Overview

This article delves into the effective selection and troubleshooting of high-temperature blower fans, highlighting the critical importance of understanding their key features and performance metrics. It outlines essential criteria such as:

- Airflow

- Static pressure

- Temperature rating

It also addresses common troubleshooting issues like:

- Overheating

- Vibration

These elements are vital for ensuring optimal fan performance in demanding industrial environments.

Introduction

High temperature blower fans are essential in industries where extreme conditions prevail, often functioning in environments that exceed 1,800°F. As technology advances, the importance of selecting the appropriate fan has escalated, as an incorrect choice can result in inefficiencies and costly downtime.

How can engineers guarantee they are making the optimal selection while also preparing to troubleshoot common issues that may arise? This guide explores the critical features, selection criteria, and maintenance strategies for high temperature blower fans, equipping readers with the necessary knowledge to enhance performance and reliability in demanding applications.

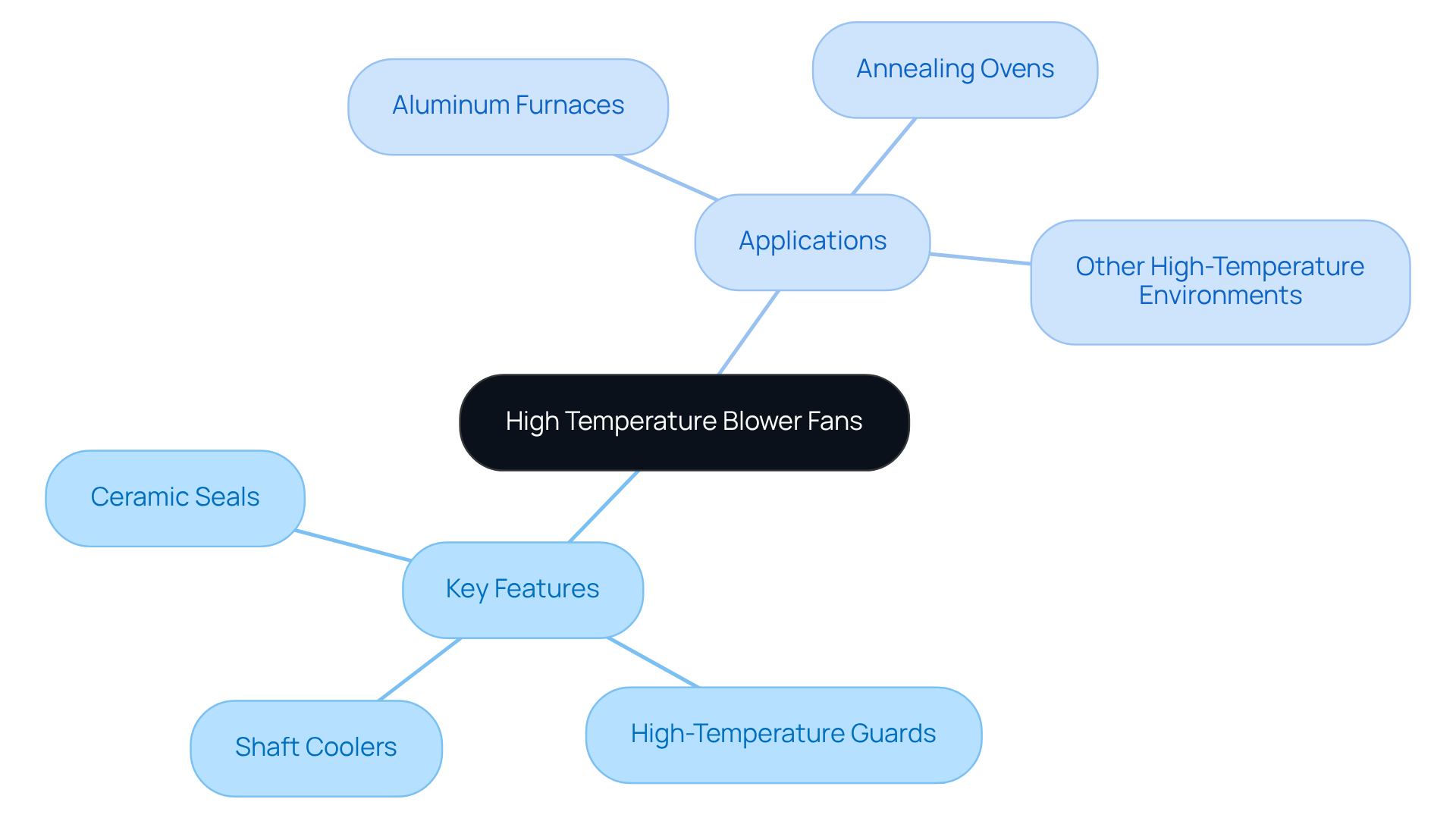

Understand High Temperature Blower Fans: Key Features and Applications

High temperature blower fans from Gagner-Toomey Associates are meticulously crafted to operate in settings where temperatures can rise beyond typical limits, often reaching up to 1800°F. Their construction typically involves high-temperature resistant materials such as stainless steel and specialized alloys, ensuring they can endure extreme conditions without compromising integrity.

Key design features include:

- Ceramic seals

- High-temperature guards

- Shaft coolers

All of which enhance the durability and operational efficiency of the units. These components are crucial for averting catastrophic failures, especially in applications subjected to corrosive gases and rapid temperature fluctuations.

Typical uses for these devices encompass numerous industrial processes, including:

- Aluminum furnaces

- Annealing ovens

- Other environments where a high temperature blower fan is essential for efficient air circulation at high temperatures

High-temperature ventilation devices, such as high temperature blower fans, are particularly vital in industrial process manufacturing, where air and heat interact considerably. Understanding the specific characteristics and material compositions of these fans is essential for selecting the suitable model tailored to the distinct requirements of each application.

Recent advancements in high-temperature fan technology from a leading firm have led to the development of customizable solutions that allow for the selection of various features based on operational requirements. This flexibility ensures that engineers can meet the specific needs of their applications, enhancing performance and reliability in extreme environments. Additionally, implementing temperature sensors on fan bearings can provide alerts if temperatures exceed safe limits, further ensuring operational safety.

Evaluate Selection Criteria: Performance Metrics and Specifications

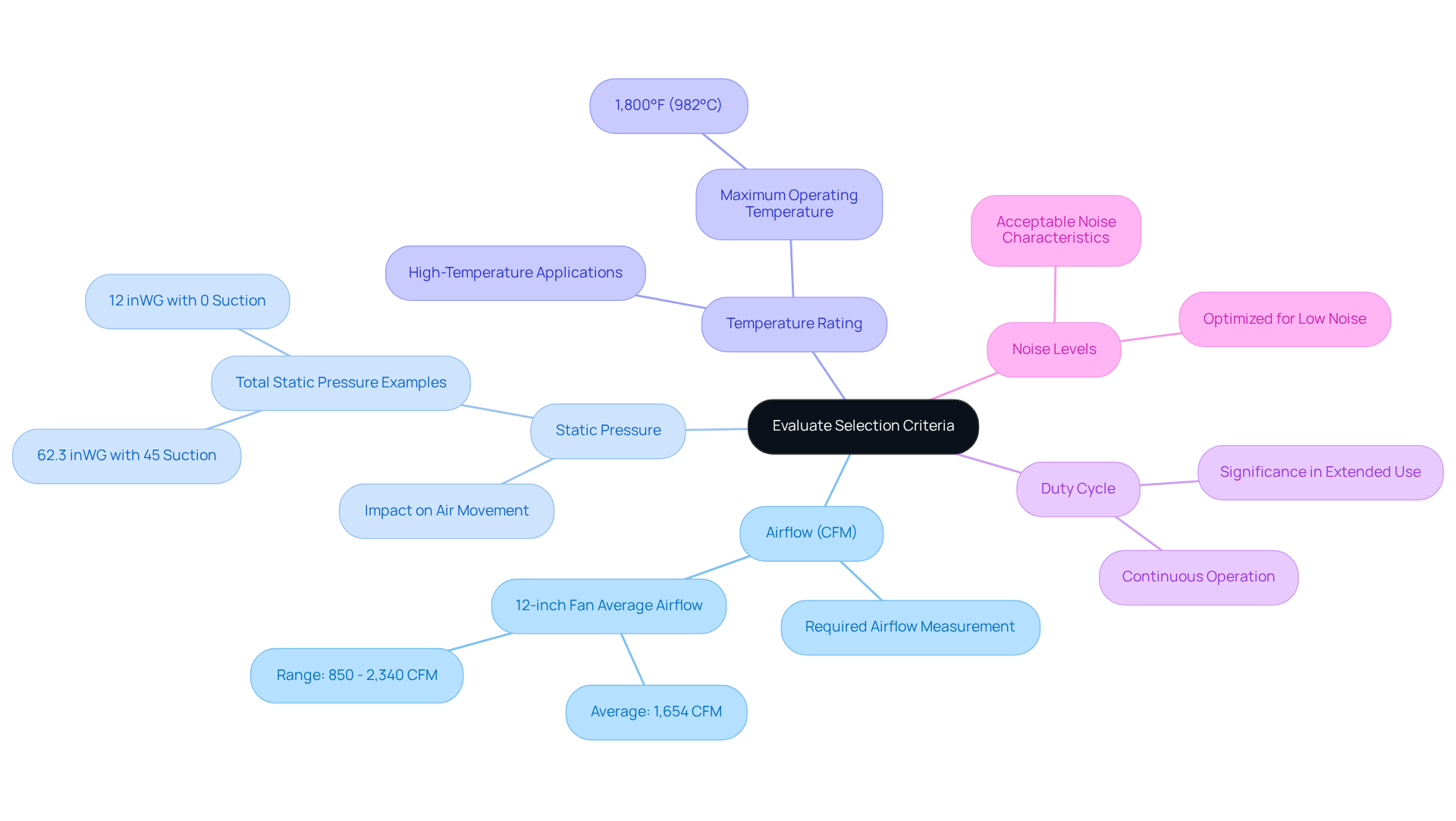

When selecting a high temperature blower fan, it is crucial to evaluate several key performance metrics and specifications, especially in light of Gagner-Toomey Associates’ extensive range of innovative cooling solutions.

- Airflow (CFM): Accurately measure the required airflow in cubic feet per minute (CFM) to ensure the fan can effectively ventilate the intended space. For instance, a 12-inch fan typically achieves an average airflow of about 1,654 CFM at 0.05 inH O static pressure, with a range from 850 to 2,340 CFM. The company provides a wide range of DC input tube axial devices, with sizes varying from 15 to 280mm, optimized for performance and efficiency, including options with IP protection available upon request.

- Static Pressure: Understand the static pressure requirements of your system, as this directly impacts the fan’s ability to move air against resistance. For example, total static pressure can reach up to 62.3 inWG under specific conditions, such as with 45 inches of suction pressure and 12 inches of discharge pressure. The centrifugal fans from the manufacturer, available in sizes ranging from 15 to 225mm, are crafted to satisfy a variety of static pressure requirements, guaranteeing dependability in multiple uses.

- Temperature Rating: Ensure the fan’s temperature rating exceeds the maximum operating temperature of the environment. High temperature blower fans can withstand temperatures reaching 1,800°F (982°C), making them suitable for demanding applications. The company’s custom solutions encompass heat sinks and cooling systems capable of withstanding extreme conditions, further enhancing their versatility.

- Duty Cycle: Determine the fan’s duty cycle, which indicates how long it can operate continuously without overheating. This is especially significant in scenarios demanding extended use, and their designs are customized for dependability in continuous operation.

- Noise Levels: Take into account the acceptable noise levels for your use case, as some fans may operate louder than others. Selecting a fan with appropriate noise characteristics is essential for maintaining a conducive working environment. The company’s products are optimized for low noise, ensuring a quieter operation.

Additionally, it is important to understand the relationship between airflow and static pressure; when airflow increases, static pressure decreases, and vice versa. For most forced air cooling applications, actual airflow is often about half of the fan’s maximum airflow. By thoroughly assessing these criteria, engineers can select a high temperature blower fan from Gagner-Toomey Associates, the world’s largest producer of air-movers, that meets their specific operational requirements, ensuring optimal performance and reliability.

Troubleshoot Common Issues: Ensuring Optimal Performance of Blower Fans

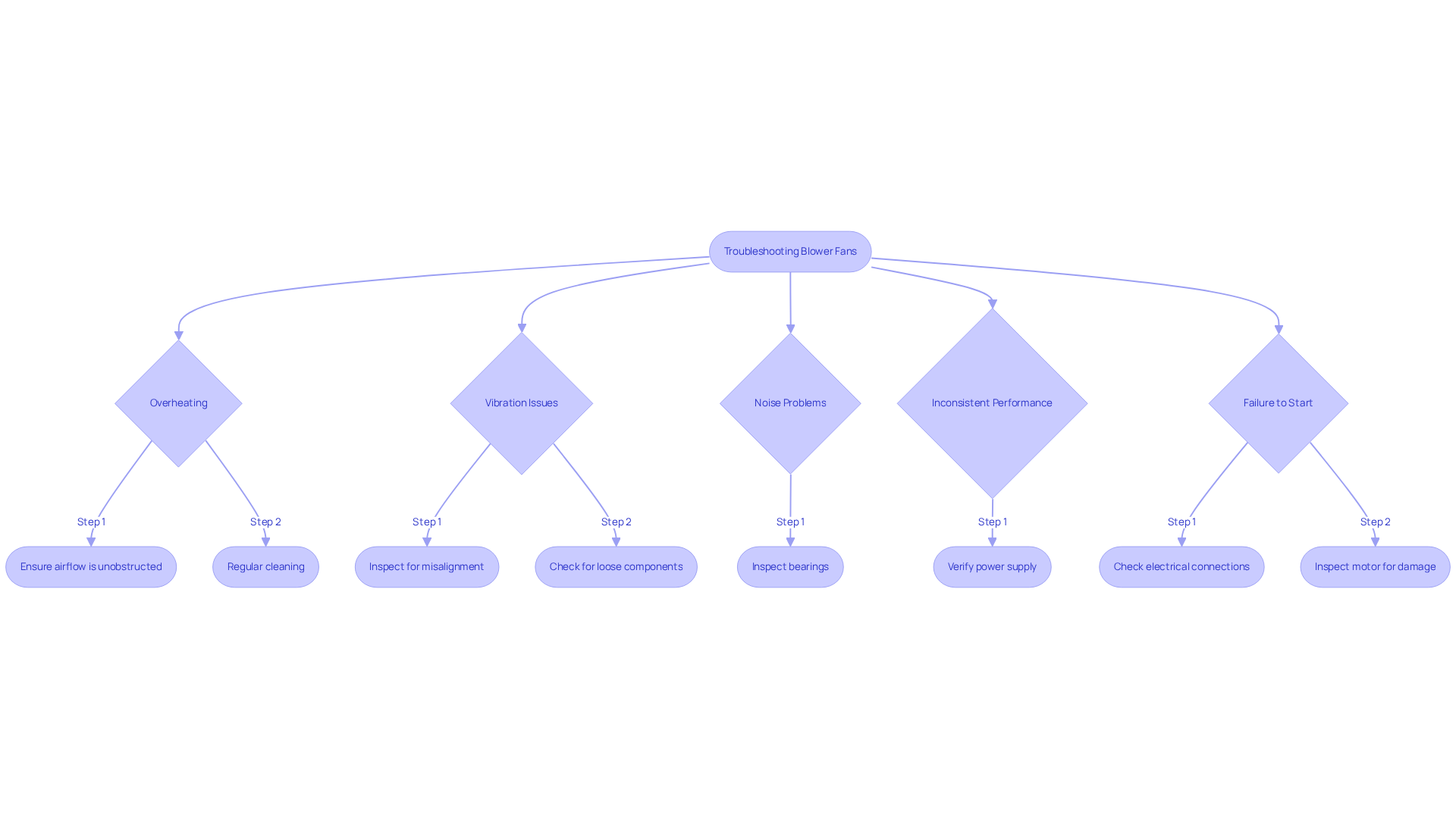

To maintain optimal performance of high-temperature blower fans, it is essential to follow these troubleshooting steps for common issues:

-

Overheating: Overheating is a prevalent issue, often caused by inadequate airflow or obstructions. Ensure that the fan is free from dust and debris, which can significantly impede performance. Regular cleaning can prevent overheating, a common problem that may lead to operational failures.

-

Vibration Issues: Excessive vibration, which can increase from a historical trend of 0.3 mils to 0.62 mils, may indicate misalignment or imbalance. Inspect the fan for loose components and ensure it is securely mounted. Addressing these issues promptly can reduce repair costs by distinguishing between repairable components and scrap, with potential reductions estimated at 50%.

-

Noise Problems: Unusual noises may signal bearing wear or foreign objects within the fan. Regular inspections and timely replacement of bearings can mitigate these issues, ensuring smooth operation.

-

Inconsistent Performance: If the fan exhibits inconsistent performance, verify the power supply and check for electrical issues. Ensure that the fan operates within its specified parameters to maintain efficiency.

-

Failure to Start: In cases where the fan fails to start, inspect electrical connections and the control system for functionality. Additionally, check the motor for any signs of damage. Regular maintenance and timely troubleshooting can greatly prolong the lifespan of your fan.

By implementing these strategies, engineers can enhance the reliability and efficiency of the high temperature blower fan, ultimately leading to improved operational performance.

Conclusion

High temperature blower fans are indispensable tools in various industrial applications, engineered to endure extreme conditions while ensuring efficiency and reliability. Selecting the appropriate fan necessitates a thorough understanding of its unique features, an evaluation of performance metrics, and an approach to common operational challenges. A well-informed choice can markedly enhance productivity and safety in environments where high temperatures are prevalent.

This article explores the essential aspects of high temperature blower fans, highlighting key features such as:

- High-temperature resistant materials

- Customizable solutions

It underscores the critical evaluation of performance metrics like:

- Airflow

- Static pressure

- Noise levels

Furthermore, addressing common issues such as:

- Overheating

- Vibration

can prevent operational failures and extend the lifespan of these vital components.

Ultimately, the significance of high temperature blower fans cannot be overstated. By prioritizing informed selection and proactive maintenance, engineers and facility managers can ensure optimal performance and reliability in their operations. Embracing advancements in blower fan technology and adhering to best practices will pave the way for enhanced efficiency and safety in demanding industrial environments.

Frequently Asked Questions

What are high temperature blower fans designed for?

High temperature blower fans are designed to operate in settings where temperatures can rise beyond typical limits, often reaching up to 1800°F.

What materials are used to construct high temperature blower fans?

They are typically made from high-temperature resistant materials such as stainless steel and specialized alloys to endure extreme conditions without compromising integrity.

What are some key design features of high temperature blower fans?

Key design features include ceramic seals, high-temperature guards, and shaft coolers, which enhance durability and operational efficiency.

In what applications are high temperature blower fans commonly used?

They are commonly used in industrial processes such as aluminum furnaces, annealing ovens, and other environments requiring efficient air circulation at high temperatures.

Why are high temperature blower fans important in industrial process manufacturing?

They are vital in industrial process manufacturing because they facilitate effective air and heat interaction, which is crucial for maintaining operational efficiency in extreme environments.

What advancements have been made in high temperature fan technology?

Recent advancements include customizable solutions that allow for the selection of various features based on operational requirements, enhancing performance and reliability.

How can operational safety be ensured when using high temperature blower fans?

Implementing temperature sensors on fan bearings can provide alerts if temperatures exceed safe limits, ensuring operational safety.