Introduction

Understanding the intricacies of Pulse Width Modulation (PWM) is essential for engineers and enthusiasts alike. This technology plays a critical role in efficiently managing power delivery across a multitude of applications. By mastering the fundamentals of PWM drivers – including their setup, specifications, and troubleshooting techniques – readers can unlock the potential for enhanced performance and energy savings in their projects.

However, as modern electronic systems grow increasingly complex, common pitfalls can hinder optimal operation. Identifying these challenges and knowing how to effectively address them is crucial for maximizing the benefits of PWM technology. This article will guide you through the essential aspects of PWM, ensuring you are well-equipped to navigate its complexities and achieve superior results in your projects.

Explain Pulse Width Modulation (PWM) Principles

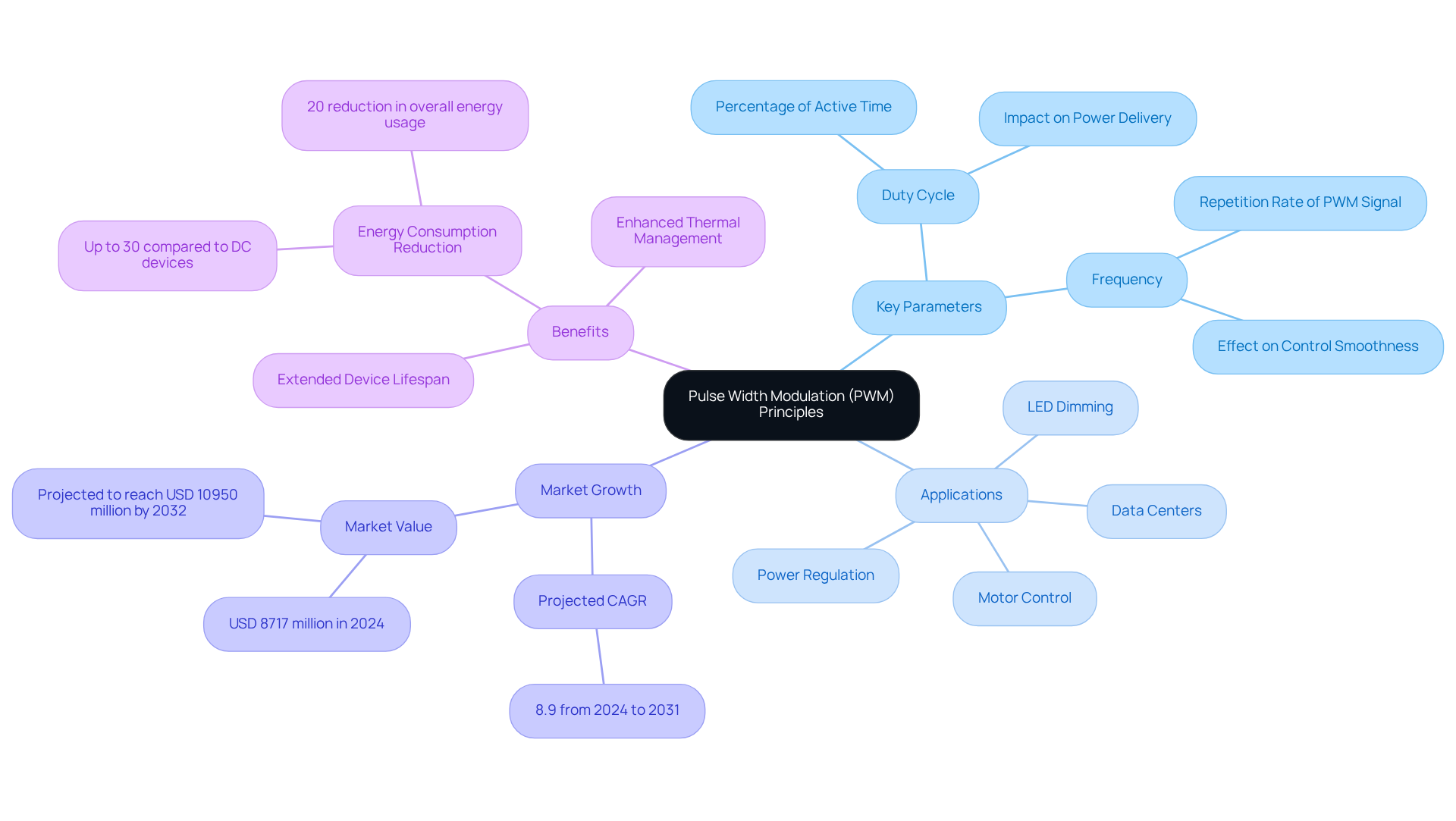

The pwm driver is a pivotal method for regulating power delivery to electrical devices by adjusting the pulse width in a waveform. Understanding its key parameters is essential:

- Duty Cycle: This represents the percentage of one period during which a signal remains active. A higher duty cycle translates to increased power delivered to the load.

- Frequency: This indicates how frequently the PWM signal repeats each second. Elevated frequencies facilitate smoother control, particularly in applications like motor speed regulation.

The pwm driver finds extensive application across various domains, including motor control, LED dimming, and power regulation, because of its efficiency and precision in managing power delivery. By rapidly toggling the signal on and off, the pwm driver effectively minimizes the average power supplied to a load while generating minimal heat, making it an optimal choice for contemporary electronic systems.

The market for PWM drivers in secondary side controllers is projected to grow at a CAGR of 8.9% from 2024 to 2031, underscoring the increasing significance of PWM technology in the industry. Notably, over 70% of electronics engineers are integrating designs that utilize a PWM driver for fans, reflecting a shift towards efficient temperature regulation. Industry leaders emphasize that the adaptability of the pwm driver enhances thermal management strategies, making it indispensable for high-performance applications. Moreover, transitioning to advanced fans using a PWM driver can result in an estimated 20% reduction in overall energy consumption, highlighting the advantages of PWM technology in energy management. The applications of the pwm driver extend to sectors such as aerospace, defense, and IT infrastructure, illustrating its relevance across diverse industries.

Detail Technical Specifications of PWM Drivers

When selecting a PWM driver, it’s crucial to evaluate several key technical specifications that can significantly impact performance:

- Output Voltage Range: This specification defines the voltage levels the driver can manage, which is essential for aligning the driver with the load requirements. A common output voltage for PWM controllers in electronics is approximately 12V DC, though variations occur based on specific use cases.

- Current Rating: The maximum current the component can supply is vital for ensuring it can support the load without overheating or failing. In battery-powered applications, this rating must align with the load’s demands to maintain efficiency and reliability.

- Switching Frequency: This parameter influences the controller’s responsiveness and the smoothness of control. Frequencies can vary significantly, generally spanning from a few kHz to several hundred kHz, depending on the application requirements.

- Efficiency: High-efficiency components are essential for minimizing power loss, particularly in battery-operated devices. Recent advancements in PWM technology can lead to an estimated 20% reduction in overall energy consumption compared to traditional setups, making efficiency a top priority.

- Thermal Management: Specifications related to heat dissipation capabilities are critical for maintaining performance and reliability. Effective thermal management strategies are essential, especially as higher PWM frequencies can lead to increased temperature rise, risking thermal damage.

By thoroughly understanding these specifications, engineers can select the most appropriate PWM driver for their specific applications. This ensures optimal performance and reliability while addressing current trends in efficiency and thermal management.

Guide Setup and Application of PWM Drivers

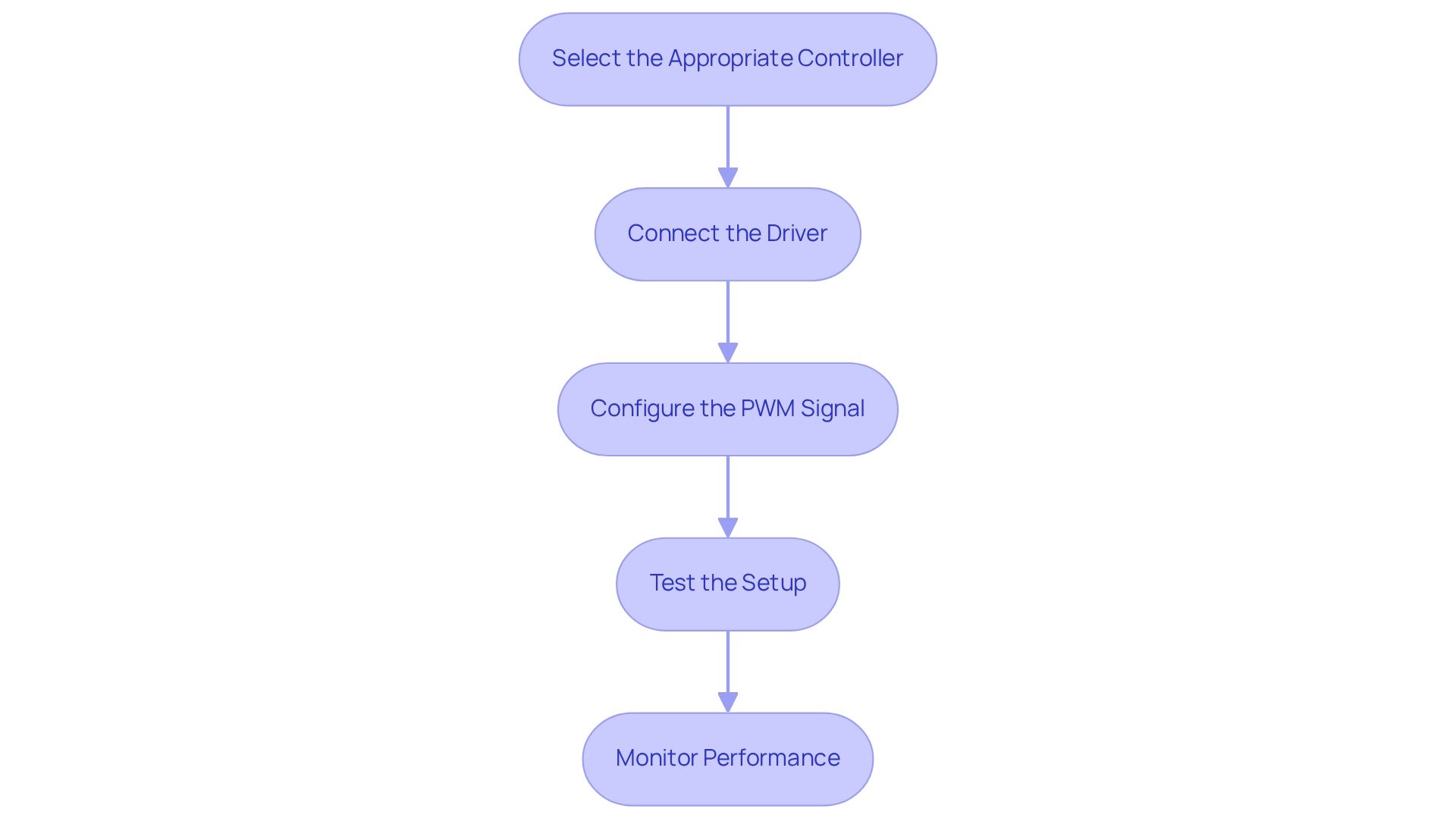

Setting up a PWM driver is crucial for achieving optimal performance and reliability in your applications. Here’s how to do it effectively:

-

Select the Appropriate Controller: Begin by choosing a PWM controller that meets your voltage and current specifications. This selection is vital, as it directly influences the efficiency and functionality of your system.

-

Connect the Driver: Follow the manufacturer’s wiring diagram to connect the PWM driver to your power source and load. To prevent data loss and ensure stable operation, secure connections are essential for the PWM driver.

-

Configure the PWM Signal: Use a microcontroller or PWM generator to set the parameters of the PWM signal, including frequency and duty cycle. This configuration is typically achieved through software programming, allowing for precise control over the output.

-

Test the Setup: Before full operation, verify that the output voltage and current are within expected ranges using a multimeter. Adjust the duty cycle as necessary to achieve the desired performance. It’s worth noting that approximately 30% of engineers report performance inconsistencies in PWM systems, making thorough testing essential.

-

Monitor Performance: Once operational, continuously observe the PWM controller’s performance to maintain safe temperature and current limits. Implement thermal management techniques, such as using shielded cables and ensuring proper grounding, to prevent overheating, which can lead to performance issues.

By adhering to these steps, engineers can effectively implement the PWM driver in their designs, enhancing precision and efficiency in applications like robotics and industrial machinery. Additionally, best practices such as ensuring proper grounding and using shielded cables can further minimize common issues like overheating and signal interference, ultimately leading to improved system reliability.

Identify Troubleshooting Techniques for PWM Drivers

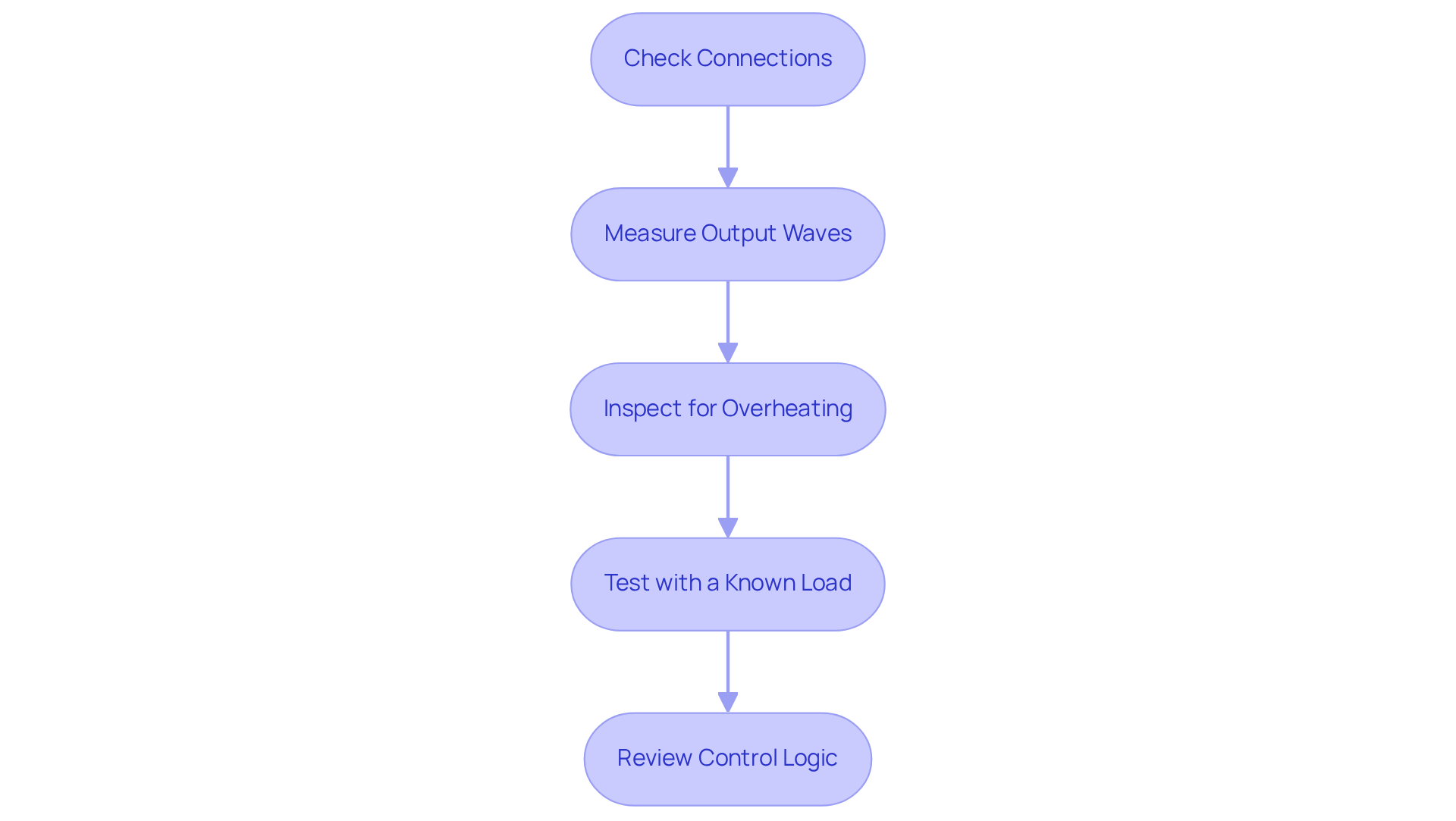

When troubleshooting PWM drivers, engineers must employ effective techniques to ensure optimal performance:

-

Check Connections: Start by verifying that all wiring is secure and correctly aligned with the schematic. Loose or incorrect connections can lead to erratic behavior, a common issue in PWM setups. In fact, a significant portion of PWM controller failures can be traced back to connection errors, underscoring the importance of thorough checks during setup.

-

Measure Output Waves: Utilize an oscilloscope to observe the PWM waveform, ensuring the correct frequency and duty cycle. An irregular signal may indicate a malfunctioning component or control signal, potentially leading to operational failures.

-

Inspect for Overheating: If the operator exhibits signs of overheating, confirm that it operates within its specified current and voltage limits. Overheating can stem from poor venting, inadequate cooling, or contamination. Incorporating heat sinks or improving airflow can significantly reduce overheating problems, which are often linked to component failures.

-

Test with a Known Load: To rule out load-related issues, test the component with a known good load. This step is crucial, as improper load conditions can obscure underlying issues with the operator.

-

Review Control Logic: Ensure that the control logic, such as microcontroller code, is properly configured to generate the desired PWM signal. Debugging the code may reveal logical errors that impact performance. As Ed Garcia from EDG Technologies notes, electric motors don’t last forever; electrical or mechanical failure is always a possibility, emphasizing the need for diligent troubleshooting.

By implementing these troubleshooting techniques, engineers can effectively diagnose and resolve issues with the PWM driver, thereby enhancing reliability in their applications.

Conclusion

Understanding the fundamentals of PWM drivers is crucial for professionals in electrical engineering and electronics design. This article has delved into the principles of Pulse Width Modulation, highlighting its significance in efficiently managing power delivery across diverse applications. By mastering the essential specifications, setup procedures, and troubleshooting techniques associated with PWM drivers, engineers can markedly enhance the performance and reliability of their systems.

Key insights include the pivotal role of duty cycle and frequency in regulating power output, along with the critical specifications to consider when selecting a PWM driver. A comprehensive setup guide was outlined, stressing the necessity for secure connections and thorough testing. Moreover, effective troubleshooting techniques were presented to assist in identifying and resolving common issues, ensuring optimal functionality.

In an era where energy efficiency and precise control are paramount, the adoption of PWM technology is increasingly vital across multiple industries. As the market for PWM drivers continues to expand, engineers are encouraged to integrate these principles into their designs. By doing so, they can not only enhance system performance but also contribute to broader efforts in energy management and sustainability. Embracing these practices will pave the way for innovative solutions in fields ranging from robotics to aerospace.

Frequently Asked Questions

What is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a method for regulating power delivery to electrical devices by adjusting the pulse width in a waveform.

What is the duty cycle in PWM?

The duty cycle represents the percentage of one period during which a signal remains active. A higher duty cycle results in increased power delivered to the load.

How does frequency relate to PWM?

Frequency indicates how frequently the PWM signal repeats each second. Higher frequencies enable smoother control, which is particularly beneficial in applications like motor speed regulation.

What are the applications of PWM drivers?

PWM drivers are extensively used in motor control, LED dimming, and power regulation due to their efficiency and precision in managing power delivery.

Why are PWM drivers considered efficient?

PWM drivers minimize the average power supplied to a load while generating minimal heat, making them an optimal choice for modern electronic systems.

What is the projected market growth for PWM drivers?

The market for PWM drivers in secondary side controllers is projected to grow at a CAGR of 8.9% from 2024 to 2031.

How are PWM drivers impacting energy consumption in electronic designs?

Over 70% of electronics engineers are integrating PWM drivers for fans, which can lead to an estimated 20% reduction in overall energy consumption.

In which industries are PWM drivers relevant?

PWM drivers are relevant across various sectors, including aerospace, defense, and IT infrastructure, highlighting their broad applicability in diverse industries.