Overview

The article presents a comprehensive step-by-step guide tailored for electronics engineers on the effective mounting of fans. It meticulously details the various types of fans, the necessary tools, mounting instructions, and troubleshooting tips. This guidance is underpinned by clear categorizations of fan types alongside their applications, supplemented with practical advice on installation and common issues. Such thoroughness ensures that engineers can achieve optimal performance and efficiency in their projects.

Introduction

Understanding the intricacies of fan mounting is essential for electronics engineers who aim to optimize cooling solutions in their designs. This comprehensive guide captures your attention by delving into the various types of fans, from axial to centrifugal, and highlighting their specific applications along with the tools needed for installation.

As we build interest, consider this: what happens when the installation doesn’t go as planned? By exploring common challenges and troubleshooting techniques, this article not only equips engineers with the knowledge to mount fans effectively but also prepares them to tackle any issues that may arise in the process.

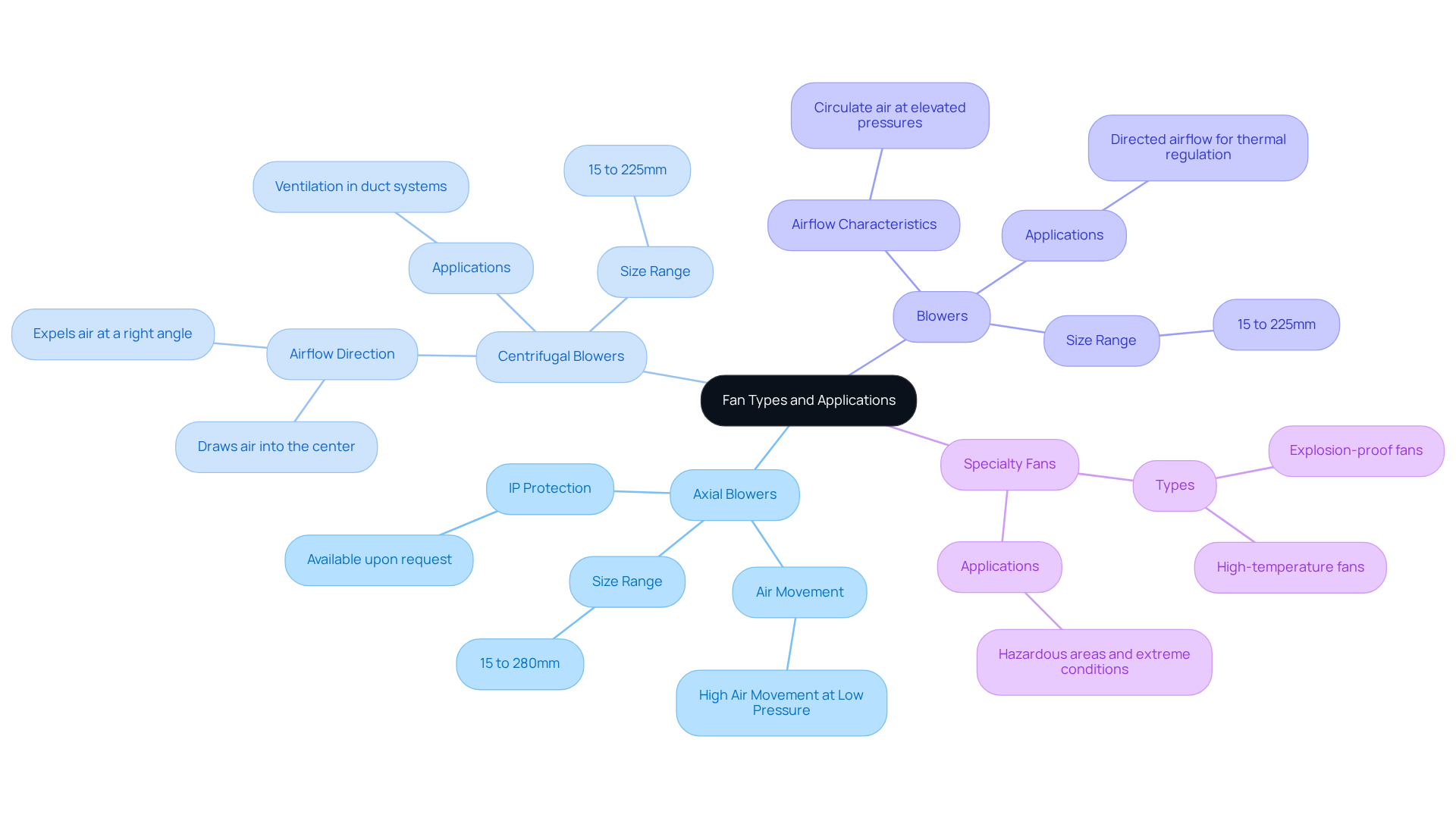

Understand Fan Types and Their Applications

Before mounting fans, it is crucial to comprehend the and their specific applications, particularly those offered by Gagner-Toomey Associates, a prominent provider of for electronics and beyond.

- Axial Blowers: These devices are designed to move air parallel to the axis of the unit. Gagner-Toomey’s , available in dimensions ranging from 15 to 280mm, are optimized for performance and efficiency, making them ideal for applications requiring , such as cooling electronic components in enclosures. Notably, most models can be equipped with IP protection upon request.

- : These blowers draw air into the center and expel it at a right angle, generating higher pressure. They excel in applications where ventilation must overcome resistance, such as in duct systems, and are offered in a variety of sizes from 15 to 225mm to cater to diverse needs.

- Blowers: Similar to centrifugal units, these blowers are engineered to circulate air at elevated pressures and are frequently employed in scenarios requiring directed airflow, thereby providing reliable options for thermal regulation. Their sizes also span from 15 to 225mm.

- Specialty Fans: Gagner-Toomey further provides specialty fans tailored for specific environments, including explosion-proof fans for hazardous areas and high-temperature fans for extreme conditions, ensuring safety and efficiency in challenging applications.

Understanding these types of mounting fans will empower you to select the appropriate fan for your project, thereby ensuring with Gagner-Toomey’s comprehensive portfolio.

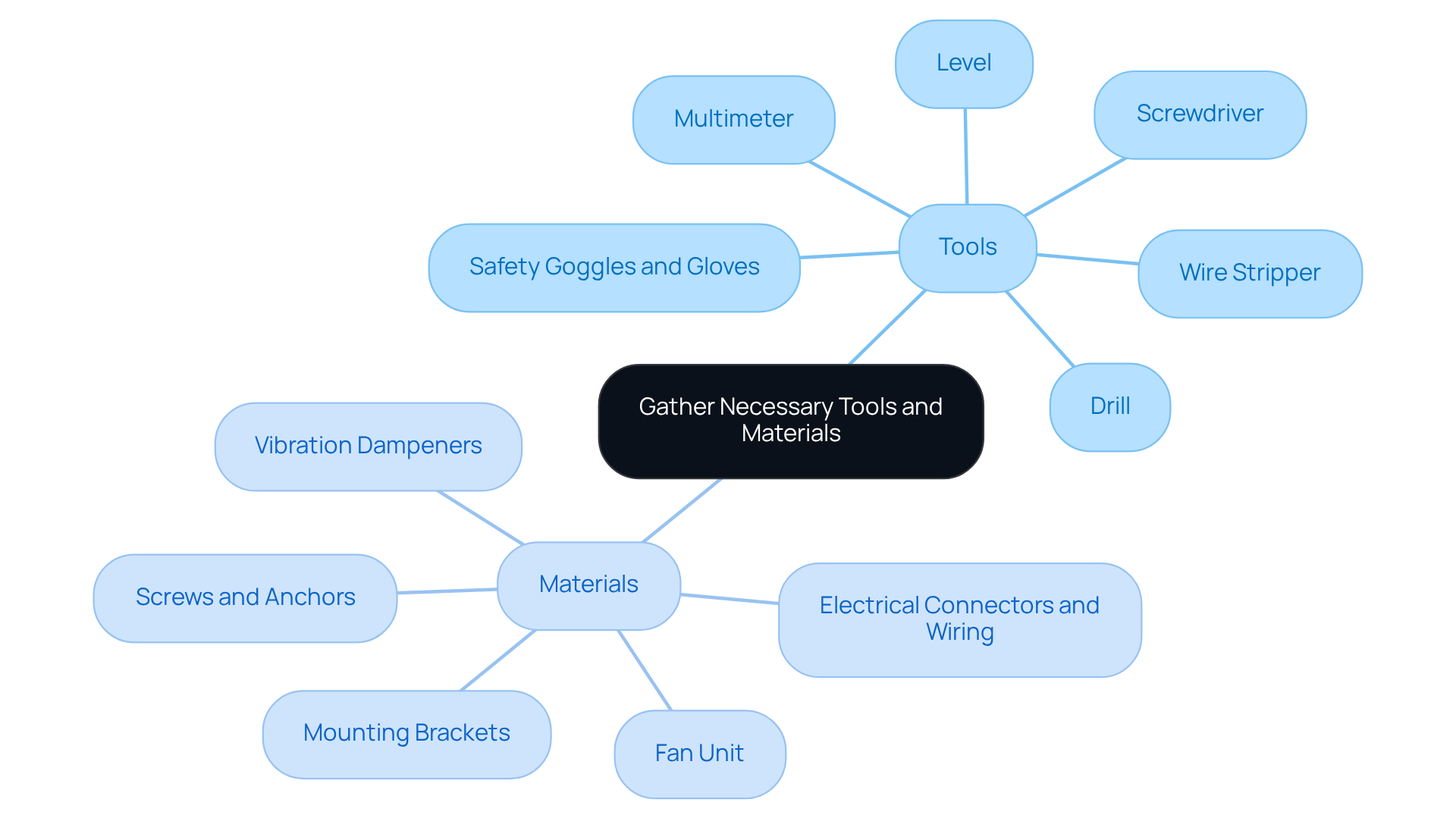

Gather Necessary Tools and Materials

To successfully mount a fan, it is and materials:

Tools:

- Screwdriver (Phillips and flathead)

- Drill with appropriate bits

- Level

- Wire stripper

- Multimeter (for electrical checks)

Materials:

- (ensure it matches your specifications)

- (specific to the fan type)

- Screws and anchors (if necessary)

- Electrical connectors and wiring (if applicable)

- Vibration dampeners (to reduce noise)

Having these items ready will and .

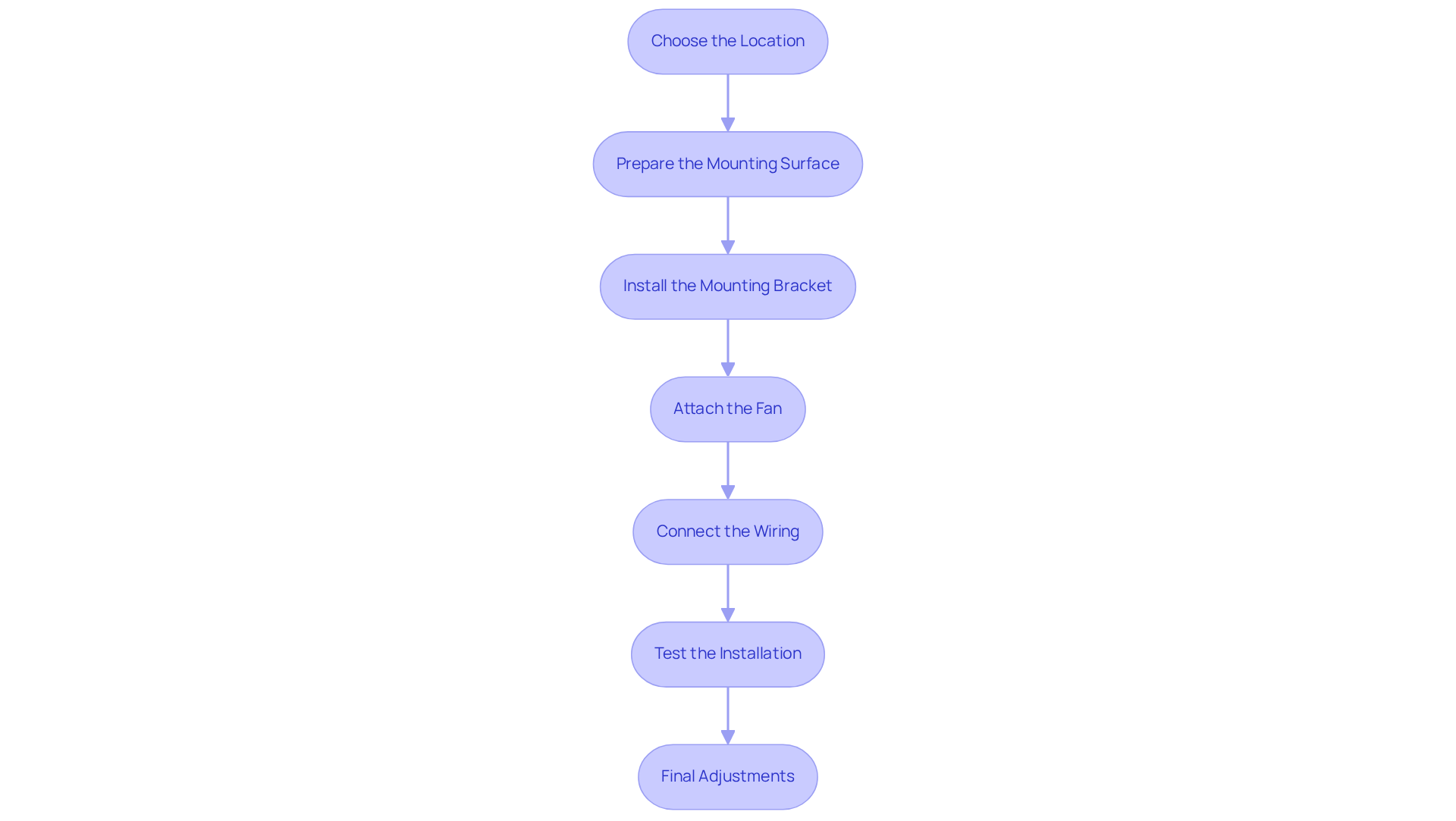

Follow Step-by-Step Mounting Instructions

To successfully mount your fan, follow these detailed instructions:

- Choose the Location: Begin by identifying the . Consider factors such as airflow direction and proximity to heat sources to ensure maximum efficiency.

- Prepare the Mounting Surface: Next, ensure that the surface is . If necessary, reinforce the area to adequately support the , which is crucial for a stable installation.

- Install the : Proceed by installing the mounting bracket. Use a level to verify that the bracket is straight. Secure it with screws, ensuring it is tightly fastened to prevent any vibrations during operation.

- Attach the Fan: Align the fan with the mounting bracket and secure it using the provided screws. It is essential that the fan is firmly attached to avoid any movement that could affect performance.

- Connect the Wiring: If the fan requires , follow the manufacturer’s wiring diagram closely. Utilize a multimeter to , ensuring safety and functionality.

- Test the Installation: After securing everything, turn on the power to . Confirm that it operates correctly while checking for any unusual noises or vibrations that may indicate issues.

- Final Adjustments: Finally, if necessary, make adjustments to the fan’s position or wiring to optimize its performance. This step is vital for achieving the best results from your installation.

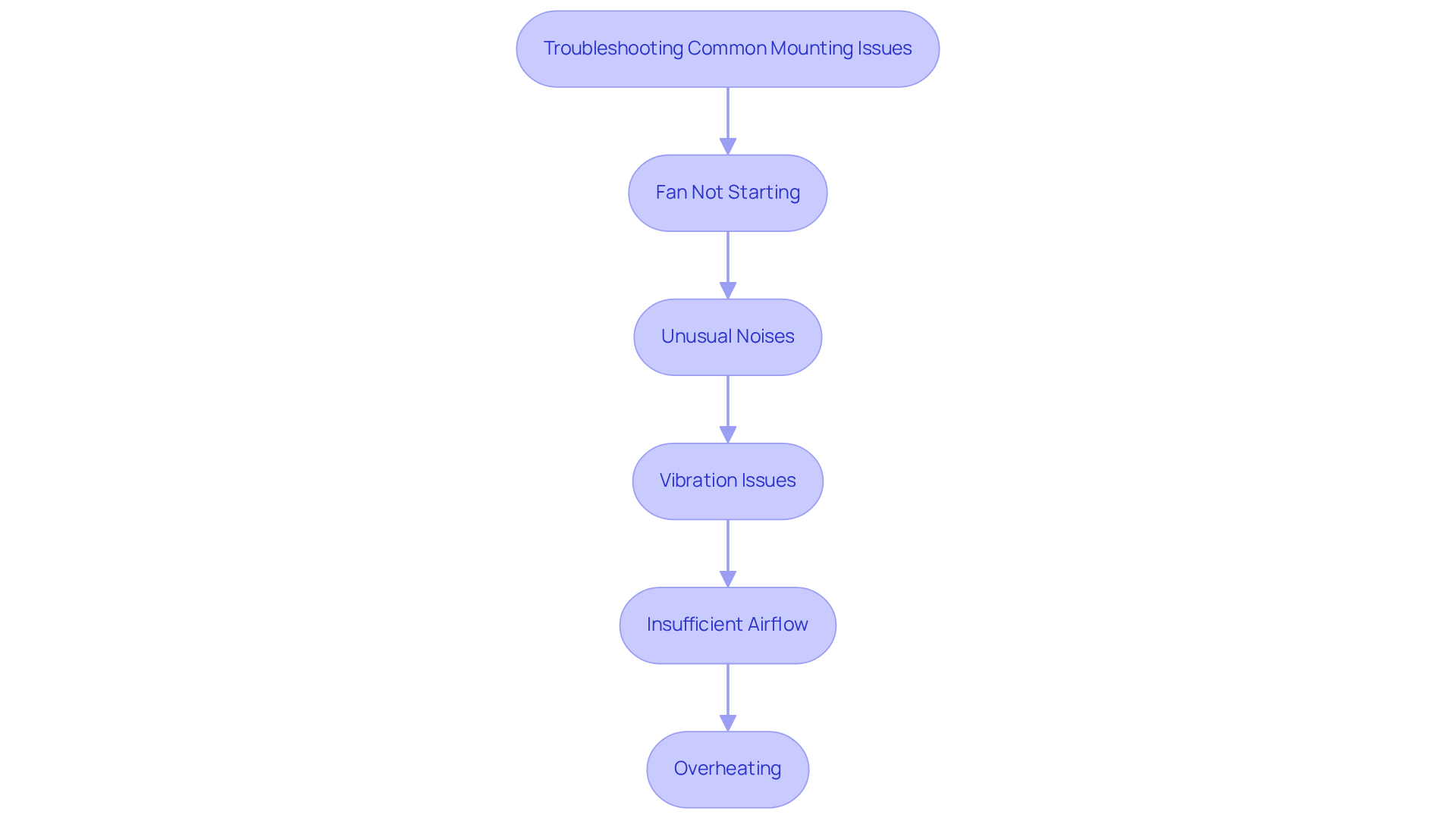

Troubleshoot Common Mounting Issues

If you encounter issues during the mounting process, consider the following troubleshooting tips:

- Fan Not Starting: Begin by checking the and ensuring all connections are secure. Utilize a multimeter to at the fan terminals.

- Unusual Noises: Should the fan produce , inspect for loose screws or misalignment. Tighten any loose components and ensure that the fan is level.

- Vibration Issues: In cases of excessive vibration, confirm that the are secured properly. Implement to minimize noise.

- : If the fan fails to provide adequate airflow, verify its installation orientation and check for any obstructions in the airflow path.

- Overheating: If the fan becomes excessively hot, examine the electrical connections and ensure it is not overloaded. If necessary, consider utilizing a fan with a .

By following these troubleshooting steps, you can effectively resolve common issues and ensure your fan operates efficiently.

Conclusion

Understanding the intricacies of mounting fans is essential for electronics engineers aiming to optimize cooling solutions in their projects. This guide details the various types of fans, including axial and centrifugal blowers, and highlights their specific applications, ensuring that engineers can make informed choices tailored to their needs.

Key points covered include:

- The importance of selecting the right fan type

- Gathering necessary tools and materials

- Following a structured step-by-step installation process

Troubleshooting common issues such as noise, vibration, and airflow problems has also been addressed, equipping engineers with the knowledge to ensure their installations are successful and efficient.

Ultimately, mastering the art of fan mounting not only enhances the performance of electronic devices but also contributes to their longevity and reliability. By employing the best practices outlined in this guide, engineers can ensure optimal thermal management in their designs, paving the way for innovative solutions that meet the demands of modern electronics. Embrace these techniques and elevate your projects to new heights of efficiency and effectiveness.

Frequently Asked Questions

What are the different types of fans offered by Gagner-Toomey Associates?

Gagner-Toomey Associates offers several types of fans, including Axial Blowers, Centrifugal Blowers, Blowers, and Specialty Fans.

What are Axial Blowers and their applications?

Axial Blowers move air parallel to the axis of the unit and are optimized for performance and efficiency. They are ideal for applications requiring high air movement at low pressure, such as cooling electronic components in enclosures.

What sizes are available for Axial Blowers?

Axial Blowers are available in sizes ranging from 15 to 280mm.

What are Centrifugal Blowers and when are they used?

Centrifugal Blowers draw air into the center and expel it at a right angle, generating higher pressure. They are ideal for applications where ventilation must overcome resistance, such as in duct systems.

What sizes do Centrifugal Blowers come in?

Centrifugal Blowers are offered in sizes from 15 to 225mm.

How do Blowers differ from Centrifugal Blowers?

Blowers are similar to centrifugal units but are specifically engineered to circulate air at elevated pressures and are often used for directed airflow, providing reliable thermal regulation.

What sizes are available for Blowers?

Blowers are available in sizes ranging from 15 to 225mm.

What are Specialty Fans and their specific uses?

Specialty Fans are tailored for specific environments, including explosion-proof fans for hazardous areas and high-temperature fans for extreme conditions, ensuring safety and efficiency in challenging applications.

Why is it important to understand the types of fans before mounting them?

Understanding the types of fans helps in selecting the appropriate fan for a project, ensuring optimal performance and efficiency.