Introduction

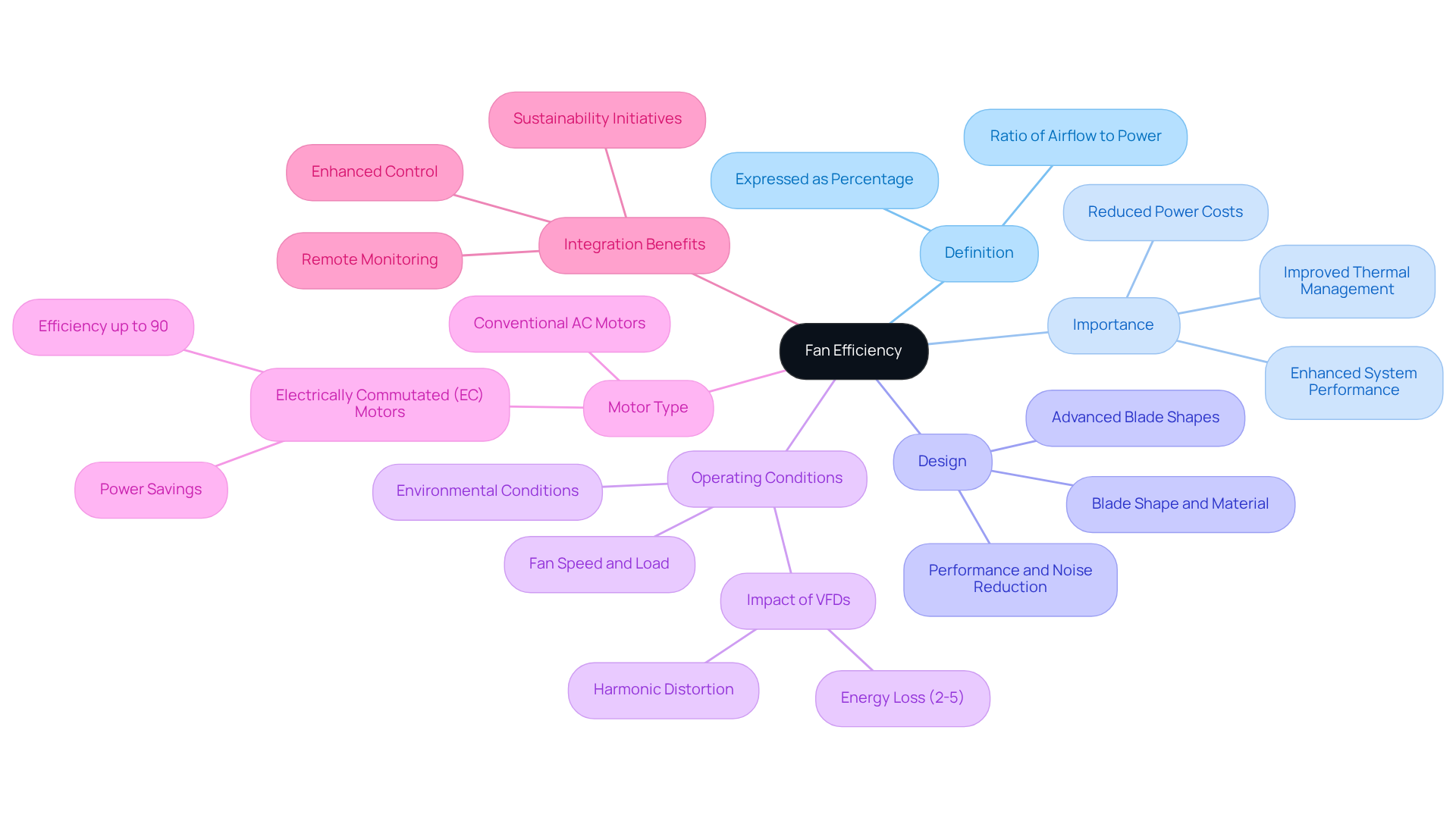

Understanding fan efficiency is crucial for electronics engineers who aim to optimize system performance and reduce energy costs. This essential metric, defined as the ratio of useful airflow to power consumption, not only influences cooling solutions but also impacts sustainability initiatives within the industry.

However, many engineers grapple with the complexities of fan design and performance metrics. This raises an important question: how can they navigate these challenges to enhance both efficiency and effectiveness in their projects? By addressing this issue, engineers can significantly improve their designs and contribute to more sustainable practices.

Define Fan Efficiency: Key Concepts and Importance

The typical fan efficiency is defined as the ratio of useful airflow generated by a fan to the power utilized, typically expressed as a percentage. This metric is vital in electronics engineering, as typical fan efficiency leads to reduced power costs, improved thermal management, and enhanced overall system performance. By understanding this concept, engineers can make informed choices when selecting ventilators for their applications, ensuring optimal cooling and substantial power savings in electronic devices.

Gagner-Toomey Associates stands out as the world’s largest manufacturer of standard and custom air-movers, offering a comprehensive portfolio of cooling solutions tailored for diverse applications, including electronics. Their product line includes DC input Tube Axial fans ranging from 15 to 280mm and Centrifugal Blowers from 15 to 225mm, as well as EC fans and blowers sized from 120 to 910mm. Key factors influencing fan efficiency include:

- Design: The shape and material of the blades are pivotal in determining airflow and energy consumption. Advanced blade shapes can improve airflow while reducing resistance, resulting in superior efficiency. Gagner-Toomey’s supporters are designed for performance, effectiveness, and low noise, making them ideal for electronic cooling.

- Operating Conditions: Efficiency is not static; it fluctuates based on the fan’s speed, load, and environmental conditions. Fans operating at optimal speeds can achieve significantly greater performance compared to those functioning below ideal levels. Additionally, Variable Frequency Drives (VFDs) can adversely affect motor performance due to harmonic distortion and increased motor heating, particularly at low speeds or during partial load operation.

- Motor Type: The type of motor powering the fan is integral to its performance. Electrically commutated (EC) motors, for example, can achieve a typical fan efficiency that reaches performance levels as high as 90%, surpassing conventional AC motors and leading to significant power savings. Gagner-Toomey’s EC devices and blowers are crafted to enhance efficiency, establishing them as a preferred option for engineers.

Integrating high-efficiency blowers into electronic cooling systems is crucial for enhancing typical fan efficiency and lowering energy usage. Research indicates that EC devices can reduce energy consumption by as much as 80%. This not only lowers operational costs but also supports sustainability initiatives by reducing the carbon footprint of electronic devices. Furthermore, the operational lifespan of EC fans ranges from 8 to 15 years, emphasizing the long-term benefits of investing in these technologies. As the industry moves towards more energy-conserving solutions, understanding and emphasizing fan effectiveness will be crucial for engineers seeking to enhance functionality and cost-effectiveness in their designs. Additionally, most models offer IP protection upon request, ensuring reliability in various operating environments.

Clarify Misconceptions: Motor vs. System Efficiency

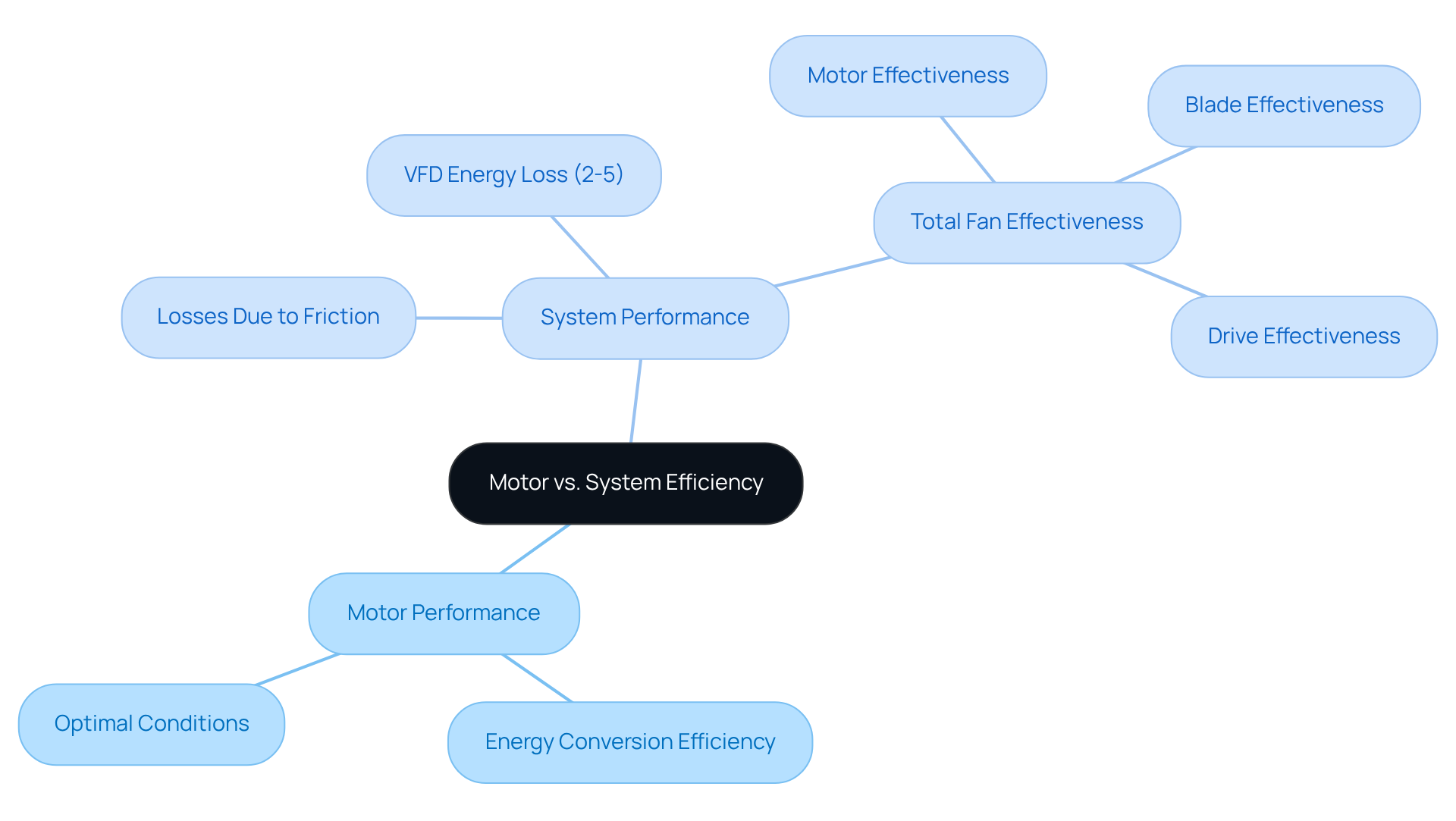

Distinguishing between motor effectiveness and system performance is crucial when evaluating fan functionality. Motor performance assesses how effectively a motor converts electrical energy into mechanical energy, typically measured under optimal conditions. However, this metric often neglects the various losses that occur within the fan system.

In contrast, system performance encompasses the entire fan assembly, including the motor, drive, and airflow delivery. It accounts for losses due to friction in bearings, inefficiencies in belts, and design flaws in the fan itself. For instance, even if a motor boasts high performance, the overall system may still underperform due to these additional losses. Notably, Variable Frequency Drives (VFDs) can lead to 2-5% energy loss during power conversion, further impacting system performance.

Understanding this distinction is vital for engineers. A fan with a high motor performance rating does not guarantee better system effectiveness. The Fan Total Effectiveness, which includes motor effectiveness, blade effectiveness, and drive effectiveness, must also be considered for a comprehensive understanding of operation. Evaluating both metrics enables more informed decisions when selecting fans, ensuring optimal performance and typical fan efficiency in real-world applications.

As Archmage pointed out, “The total fan performance is an input that details the complete fan system, encompassing the motor performance, blade performance, and drive performance.” This holistic approach helps avoid the pitfalls of outdated efficiency comparisons and leads to improved engineering outcomes.

Evaluate Fan Performance: Practical Benchmarks and Metrics

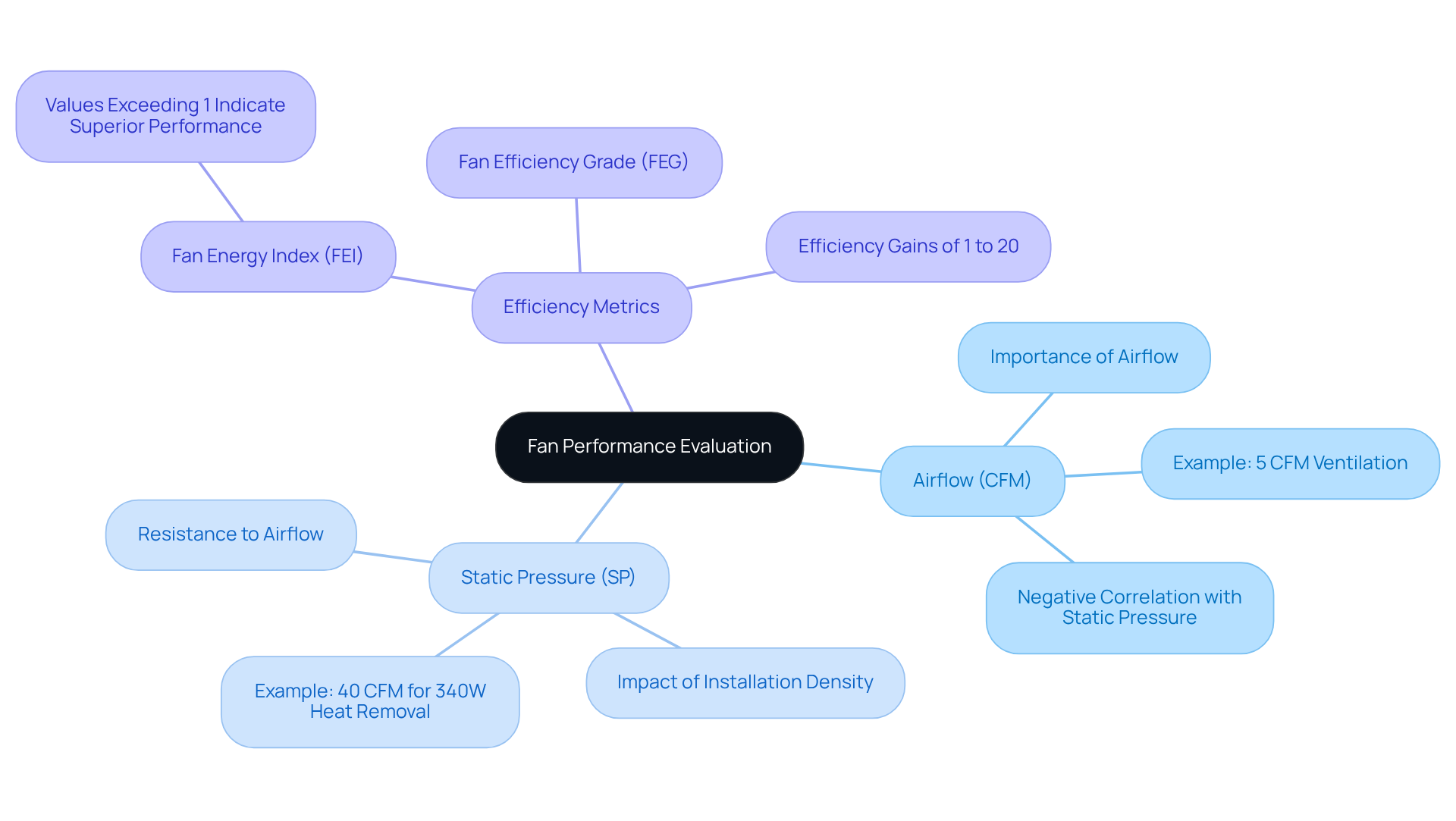

To effectively evaluate fan performance, engineers must consider several key benchmarks and metrics that are crucial for optimal operation and typical fan efficiency.

-

Airflow (CFM): Cubic Feet per Minute (CFM) quantifies the volume of air moved by the fan. For example, a fan producing 5 CFM will take approximately 25 minutes to ventilate a 5 ft x 5 ft x 5 ft enclosure. Higher CFM ratings indicate superior airflow capabilities, which are essential for cooling applications where heat generation is significant. It’s important to understand that airflow and static pressure have a negative correlation; as airflow increases, static pressure decreases, and vice versa.

-

Static Pressure (SP): This metric measures the resistance the fan must overcome to move air through a system. Understanding static pressure is crucial, as it directly impacts airflow. For instance, at sea level, approximately 40 CFM is necessary to remove 340W of heat. Engineers must recognize that maximum airflow and static pressure cannot be achieved simultaneously, making it vital to balance these factors based on specific application needs. Additionally, installation density can significantly influence airflow and static pressure; higher installation density typically leads to increased static pressure and reduced airflow.

Efficiency metrics, including typical fan efficiency measures like the Fan Energy Index (FEI) and Fan Efficiency Grade (FEG), provide standardized measures of fan operation, facilitating easier comparisons between different models. Values exceeding 1 in the FEI suggest outstanding results, while improvements of 1 to 20% have been demonstrated in laboratory environments with commercial motors and drives.

By employing these benchmarks, engineers can precisely evaluate whether a fan meets the specific criteria of their cooling applications. Real-world examples, such as the influence of enclosure design on fan efficiency and the effects of accessories on airflow and static pressure, further illustrate the importance of these metrics in practical scenarios. Insights from Gagner-Toomey Associates underscore the significance of these metrics in achieving dependable and efficient cooling, ultimately enhancing system longevity and functionality.

Standardize Comparisons: The Role of FEI and Reporting Practices

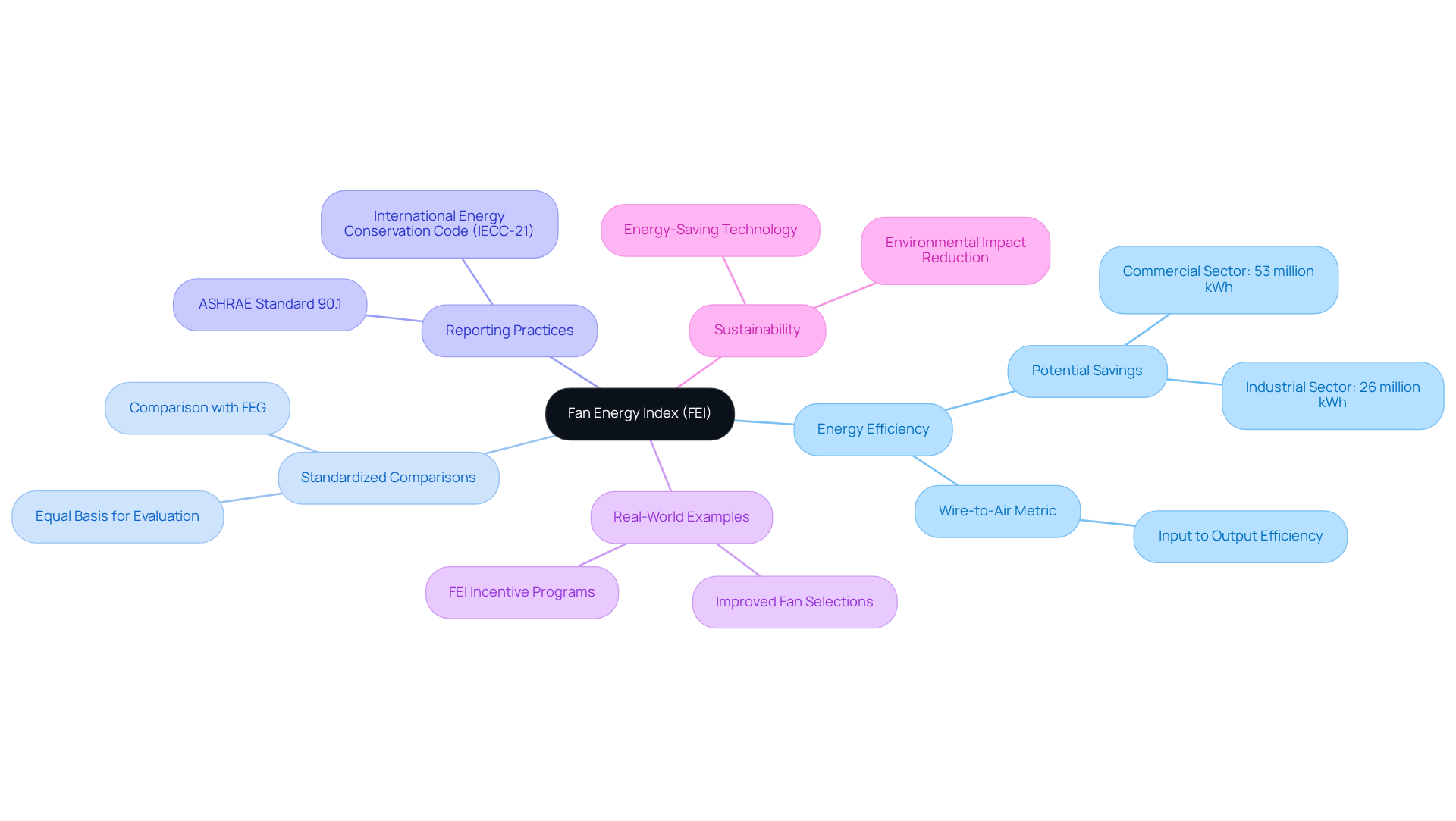

The Fan Energy Index (FEI) serves as a vital metric for standardizing comparisons among fan systems, evaluating energy efficiency across the entire operating range rather than just at peak output. This comprehensive approach empowers engineers to select devices that perform effectively under real-world conditions, ensuring optimal functionality in diverse applications, including low-pressure, high-flow scenarios.

By utilizing FEI, engineers can assess fans from different manufacturers on an equal basis, facilitating the identification of the most efficient options tailored to specific requirements. This is especially critical in the electronics sector, where precision and reliability are essential. Notably, the potential savings from implementing FEI-compliant systems can reach approximately 53 million kWh annually for the commercial sector and 26 million kWh for the industrial sector.

Consistent reporting practices, including standardized metrics like FEI and the Fan Efficiency Grade (FEG), are crucial for ensuring transparency and reliability in fan performance data. Engineers should prioritize these metrics in product specifications to make informed decisions. The incorporation of FEI in the 2019 edition of ASHRAE Standard 90.1 and the 2021 International Conservation Code (IECC-21) signifies a shift towards standardized reporting that enhances resource conservation on a global scale.

Real-world examples illustrate the effectiveness of standardized reporting practices. For instance, the introduction of FEI has allowed designers to refine fan selections based on specific operational conditions, leading to improved energy performance and reduced operational costs. Furthermore, FEI incentive programs support businesses in upgrading their ventilation systems by lowering initial expenses, making it a practical consideration for engineers. By emphasizing FEI, engineers can ensure their fan selections not only comply with regulatory standards but also contribute to sustainable building practices. FEI is termed a ‘wire-to-air’ metric because it evaluates efficiency from the input power to the output power of a fan, offering a comprehensive view of fan performance.

Conclusion

Understanding typical fan efficiency is crucial for electronics engineers who aim to optimize cooling systems while minimizing energy consumption. This article has delved into the multifaceted nature of fan efficiency, underscoring its significance in achieving effective thermal management and reducing costs in electronic devices. By grasping the critical components that influence efficiency, engineers can make informed decisions that enhance both performance and sustainability in their designs.

Key insights discussed include:

- The importance of fan design

- Operating conditions

- Motor types in determining efficiency

The role of metrics such as the Fan Energy Index (FEI) and Fan Efficiency Grade (FEG) in standardizing comparisons among fan systems has been emphasized, providing engineers with essential tools to evaluate performance comprehensively. Furthermore, the distinction between motor effectiveness and overall system performance has been clarified, highlighting the necessity of a holistic approach to fan selection.

As the industry increasingly prioritizes energy efficiency and sustainability, engineers are encouraged to leverage these insights and metrics in their projects. Integrating high-efficiency fans not only leads to reduced operational costs but also supports broader environmental goals. By staying informed and adopting best practices in fan efficiency, engineers can significantly contribute to the advancement of electronic systems, ensuring they are not only effective but also environmentally responsible.

Frequently Asked Questions

What is fan efficiency?

Fan efficiency is defined as the ratio of useful airflow generated by a fan to the power utilized, typically expressed as a percentage.

Why is fan efficiency important in electronics engineering?

Fan efficiency is vital because it leads to reduced power costs, improved thermal management, and enhanced overall system performance, allowing engineers to make informed choices when selecting ventilators for their applications.

What types of fans does Gagner-Toomey Associates manufacture?

Gagner-Toomey Associates manufactures a range of fans including DC input Tube Axial fans (15 to 280mm), Centrifugal Blowers (15 to 225mm), and EC fans and blowers (120 to 910mm).

What factors influence fan efficiency?

Key factors influencing fan efficiency include design (shape and material of the blades), operating conditions (speed, load, and environmental factors), and the type of motor used (e.g., EC motors).

How do blade design and material affect fan efficiency?

Advanced blade shapes and materials can improve airflow while reducing resistance, resulting in superior efficiency, which is essential for effective electronic cooling.

How do operating conditions affect fan efficiency?

Fan efficiency can fluctuate based on the fan’s speed, load, and environmental conditions. Fans operating at optimal speeds can achieve significantly better performance compared to those functioning below ideal levels.

What is the impact of motor type on fan efficiency?

The type of motor powering the fan significantly affects its performance. Electrically commutated (EC) motors can achieve fan efficiency levels as high as 90%, surpassing conventional AC motors and leading to significant power savings.

What are the benefits of integrating high-efficiency blowers into electronic cooling systems?

Integrating high-efficiency blowers can enhance fan efficiency and lower energy usage, potentially reducing energy consumption by as much as 80%, which lowers operational costs and supports sustainability initiatives.

What is the operational lifespan of EC fans?

The operational lifespan of EC fans ranges from 8 to 15 years, emphasizing the long-term benefits of investing in these technologies.

Do Gagner-Toomey’s fans offer protection for various operating environments?

Yes, most models offer IP protection upon request, ensuring reliability in various operating environments.