Overview

The article titled “Master Radial Fan Blower Selection: A Step-by-Step Guide” addresses the critical criteria and processes necessary for selecting the appropriate radial fan blower across various applications. It underscores the significance of assessing factors such as:

- Airflow rate

- Static pressure

- Efficiency

- Noise levels

- Durability

Detailed steps are provided for researching and comparing different options, ensuring optimal performance and reliability in industrial settings.

Introduction

Understanding the intricacies of radial fan blowers is essential for anyone involved in industrial applications. These devices play a crucial role in managing airflow and maintaining optimal conditions across various environments. This guide presents a comprehensive, step-by-step approach to selecting the right radial fan blower, emphasizing the importance of efficiency, performance, and durability. However, with a myriad of options available, navigating the complexities of specifications and requirements to ensure the best choice is made becomes imperative.

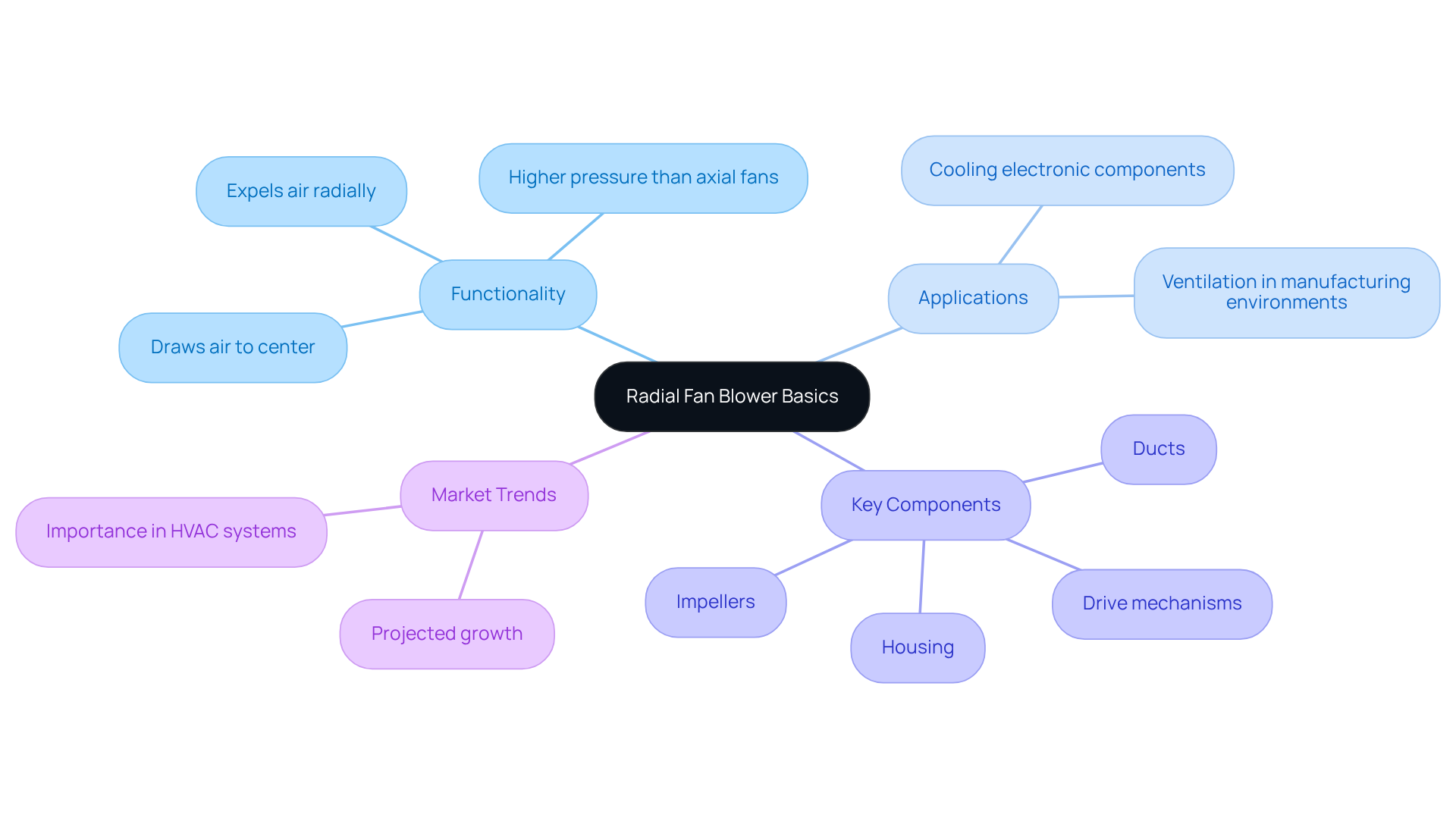

Understand Radial Fan Blower Basics

s, commonly referred to as centrifugal units, function by drawing air into their center and expelling it radially outward. This distinctive design of the radial fan blower allows it to produce significantly higher pressures compared to axial fans, rendering it ideal for applications demanding .

, recognized as the largest producer of standard and custom air movers globally, offers a comprehensive range of that are . These fans cater to various industrial applications, including:

- The

- Providing ventilation in manufacturing environments

Notably, their centrifugal fans achieve , a critical factor for compliance with health and safety standards in manufacturing settings. Furthermore, industry specialists commend Gagner-Toomey Associates‘ centrifugal fans for their reliability and adaptability, emphasizing their .

Key components of radial fan blowers include:

- Impellers

- Housing

- Inlet and outlet ducts

- Drive mechanisms

All contributing to enhanced operational performance. Understanding the of radial devices is crucial for selecting the appropriate unit for specific needs, particularly in such as electronics cooling, where maintaining optimal temperatures is vital for performance.

As the centrifugal air mover market is projected to grow significantly, recognizing the importance of these devices in HVAC systems and other applications becomes increasingly essential. Gagner-Toomey Associates provides a wide selection of sizes for their DC input Tube Axial devices, ranging from 15 to 280mm, and centrifugal units from 15 to 225mm, with IP protection available in most models upon request.

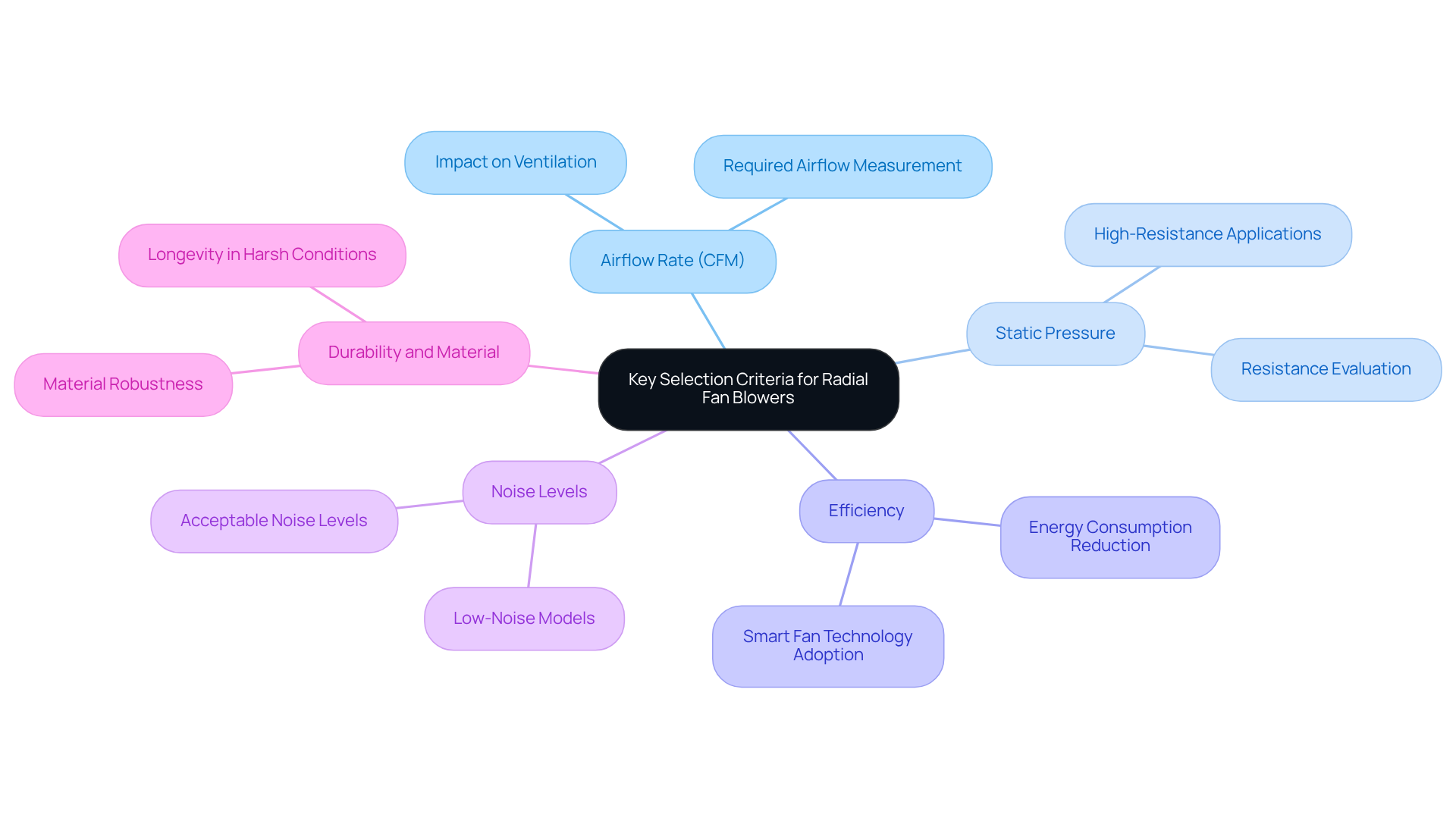

Evaluate Key Selection Criteria

When selecting a radial fan blower, several key criteria must be considered to ensure and efficiency:

- : Accurately determine the required airflow for your application, measured in cubic feet per minute (CFM). This metric is essential for ensuring adequate ventilation or cooling; insufficient airflow can lead to overheating and system failures.

- : Evaluate the resistance the fan will encounter within the system. Higher static pressure ratings indicate a fan’s capability to overcome resistance from ductwork, filters, and other components. For instance, static pressure ratings for radial fan blowers can vary significantly, with some models achieving up to 12 inches of water gauge (inWG), making them suitable for .

- Efficiency: Prioritize devices with to reduce energy consumption and operational costs. can result in significant savings over time, especially in situations where ventilators operate continuously. The adoption of smart fan technology has increased by over 30% in the past year, reflecting a growing trend towards energy-efficient solutions in the electronics sector.

- Noise Levels: Assess the for your application. In noise-sensitive environments, such as offices or laboratories, fans designed for quieter operation are crucial. Numerous producers currently provide low-noise models that function under 30 dBA, guaranteeing minimal disturbance while preserving effectiveness.

- Durability and Material: Consider the , especially if it will be exposed to harsh conditions or corrosive environments. Fans made from robust materials can withstand challenging operational settings, enhancing longevity and reliability.

By carefully assessing these criteria, engineers can choose radial fan blowers that not only fulfill performance requirements but also enhance and operational effectiveness.

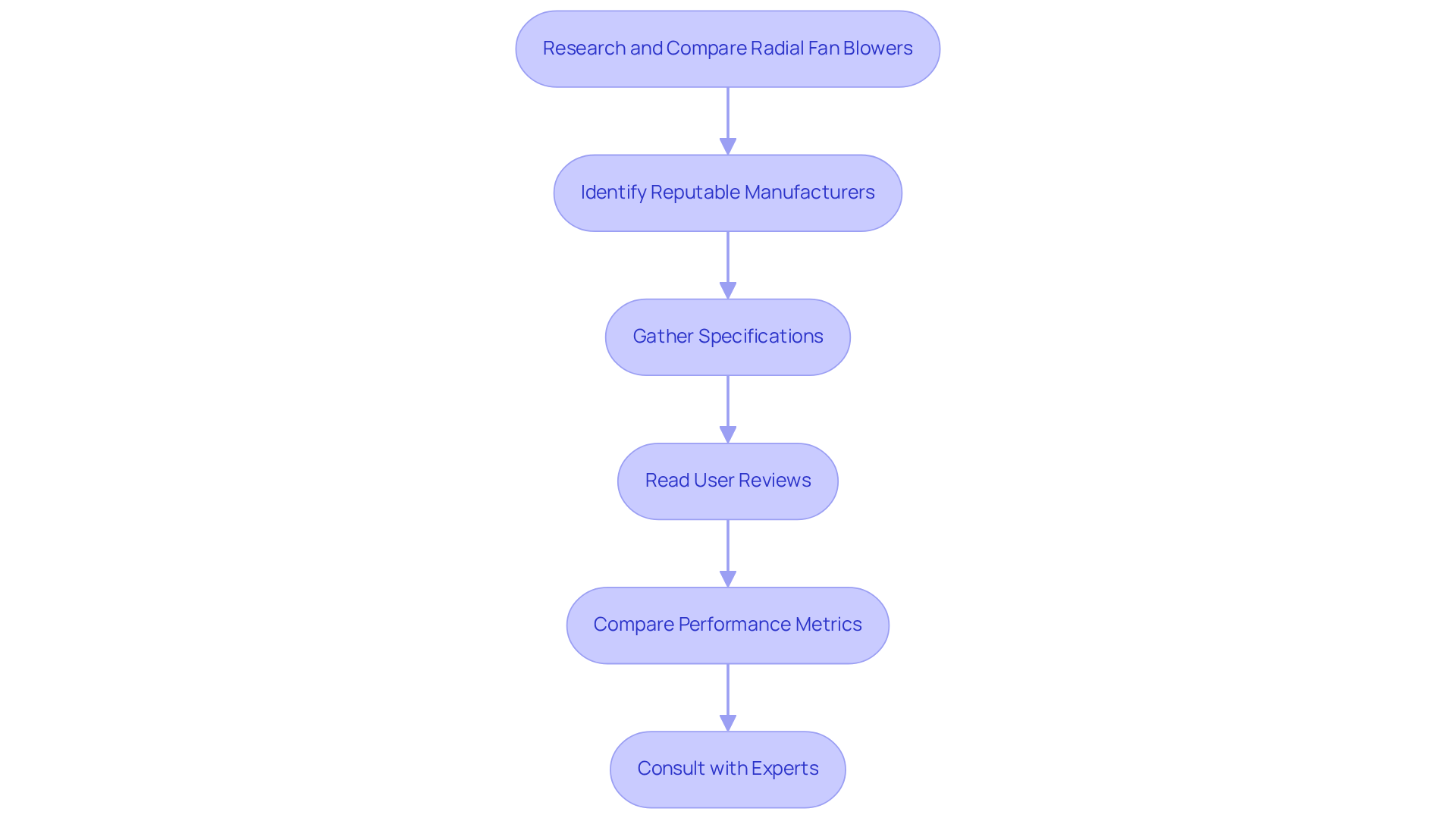

Research and Compare Available Options

To effectively research and compare s, it is essential to follow these structured steps:

- Identify Reputable Manufacturers: Begin by compiling a list of manufacturers recognized for their . include EBM-Papst, renowned for its innovative GreenTech EC technology, which combines with optimized aerodynamics, and ACDCFAN, specializing in robust designs for harsh environments, such as their radial fan blower.

- Gather Specifications: Next, collect , focusing on critical metrics such as airflow rate (measured in CFM), static pressure, efficiency ratings, and noise levels. This information is typically available on manufacturer websites or in product datasheets. For example, radial fan blowers with are often preferred due to their ability to handle higher static pressures while maintaining lower noise levels.

- Read User Reviews: It is also important to seek out to gain insights into the effectiveness and reliability of various fan models. Pay particular attention to feedback regarding durability and customer service experiences, as these factors can significantly influence long-term satisfaction. As noted by industry experts, understanding user experiences can provide valuable context for your selection process.

- Compare : Create a comparison chart to evaluate the performance metrics of each fan side by side. This visual depiction enables swift recognition of the optimal choices according to your specific standards, such as energy performance and operational noise. Visual aids are frequently utilized in the industry to enhance clarity and effectiveness in decision-making.

- Consult with Experts: Finally, if possible, or colleagues who have hands-on experience with specific fan models. Their insights can provide , particularly when comparing specifications and understanding the nuances of different fan technologies. As highlighted by experts in the domain, selecting the appropriate radial fan blower can significantly enhance system functionality and energy savings.

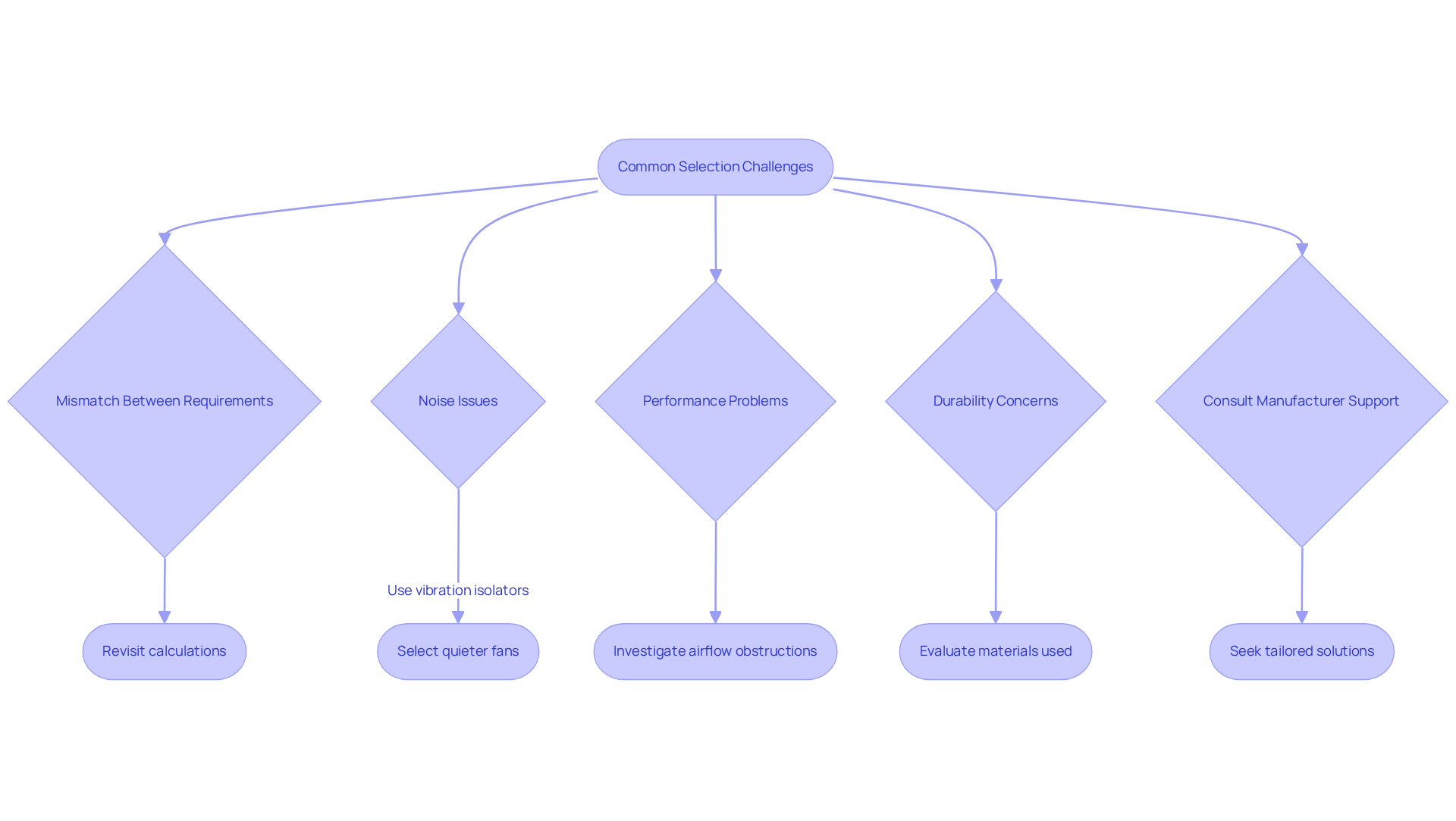

Troubleshoot Common Selection Challenges

When navigating challenges in the radial fan selection process, it is crucial to consider these :

- : If the fan fails to meet your airflow or pressure requirements, it is imperative to revisit your calculations. Ensure that you have accurately assessed your system’s needs, as improper evaluations can lead to . Studies indicate that mismatched specifications can result in a 30% decrease in efficiency.

- Noise Issues: Elevated noise levels are a common complaint in fan installations. Recent surveys reveal that over 40% of engineers report related to improper fan selection. To mitigate this, select fans specifically designed for quieter operation or implement sound-dampening measures, such as acoustic enclosures or vibration isolators. A case study demonstrated that implementing vibration isolators reduced noise levels by 15 dB in a manufacturing facility.

- : If the fan is underperforming, it is essential to investigate potential obstructions in the airflow path, improper installation, or incorrect sizing. Ensure that the system’s requirements are appropriately matched to the radial fan blower. Routine examinations can assist in recognizing problems early, avoiding escalation, and guaranteeing optimal function. As engineer Marek Skarżyński states, ” can prevent declines in function and extend the lifespan of your equipment.”

- Durability Concerns: in the fan’s construction if durability is a concern. Consider models designed for harsh environments or heavy-duty applications, as these are often built to withstand more demanding conditions. For instance, fans made with corrosion-resistant materials can last significantly longer in industrial settings.

- : For persistent issues, do not hesitate to reach out to the manufacturer’s technical support. They can provide valuable insights and tailored solutions to address your specific challenges, ensuring that you achieve the best performance from your fan selection.

Conclusion

Selecting the right radial fan blower is essential for achieving optimal performance in various industrial applications. This guide has illuminated the intricacies of radial fan blowers, emphasizing their unique design and operational advantages, particularly in high-pressure scenarios. Understanding the fundamental mechanics and selection criteria of these devices is crucial for engineers and decision-makers aiming to enhance efficiency and reliability in their systems.

Key aspects discussed include:

- The importance of airflow rates

- Static pressure

- Energy efficiency

- Considerations for noise levels

- Material durability

The article also outlined a systematic approach to researching and comparing available options, highlighting the value of user reviews and expert consultations. By addressing common selection challenges, such as mismatched specifications and noise issues, this guide equips readers with the knowledge needed to make informed decisions in radial fan blower selection.

Ultimately, the significance of choosing the right radial fan blower cannot be overstated. As industries continue to evolve, the demand for efficient and reliable air movement solutions will only grow. Engaging with reputable manufacturers, staying informed about the latest innovations, and applying best practices in selection will ensure that systems operate at their best, contributing to overall productivity and energy savings. Embracing this knowledge today will pave the way for successful and sustainable operations in the future.

Frequently Asked Questions

What is a radial fan blower?

A radial fan blower, also known as a centrifugal unit, draws air into its center and expels it radially outward, allowing for higher pressures compared to axial fans.

What applications are radial fan blowers suitable for?

Radial fan blowers are ideal for applications requiring substantial airflow against resistance, such as cooling electronic components and providing ventilation in manufacturing environments.

What is the dust collection rate of Gagner-Toomey Associates’ centrifugal fans?

Gagner-Toomey Associates’ centrifugal fans achieve dust collection rates exceeding 90%, which is important for compliance with health and safety standards in manufacturing settings.

What are the key components of radial fan blowers?

The key components include impellers, housing, inlet and outlet ducts, and drive mechanisms, all of which contribute to enhanced operational performance.

Why is it important to understand the operational mechanics of radial fan blowers?

Understanding the operational mechanics and average efficiency ratings is crucial for selecting the appropriate unit for specific needs, especially in high-demand environments like electronics cooling, where maintaining optimal temperatures is vital.

What is the projected growth of the centrifugal air mover market?

The centrifugal air mover market is projected to grow significantly, highlighting the importance of these devices in HVAC systems and other applications.

What size options are available for Gagner-Toomey Associates’ centrifugal units?

Gagner-Toomey Associates offers a wide selection of sizes for their centrifugal units, ranging from 15 to 225mm, with IP protection available in most models upon request.