Overview

Pulse Width Modulation (PWM) stands as a pivotal technique in electronics, enabling efficient power delivery control to devices by modulating the duration of the ‘on’ and ‘off’ states of a digital signal. Its significance is underscored through various applications, including:

- Motor control

- LED dimming

- Energy supplies

- Audio systems

- Heating components

The advantages of PWM, such as high efficiency and simplicity, are compelling; however, it is important to acknowledge its limitations, including:

- Potential electromagnetic interference

- Audible noise

Understanding these elements is crucial for leveraging PWM effectively in diverse electronic applications.

Introduction

Pulse Width Modulation (PWM) represents a fundamental technology in modern electronics, providing precise control over energy delivery across a multitude of applications. This technique not only enhances operational efficiency but also facilitates innovative solutions in areas such as motor control, lighting, and audio systems. Nonetheless, like any advanced technology, PWM is accompanied by its own unique challenges and limitations. Engineers must explore strategies to leverage the advantages of PWM while addressing its drawbacks, thereby maximizing performance in their designs.

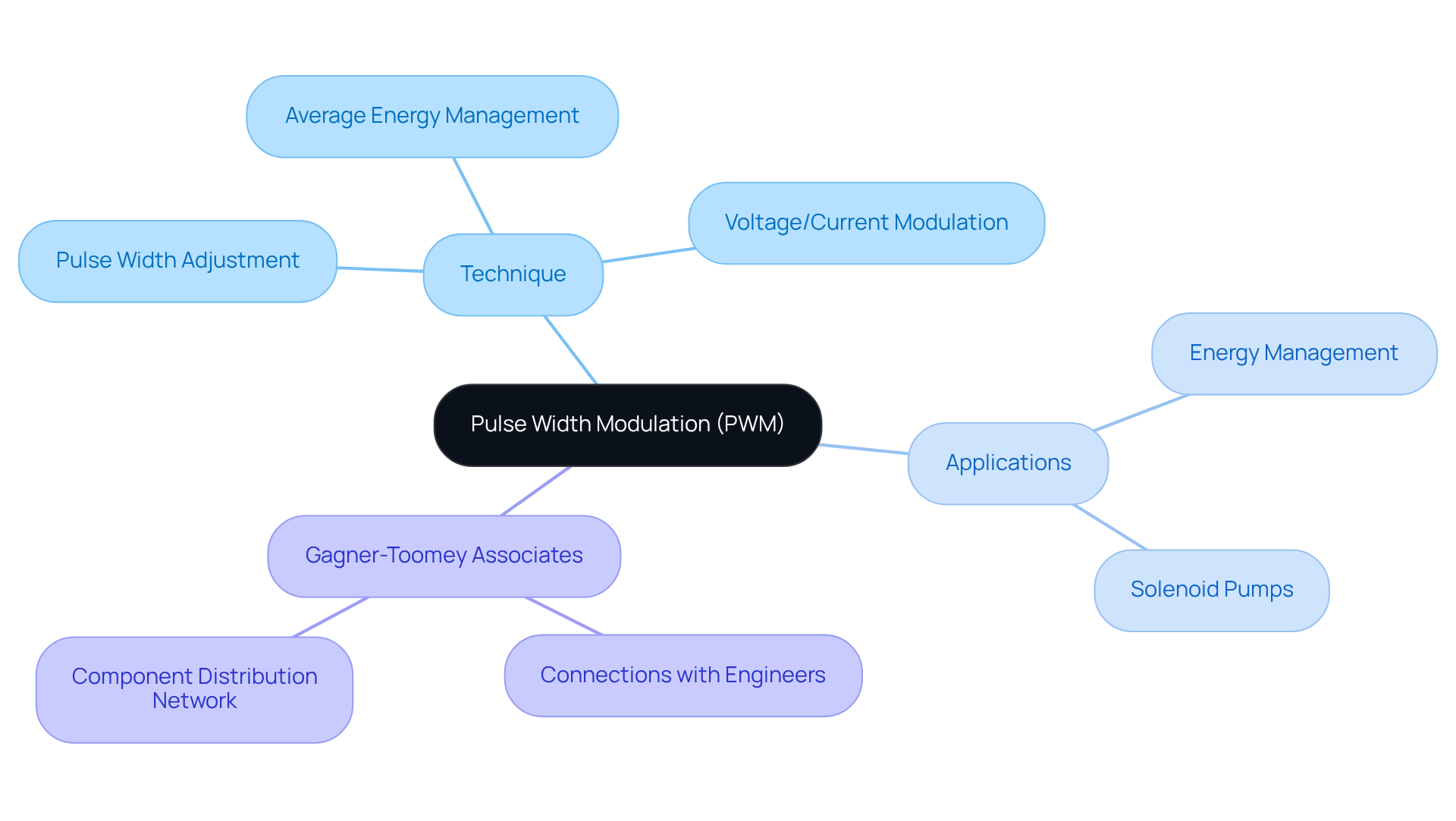

Define Pulse Width Modulation (PWM)

Pulse Width Modulation (PWM) represents a pivotal technique for encoding information through a variable signal. This method involves the precise adjustment of pulse widths within a digital signal to effectively manage the average energy supplied to a load. By manipulating the duration of the ‘on’ time relative to the ‘off’ time over a defined period, PWM adeptly modulates the average voltage and current delivered to devices. This capability renders PWM electronics essential for energy management and regulation.

Furthermore, Gagner-Toomey Associates plays an instrumental role in this sector by facilitating connections between engineers and a dependable network of component distributors. This ensures the availability of high-performance solenoid pumps and other critical components, which are indispensable for the effective implementation of PWM electronics across a diverse array of applications.

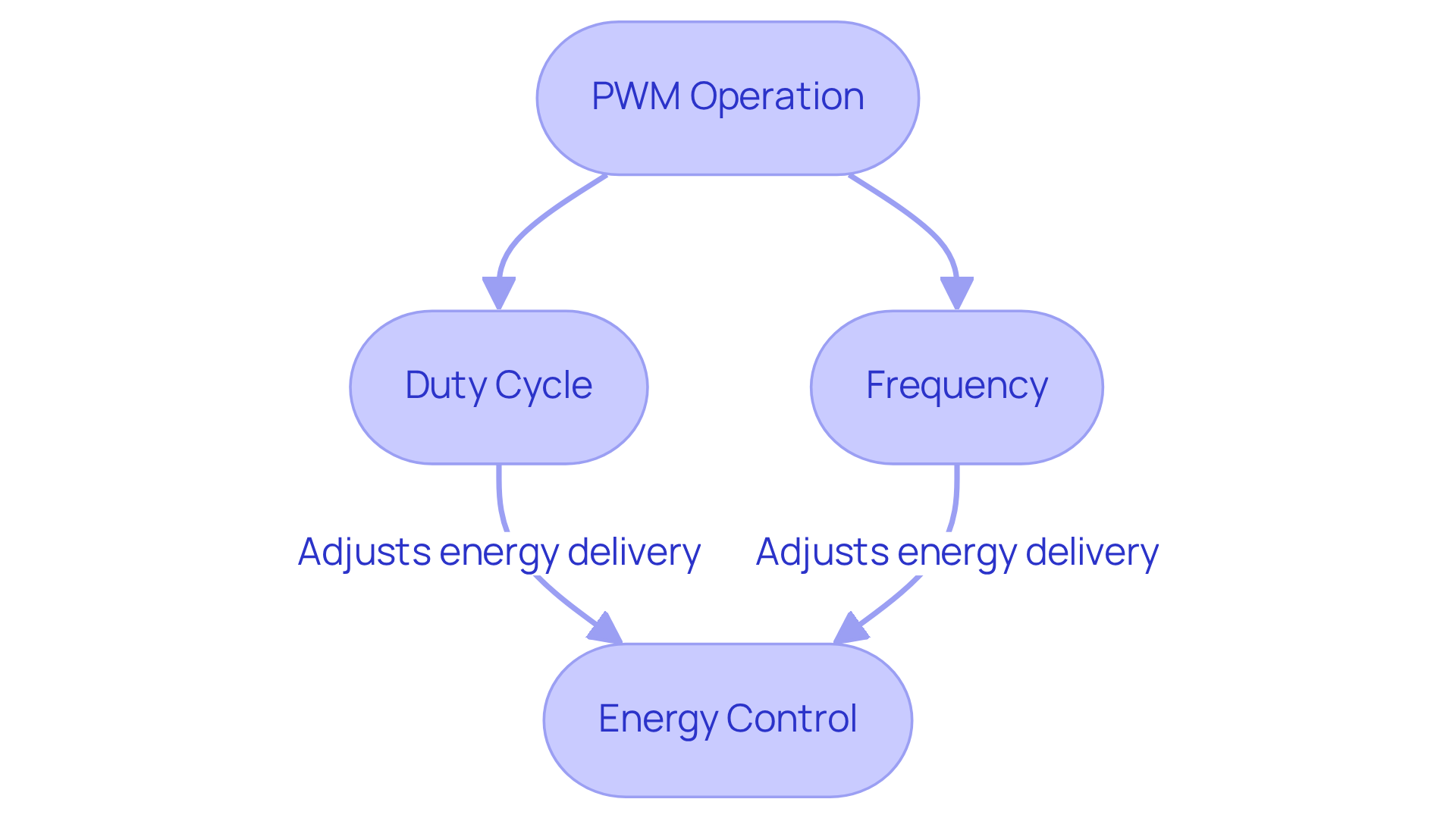

Explain How PWM Works

PWM operates by rapidly toggling a digital signal between high (on) and low (off) states, a method that effectively manages energy delivery. The critical parameters in PWM are the duty cycle and frequency. The duty cycle represents the percentage of time the signal remains in the ‘on’ state throughout a complete cycle; for instance, a 50% duty cycle indicates that the signal is on for half the duration and off for the other half. Meanwhile, frequency dictates the speed at which these cycles transpire. By adjusting the duty cycle, PWM can control the average energy supplied to a load, such as a motor or LED, thereby simulating an analog signal through digital techniques. This approach is particularly efficient as it minimizes power loss during the switching process, making PWM an invaluable tool in various applications.

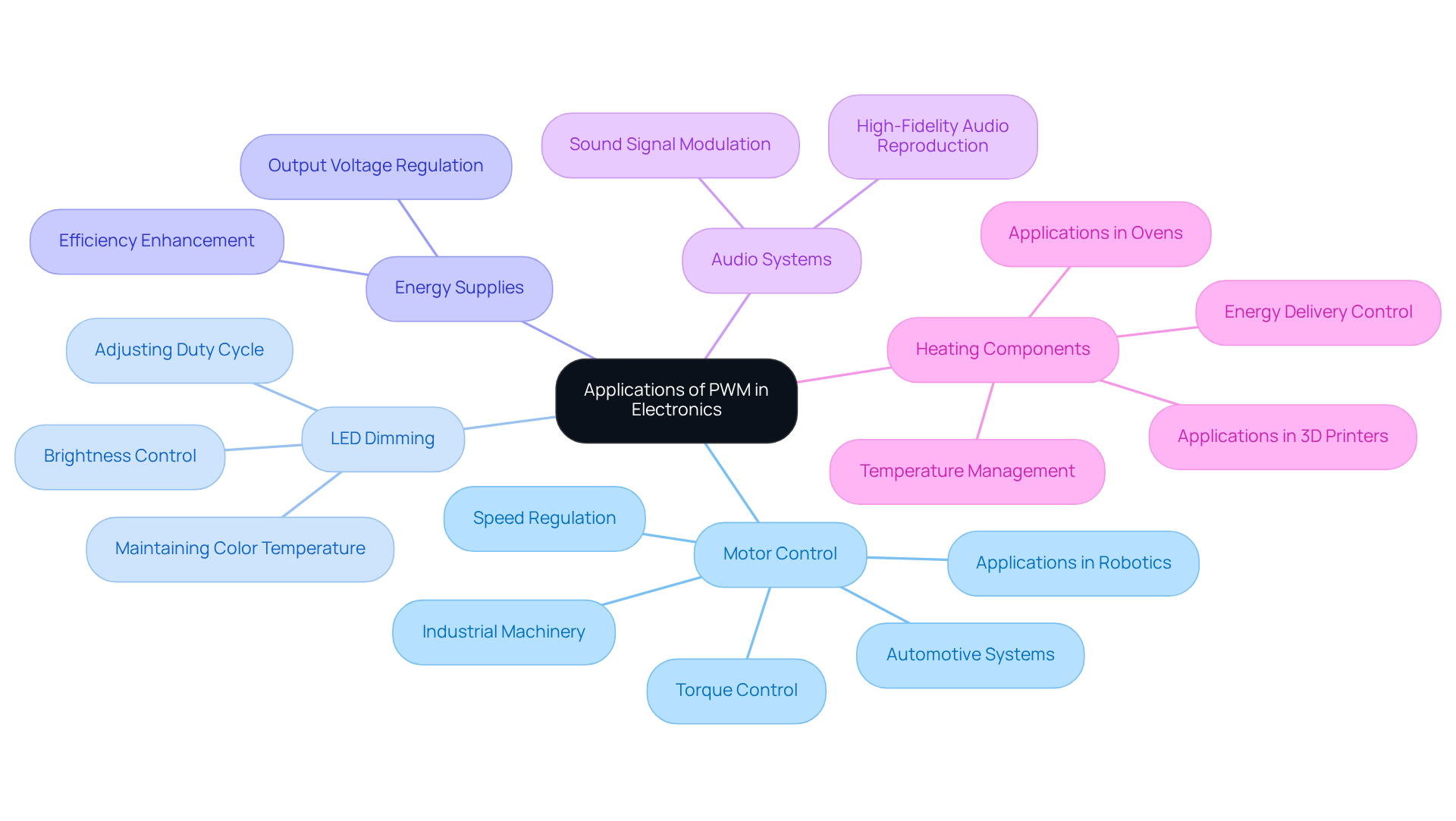

Explore Applications of PWM in Electronics

PWM is widely recognized for its versatility across numerous applications, including:

- Motor Control: PWM is instrumental in regulating the speed and torque of electric motors, finding utility in robotics, automotive systems, and industrial machinery.

- LED Dimming: By adjusting the duty cycle, PWM electronics effectively reduce LED brightness without compromising color temperature, making it an ideal solution for lighting applications.

- Energy Supplies: In switch-mode energy sources, PWM electronics plays a crucial role in output voltage regulation, significantly enhancing overall efficiency.

- Audio Systems: PWM electronics are used to modulate sound signals, facilitating high-fidelity audio reproduction in various audio applications.

- Heating Components: PWM electronics provides precise control over energy delivery to heating components, ensuring accurate temperature management in environments such as 3D printers and ovens.

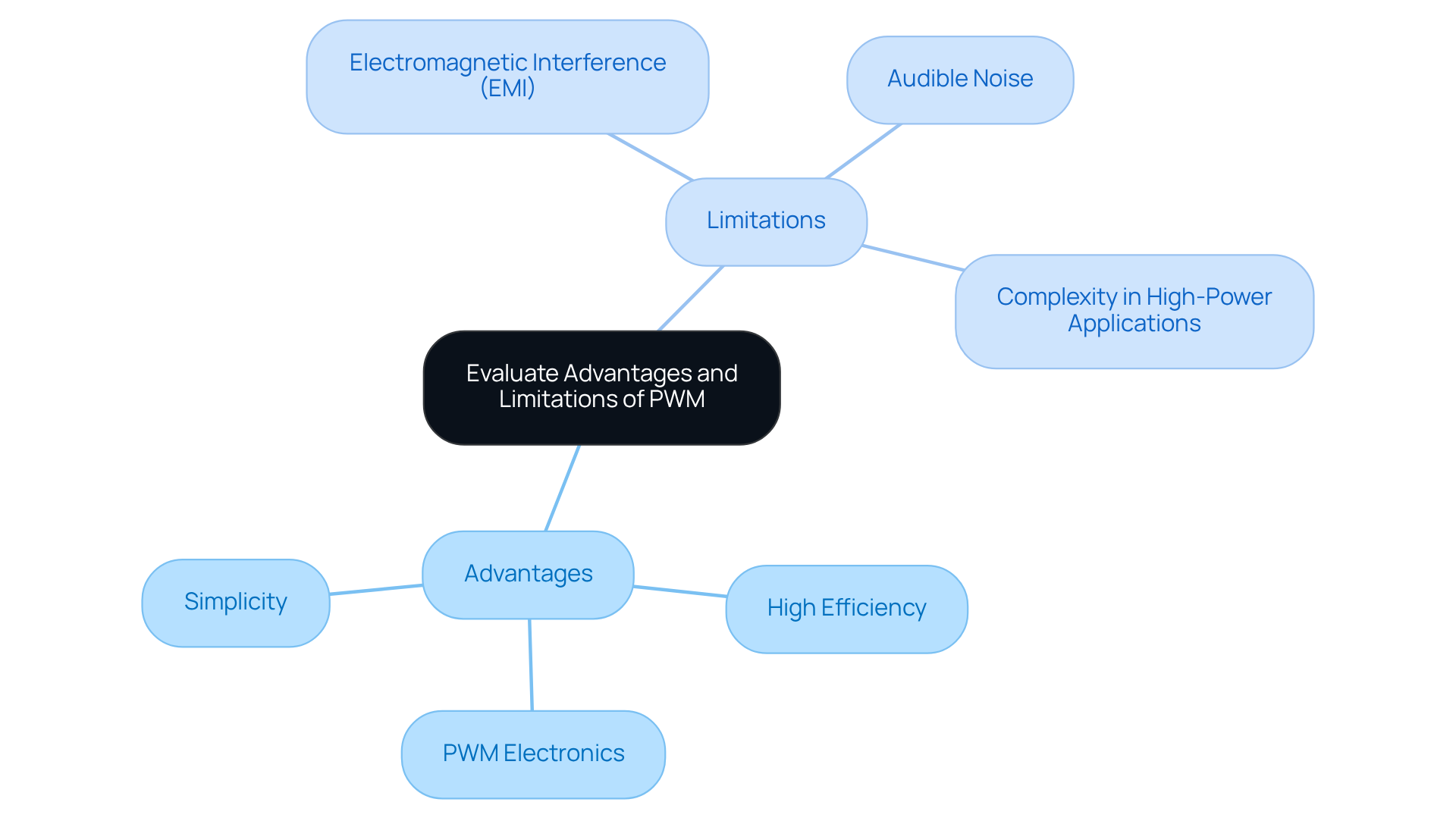

Evaluate Advantages and Limitations of PWM

Advantages of PWM include:

- High Efficiency: PWM minimizes power loss during switching, making it an energy-efficient method for controlling power.

- PWM Electronics: It allows for precise regulation of the average power supplied to a load, which is essential in scenarios demanding accuracy.

- Simplicity: PWM circuits can be simpler and cheaper to implement compared to linear control methods.

Limitations of PWM include:

- Electromagnetic Interference (EMI): Rapid switching can generate EMI, which may affect nearby electronic devices.

- Audible Noise: In some applications, the switching frequency can produce audible noise, which may be undesirable.

- Complexity in High-Power Applications: Managing high currents and voltages can complicate PWM circuit design, requiring additional components for protection and stability.

Conclusion

Pulse Width Modulation (PWM) stands as a cornerstone technique in electronics, facilitating efficient energy management and control across diverse applications. By adjusting the duration of the ‘on’ and ‘off’ states within a digital signal, PWM allows for precise regulation of voltage and current, rendering it indispensable for contemporary electronic devices.

Key insights into the operation of PWM have been elucidated, emphasizing its critical parameters—duty cycle and frequency. These elements govern the efficiency and effectiveness of PWM in various applications, including:

- Motor control

- LED dimming

- Energy supply regulation

- Audio modulation

- Temperature management

Furthermore, the advantages of PWM, such as its high efficiency and simplicity, are juxtaposed with limitations like electromagnetic interference and audible noise, offering a balanced perspective on its capabilities.

Grasping the principles of PWM not only deepens one’s understanding of electronics but also highlights its pivotal role in fostering innovation across multiple fields. As technology advances, mastering PWM will remain crucial for engineers and enthusiasts alike, paving the way for more efficient and sophisticated electronic systems. Embracing this knowledge can lead to enhanced designs and applications, ultimately contributing to significant advancements in energy efficiency and control within the electronic landscape.

Frequently Asked Questions

What is Pulse Width Modulation (PWM)?

Pulse Width Modulation (PWM) is a technique for encoding information by adjusting the widths of pulses within a digital signal to manage the average energy supplied to a load.

How does PWM work?

PWM works by manipulating the duration of the ‘on’ time relative to the ‘off’ time over a defined period, allowing it to modulate the average voltage and current delivered to devices.

Why is PWM important in electronics?

PWM is essential for energy management and regulation, making it a crucial technique for controlling power in various electronic applications.

What role does Gagner-Toomey Associates play in PWM electronics?

Gagner-Toomey Associates connects engineers with a reliable network of component distributors, ensuring the availability of high-performance solenoid pumps and other critical components necessary for implementing PWM electronics.

What applications utilize PWM technology?

PWM technology is used across a diverse array of applications that require effective energy management and regulation.