Overview

The article delves into the effective utilization of a fan curve calculator by engineers to optimize cooling performance across various applications. It underscores the significance of comprehending fan curves, airflow, static pressure, and efficiency. The article provides a systematic approach, guiding readers through the setup of the calculator, the accurate input of data, and the interpretation of results. This process is essential for enhancing thermal management and energy efficiency in electronic systems.

Introduction

Understanding the intricate relationship between airflow and static pressure is crucial for engineers aiming to optimize cooling systems. Fan curves serve as essential tools in this process, enabling professionals to select the right fans for specific applications and enhance overall performance. However, navigating the complexities of fan curve calculations can present challenges.

How can engineers ensure they are making the best choices for their designs? This guide provides a step-by-step approach to mastering the fan curve calculator, empowering engineers to unlock the full potential of their cooling solutions.

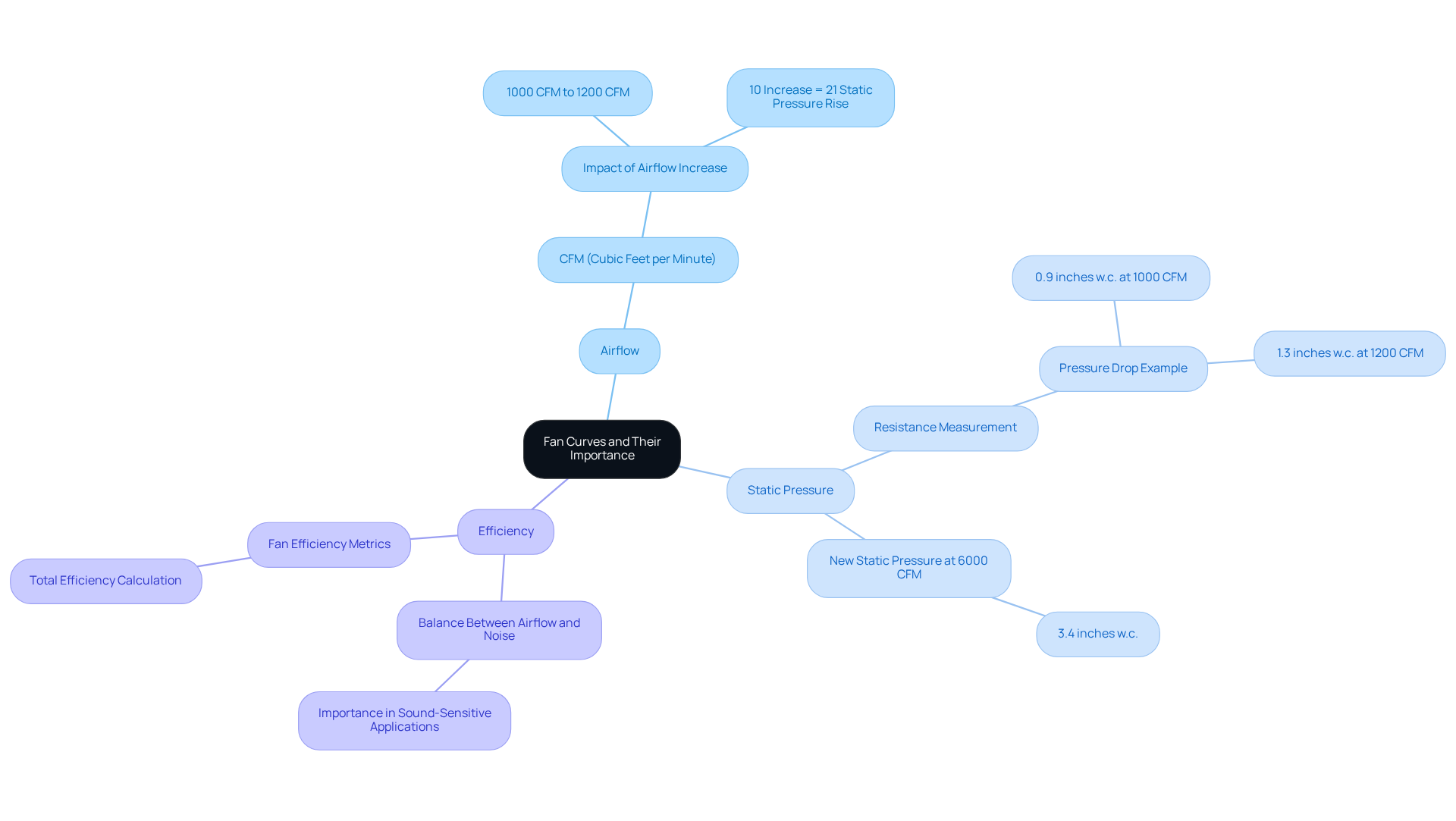

Understand Fan Curves and Their Importance

Blade shapes illustrate the critical connection between airflow and static pressure in devices, serving as essential tools for engineers to assess cooling efficiency across varying conditions. A thorough understanding of these curves is vital for using a fan curve calculator to select the appropriate fan for specific applications, which ensures optimal cooling performance. Gagner-Toomey Associates, the world’s largest manufacturer of standard and custom air-movers, provides an extensive portfolio of cooling solutions, including DC input tube axial fans ranging from 15 to 280mm and centrifugal blowers from 15 to 225mm, all optimized for performance, efficiency, and low noise. Key factors to consider include:

- Airflow (CFM): This metric represents the volume of air a fan can move, measured in cubic feet per minute. For instance, enhancing ventilation from 1000 CFM to 1200 CFM can significantly alter the dynamics of the setup. Notably, a 10% increase in air movement results in a 21% rise in static pressure, which is crucial for understanding the performance of the system.

- Static Pressure (inches H2O): This measurement indicates the resistance the fan must overcome to push air through the system. A pertinent example is that a pressure drop of 0.9 inches w.c. at 1000 CFM can escalate to 1.3 inches w.c. when air movement increases to 1200 CFM. Moreover, the horsepower required at 6000 CFM is calculated to be 5.4, underscoring the power demands at various ventilation levels.

- Efficiency: This reflects the equilibrium between airflow and noise levels, which is particularly vital in sound-sensitive applications. Grasping fan efficiency metrics enables engineers to select fans that minimize noise while maximizing performance.

Mastering fan profiles empowers engineers to make informed decisions that enhance the reliability and performance of electronic devices. Gagner-Toomey Associates emphasizes that understanding the relationship between fan curves and cooling efficiency through the use of a fan curve calculator can lead to significant improvements in energy management and overall performance across diverse applications, including automotive, telecom, and industrial sectors. By leveraging this knowledge, engineers can optimize designs, ensuring that electronic components function effectively and sustainably. Furthermore, the actual airflow is typically around fifty percent of the fan’s maximum output for forced air cooling applications, a critical aspect in system design. Understanding fan laws is also essential for predicting performance variations, enabling engineers to foresee how changes in airflow will impact static pressure and horsepower requirements.

Access and Set Up the Fan Curve Calculator

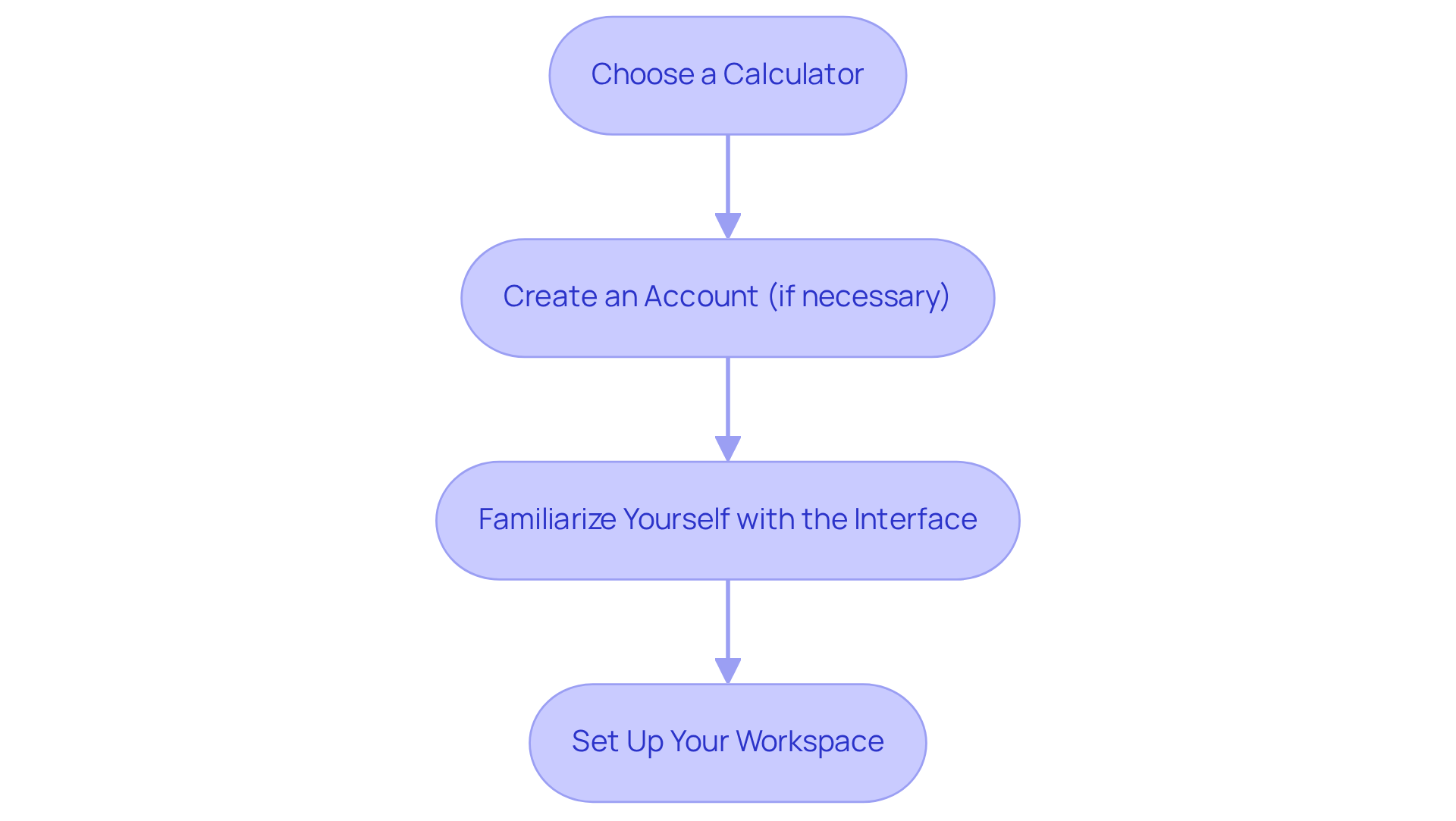

To effectively utilize the fan curve calculator, adhere to the following steps:

- Choose a Calculator: Begin by selecting a fan performance calculator that aligns with your specific needs. Numerous manufacturers offer online calculators, or you may opt for software tools tailored for this purpose.

- Create an Account (if necessary): Be aware that some calculators might necessitate account creation for access. Follow the provided prompts to register accordingly.

- Familiarize Yourself with the Interface: Allocate a few minutes to explore the features of the calculator. Pay attention to sections concerning input data, output results, and any additional settings that may enhance your experience.

- Set Up Your Workspace: Ensure your environment is quiet and free from distractions. This will facilitate a focused approach to accurately inputting data.

By meticulously configuring the fan curve calculator, you will be well-prepared to input data and efficiently assess results.

Input Relevant Data for Accurate Calculations

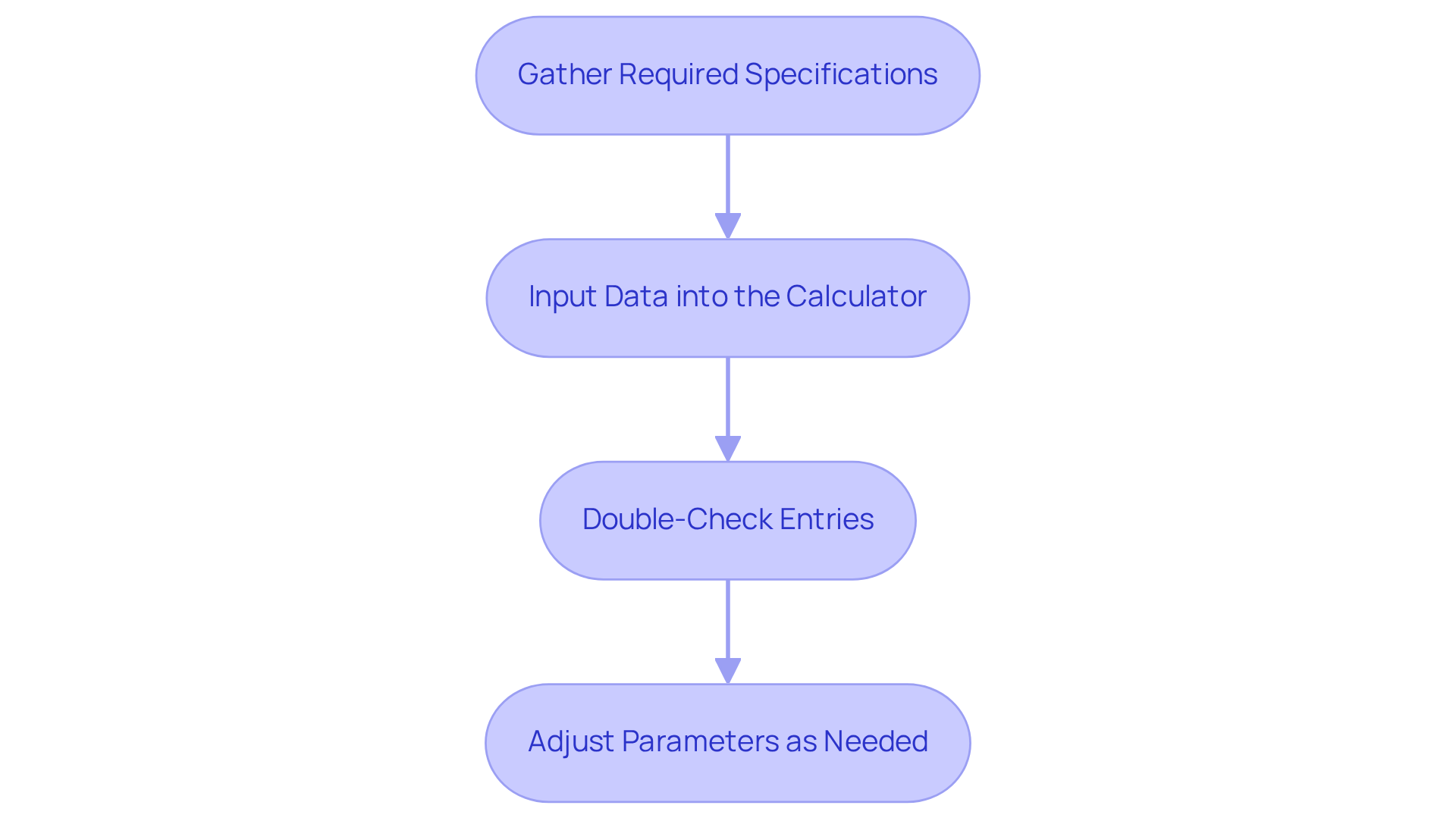

To achieve accurate calculations, it is essential to follow these steps when inputting data into the fan curve calculator:

-

Gather Required Specifications: Begin by collecting all necessary specifications for the fan and the system it will be cooling. This includes crucial details such as:

- Fan model and manufacturer

- Desired airflow rate (CFM)

- Maximum allowable static pressure

- Operating temperature range

-

Input Data into the Calculator: Next, enter the gathered data into the appropriate fields within the calculator. It is vital to ensure that units are consistent (e.g., CFM for airflow, inches H2O for static pressure) to avoid discrepancies in calculations.

-

Double-Check Entries: After inputting the data, it is imperative to review all entries for accuracy. Mistakes in data entry can lead to incorrect results, potentially compromising the design integrity.

-

Adjust Parameters as Needed: If the initial results do not meet expectations, consider adjusting parameters such as fan speed or configuration. This exploration of different scenarios can yield more satisfactory outcomes.

By meticulously inputting relevant data into the fan curve calculator, you can ensure that the calculations accurately reflect the true performance characteristics of the cooling system.

Interpret Results and Apply Findings to Design

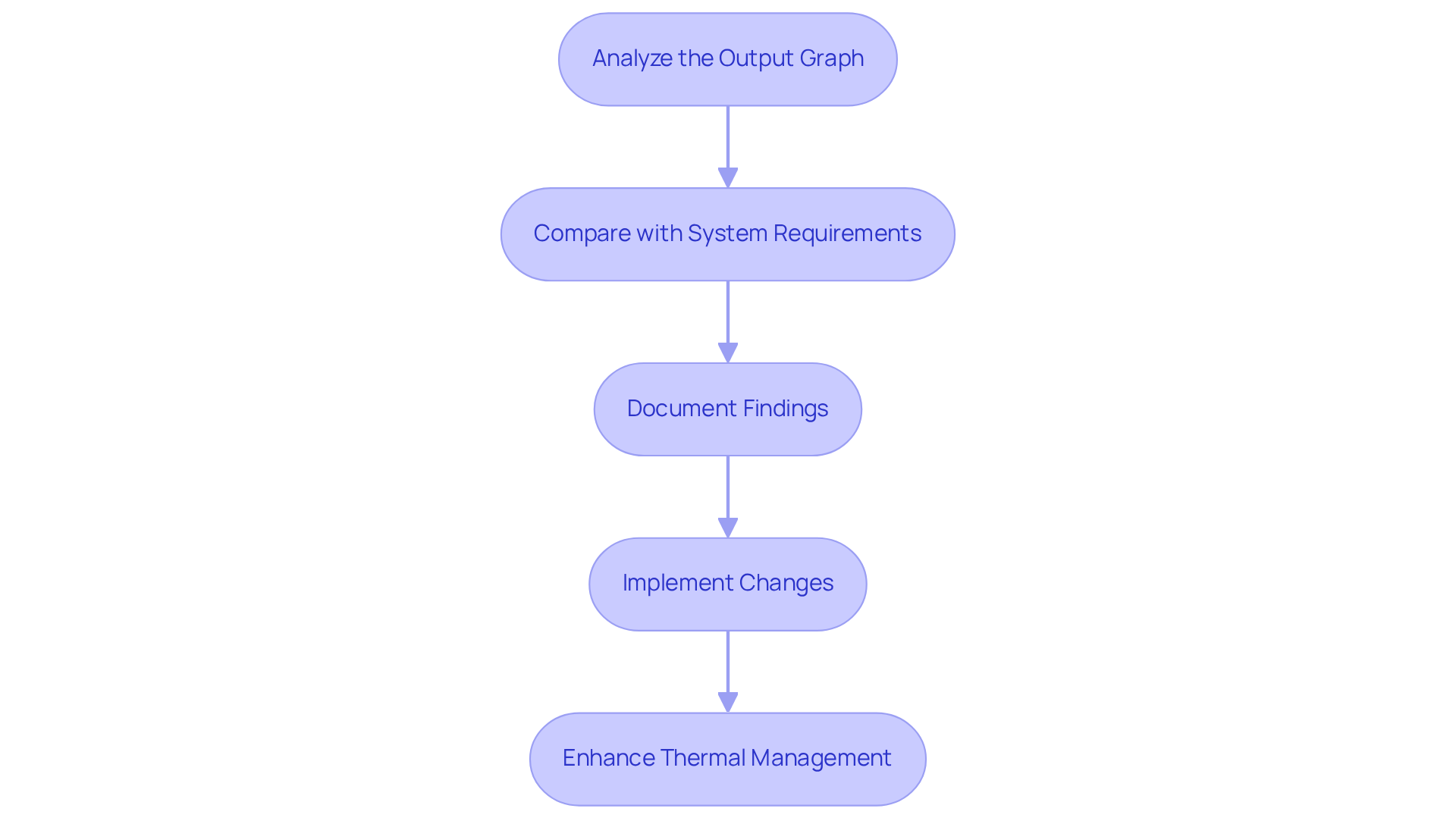

Once you have obtained results from the fan curve calculator, follow these steps to interpret and apply your findings:

-

Analyze the Output Graph: Review the graph of fan performance generated by the fan curve calculator. Focus on key points such as:

- The intersection of airflow and static pressure, which indicates the operating point of the fan.

- The efficiency curve, highlighting the optimal performance range for your application.

-

Compare with System Requirements: Ensure that the calculated airflow (measured in cubic feet per minute, CFM) and static pressure (in inches of water gauge, in. H2O) align with the cooling requirements of your electronic system. If discrepancies arise, consider selecting a different fan or adjusting your design parameters to achieve the desired performance. Remember, a fan utilizes 20 brake horsepower at its operating point for optimizing energy consumption, which is crucial for effective fan selection.

-

Document Findings: Record the results and insights gained during your analysis. This documentation is crucial for future reference and design iterations, allowing for continuous improvement in your engineering processes. As mentioned, “By learning how to read and interpret fan graphs, you will be able to improve your cooling system, thus resulting in the smooth operation of your equipment.”

-

Implement Changes: Based on your analysis, make necessary adjustments to the design. This may involve selecting a different fan model, modifying the layout to enhance airflow pathways, or integrating additional thermal interface materials to optimize thermal management.

By effectively interpreting results and applying findings, engineers can significantly enhance the thermal management of their designs, leading to improved performance and reliability. Case studies, such as those on “Utilizing Fan Curves for Thermal Management,” have shown that understanding fan curves can lead to substantial energy savings and operational efficiency in electronic systems, underscoring the importance of this analytical process.

Conclusion

Mastering the fan curve calculator is crucial for engineers committed to optimizing cooling efficiency across various applications. A thorough understanding of fan curves empowers professionals to select the appropriate fan, thereby ensuring that electronic components function effectively and sustainably. By grasping the intricate relationship between airflow, static pressure, and efficiency, engineers can make informed decisions that significantly enhance performance and reliability in their designs.

This guide has shared essential insights, highlighting the importance of accurately inputting data, interpreting results, and applying findings to refine thermal management strategies. Critical steps, such as gathering specifications, analyzing output graphs, and adjusting design parameters, are vital for achieving optimal performance. By emphasizing the significance of fan curves in engineering, we not only illuminate their role in energy management but also underscore the potential for substantial operational efficiency gains.

Ultimately, the knowledge acquired from this guide serves as a formidable tool for engineers. By leveraging fan curve calculators, professionals can elevate their designs, ensuring that cooling systems effectively meet the demands of modern electronic applications. Embracing this analytical approach will not only lead to improved performance but also foster innovation within the engineering field.

Frequently Asked Questions

What are fan curves and why are they important?

Fan curves illustrate the relationship between airflow and static pressure in devices, helping engineers assess cooling efficiency under varying conditions. Understanding these curves is crucial for selecting the appropriate fan using a fan curve calculator to ensure optimal cooling performance.

What factors should be considered when selecting a fan?

Key factors include airflow (CFM), static pressure (inches H2O), and efficiency. Airflow measures the volume of air a fan can move, static pressure indicates the resistance the fan must overcome, and efficiency reflects the balance between airflow and noise levels.

How does airflow (CFM) affect performance?

Airflow, measured in cubic feet per minute (CFM), significantly impacts system dynamics. For example, increasing airflow from 1000 CFM to 1200 CFM can lead to a 21% rise in static pressure, which is essential for understanding overall system performance.

What does static pressure indicate in a fan system?

Static pressure measures the resistance the fan must overcome to push air through the system. For instance, a pressure drop of 0.9 inches w.c. at 1000 CFM can rise to 1.3 inches w.c. when airflow increases to 1200 CFM.

Why is efficiency important in fan selection?

Efficiency reflects the balance between airflow and noise levels, which is particularly important in sound-sensitive applications. Understanding efficiency metrics helps engineers choose fans that minimize noise while maximizing performance.

How does understanding fan profiles benefit engineers?

Mastering fan profiles allows engineers to make informed decisions that enhance the reliability and performance of electronic devices. This knowledge leads to significant improvements in energy management and overall performance across various applications.

What is the typical actual airflow for forced air cooling applications?

The actual airflow is typically around fifty percent of the fan’s maximum output in forced air cooling applications, which is a critical aspect in system design.

What role do fan laws play in predicting performance?

Understanding fan laws is essential for predicting performance variations, enabling engineers to foresee how changes in airflow will impact static pressure and horsepower requirements.