their projects. By doing so, they will enhance system functionality while contributing to energy savings and operational efficiency over time.

Frequently Asked Questions

What is the significance of high CFM in cooling systems?

High CFM (Cubic Feet per Minute) ratings are essential in cooling systems as they dictate the volume of air that can be moved, effectively dissipating heat and maintaining optimal temperatures to prevent component failure.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is the world’s largest producer of standard and custom air-movers, offering a comprehensive range of DC input Tube Axial devices and Centrifugal Blowers optimized for efficiency and minimal noise.

How does a 12v DC fan with high CFM benefit electronic applications?

A well-designed temperature regulation system utilizing a 12v DC fan with high CFM can reduce the temperature of sensitive components by several degrees, significantly enhancing performance and reliability.

Why is it important for engineers to use high CFM fans in temperature control solutions?

Engineers must prioritize high CFM fans when designing temperature control solutions, especially in high-density electronic environments, to mitigate heat accumulation and reduce the risk of component failure.

What is the relationship between CFM and static pressure in cooling systems?

Understanding the relationship between CFM and static pressure is vital as it directly influences airflow efficiency and the overall effectiveness of the cooling system.

How can Gagner-Toomey’s cooling solutions impact the longevity of electronic components?

By ensuring adequate CFM with Gagner-Toomey’s innovative cooling solutions, engineers can enhance the longevity of electronic components and improve system reliability.