Introduction

Understanding the mechanics of large DC fans is crucial for engineers who seek to optimize electronic systems effectively. These devices not only convert electrical energy into efficient airflow but also provide significant benefits, including energy efficiency and quiet operation. However, as technology advances, the challenge for engineers is to select the appropriate type of DC fan and integrate it seamlessly into their designs. To harness the full potential of these fans while overcoming integration hurdles, engineers can employ targeted strategies that enhance performance and reliability.

Explore the Fundamentals of DC Fans

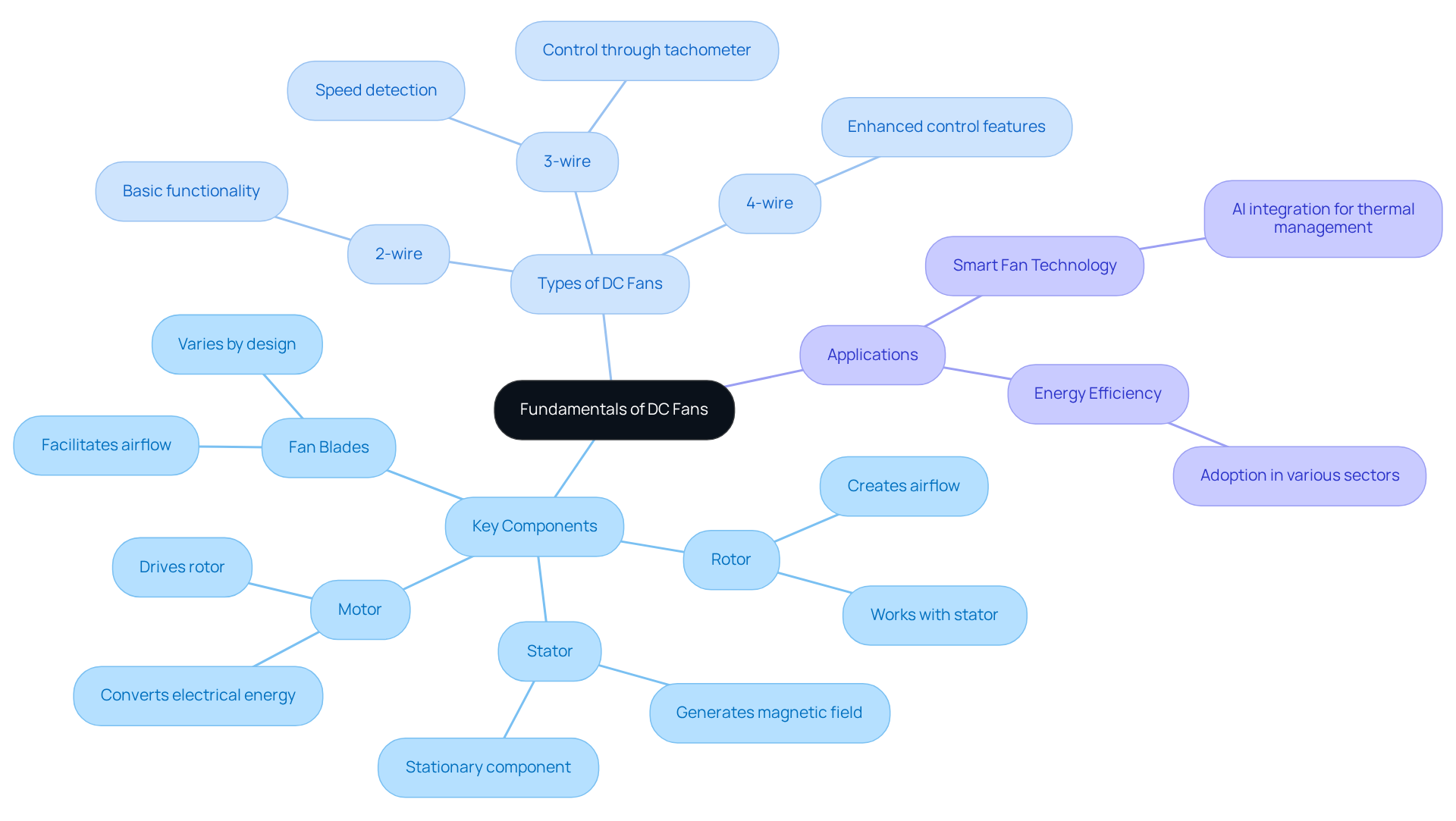

DC enthusiasts, or direct current devices, play a crucial role in converting electrical energy into mechanical energy, generating airflow effectively. These devices consist of several key components: the rotor, stator, motor, and fan blades. The rotor rotates to create airflow, working in tandem with the stationary stator, which generates the magnetic field essential for the rotor’s movement. Operating on the principle of electromagnetic induction, DC devices utilize direct current to establish a magnetic field that drives the rotor’s rotation.

Understanding the various types of large DC fans, including 2-wire, 3-wire, and 4-wire configurations, is vital for engineers. Each type offers distinct functionalities; for instance, 3-wire and 4-wire devices provide additional features like speed detection and control through a tachometer wire. This foundational knowledge is critical for selecting the appropriate large DC fan for specific applications, ensuring optimal performance in electronic systems.

Case studies highlight the practical applications of DC blowers across various sectors. For example, advancements in smart fan technology have integrated AI for enhanced thermal management in data centers, optimizing cooling operations. Furthermore, the increasing demand for energy-efficient solutions has led to a greater adoption of brushless DC units, known for their superior energy efficiency and extended lifespan compared to conventional models. As the market evolves, engineers must remain informed about these developments to fully leverage the potential of direct current devices in their designs.

Evaluate the Benefits of DC Fans in Electronics

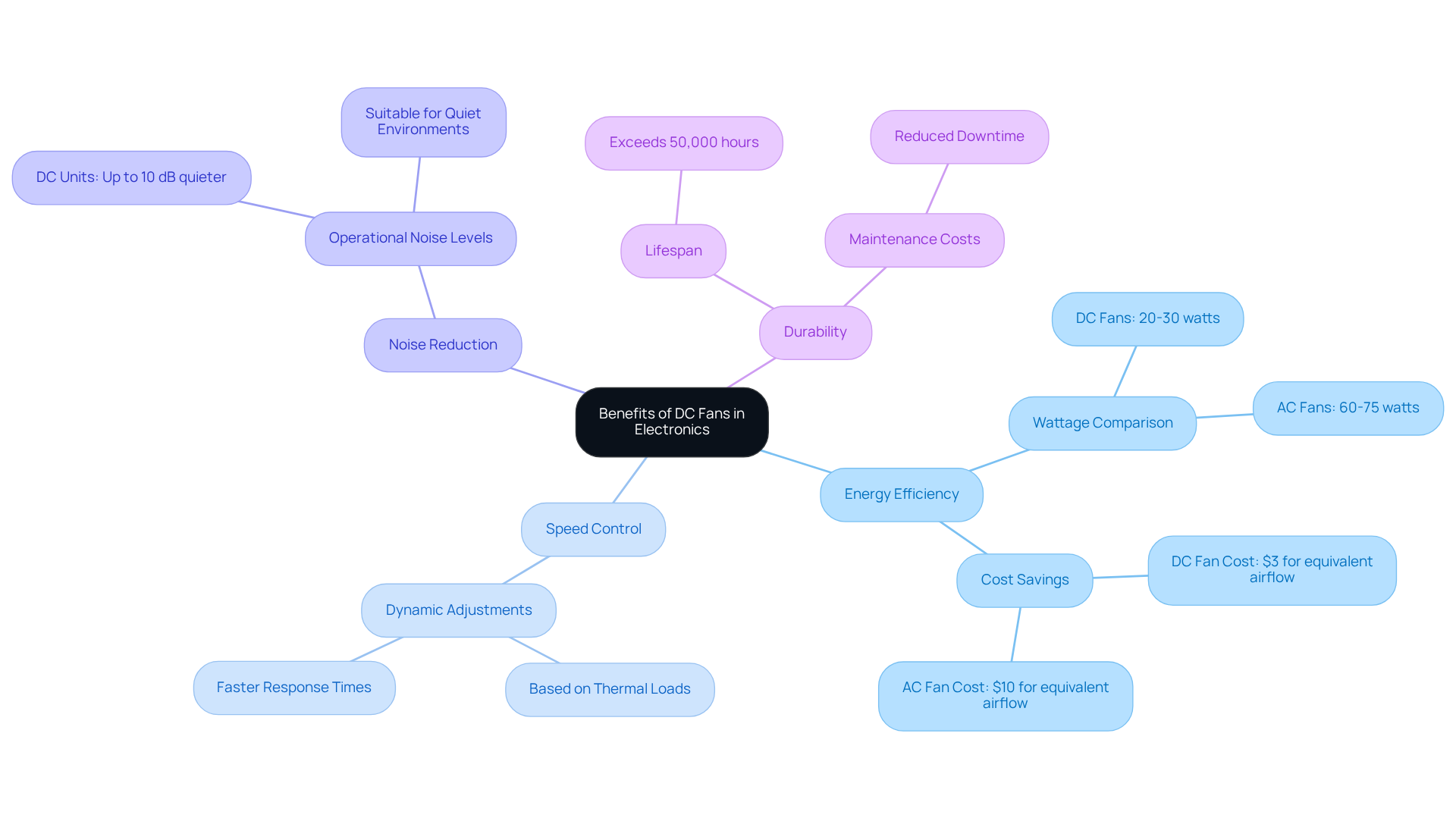

DC enthusiasts recognize the numerous benefits that make DC devices a preferred choice in electronic applications. One of the most significant advantages is their energy efficiency. DC devices typically consume between 20-30 watts, which is up to 70% less power than their AC counterparts, which generally use 60-75 watts. This substantial difference translates into significant cost savings on electricity bills.

Moreover, DC devices offer superior speed control, allowing for dynamic adjustments based on thermal loads. This capability enhances overall system performance, making them more adaptable to varying operational demands. Noise reduction is another critical benefit; DC units operate more quietly due to their brushless motor design, achieving noise reductions of up to 10 dB compared to standard AC devices. This feature makes them particularly suitable for environments where sound levels are a concern.

Furthermore, the durability of DC devices is noteworthy. With lifespans often exceeding 50,000 hours, they significantly reduce maintenance costs and downtime. These advantages collectively enhance the reliability and efficiency of electronic devices, establishing DC motors as a vital component in contemporary engineering designs.

In conclusion, the energy efficiency, speed control, noise reduction, and durability of DC devices not only improve performance but also contribute to long-term cost savings and operational effectiveness. For engineers and decision-makers, integrating DC technology into designs is not just beneficial; it is essential for advancing modern electronic applications.

Implement and Integrate DC Fans in Electronic Systems

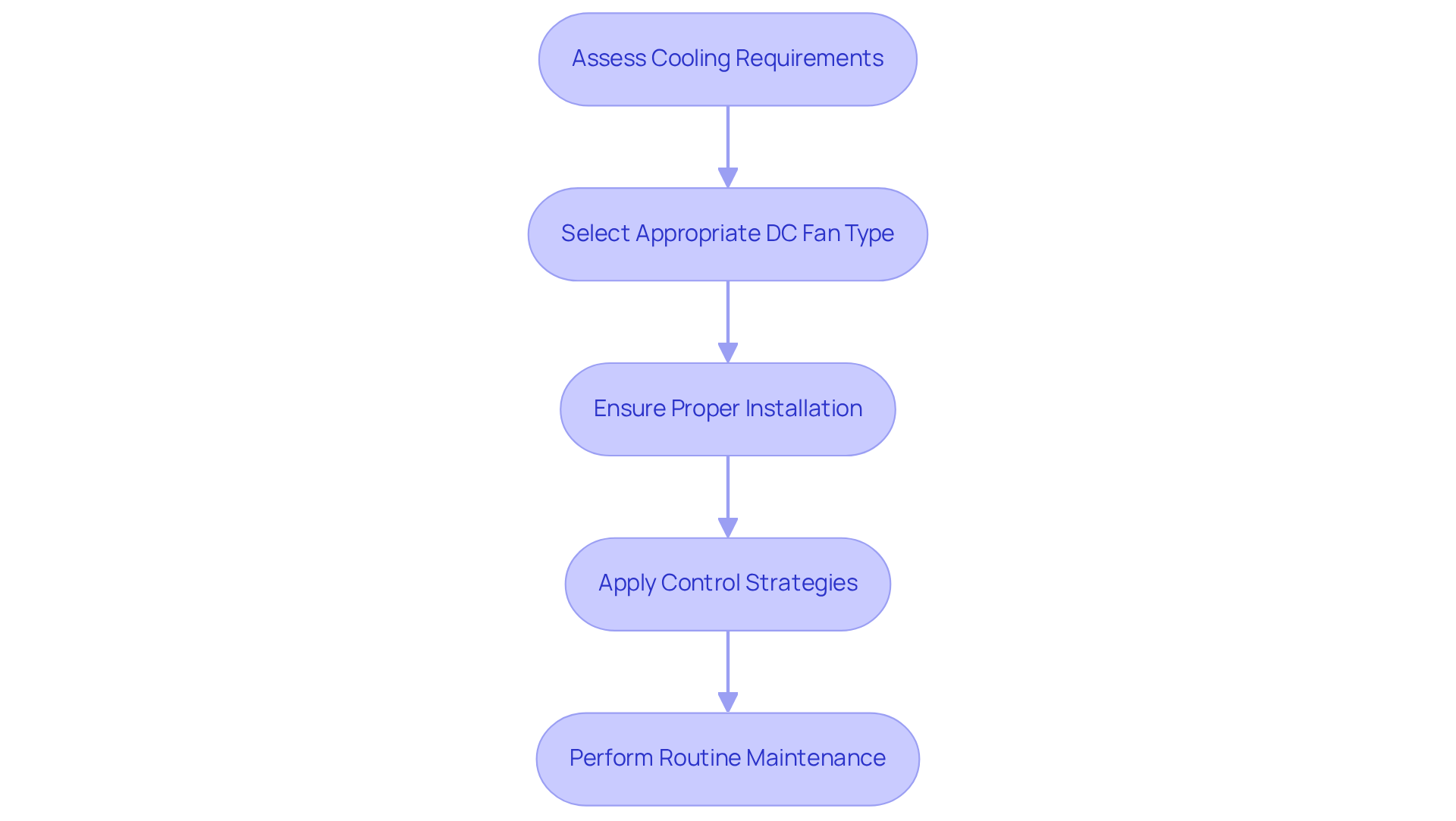

Incorporating DC airflow devices into electronic systems requires a systematic approach to ensure optimal performance. Engineers must first assess the cooling requirements of their specific applications, considering factors such as heat generation, airflow needs, and spatial constraints. Excess heat can lead to equipment malfunction and increased operational costs, making effective temperature regulation crucial for preventing material aging and ensuring device longevity. Notably, the global cooling market is projected to grow by nearly 14% annually, underscoring the increasing importance of efficient cooling solutions.

Once cooling requirements are established, selecting the appropriate type of DC fan becomes essential. A 4-wire fan is ideal for applications needing precise speed control, while a simpler 2-wire fan may suffice for less demanding setups. Proper installation is equally important; fans should be strategically positioned to maximize airflow across heat-generating components, minimizing obstructions that could impede performance.

Applying control strategies, such as pulse width modulation (PWM), can significantly enhance fan performance by adjusting speed based on current thermal conditions. This technology enables savings of up to 20% in overall consumption, making it a favored option among engineers. Furthermore, DC fans are recognized for using up to 70% less energy compared to AC models, highlighting their energy efficiency and quieter operation.

Routine maintenance inspections are essential to ensure that ventilators function efficiently over time. Addressing issues such as dust buildup or mechanical wear can extend the longevity of the devices, which often exceed 20,000 hours in challenging environments. For instance, a DC fan unit installed in Southeast Asia operated flawlessly for over ten years, demonstrating the reliability of these devices. By following these steps, engineers can successfully integrate DC fans into their designs, ensuring reliable cooling and improved system performance, ultimately contributing to the sustainability objectives of modern electronic systems.

Conclusion

Mastering the complexities of large DC fans is crucial for engineers aiming to elevate their electronic systems. These devices not only convert electrical energy into mechanical energy with remarkable efficiency but also provide a host of advantages that render them essential in contemporary applications. By grasping the fundamentals, benefits, and integration strategies of DC fans, engineers can make informed decisions that significantly enhance performance and efficiency.

Key points throughout this discussion include the operational principles of DC fans, their various types, and the substantial benefits they offer – such as energy efficiency, superior speed control, and durability. Moreover, the importance of proper integration techniques was emphasized, including the assessment of cooling requirements and the application of control strategies like pulse width modulation. Collectively, these insights underscore the pivotal role that DC fans play in bolstering the reliability and functionality of electronic systems.

Given these considerations, engineers are strongly encouraged to harness the potential of large DC fans in their designs. By capitalizing on their energy efficiency and advanced features, it is feasible to lower operational costs and enhance overall system performance. As the demand for innovative cooling solutions continues to escalate, staying abreast of the latest advancements in DC fan technology will be vital for driving progress in the field of electronics.

Frequently Asked Questions

What are DC fans and their primary function?

DC fans, or direct current devices, convert electrical energy into mechanical energy to generate airflow effectively.

What are the key components of a DC fan?

The key components of a DC fan include the rotor, stator, motor, and fan blades.

How does the rotor in a DC fan function?

The rotor rotates to create airflow, working in conjunction with the stationary stator, which generates the magnetic field necessary for the rotor’s movement.

What principle do DC devices operate on?

DC devices operate on the principle of electromagnetic induction, using direct current to establish a magnetic field that drives the rotor’s rotation.

What are the different types of large DC fans?

The different types of large DC fans include 2-wire, 3-wire, and 4-wire configurations.

What functionalities do 3-wire and 4-wire DC fans offer?

3-wire and 4-wire DC fans provide additional features such as speed detection and control through a tachometer wire.

Why is it important for engineers to understand DC fan configurations?

Understanding the various configurations is critical for selecting the appropriate large DC fan for specific applications, ensuring optimal performance in electronic systems.

How are DC blowers applied in various sectors?

DC blowers are used in various sectors, with advancements in smart fan technology integrating AI for enhanced thermal management in data centers, optimizing cooling operations.

What trend is driving the adoption of brushless DC units?

The increasing demand for energy-efficient solutions is leading to greater adoption of brushless DC units, which offer superior energy efficiency and a longer lifespan compared to conventional models.

Why must engineers stay informed about developments in DC fan technology?

Engineers must remain informed about developments to fully leverage the potential of direct current devices in their designs and applications.