Introduction

Understanding the complexities of AC motors is crucial for engineers who seek to boost industrial efficiency and performance. These motors play a vital role in numerous applications, providing significant benefits in speed control that directly impact energy consumption and operational flexibility. As the demand for precision and sustainability in industrial environments increases, engineers face the challenge of mastering various speed control methods.

What strategies can engineers implement to optimize AC motor performance while navigating the intricacies of modern technology? By exploring effective approaches, engineers can enhance their understanding and application of AC motors, ultimately leading to improved operational outcomes.

Understand AC Motors and Their Importance in Speed Control

AC engines play a pivotal role in various industrial applications, serving as the backbone of machinery that drives manufacturing processes. Utilizing alternating current (AC), these engines are renowned for their durability, efficiency, and minimal maintenance needs. Understanding the fundamental concepts of AC machinery – specifically their structure, which includes the stator and rotor, and their functionality through electromagnetic induction – is essential for engineers seeking to implement effective control solutions.

The ability to regulate the speed of a speed control AC motor significantly impacts energy efficiency and operational flexibility. This capability establishes AC engines as a critical component in modern industrial automation systems. Engineers must prioritize mastering these concepts to enhance system performance and drive innovation in their respective fields.

Explore Speed Control Methods for AC Motors

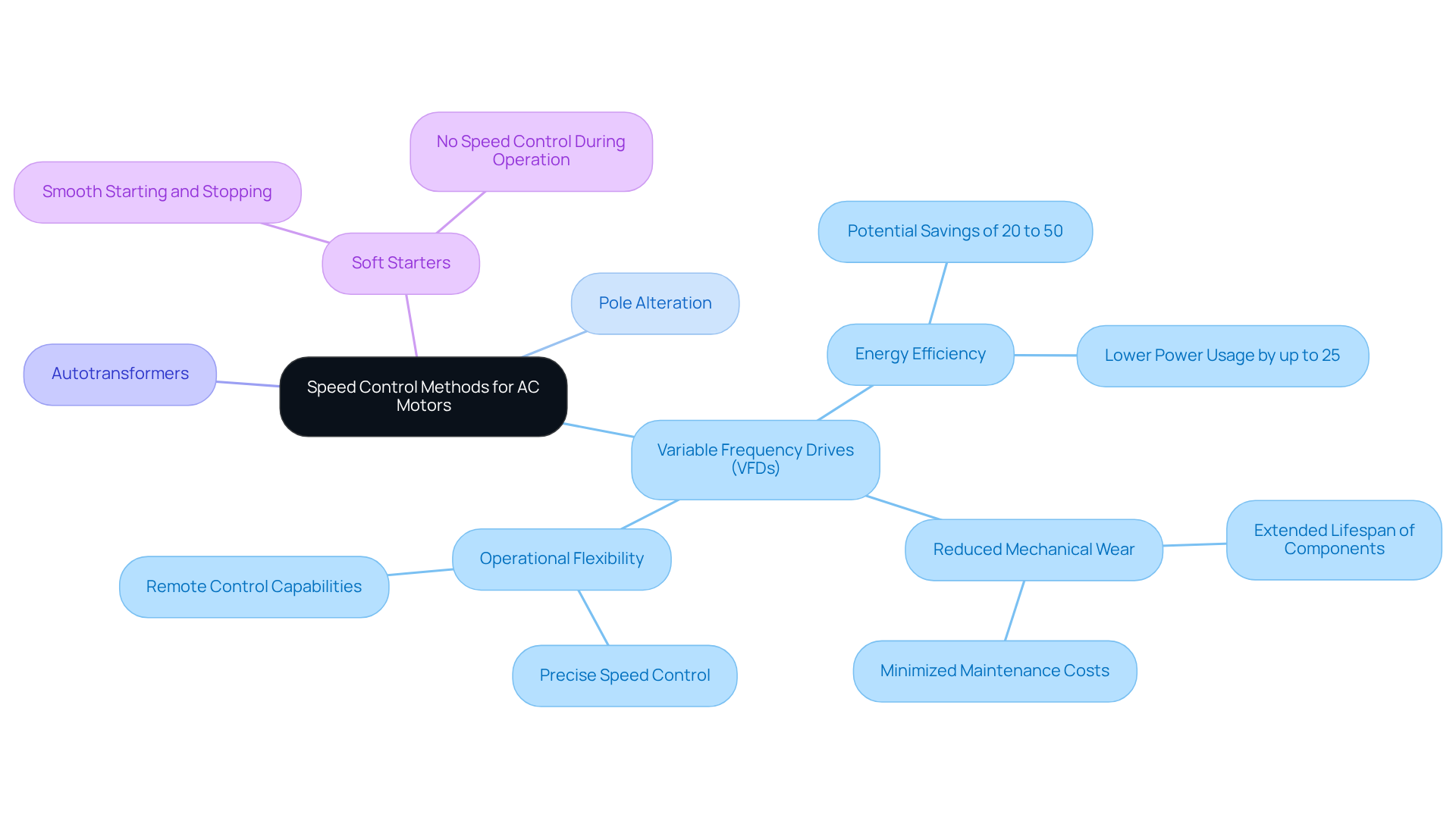

Regulating the pace of speed control AC motors presents a significant challenge, yet various techniques exist to address this issue, each offering unique advantages tailored to specific applications. The foremost method is the implementation of Variable Frequency Drives (VFDs), which adeptly adjust the frequency of the power supply to enable speed control AC motors with precision. This technique not only facilitates meticulous speed adjustments but also markedly improves energy efficiency, with potential savings ranging from 20% to 50% in applications such as pumps and fans. Moreover, VFDs reduce mechanical wear, extending the lifespan of components and minimizing maintenance costs.

Alternative methods include:

- Altering the number of poles in the machine

- Utilizing autotransformers

- Employing soft starters

While these options can be effective, they often fall short in terms of the operational flexibility and efficiency that VFDs provide. For instance, while soft starters enable smooth starting and stopping of machinery, they do not offer speed control during operation.

In practical applications, speed control AC motors are increasingly preferred in industrial environments because of their ability to optimize production processes and enhance product quality. Given that electric motors account for approximately 70% of electricity consumption in industrial settings, the adoption of VFDs aligns seamlessly with sustainability goals and regulatory compliance. This makes them an astute choice for engineers aiming to boost operational efficiency and reduce energy expenditures. Furthermore, the global market for variable frequency drives is projected to reach USD 47.79 billion by 2033, growing at a CAGR of 5.94% from 2025 to 2033, underscoring the rising significance of VFDs in the industry. The decreasing cost of VFDs has also rendered them a more financially viable option for businesses.

To ensure optimal performance and reliability, engineers must evaluate the specific requirements of each application when selecting the most effective speed control AC motor method. However, it is crucial to remain vigilant about common pitfalls associated with VFD implementation, such as the misapplication of technology, to mitigate potential challenges. A case study involving Willis Electrical’s collaboration in the oil and gas sector exemplifies the tangible benefits of VFDs, highlighting their ability to enhance operational flexibility and lower overall operating costs.

Implement Maintenance and Troubleshooting Strategies for AC Motor Speed Control

Regular upkeep is crucial for ensuring the optimal performance of air conditioning engines. Engineers must establish a consistent maintenance schedule that encompasses cleaning, lubrication, and thorough inspections of electrical connections. Common troubleshooting strategies include monitoring engine temperature, checking for unusual vibrations, and verifying proper alignment.

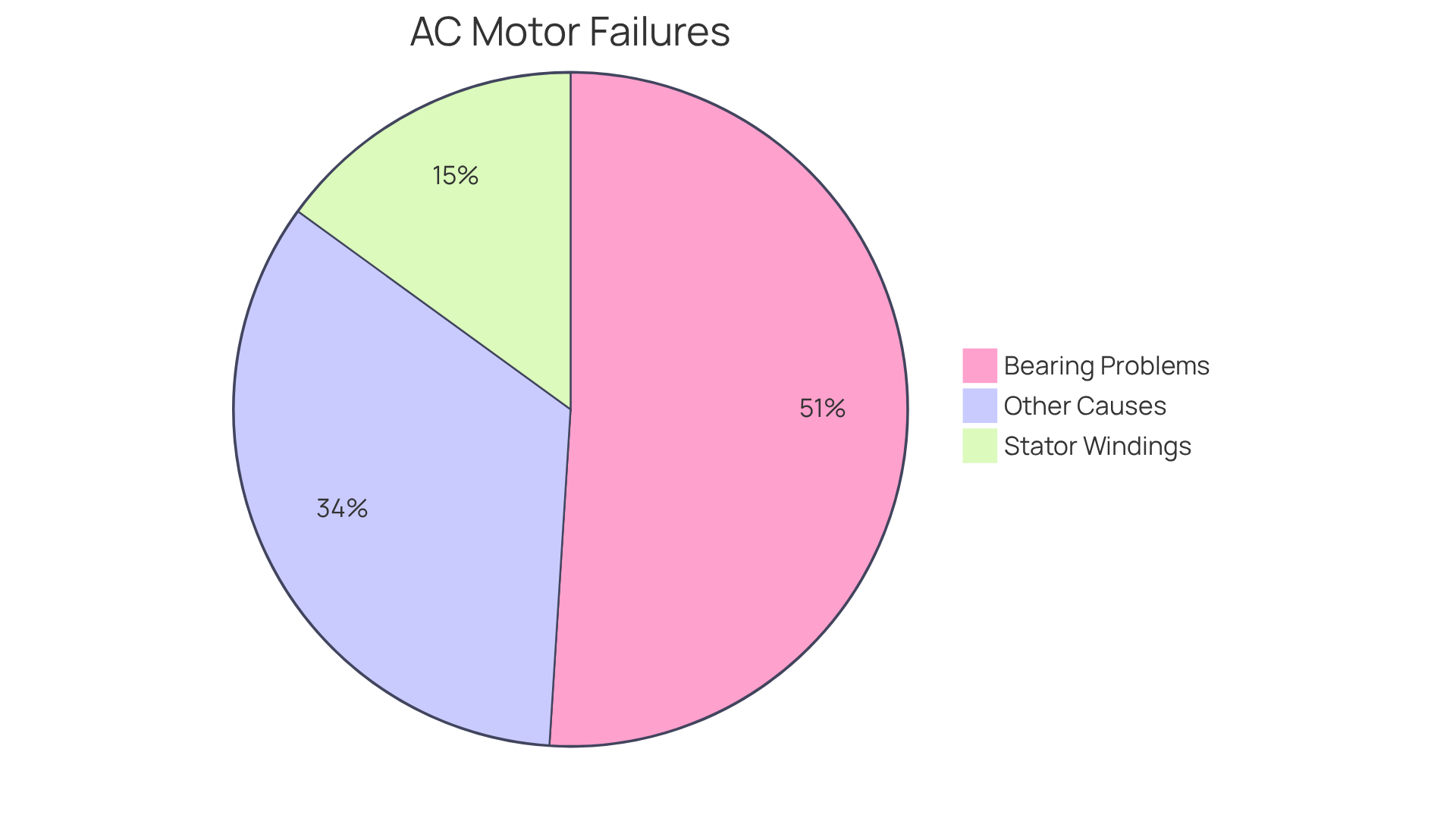

Statistics reveal that a staggering 51% of AC motor failures are linked to bearing problems, underscoring the necessity for diligent maintenance practices. Moreover, 30 to 40% of industrial facilities utilize some form of predictive maintenance, highlighting its growing importance in the industry. By employing predictive maintenance techniques such as vibration analysis and thermal imaging, potential issues can be identified proactively before they escalate into failures.

For instance, a case study on AC machinery failure analysis indicated that 15% of failures involve stator windings, often due to overheating and overloading. Additionally, 67% of manufacturers implement preventive care strategies to minimize downtime, emphasizing the significance of proactive approaches.

By addressing these maintenance requirements proactively, engineers can significantly extend the lifespan of AC devices and reduce unexpected downtimes, ultimately enhancing operational efficiency.

Select Appropriate Components for Effective Speed Control

Choosing the right components is crucial for the effective implementation of control systems in alternating current machines. Variable Frequency Drives (VFDs) are pivotal in adjusting the rotation rate, enabling precise control that enhances efficiency and performance. These drives facilitate smooth acceleration and deceleration, significantly minimizing mechanical stress and prolonging equipment lifespan. For example, in the oil and gas industry, a tailored VFD solution from Willis Electrical not only improved operational flexibility but also yielded substantial energy savings, showcasing its effectiveness in challenging environments. This solution incorporated features such as built-in overload protection, ensuring reliability and safety even in high-temperature conditions.

Controllers managing VFD operations are equally essential, as they guarantee optimal performance by reacting to real-time feedback from sensors that monitor velocity and load conditions. Engineers must take into account factors like the motor’s power rating, specific application needs, and environmental conditions when selecting these components. Ensuring compatibility among all elements is vital for developing a dependable and efficient speed control system.

Market trends reveal a rising demand for variable frequency drives, especially in low-power applications, which are expected to dominate the market due to their energy-saving advantages. The variable frequency drive market is projected to expand from USD 24.7 billion in 2025 to USD 32.0 billion by 2030, propelled by increased industrial automation and energy efficiency demands. This trend highlights the significance of speed control AC motors in contemporary AC motor applications, making their selection a critical consideration for engineers focused on optimizing performance and minimizing operational costs.

Conclusion

Mastering speed control for AC motors is crucial for engineers aiming to boost operational efficiency and drive innovation in industrial applications. Understanding AC motors, their functionality, and various control methods is foundational for optimizing performance and energy consumption.

Key insights reveal the importance of Variable Frequency Drives (VFDs) as a premier solution for speed regulation. These drives significantly improve energy efficiency and reduce mechanical wear. Regular maintenance and proactive troubleshooting strategies are equally essential, as they can mitigate failures and extend the lifespan of AC motors. Selecting the right components, including VFDs and controllers, ensures systems operate at peak performance while catering to the specific needs of diverse applications.

Given the rising demand for energy-efficient solutions and the anticipated growth of the VFD market, engineers must prioritize adopting best practices in speed control for AC motors. Staying informed about the latest technologies and methodologies not only enhances system reliability and efficiency but also contributes to sustainability goals within industries. Embracing these principles will lead to improved operational outcomes, making the mastery of AC motor speed control a critical focus for engineering excellence.

Frequently Asked Questions

What are AC motors and why are they important?

AC motors are electric motors that utilize alternating current to operate. They are crucial in various industrial applications as they serve as the backbone of machinery that drives manufacturing processes.

What are the key features of AC motors?

AC motors are known for their durability, efficiency, and minimal maintenance needs.

What are the main components of an AC motor?

The main components of an AC motor include the stator and rotor.

How do AC motors function?

AC motors function through the principle of electromagnetic induction.

Why is speed control important for AC motors?

Regulating the speed of an AC motor significantly impacts energy efficiency and operational flexibility, making it essential for modern industrial automation systems.

What should engineers focus on regarding AC motors?

Engineers should prioritize mastering the fundamental concepts of AC motors to enhance system performance and drive innovation in their fields.