Overview

This article delves into essential practices for engineers aiming to master speed control in fan systems. Understanding airflow dynamics, pressure relationships, and the various types of fans is crucial for enhancing performance. By grasping these concepts, engineers can significantly improve the efficiency and reliability of their applications.

To support this, we explore various speed control methods, including:

- Pulse Width Modulation (PWM)

- Variable Frequency Drives (VFDs)

These techniques are vital for optimizing fan operation. However, it’s not just about the methods; proper sizing, regular maintenance, and effective monitoring are equally important. These factors ensure that systems operate at peak efficiency, particularly in critical applications like electronics cooling.

In conclusion, mastering speed control in fan systems requires a comprehensive understanding of both theoretical and practical aspects. By implementing these best practices, engineers can enhance system performance and reliability, ultimately leading to more efficient operations.

Introduction

Understanding the complexities of fan systems is crucial for engineers aiming to optimize performance in various applications, especially in electronics cooling. By mastering the fundamentals of airflow dynamics, pressure relationships, and different fan types, professionals can achieve significant efficiencies and bolster system reliability.

However, with a variety of speed control methods available—each offering distinct advantages and challenges—how can engineers identify the most effective approach for their specific requirements? This article explores best practices for fan systems, providing engineers with the insights needed to enhance their designs and ensure optimal functionality.

By delving into these critical aspects, engineers will be equipped to make informed decisions that elevate their projects and drive performance.

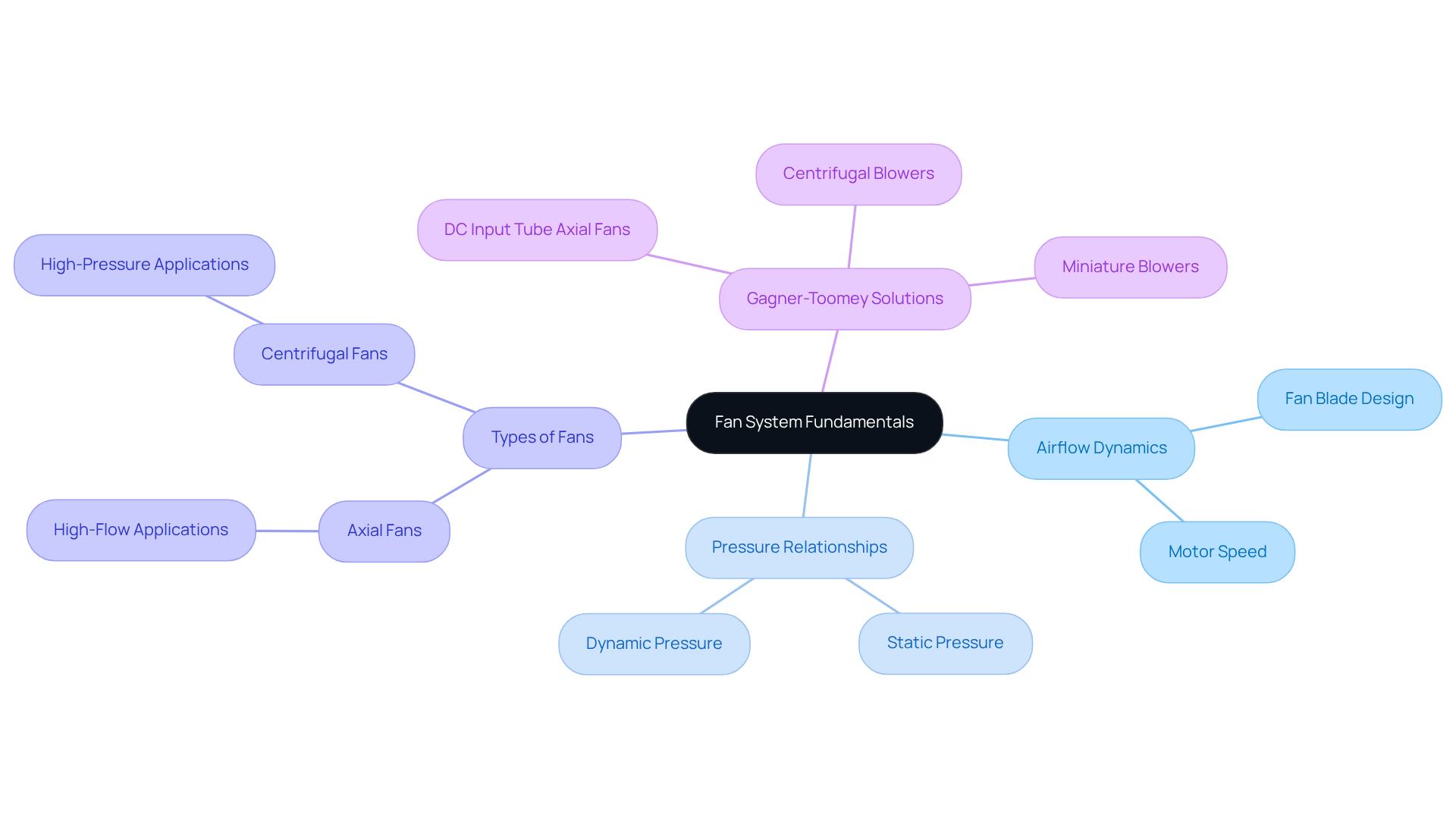

Understand Fan System Fundamentals

Fan systems play a crucial role in various applications, especially in electronics cooling, where speed control for fan enables them to convert electrical energy into mechanical energy to facilitate effective heat dissipation. Gagner-Toomey Associates, recognized as the world’s largest producer of standard and custom air-movers, provides an extensive range of DC input tube axial fans and centrifugal blowers designed for optimal functionality, efficiency, and low noise.

Airflow Dynamics: Understanding airflow generation is vital, influenced by factors such as fan blade design and motor speed. The design of fan blades significantly impacts flow patterns, which in turn affects cooling efficiency and overall system functionality. Gagner-Toomey’s innovative cooling solutions, including miniature blower and fan options, enhance ventilation management in confined spaces, with sizes ranging from 15x3mm to 280mm.

Pressure Relationships: Engineers must grasp the concepts of static and dynamic pressure, as these metrics are essential for evaluating fan performance in specific applications. Effective pressure management is key to ensuring optimal airflow and cooling efficiency, which is essential for speed control for fan. Gagner-Toomey’s diverse selection of ventilators and blowers, including options with IP protection available upon request, empowers engineers to select the right solution tailored to their pressure requirements.

Types of Fans: A solid understanding of axial and centrifugal fans, along with their operational principles and appropriate applications, is crucial for selecting the right device for any task. Each type serves distinct functions; axial fans are typically used in high-flow, low-pressure scenarios, while centrifugal fans excel in high-pressure environments. Gagner-Toomey’s extensive portfolio features a variety of fan types, offering numerous choices for diverse applications.

By mastering these fundamentals and leveraging Gagner-Toomey’s advanced thermal management solutions, engineers can make informed decisions that enhance system efficiency and reliability, ultimately leading to superior performance in electronics cooling applications.

Explore Fan Speed Control Methods

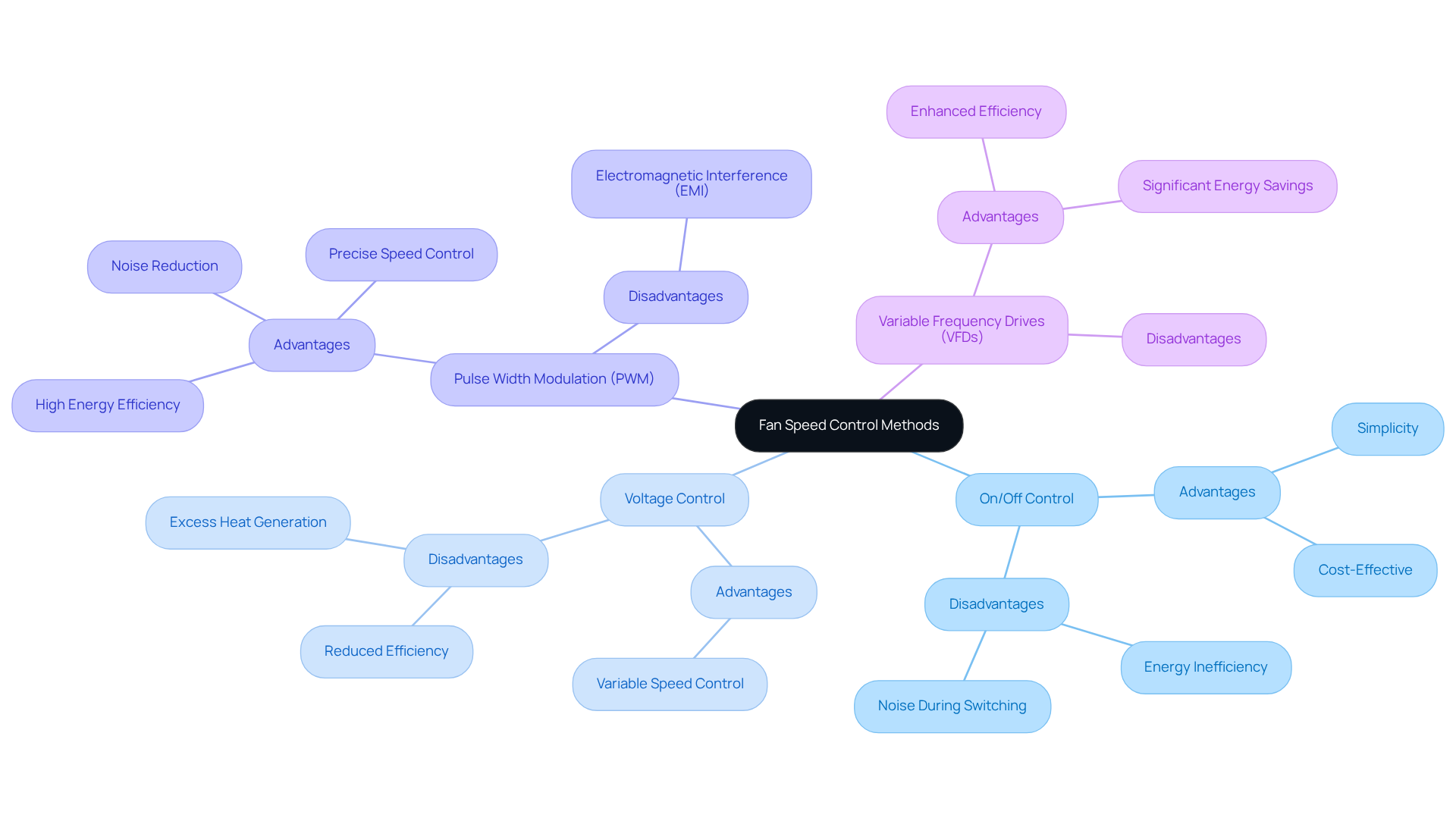

Fan speed control can be achieved through several methods, each offering distinct advantages:

-

On/Off Control: This straightforward approach is suitable for applications where precise control is not essential. However, it often leads to energy inefficiencies, as the fan operates at full speed or not at all.

-

Voltage Control: By adjusting the voltage supplied to the fan motor, speed can be varied. While this method allows for some control, it can generate excess heat and reduce overall efficiency.

-

Pulse Width Modulation (PWM): PWM is a sophisticated technique that enables precise speed control for fans by varying the duty cycle of the voltage signal. This method is highly efficient, capable of reducing energy consumption by up to 30% while maintaining optimal operating temperatures. Additionally, PWM significantly minimizes noise, making it ideal for applications requiring quiet operation. For example, high-frequency PWM, functioning at frequencies over 20 kHz, can operate fans at speeds as low as 10% of their maximum capacity, improving energy efficiency without compromising effectiveness. As noted by Wojciech Wojtkowski, “the main benefits of PWM-controlled switching converters consist of high energy efficiency, compact size, and enhanced thermal management compared to linear regulators.”

-

Variable Frequency Drives (VFDs): VFDs control the speed of AC motors by varying the frequency of the electrical supply. This approach not only enhances efficiency but also provides significant energy savings, making it a favored option in numerous industrial uses.

While PWM offers numerous benefits, it is important to consider potential drawbacks, such as the electromagnetic interference (EMI) associated with pulsed operation. Understanding these options enables engineers to enhance fan systems efficiently by implementing speed control for fan systems, ensuring they meet operational expectations, energy efficiency targets, and noise limitations.

Implement Best Practices for Enhanced Performance

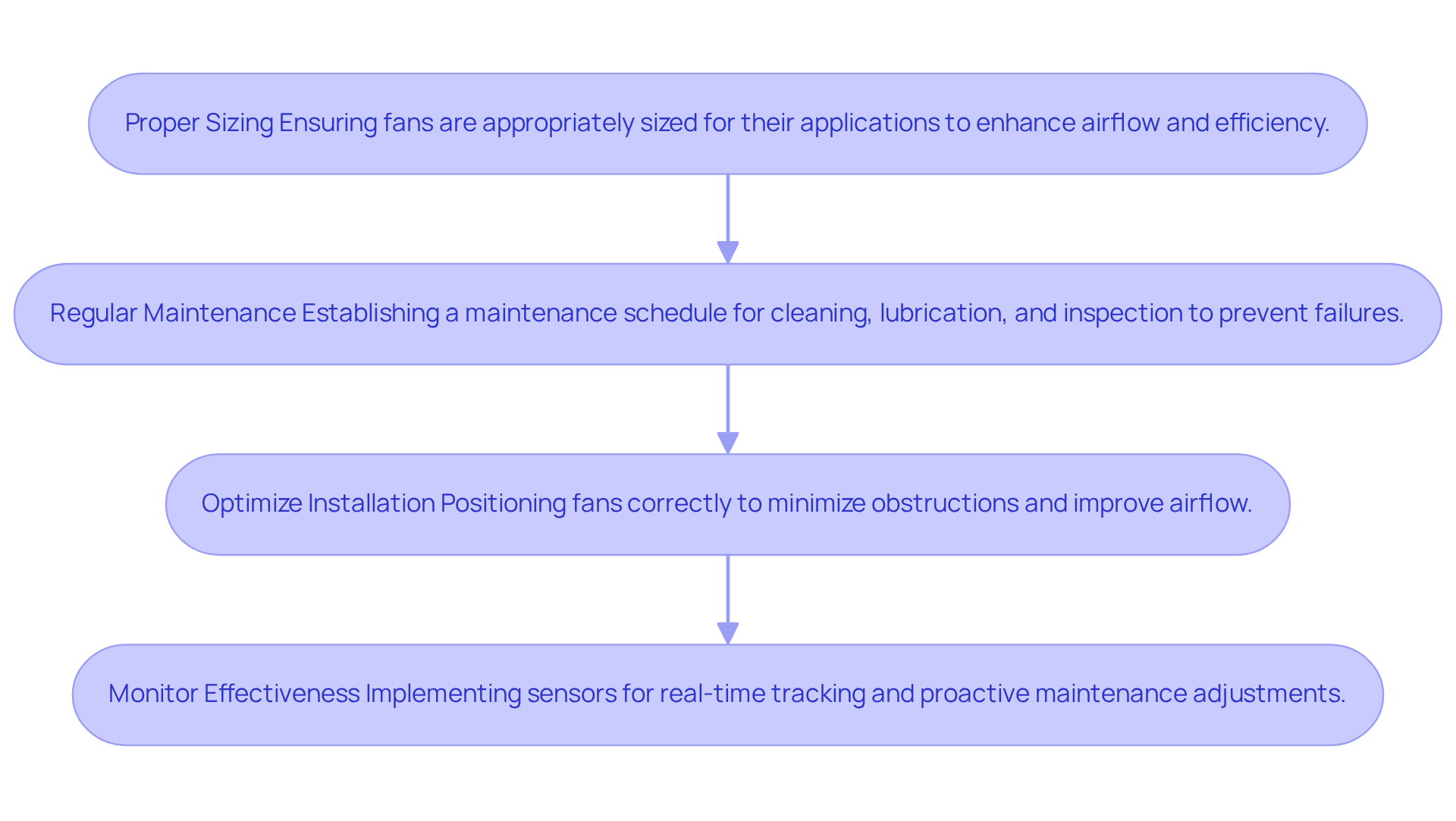

To maximize fan system performance, engineers must adhere to several best practices that ensure efficiency and reliability:

-

Proper Sizing: Ensuring fans are appropriately sized for their specific applications is crucial. Oversizing or undersizing can lead to inefficiencies, increased energy consumption, and premature wear. Industry specialists emphasize that proper sizing enhances airflow and achieves desired results. For instance, unclean ventilators can lose up to 30% of their efficiency, underscoring the importance of precise sizing and regular upkeep.

-

Regular Maintenance: Establishing a comprehensive maintenance schedule is vital. This should encompass routine cleaning, lubrication, and inspection of fan components. Regular maintenance not only prevents failures but also boosts efficiency. Keeping thorough documentation of maintenance tasks aids in monitoring results and organizing future efforts.

-

Optimize Installation: Correctly positioning fans is key to minimizing obstructions to air movement. Ensuring that intake and exhaust routes are unobstructed can significantly improve efficiency. Engineers should consider the layout of the installation environment to maximize airflow and reduce turbulence, which is essential for effective thermal management.

-

Monitor Effectiveness: Implementing sensors and monitoring systems allows for real-time tracking of fan effectiveness metrics. This enables timely adjustments and proactive maintenance, ensuring that any deviations from normal operating conditions are addressed promptly. The integration of predictive maintenance technologies, such as IIoT sensors and AI analytics, can further enhance monitoring practices.

By adhering to these best practices, engineers can significantly improve the reliability and efficiency of fan systems in their applications, ultimately resulting in enhanced operational effectiveness.

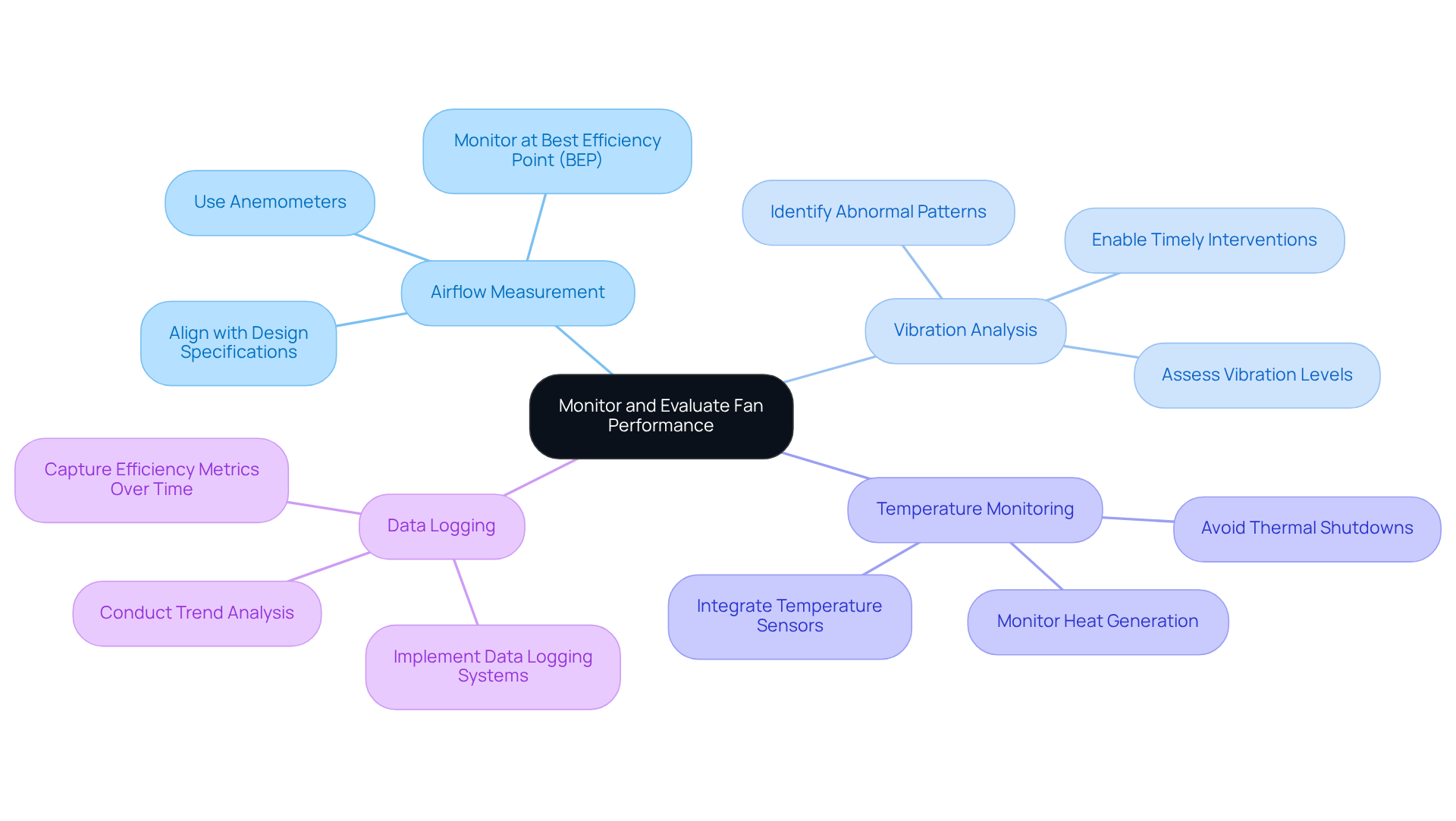

Monitor and Evaluate Fan Performance

Effective monitoring of fan functionality, particularly through speed control for fan, is crucial for ensuring optimal operation and longevity. To achieve this, several key metrics must be tracked:

- Airflow Measurement: Utilize anemometers to accurately measure airflow rates, ensuring they align with design specifications. This is vital, as the speed control for fan ventilation measurements directly impact system efficiency and performance. At the Best Efficiency Point (BEP), the implementation of speed control for fan is essential as it minimizes the power input per unit of air movement, making precise measurement indispensable.

- Vibration Analysis: Regularly assess vibration levels to identify abnormal patterns that may signal mechanical issues or misalignment. For example, vibration analysis techniques can uncover early signs of wear, enabling timely interventions that prevent costly downtime. As Brian Simkins, Senior Sales Engineer, points out, “Measuring airflow in ductwork is more difficult than measuring flow in pipes,” highlighting the necessity of precise measurement techniques.

- Temperature Monitoring: Integrate temperature sensors to monitor heat generated by the fan and its components. Keeping temperatures within safe limits is essential to avoid thermal shutdowns, particularly in high-density electronics applications.

- Data Logging: Implement data logging systems to capture efficiency metrics over time. This allows for trend analysis and proactive maintenance planning, ensuring that any deviations from expected outcomes can be addressed before they escalate into significant issues.

Practical applications demonstrate that accurate ventilation assessment and vibration evaluation, along with speed control for fan systems, not only enhance operation but also extend their lifespan. For instance, in the case study of ‘Electronics Cooling for High-Density Devices,’ thermal engineers employed the PQ curve to select fans that maintain necessary ventilation under restrictive conditions, ensuring reliability and efficiency. By systematically monitoring these parameters, engineers can significantly boost the reliability of fan systems, ensuring they operate efficiently and effectively under varying conditions. Moreover, avoiding common pitfalls, such as misplacing airflow sensors after control dampers, can further enhance measurement accuracy and system performance.

Conclusion

Mastering speed control for fan systems is crucial for engineers who seek to optimize performance across various applications, especially in electronics cooling. Understanding the fundamentals of fan systems—airflow dynamics, pressure relationships, and the types of fans available—enables engineers to make informed decisions that enhance both efficiency and reliability. By leveraging advanced technologies and adhering to best practices, fan systems can not only meet operational demands but also contribute significantly to energy conservation.

Key insights throughout this article underscore the importance of effective fan speed control methods, such as:

- Pulse Width Modulation (PWM)

- Variable Frequency Drives (VFDs)

These techniques facilitate precise adjustments, leading to substantial energy savings and improved thermal management. Furthermore, implementing best practices like:

- Proper sizing

- Regular maintenance

- Effective monitoring strategies

can further enhance fan performance. This ensures that systems operate at their peak while minimizing downtime and inefficiencies.

In conclusion, the significance of proficient fan system management cannot be overstated. Engineers are encouraged to adopt these best practices and innovative control methods to elevate their designs and uphold high standards of operational excellence. By concentrating on energy efficiency and performance monitoring, the potential for enhanced system longevity and reliability becomes attainable, ultimately benefiting a wide range of applications within the engineering domain.

Frequently Asked Questions

What is the role of fan systems in electronics cooling?

Fan systems are crucial in electronics cooling as they convert electrical energy into mechanical energy to facilitate effective heat dissipation.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, providing a wide range of DC input tube axial fans and centrifugal blowers designed for optimal functionality, efficiency, and low noise.

How does fan blade design affect airflow dynamics?

The design of fan blades significantly impacts flow patterns, which in turn affects cooling efficiency and the overall functionality of the system.

What are the sizes of fans offered by Gagner-Toomey for confined spaces?

Gagner-Toomey offers miniature blower and fan options in sizes ranging from 15x3mm to 280mm.

Why is it important for engineers to understand static and dynamic pressure?

Understanding static and dynamic pressure is essential for evaluating fan performance in specific applications and for effective pressure management, which ensures optimal airflow and cooling efficiency.

What types of fans are available from Gagner-Toomey and what are their applications?

Gagner-Toomey offers axial and centrifugal fans. Axial fans are typically used in high-flow, low-pressure scenarios, while centrifugal fans excel in high-pressure environments.

How can engineers enhance system efficiency and reliability in electronics cooling applications?

By mastering fan system fundamentals and leveraging Gagner-Toomey’s advanced thermal management solutions, engineers can make informed decisions that enhance system efficiency and reliability.