Introduction

Understanding the delicate balance between fan static pressure and airflow is crucial for engineers who aim to optimize HVAC systems. This relationship significantly influences energy efficiency and the overall performance of air movement across various environments. However, navigating the complexities of static pressure and airflow can be challenging, particularly in high-resistance systems.

What strategies can engineers employ to master this balance? By focusing on effective airflow while maintaining system efficiency, professionals can enhance performance and reduce energy consumption. It’s essential to explore proven techniques and innovative solutions that address these challenges head-on.

Define Static Pressure and Airflow in Fan Systems

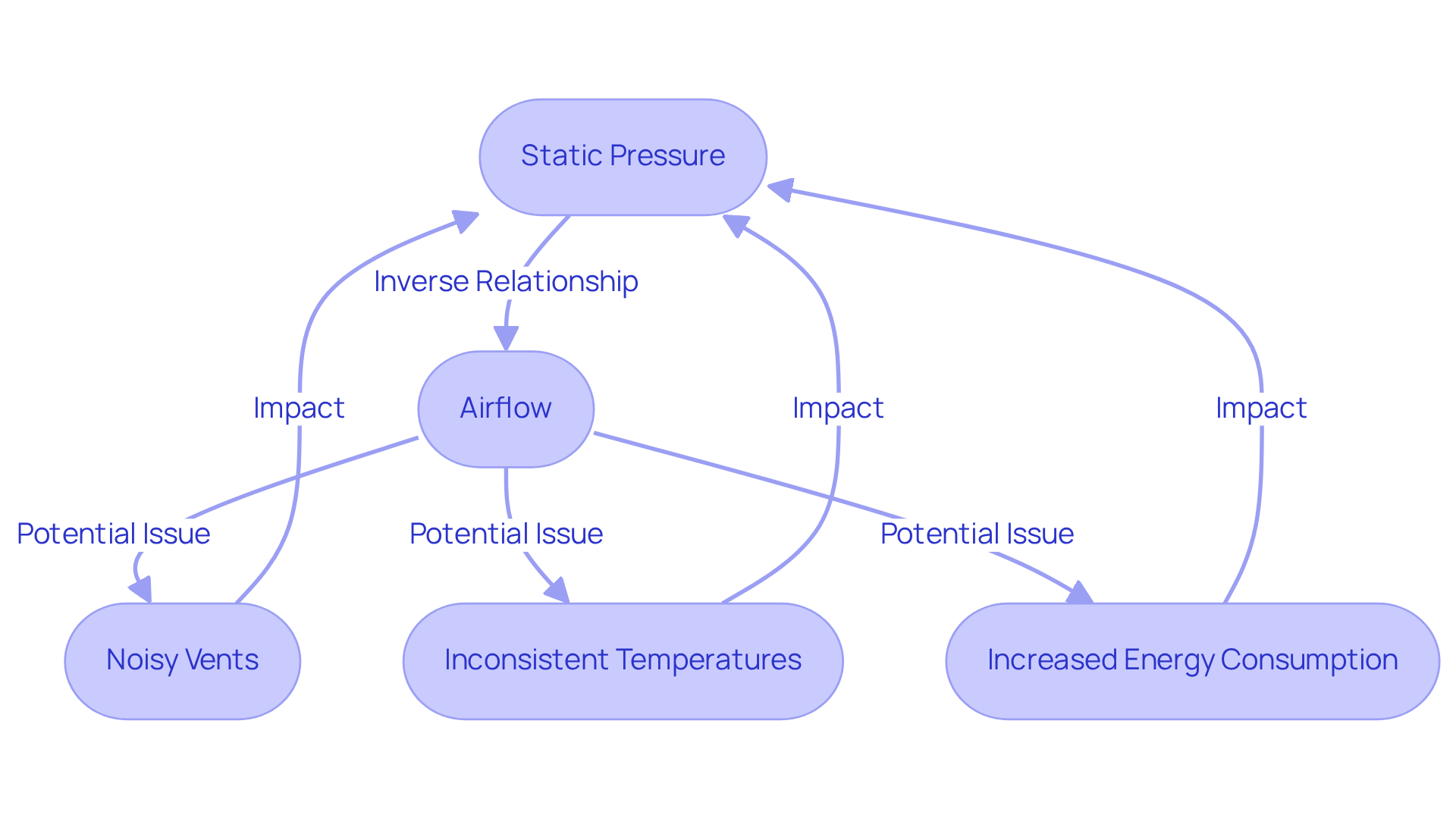

Static force represents the resistance that air encounters as it navigates through systems like ducts or filters. This resistance is quantified in inches of water gauge (inH2O) or Pascals (Pa). Conversely, airflow denotes the volume of air a fan can move, typically measured in cubic feet per minute (CFM). Understanding the interplay between fan static pressure vs airflow is essential, as an increase in fan static pressure often results in a decrease in airflow, and vice versa. This inverse relationship is pivotal when designing systems that demand efficient air movement, particularly in high-resistance environments where fan static pressure vs airflow is affected by dense filters or narrow ducts.

For instance, elevated static force can lead to issues such as noisy vents and inconsistent temperatures, ultimately increasing energy consumption. The three Fan Laws are crucial for comprehending how changes in airflow affect air resistance and horsepower requirements. This knowledge empowers engineers to make informed decisions when selecting fans and designing systems. As Alexander Popp, Content Manager at Sylvane, aptly states, “Understanding CFM and static force may seem daunting, but these factors are fundamental to your HVAC system’s performance.” Engaging HVAC professionals for accurate measurement and adjustment of airflow resistance is highly recommended to ensure optimal system performance.

Evaluate Performance of Static Pressure Fans

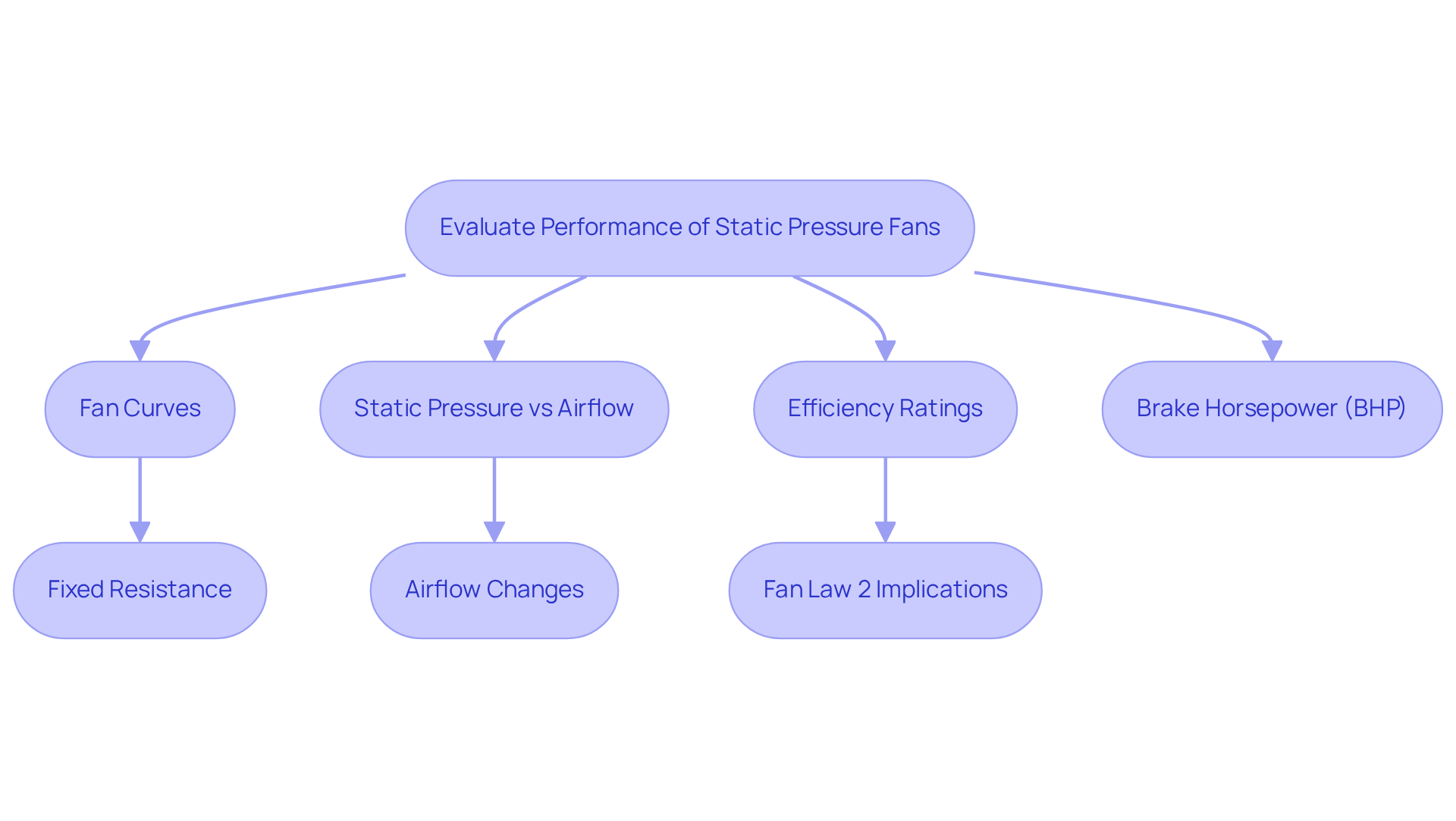

Static airflow devices are crucial for generating elevated force, enabling them to overcome resistance in duct systems and various barriers. Their performance is assessed through fan curves, which visually represent the relationship in terms of fan static pressure vs airflow at different speeds. In HVAC applications, where air must navigate through filters or extensive duct systems, fans with fixed resistance are indispensable. Engineers must evaluate key factors such as the fan’s highest fixed rating, its efficiency across various operating points, and the Brake Horsepower (BHP) at the operating point, which stands at 6.9.

For example, a fan with a high resistance rating is vital for systems facing significant air resistance, ensuring that adequate airflow is maintained despite these challenges. Understanding fan static pressure vs airflow empowers engineers to make informed decisions about fan selection, optimizing system performance while adhering to efficiency standards. An FEI greater than 1 indicates that the fan operates more efficiently than the baseline fan, a critical aspect for energy-efficient designs.

A practical application of Fan Law 2 illustrates that a 10% increase in airflow can result in a 21% rise in static force, while a 10% decrease in RPM leads to a 19% drop in static force. This underscores the necessity of selecting blowers capable of managing these demands effectively. Additionally, case studies demonstrate how variable speed devices can adapt to changing system conditions, providing substantial energy savings while maintaining performance.

By mastering the intricacies of fan curves and adhering to AMCA Standard 205 – which recommends no more than a 15-percentage-point deviation below the fan’s total peak efficiency for selecting an efficient fan – engineers can significantly enhance the reliability and efficiency of HVAC systems. This ultimately leads to improved operational outcomes.

Compare Static Pressure and Airflow Fans: Strengths and Weaknesses

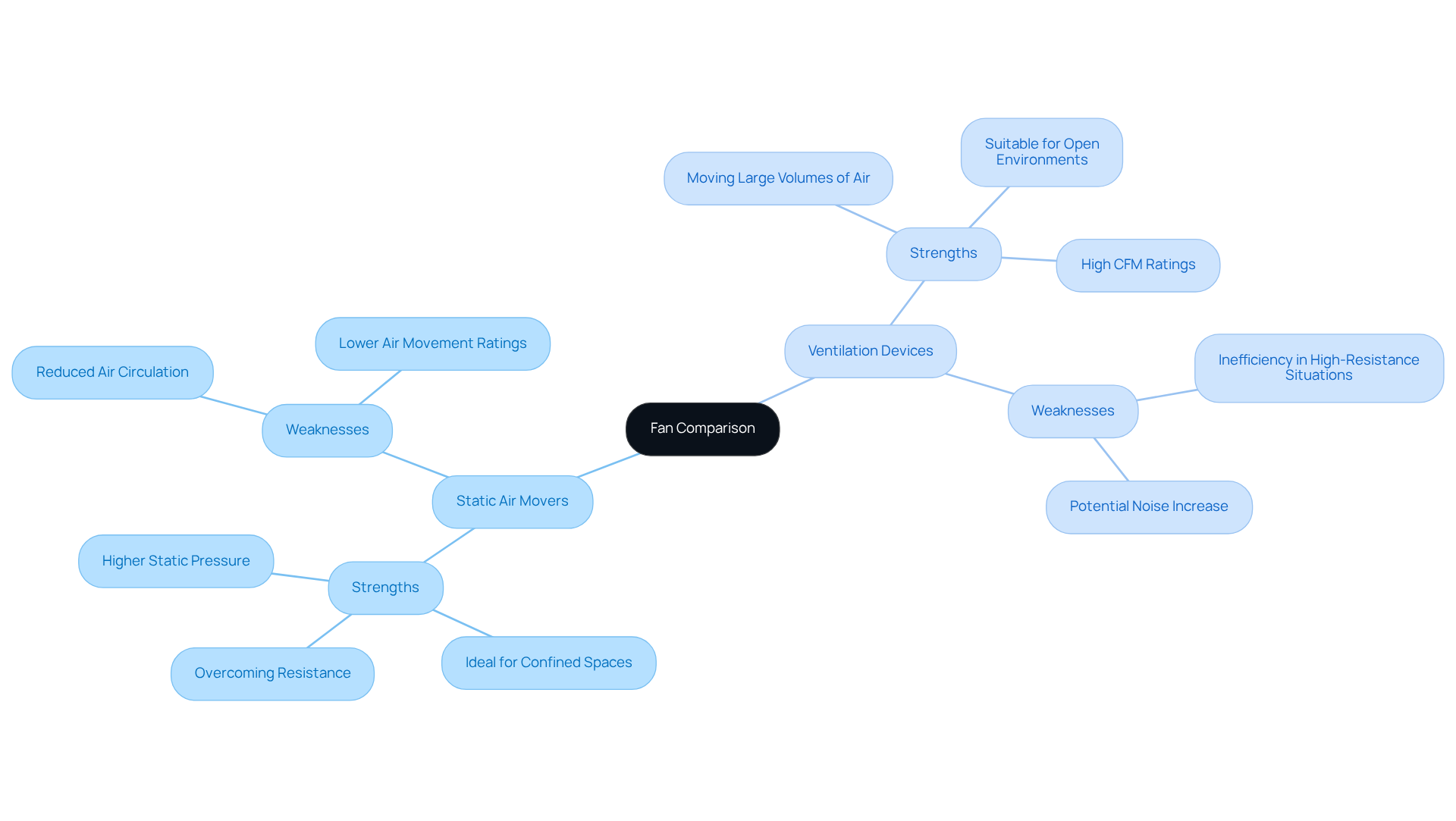

Static air movers are engineered for applications requiring airflow through confined spaces, such as radiators and tower-style CPU heatsinks. Their design excels at overcoming resistance, making them ideal for scenarios where air movement is restricted. Thicker units can push more air and generate higher static pressure, significantly enhancing their effectiveness in these contexts. However, this capability often leads to reduced air circulation compared to ventilation devices.

In contrast, ventilation devices are tailored for moving substantial amounts of air in open environments, making them suitable for cooling applications with minimal resistance. While they perform efficiently in such settings, they may falter in high-resistance situations. Engineers must carefully evaluate cooling requirements to determine the suitability of ventilation devices, balancing their strengths and weaknesses against specific needs.

For instance, in computer cooling systems, the relationship of fan static pressure vs airflow is crucial, as static pressure devices are typically favored for cooling components equipped with dense heatsinks, where efficient circulation is paramount. Conversely, ventilation fans are commonly employed for case ventilation, where their ability to move large volumes of air can significantly enhance overall cooling efficiency.

Consulting manufacturer’s fan performance data is essential to ensure the fan aligns with the load. Understanding these dynamics is crucial for engineers aiming to implement the most effective cooling strategies in their designs.

Apply Static Pressure and Airflow Concepts in System Design

In system design, engineers face the critical task of evaluating specific airflow requirements while considering fan static pressure vs airflow and the resistance factors inherent in the environment. This initial assessment begins with determining the overall fixed force that the fan must surpass, ensuring that the selected fan meets or exceeds this essential criterion.

Factors such as ductwork layout – including sharp bends and extended runs – can significantly increase resistance and must be carefully considered. Utilizing fan performance curves is crucial for selecting the appropriate fan for the application. For example, in data centers where effective cooling is paramount, stationary airflow devices are often preferred to guarantee efficient air circulation to all components. These devices not only enhance airflow but also contribute to energy savings; effective temperature control strategies can reduce overall energy usage by as much as 45%.

Moreover, engineers should recognize that still airflow fans maintain CPU temperatures approximately 3 degrees Celsius lower than ventilation fans in radiator configurations, underscoring their efficiency in high-resistance environments. It is also a common misconception that a fixed setpoint of 1.5 in. WC is optimal; understanding this can help prevent inefficiencies.

By mastering the calculation of static pressure and understanding the relationship of fan static pressure vs airflow, engineers can make informed decisions that optimize both performance and sustainability in their designs.

Conclusion

Understanding the dynamics of fan static pressure and airflow is essential for engineers designing efficient HVAC systems. An increase in static pressure often leads to a decrease in airflow, and vice versa. Recognizing this interplay is vital for optimizing system performance, especially in high-resistance environments.

Key insights include:

- The importance of fan curves in evaluating performance

- The strengths and weaknesses of static pressure versus airflow fans

- The necessity of careful system design

Engineers must assess specific airflow requirements, consider inherent resistance factors, and utilize performance metrics to select the most suitable fans for their applications. Mastering these concepts not only enhances operational efficiency but also contributes to energy savings and improved system reliability.

Ultimately, effectively balancing fan static pressure and airflow is crucial for achieving optimal HVAC performance. By applying these principles, engineers can ensure their designs meet modern application demands while promoting sustainability and efficiency. Embracing these best practices leads to better cooling strategies, reduced energy consumption, and enhanced overall system effectiveness.

Frequently Asked Questions

What is static pressure in fan systems?

Static pressure represents the resistance that air encounters as it moves through systems like ducts or filters, measured in inches of water gauge (inH2O) or Pascals (Pa).

How is airflow defined in the context of fan systems?

Airflow denotes the volume of air a fan can move, typically measured in cubic feet per minute (CFM).

What is the relationship between static pressure and airflow?

There is an inverse relationship between fan static pressure and airflow; an increase in static pressure often results in a decrease in airflow, and vice versa.

Why is understanding the interplay between static pressure and airflow important?

Understanding this interplay is essential for designing systems that require efficient air movement, especially in high-resistance environments with dense filters or narrow ducts.

What issues can arise from elevated static pressure in fan systems?

Elevated static pressure can lead to noisy vents, inconsistent temperatures, and increased energy consumption.

What are the Fan Laws, and why are they important?

The Fan Laws are principles that help understand how changes in airflow affect air resistance and horsepower requirements, aiding engineers in selecting fans and designing systems effectively.

What should be done to ensure optimal performance of HVAC systems?

It is recommended to engage HVAC professionals for accurate measurement and adjustment of airflow resistance to ensure optimal system performance.