Overview

Mastering PWM control is essential for electronics engineers, as it facilitates efficient power management and precise control of devices such as motors and LEDs. PWM’s ability to adjust the duty cycle is a critical feature that enables effective regulation of power delivery. This capability enhances energy efficiency and minimizes heat production across various applications, making it increasingly important in the context of modern electronic design.

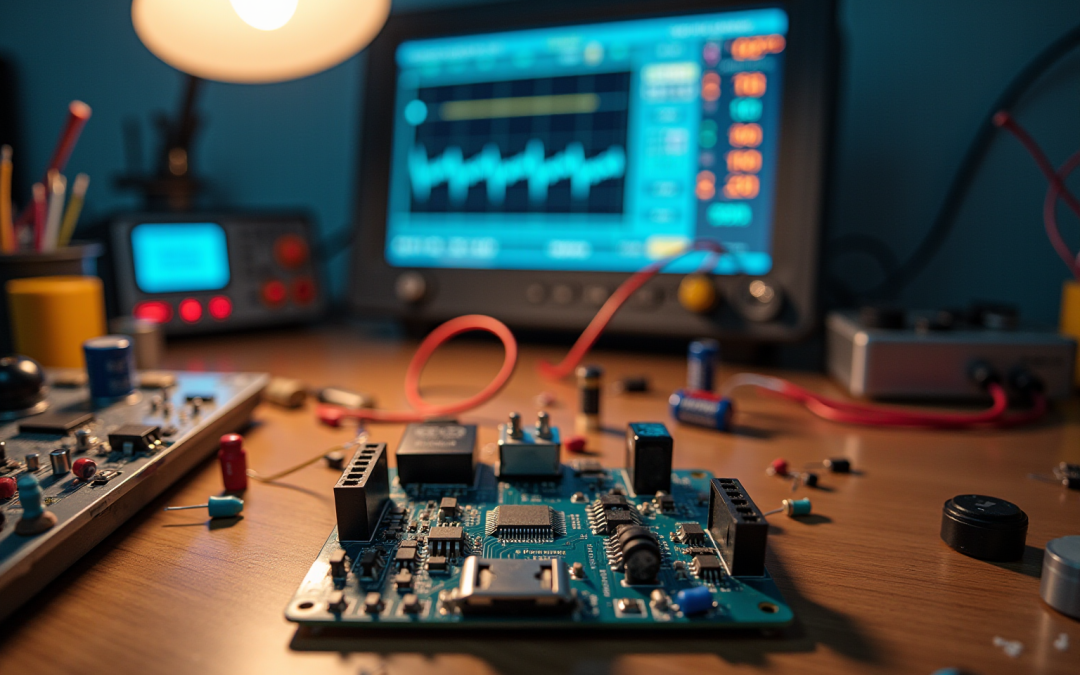

Introduction

In the rapidly evolving landscape of electronics, Pulse Width Modulation (PWM) emerges as a transformative technique that is fundamentally reshaping device operation. By varying the width of pulses, PWM facilitates precise control over power delivery, rendering it essential for a diverse array of applications, from motor control to LED dimming.

Its importance is magnified in an era where energy efficiency is crucial, particularly within sectors such as consumer electronics and automotive, where the demand for sustainable solutions continues to escalate. As technology progresses, the integration of PWM expands, highlighting its critical role in optimizing performance and enhancing the reliability of modern electronic systems.

This article explores the mechanics of PWM, its practical applications, and provides a comprehensive guide for engineers eager to implement this vital technique in their designs.

Define Pulse Width Modulation (PWM) and Its Importance in Electronics

Pulse Width Modulation (PWM) control stands as a pivotal technique in electronics, encoding the amplitude of a signal through the variation of pulse width. This method is essential for PWM control to manage power delivery to devices such as motors and LEDs, facilitating precise adjustments to the signal’s duty cycle. The significance of PWM control is underscored by its ability to enhance efficiency and effectively regulate power usage, thereby minimizing heat production and enabling meticulous management of electronic components.

By using PWM control to manipulate pulse width, engineers can control the average power supplied to a load without the need for complex analog circuitry. This simplicity positions PWM control as a preferred method across a wide range of applications, including motor control, lighting, and heating systems. Recent advancements in PWM control technology have broadened its capabilities, particularly in power management, where it plays a crucial role in optimizing energy efficiency.

As we look towards 2025, the trend of integrating PWM control into electronic systems is on the rise, propelled by the growing demand for energy-efficient solutions in sectors such as consumer electronics and automotive. Recent statistics reveal that the SMPS market is significantly shaped by the rapid industrialization in the Asia Pacific region, which commands a substantial share due to the demands from consumer electronics and automotive sectors. This trend highlights the critical role of PWM control in addressing the needs of these rapidly industrializing economies. Furthermore, a prominent participant in the defense sector noted, “We were very satisfied to engage with them as they customized reports exactly according to our needs,” emphasizing the necessity for high precision and considerable quality in PWM applications.

With an increasing emphasis on compliance and quality, the application of PWM control is evolving in sophistication, reflecting the dynamic landscape of electronics engineering. The recent launch of new multi-range DC power supplies by B&K Precision exemplifies how advancements in PWM control technology are being developed in response to the escalating demand for energy-efficient solutions.

Explain the Technical Mechanism of PWM: How It Works

PWM control functions by rapidly toggling a digital signal between high and low states at a defined frequency. The two primary parameters of PWM control are the signal frequency and the duty ratio. The duty ratio represents the percentage of time the signal remains in the high state during one complete cycle. For instance, a 50% duty ratio indicates that the signal is high for half the duration and low for the other half. The frequency of the PWM signal governs the speed of these transitions, directly affecting the system’s responsiveness.

By adjusting the duty cycle through PWM control, engineers can efficiently manage the average voltage and current delivered to a load, which is crucial for effective power management. This capability proves particularly advantageous in scenarios requiring precise power delivery, such as motor speed control and LED dimming. Recent developments in PWM control technology underscore its versatility, enabling integration with tachometer feedback systems to enhance thermal management in DC fans. This synergy not only boosts cooling efficiency but also adapts to fluctuating thermal demands, illustrating the practical advantages of PWM in real-world applications.

Grasping the technical workings of PWM control is essential for electronics engineers, as it empowers them to optimize performance across diverse applications. Gagner-Toomey Associates has supported 32 countries and over 400 clients in the past 17 years, showcasing their extensive expertise in the field. As Annie Chan, Account Manager of CCHV and EAGLE fan, articulates, “The purpose of this article is to share knowledge related to DC fans for optimizing your thermal solutions.” Recent research indicates that fine-tuning PWM control frequency and duty cycle can yield substantial enhancements in system efficiency and responsiveness, establishing PWM control as a critical tool in contemporary electronics. Moreover, while PWM regulation can function without a tachometer, it limits the ability to measure actual fan speed, a vital consideration for engineers. A case study on the integration of PWM control and tachometer feedback reveals that combining these technologies facilitates accurate speed regulation and improved cooling efficiency, adapting to varying thermal requirements.

Explore Practical Applications of PWM in Electronics Design

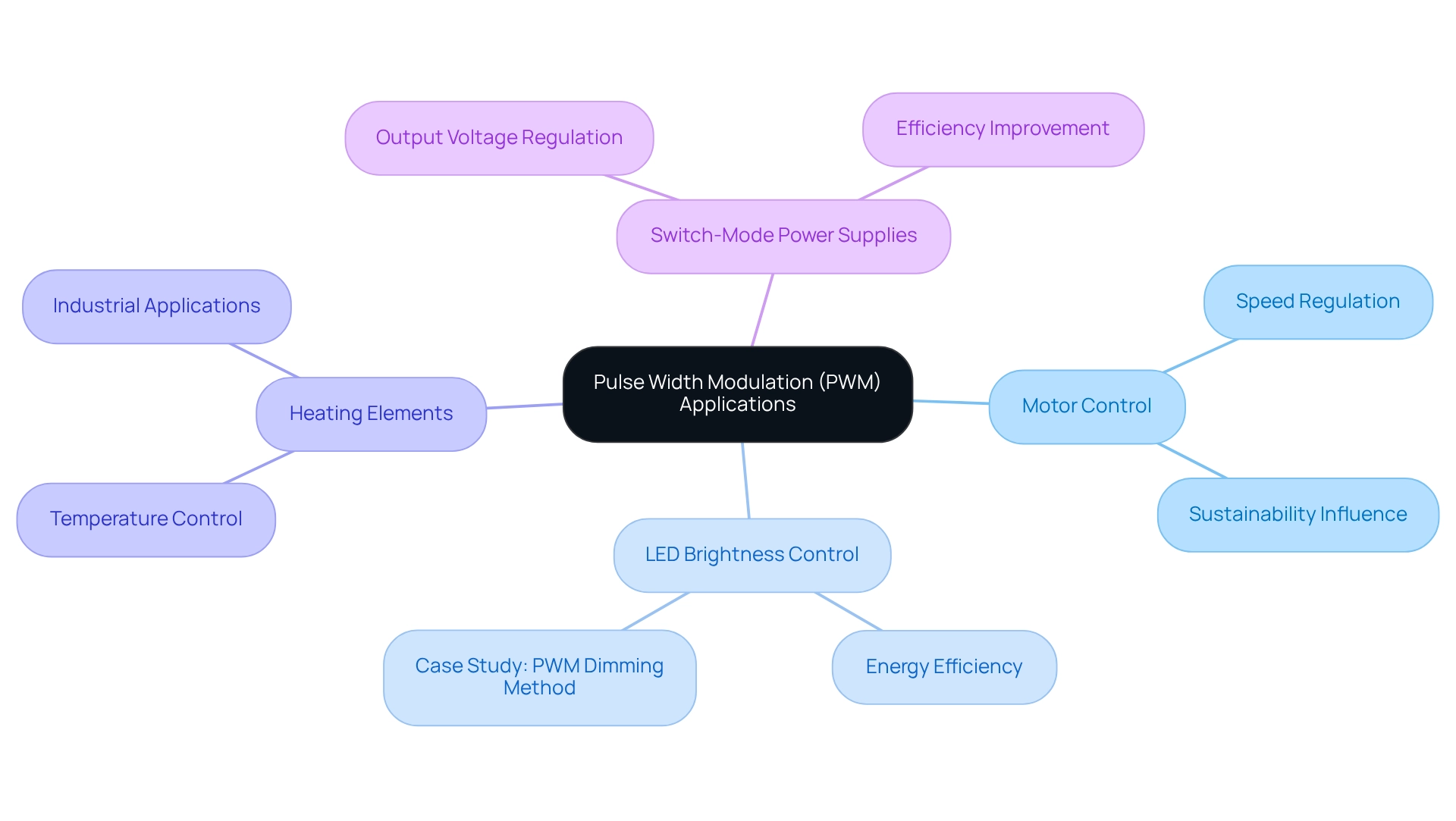

PWM control is integral to numerous applications in electronics design, showcasing its versatility and efficiency.

- Motor Control: PWM control is extensively utilized to regulate the speed of DC motors by modulating the average voltage supplied. This approach enables smooth acceleration and deceleration, rendering it vital in robotics and automation, where accurate motor management is crucial. Recent statistics indicate that the global drive toward sustainability significantly influences the development of environmentally friendly motor technology, further emphasizing the importance of PWM control in this sector.

- By adjusting the duty cycle of the PWM control signal, engineers can effectively manage LED brightness. This technique not only enhances energy efficiency but also contributes to longer lifespans for lighting solutions, as evidenced by its widespread adoption in modern energy-efficient lighting systems. The case study titled ‘Pulse Width Modulation (PWM) Dimming Method’ illustrates the effectiveness of PWM control in dimming LEDs, offering a concrete example of its use.

- Additionally, PWM control is crucial in regulating the power supplied to heating elements, ensuring accurate temperature control in applications such as soldering and heating pads. This capability is essential for maintaining optimal performance in various industrial processes. Recent advancements in PWM control technology have broadened its uses in this area, reflecting ongoing innovation.

- In switch-mode power supplies, PWM control is employed to regulate output voltage and current, significantly improving efficiency and minimizing heat generation. This tool is especially pertinent in the context of the global drive for sustainable technology, as it facilitates the advancement of eco-friendly power solutions, particularly through PWM control, which is also utilized for generating audio signals and managing devices in communication systems.

- Its adaptability across different fields underscores its importance in contemporary electronics design, especially as recent advancements in PWM control technology continue to foster innovation, with applications expanding into new areas like heating elements and power supplies, illustrating the ongoing evolution of this vital regulation method.

Guide to Implementing PWM Control: Step-by-Step Instructions

Implementing PWM control in your electronic project involves several key steps:

- Select the PWM Frequency: Identify the appropriate frequency for your use case. Frequencies typically range from a few hundred Hz to several kHz, influenced by the load type and the desired response time.

- Choose a Microcontroller or PWM Controller: Opt for a microcontroller or dedicated PWM controller that can support your selected frequency and has enough output channels for your needs. Notably, microcontrollers like the Teensy 3.6 can implement Ethernet using a special shield, enhancing connectivity options for your projects.

- Configure the PWM Output: In your microcontroller’s firmware, set up the PWM output by configuring timers and defining the duty ratio for the PWM signal. Consider the FSEC setting, which can be edited for applications requiring code secrecy or security, to ensure your implementation is secure.

- Connect the Load: Wire the load—such as a motor or LED—to the PWM output pin, ensuring the circuit can handle the load’s current and voltage requirements.

- Test the PWM Control: Utilize an oscilloscope to verify the frequency and duty ratio of the PWM control signal, making adjustments as needed to meet performance expectations.

- Implement Control Logic: Develop the control logic in your firmware to dynamically adjust the duty cycle based on user input or sensor feedback, allowing for responsive load control.

- Monitor and Optimize: Continuously assess the performance of your system with PWM control, making necessary adjustments to enhance efficiency and responsiveness.

In 2025, best practices for selecting PWM frequency emphasize understanding the specific requirements of your application, including load characteristics and desired performance outcomes. The C2000Ware for C2000 microcontrollers provides a robust software package that aids in reducing development time, offering device-specific drivers and libraries that support efficient PWM control. Additionally, the C28x/CLA Compiler Qualification Kit assists customers in qualifying their use of the TI C28x/CLA C/C++ Compiler to functional safety standards such as IEC 61508, ISO 26262, and EN 50657. By leveraging these resources and insights, engineers can ensure their projects are both effective and innovative.

Conclusion

The exploration of Pulse Width Modulation (PWM) underscores its essential role in contemporary electronics, driven by its capacity to provide precise control over power management. By varying the pulse width, engineers can optimize performance across a spectrum of applications, from motor control to LED dimming, all while enhancing energy efficiency and minimizing heat generation. As industries increasingly gravitate towards sustainable solutions, the demand for PWM technology continues to escalate, underscoring its significance across diverse sectors, including consumer electronics and automotive.

A comprehensive understanding of the technical mechanics of PWM, particularly the significance of duty cycle and frequency, equips engineers with the necessary tools to implement this technology effectively. The versatility of PWM is further exemplified through its practical applications in heating elements, power supplies, and signal generation. Each application not only highlights how PWM enhances efficiency but also contributes to the longevity and reliability of electronic systems.

Implementing PWM control necessitates meticulous planning and execution, encompassing the selection of the appropriate frequency and the configuration of control logic. By adhering to structured guidelines, engineers can fully harness the potential of PWM in their designs, ensuring their projects align with the evolving demands of the electronics landscape. As technology continues to advance, the role of PWM will undoubtedly broaden, reinforcing its status as a crucial technique in the relentless pursuit of innovation and energy efficiency.

Frequently Asked Questions

What is Pulse Width Modulation (PWM) control?

Pulse Width Modulation (PWM) control is a technique in electronics that encodes the amplitude of a signal by varying the pulse width. It is essential for managing power delivery to devices such as motors and LEDs, allowing for precise adjustments to the signal’s duty cycle.

Why is PWM control significant in electronics?

PWM control enhances efficiency and regulates power usage, minimizing heat production and enabling meticulous management of electronic components. It simplifies the control of average power supplied to a load without the need for complex analog circuitry.

In which applications is PWM control commonly used?

PWM control is commonly used in various applications, including motor control, lighting, and heating systems.

How has recent technology impacted PWM control?

Recent advancements in PWM control technology have broadened its capabilities, particularly in power management, optimizing energy efficiency in electronic systems.

What is the trend regarding PWM control as we approach 2025?

The trend of integrating PWM control into electronic systems is increasing due to the growing demand for energy-efficient solutions in sectors such as consumer electronics and automotive.

How does industrialization in the Asia Pacific region affect the PWM market?

Rapid industrialization in the Asia Pacific region significantly shapes the SMPS market, driven by demands from consumer electronics and automotive sectors, highlighting the critical role of PWM control in these economies.

What recent developments illustrate advancements in PWM control technology?

The launch of new multi-range DC power supplies by B&K Precision showcases how advancements in PWM control technology are being developed in response to the increasing demand for energy-efficient solutions.

How is the application of PWM control evolving?

The application of PWM control is evolving in sophistication, reflecting the dynamic landscape of electronics engineering, with an increasing emphasis on compliance and quality.