Overview

This article delves into the design and applications of thermoelectric coolers (TECs) specifically for engineers, emphasizing the principles of thermoelectric cooling, key components, real-world applications, and performance optimization strategies. It underscores the critical importance of understanding the Peltier effect, selecting appropriate materials, and implementing effective thermal management techniques to enhance the efficiency and applicability of TECs across diverse fields. These include:

- Consumer electronics

- Medical devices

- Automotive systems

By grasping these concepts, engineers can significantly elevate the performance and versatility of TECs in their respective domains.

Introduction

Understanding the intricate workings of thermoelectric coolers (TECs) is essential for engineers aiming to innovate in the realm of temperature control. These devices, which harness the Peltier effect, provide a unique solution to a diverse array of cooling challenges across various industries, from consumer electronics to medical applications. As the demand for efficient and reliable cooling solutions continues to grow, engineers are confronted with a critical question: how can they optimize the performance of these systems to meet evolving technological needs? This article delves into the principles, components, and real-world applications of thermoelectric cooling, offering insights that empower engineers to master this pivotal technology.

Explore the Principles of Thermoelectric Cooling

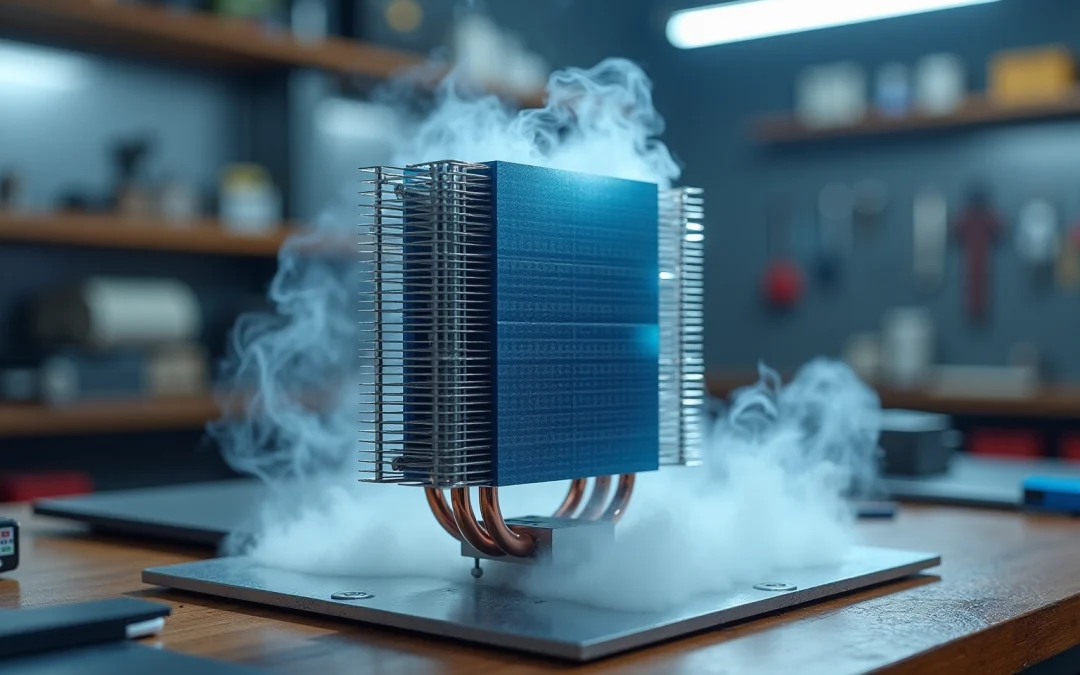

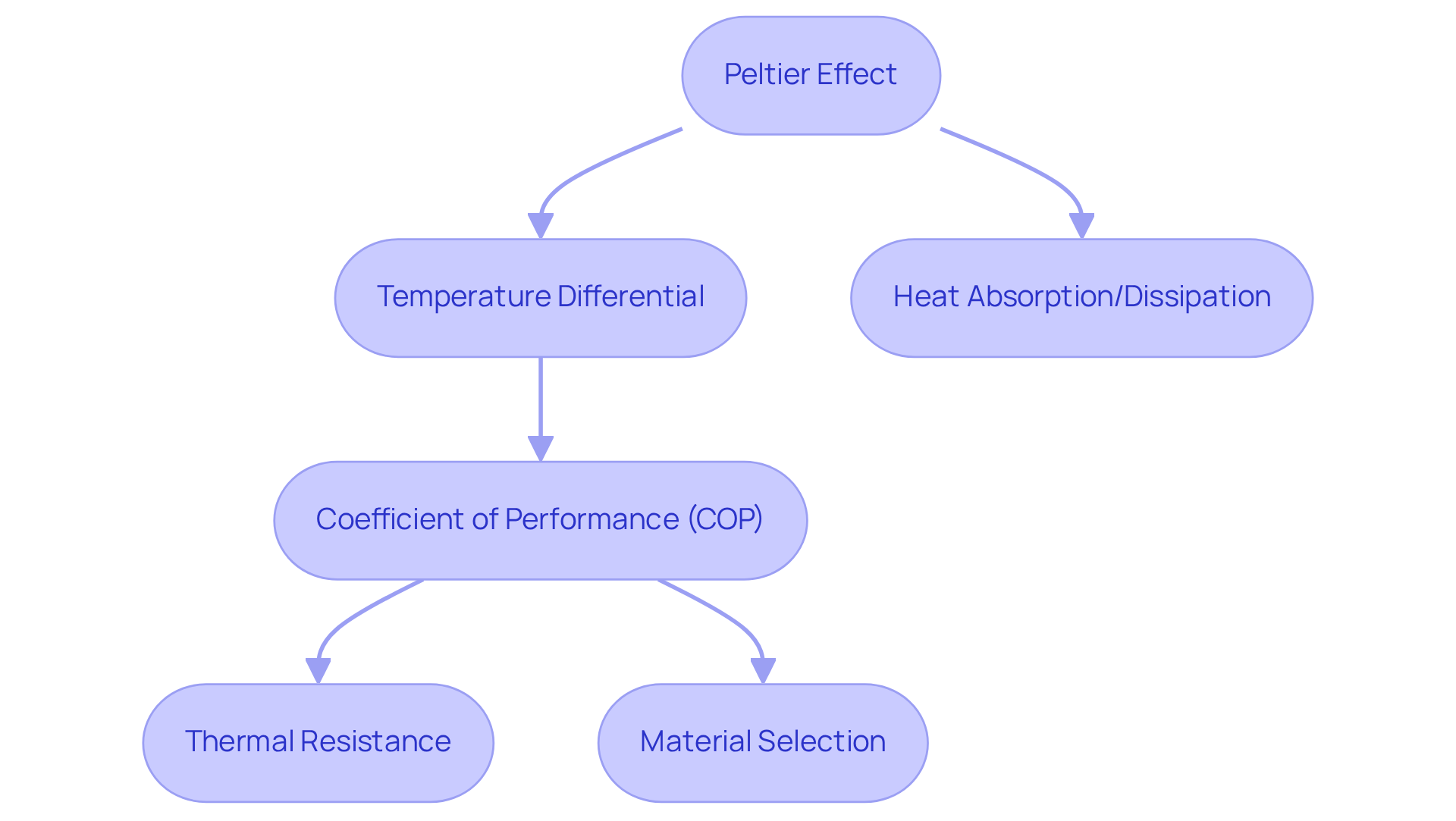

Thermoelectric refrigeration fundamentally relies on the Peltier effect, a phenomenon that occurs when an electric current traverses two distinct semiconductor materials, typically p-type and n-type. This interaction engenders a temperature differential, facilitating heat absorption on one side of the thermo cooler while dissipating it on the opposite side. Mastery of this principle is paramount for engineers aspiring to develop high-efficiency thermo cooler solutions.

The performance of a TEC is quantified by its coefficient of performance (COP), a critical metric that reflects the efficiency of heat transfer relative to electrical energy input. To , engineers must also consider thermal resistance and select appropriate materials, as these factors significantly influence overall efficiency.

Recent advancements in research have focused on augmenting the COP of energy conversion technologies, underscoring the ongoing evolution of this innovation across various applications, including medical solutions.

Gagner-Toomey Associates, a leading supplier of innovative temperature control solutions, offers a comprehensive range of power conversion products, including DC/DC converters and medical power supplies, which are essential for optimizing thermodynamic refrigeration systems that incorporate a thermo cooler. Their diverse portfolio also encompasses EMI filters, ensuring that engineers have access to the requisite components for effective thermal management in medical, industrial, and server applications.

Examine the Structure and Components of Thermoelectric Coolers

Thermo coolers are made up of several key components that work together to achieve efficient cooling.

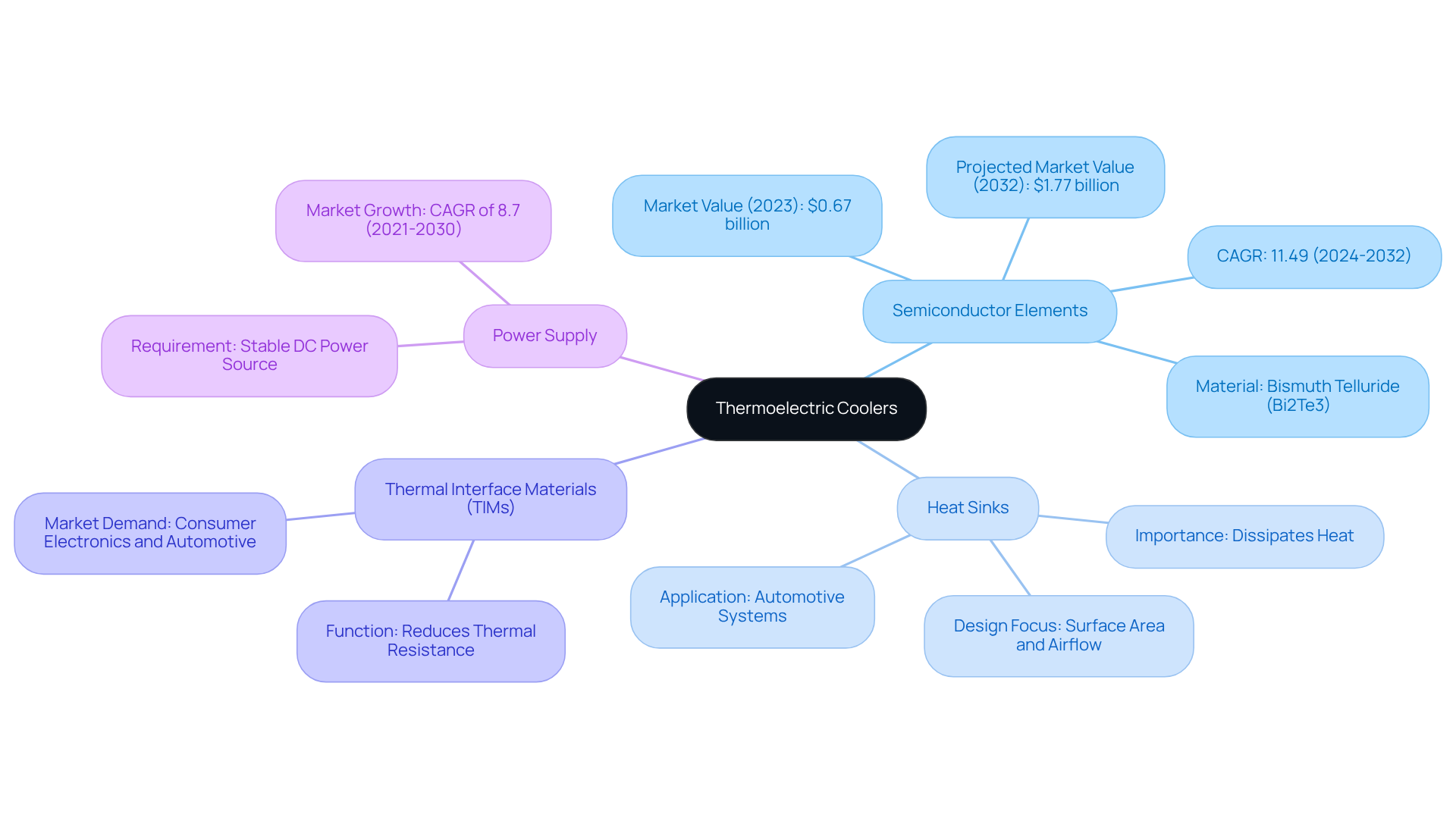

- Semiconductor Elements: Serving as the heart of the TEC, these elements are typically constructed from bismuth telluride (Bi2Te3) for room temperature applications. The arrangement of p-type and n-type semiconductors is critical for establishing the necessary thermal gradient. The thermoelectric materials market was valued at USD 0.67 billion in 2023 and is projected to reach USD 1.77 billion by 2032, driven by the increasing demand for efficient energy recovery solutions.

- Heat Sinks: These components are essential for dissipating heat from the hot side of the TEC, thereby enhancing the efficiency of the refrigeration process. Their design must prioritize maximizing surface area and airflow. An engineer specializing in heat sink design emphasizes, “The effectiveness of a heat sink is crucial for the overall performance of a TEC, especially in high-demand applications like automotive systems.”

- Thermal Interface Materials (TIMs): TIMs are vital for improving thermal contact between the TEC and the surfaces it is cooling or heating, effectively reducing thermal resistance. The growing demand for thermo coolers in consumer electronics and automotive applications underscores the significance of efficient TIMs in achieving peak performance.

- Power Supply: A stable DC power source is necessary to drive the current through the TEC. Engineers must ensure that the power supply aligns with the TEC’s specifications to prevent damage or inefficiency. The market for thermo coolers, which regulate temperature, is anticipated to expand at a CAGR of 8.7% from 2021 to 2030, highlighting the increasing importance of reliable power solutions.

Understanding these components is essential for engineers aiming to develop and implement . As the demand for innovative temperature control solutions escalates—particularly in fields such as consumer electronics and automotive systems—keeping abreast of the latest trends in heat sink design and semiconductor materials will be crucial for success. Additionally, emerging opportunities in multistage applications and novel usage areas for thermo coolers present exciting avenues for innovation.

Implement Thermoelectric Coolers in Real-World Applications

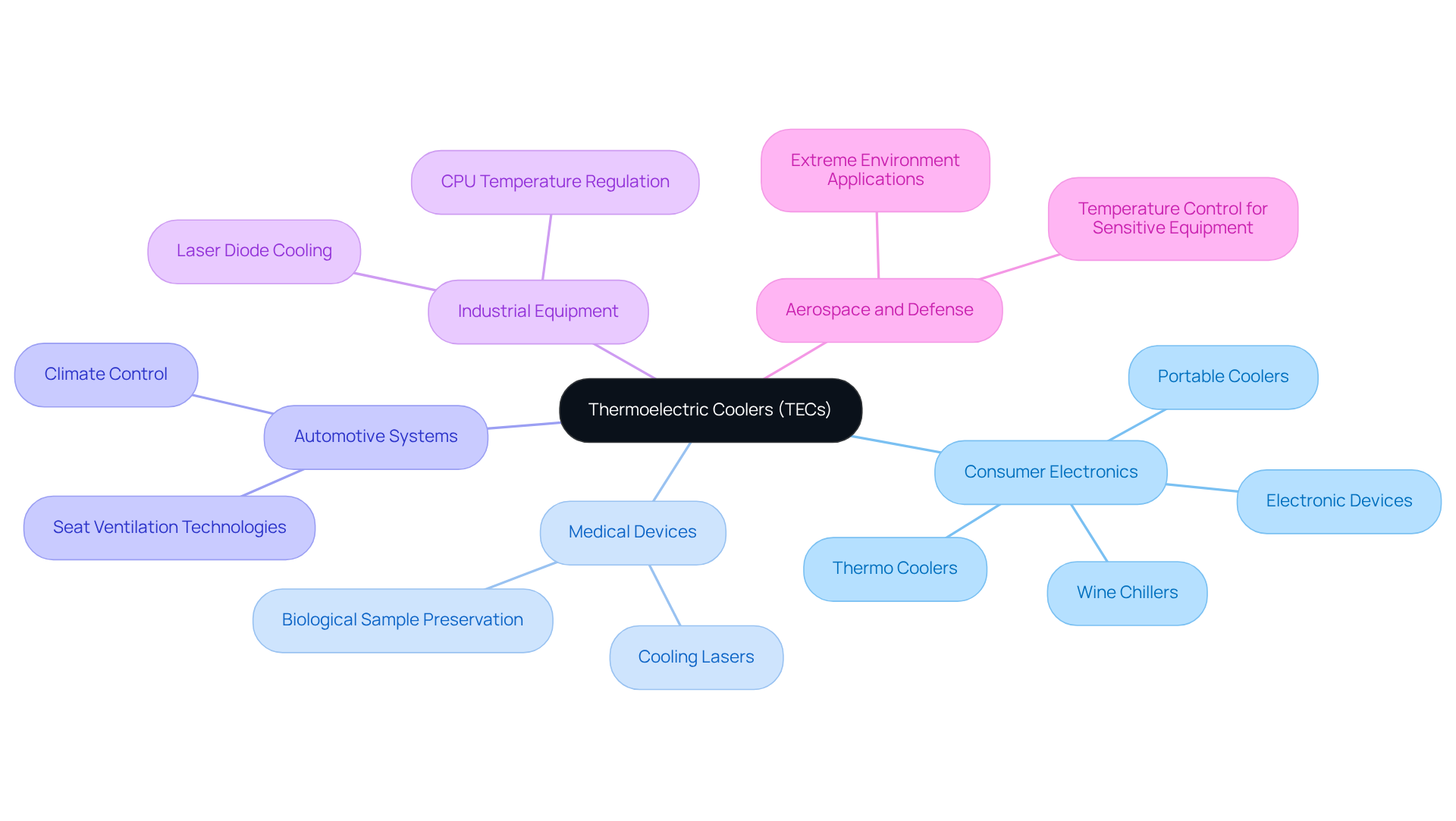

Thermoelectric coolers (TECs) are essential components in a variety of applications, effectively addressing specific .

- Consumer Electronics: TECs are frequently integrated into thermo coolers, portable coolers, wine chillers, and electronic devices that demand precise temperature regulation.

- Medical Devices: In the medical field, TECs play a crucial role in cooling lasers and maintaining the integrity of delicate biological samples.

- Automotive Systems: These systems utilize thermo coolers to enhance passenger comfort in climate control and seat ventilation technologies.

- Industrial Equipment: TECs are vital for regulating the temperature of electronic components, such as CPUs and laser diodes, thereby preventing overheating and ensuring optimal performance.

- Aerospace and Defense: In these sectors, thermo coolers provide reliable temperature control solutions for sensitive equipment that operates in extreme environments.

By comprehensively understanding these applications, engineers can effectively evaluate and implement energy-efficient refrigeration solutions.

Optimize Performance of Thermoelectric Cooling Systems

To optimize the performance of thermoelectric cooling systems, engineers must implement several key strategies:

- Thermal Management: Effective heat dissipation is crucial. Employing high-quality heat sinks and optimizing airflow around the thermo cooler minimizes thermal resistance, thereby improving efficiency in heat dissipation. This approach is essential for maintaining optimal operating temperatures and preventing overheating.

- Power Management: Selecting a power supply that aligns with the TEC’s specifications is vital to avoid inefficiencies and overheating. The integration of pulse-width modulation (PWM) technology can significantly enhance control over the temperature management process, allowing for precise adjustments in power delivery. PWM provides advantages compared to conventional techniques, such as high efficiency and robust anti-interference capability, enabling output power regulation with an accuracy of 0.1% or greater. This precision is especially advantageous in sustaining the desired thermal performance.

- Material Selection: The choice of materials for the TEC and its components plays a significant role in efficiency. , such as wide bandgap semiconductors like SiC and GaN, can significantly enhance the heat dissipation ability and overall performance of the setup, allowing for higher frequency control and improved thermal management.

- Design: A carefully planned arrangement is crucial for reducing thermal losses and enhancing TEC efficiency. Engineers should consider the placement of the TEC in relation to both the heat source and the object being cooled. Methods like optimizing the distance between components and ensuring adequate insulation can lead to substantial enhancements in thermal performance.

By applying these optimization techniques, engineers can enhance the performance of their thermo cooler systems, leading to more effective and reliable solutions for various applications.

Conclusion

Mastering the design and application of thermoelectric coolers (TECs) is essential for engineers aiming to leverage the advantages of this innovative cooling technology. By grasping the principles of thermoelectric cooling, particularly the Peltier effect, and acknowledging the importance of components such as semiconductor elements, heat sinks, and thermal interface materials, engineers can devise efficient and effective cooling solutions tailored to diverse industries.

This article underscores several pivotal areas:

- The foundational principles of thermoelectric cooling

- The critical components influencing TEC performance

- The varied applications spanning consumer electronics, medical devices, automotive systems, and beyond

Moreover, strategies for optimizing performance—encompassing effective thermal and power management, material selection, and thoughtful design—are vital for enhancing the efficiency and reliability of thermoelectric cooling systems.

As the demand for energy-efficient temperature control solutions escalates, engineers are urged to remain abreast of the latest advancements in thermoelectric cooling technology. By adopting innovative design practices and optimizing system performance, engineers can not only address current industry requirements but also propel future developments in thermoelectric cooling applications, ultimately contributing to a more sustainable and efficient technological landscape.

Frequently Asked Questions

What is thermoelectric refrigeration based on?

Thermoelectric refrigeration is fundamentally based on the Peltier effect, which occurs when an electric current passes through two distinct semiconductor materials, typically p-type and n-type, creating a temperature differential.

How does the Peltier effect work in thermoelectric coolers?

The Peltier effect facilitates heat absorption on one side of the thermo cooler while dissipating it on the opposite side, allowing for effective temperature control.

What is the coefficient of performance (COP) in thermoelectric coolers?

The coefficient of performance (COP) is a critical metric that quantifies the efficiency of heat transfer in relation to the electrical energy input in thermoelectric coolers (TECs).

What factors must engineers consider to enhance TEC performance?

To enhance TEC performance, engineers must consider thermal resistance and select appropriate materials, as these factors significantly influence overall efficiency.

What recent advancements have been made in thermoelectric cooling technology?

Recent advancements have focused on increasing the COP of energy conversion technologies, highlighting the ongoing evolution of thermoelectric cooling innovations across various applications, including medical solutions.

Who is Gagner-Toomey Associates and what do they offer?

Gagner-Toomey Associates is a leading supplier of innovative temperature control solutions, offering a comprehensive range of power conversion products, including DC/DC converters and medical power supplies, essential for optimizing thermodynamic refrigeration systems that use thermoelectric coolers.

What additional components does Gagner-Toomey Associates provide?

Gagner-Toomey Associates also provides EMI filters, ensuring that engineers have access to the necessary components for effective thermal management in medical, industrial, and server applications.