Overview

This article delves into the advantages and maintenance of sensored brushless DC (BLDC) motors, which stand out for their enhanced efficiency, precise control, and reduced noise when compared to other motor types. By detailing the integration of sensors, it illustrates how these motors achieve optimal performance in demanding applications. Furthermore, it discusses maintenance practices that can significantly extend their lifespan, underscoring the importance of proper care in maximizing the benefits of BLDC technology.

Introduction

Sensored Brushless DC (BLDC) motors are transforming the electric drive systems landscape, showcasing sophisticated technology and remarkable efficiency. These motors, equipped with feedback sensors, not only enhance operational precision but also meet the rigorous demands of applications in robotics, electric vehicles, and industrial automation.

As industries increasingly prioritize performance and reliability, a critical question emerges: how can users maximize the benefits of these advanced motors while ensuring their longevity and optimal functionality?

This article explores the advantages, maintenance practices, and essential insights surrounding sensored BLDC motors, offering a comprehensive guide for both enthusiasts and professionals.

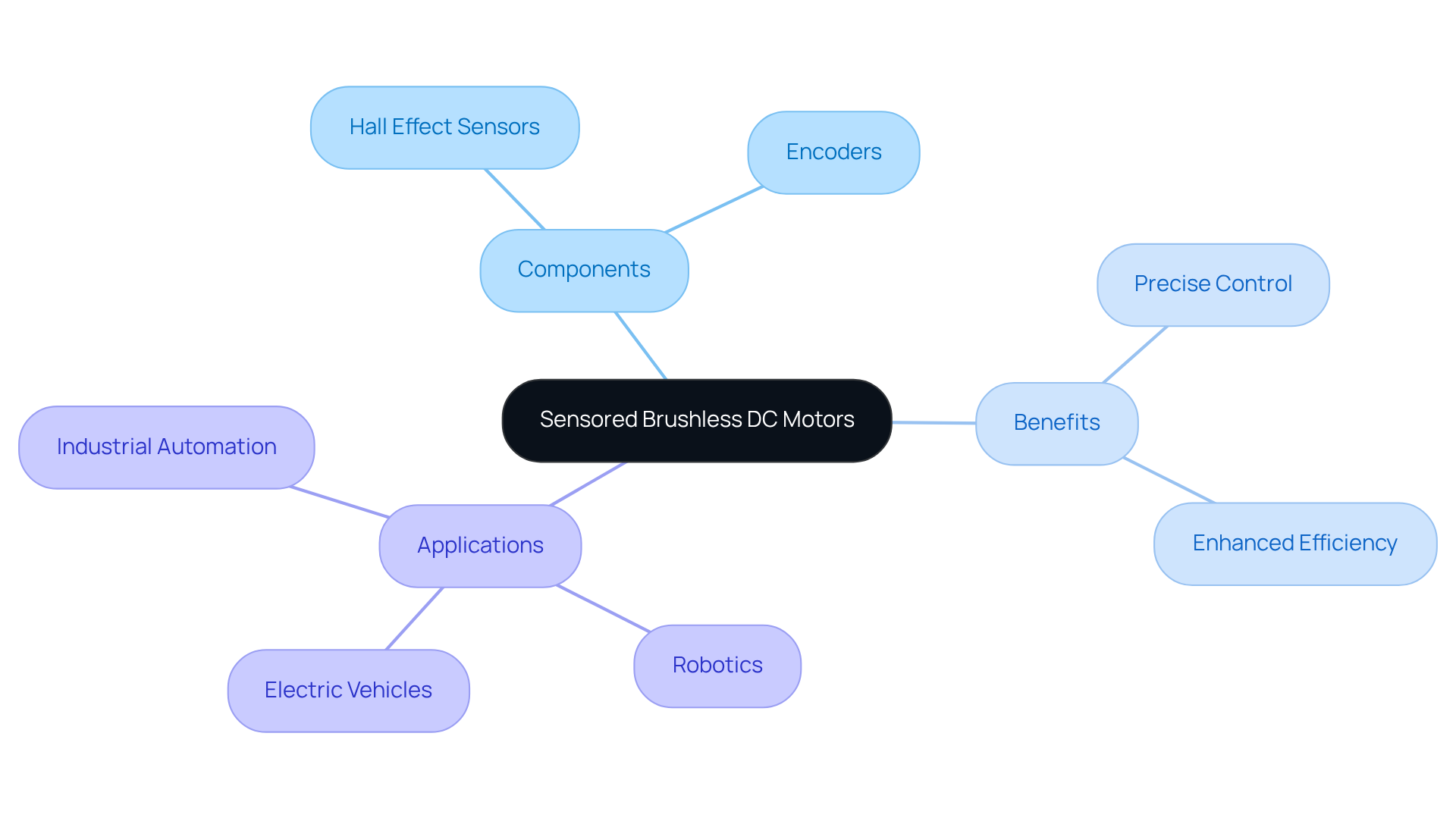

Define Sensored Brushless DC Motors

Sensored BLDC motors represent a sophisticated category of electric devices that utilize sensors for feedback on rotor position, facilitating precise operational control. Unlike their sensorless counterparts, a sensored BLDC motor integrates Hall effect sensors or encoders, which accurately identify the rotor’s position. This integration not only enables smoother operation but also significantly enhances efficiency.

These machines are extensively employed in applications that demand high reliability and performance, such as robotics, electric vehicles, and industrial automation. By incorporating sensors, these devices improve their responsiveness to varying load conditions, making them particularly suitable for complex electronic systems. The ability to adapt to different operational demands is crucial in ensuring optimal performance in diverse environments.

In conclusion, the sensored BLDC motor machines stand out for their capability to deliver precise control and efficiency, positioning them as essential components in advanced technological applications.

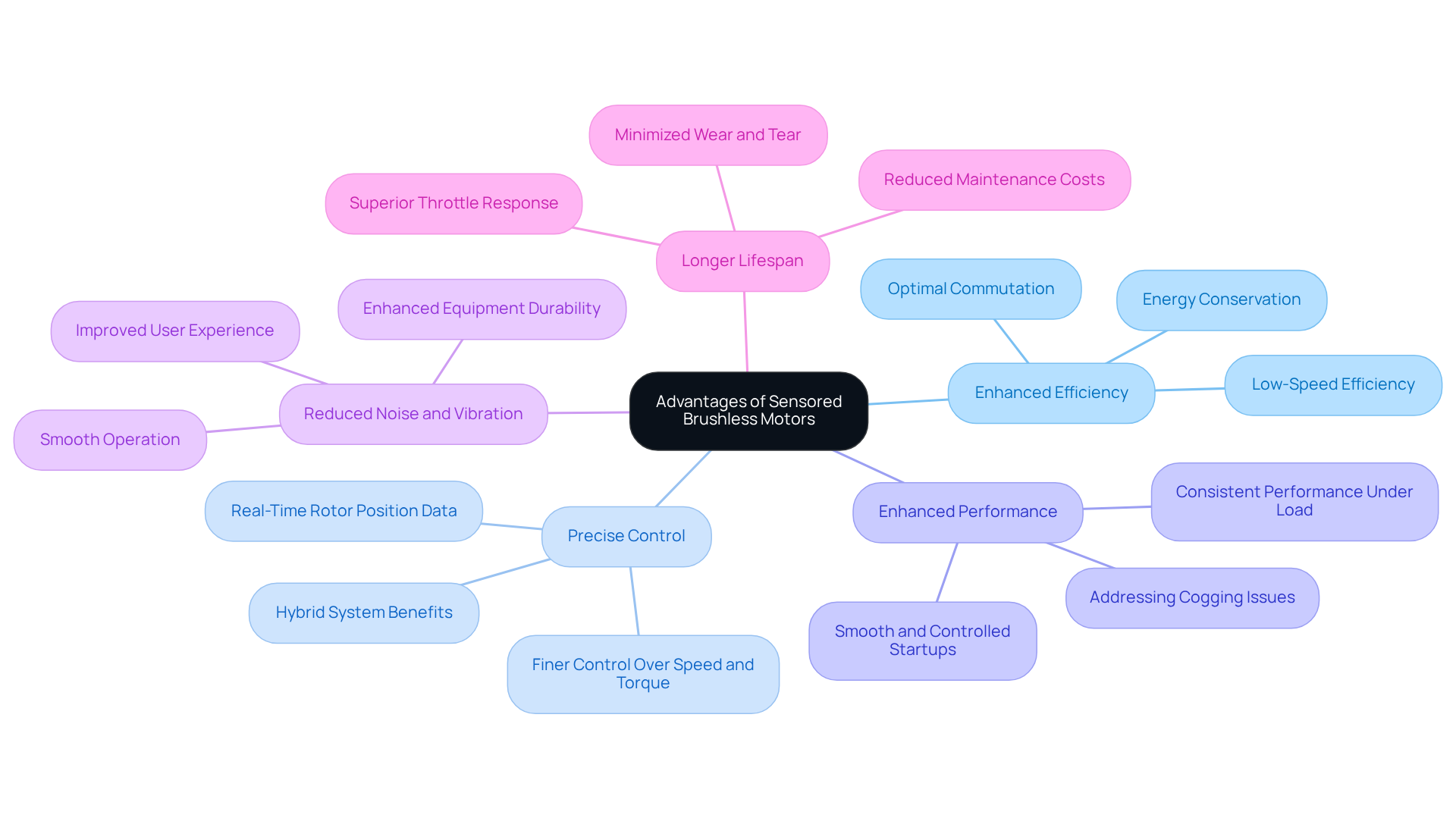

Explore Advantages of Sensored Brushless Motors

Sensored brushless motors offer numerous advantages over traditional brushed motors and sensorless designs, establishing themselves as a premier choice for high-performance applications:

-

Enhanced Efficiency: The integration of sensors facilitates optimal commutation, significantly reducing energy losses and enhancing overall efficiency. This advantage is particularly crucial in contexts where energy conservation is paramount. Equipped engines excel in low-speed efficiency, making them ideal for tasks that require steady, consistent power, such as scale trail driving and precision remote control applications.

-

Precise Control: By providing real-time rotor position data, equipped motors enable finer control over speed and torque. This precision is essential in applications demanding high accuracy, such as RC racing and robotics. As highlighted by Castle Creations, “Our designed system enables users to merge the advantages of both worlds in an unmatched HYBRID between smooth monitored startups and a high-efficiency sensorless drive.”

-

Enhanced Performance: Sensored drives excel in managing varying load conditions, maintaining consistent performance even under stress. This capability is crucial for tasks requiring steady power, such as scale trail driving and precision machinery. Case studies have demonstrated that equipped engines deliver smooth and controlled startups, effectively addressing the stuttering or cogging issues commonly encountered by sensor-free systems at low speeds.

-

Reduced Noise and Vibration: The smooth operation of sensored BLDC motors results in lower noise and vibration levels, which is vital in sensitive environments. This reduction not only improves user experience but also enhances equipment durability, making them suitable for scenarios where noise reduction is essential.

-

Longer Lifespan: The absence of brushes minimizes wear and tear, leading to a longer operational lifespan and reduced maintenance costs. This durability represents a significant advantage in both consumer electronics and industrial applications. According to industry insights, engines equipped with a sensored BLDC motor provide superior throttle response compared to those without sensors, further underscoring their efficiency and performance.

These advantages underscore why sensored BLDC motor devices are increasingly favored in diverse high-performance fields, from consumer electronics to industrial machinery, where efficiency and precision are of utmost importance.

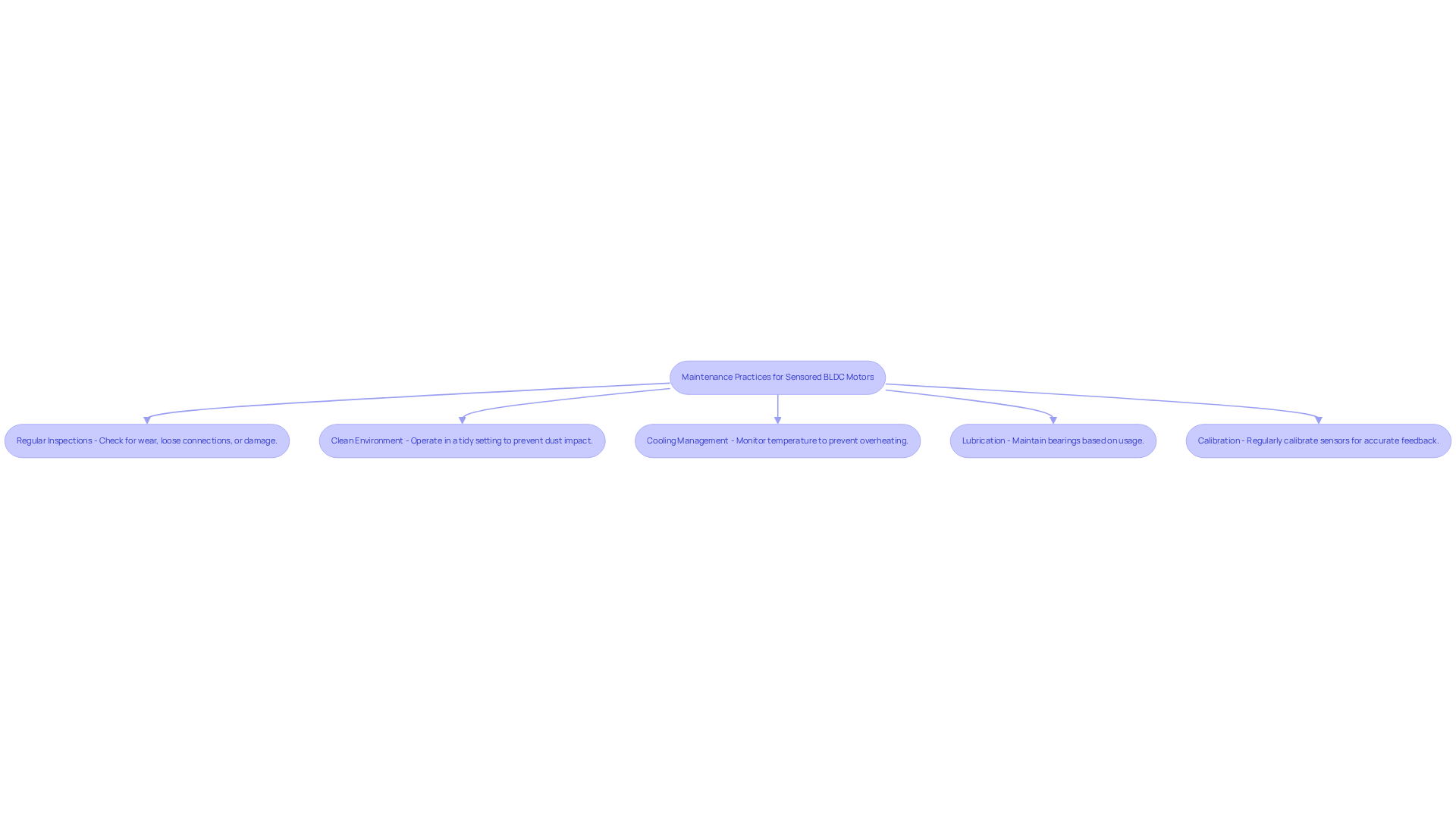

Assess Maintenance Needs and Lifespan of Sensored Motors

Sensored bldc motors are inherently low-maintenance due to their brushless design. However, certain practices can significantly enhance their lifespan and performance.

-

Regular Inspections: It is crucial to periodically check for signs of wear, loose connections, or damage to the sensors and wiring. This proactive approach can prevent potential failures.

-

Clean Environment: Operating the engine in a tidy setting is essential to prevent dust and debris from impacting functionality. A clean environment contributes to optimal performance.

-

Cooling Management: Monitoring the operating temperature is vital, as excessive heat can shorten the lifespan of electronic components. Implementing effective cooling solutions can mitigate this risk, ensuring longevity.

-

Lubrication: Although BLDC machines do not possess brushes that necessitate lubrication, it is important to note that bearings might require regular upkeep based on usage. This maintenance is key to sustaining performance.

-

Calibration: Regularly calibrating the sensors is essential to ensure accurate feedback and optimal performance. This practice guarantees that the motor operates within its intended parameters.

With proper care, a sensored bldc motor can boast a lifespan exceeding 10,000 hours, making it a reliable choice for long-term applications.

Conclusion

Sensored brushless DC motors signify a transformative leap in electric motor technology, characterized by their incorporation of sensors that deliver essential feedback on rotor position. This feature not only enhances operational precision but also markedly improves efficiency, rendering these motors crucial in high-demand applications such as robotics, electric vehicles, and industrial automation.

The advantages of sensored BLDC motors are manifold:

- They achieve enhanced efficiency through optimal commutation.

- They provide precise control for high-accuracy tasks.

- They exhibit superior performance under varying load conditions.

- They generate reduced noise and vibration.

- Their lifespan is extended due to the elimination of brushes.

Collectively, these attributes highlight the growing preference for sensored motors across diverse sectors, from consumer electronics to intricate industrial machinery.

As the necessity for efficient and reliable motor solutions escalates, recognizing the benefits of sensored brushless DC motors becomes imperative. By comprehending their advantages and adopting appropriate maintenance practices, users can optimize performance and longevity, ensuring these advanced motors remain at the cutting edge of technological innovation. Investing in sensored BLDC technology not only amplifies operational capabilities but also fosters sustainable practices in energy consumption and equipment durability.

Frequently Asked Questions

What are sensored brushless DC motors (BLDC motors)?

Sensorless BLDC motors are electric devices that use sensors for feedback on rotor position, allowing for precise operational control.

How do sensored BLDC motors differ from sensorless BLDC motors?

Sensorless BLDC motors integrate Hall effect sensors or encoders to accurately identify the rotor’s position, while sensorless BLDC motors do not use such sensors.

What advantages do sensored BLDC motors offer?

They provide smoother operation and enhanced efficiency, as well as improved responsiveness to varying load conditions.

In what applications are sensored BLDC motors commonly used?

They are extensively used in robotics, electric vehicles, and industrial automation, where high reliability and performance are essential.

Why is the ability to adapt to different operational demands important for sensored BLDC motors?

This adaptability is crucial for ensuring optimal performance in diverse environments and complex electronic systems.

What makes sensored BLDC motors essential in advanced technological applications?

Their capability to deliver precise control and efficiency positions them as key components in applications that require high performance and reliability.