Overview

High-temperature exhaust fans play a critical role in effectively removing hot air and pollutants across industries such as metalworking and chemical processing. These fans are engineered to operate in extreme temperatures, capable of withstanding conditions up to 2000°F.

Selecting the right type of fan is paramount; factors such as airflow capacity, temperature rating, and material construction must be meticulously considered. This ensures optimal performance while simultaneously reducing operational costs in demanding environments. By prioritizing these considerations, industries can enhance their operational efficiency and maintain a safer working atmosphere.

Introduction

High-temperature exhaust fans are indispensable components in industries characterized by extreme conditions, such as metalworking and chemical processing. These robust units not only manage hazardous heat and pollutants but also play a pivotal role in ensuring workplace safety and operational efficiency.

However, the selection process for the appropriate fan can be overwhelming, given the extensive array of options and specifications available. What critical factors must engineers consider to guarantee optimal performance and reliability in these demanding environments?

Understand High-Temperature Exhaust Fans

High temp exhaust fans are engineered to function in extreme conditions, capable of withstanding temperatures up to 2000°F (1093°C). In industries such as metalworking, chemical processing, and food production, the high temp exhaust fan plays a critical role by effectively eliminating hot air, smoke, and pollutants from work environments. Constructed from durable materials like reinforced steel and heat-resistant coatings, these units are meticulously designed to endure harsh operational settings. Gagner-Toomey Associates, recognized as the world’s largest manufacturer of both standard and custom air-movers, offers a comprehensive range of elevated-temperature ventilation solutions, including high temp exhaust fans, optimized for performance, efficiency, and low noise, with options for IP protection available upon request.

In the marketplace, high temp exhaust fans hold significant importance in the metalworking and chemical processing sectors, which are anticipated to witness substantial growth driven by increasing industrial demands. The global market for elevated-temperature axial blowers is forecasted to reach USD 4.11 billion by 2033, reflecting a compound annual growth rate (CAGR) of 5.7% from 2025 to 2033.

Understanding the various types of high temp exhaust fans is crucial for maximizing their application.

- Centrifugal blowers are particularly adept at managing high static pressures, making them ideal for ducted systems.

- Axial units are preferred for direct airflow applications due to their efficiency in transporting large air volumes.

For example, centrifugal fans are frequently employed in environments that require robust airflow against resistance, whereas axial fans are commonly utilized in situations that demand high airflow rates with minimal pressure drops.

Industry experts underscore the significance of selecting the appropriate fan type for specific applications. As noted by specialists, selecting the appropriate high temp exhaust fan can significantly reduce maintenance and operational costs, ensuring a safer and more efficient working environment. This strategic selection process is vital for enhancing performance and reliability in challenging industrial contexts.

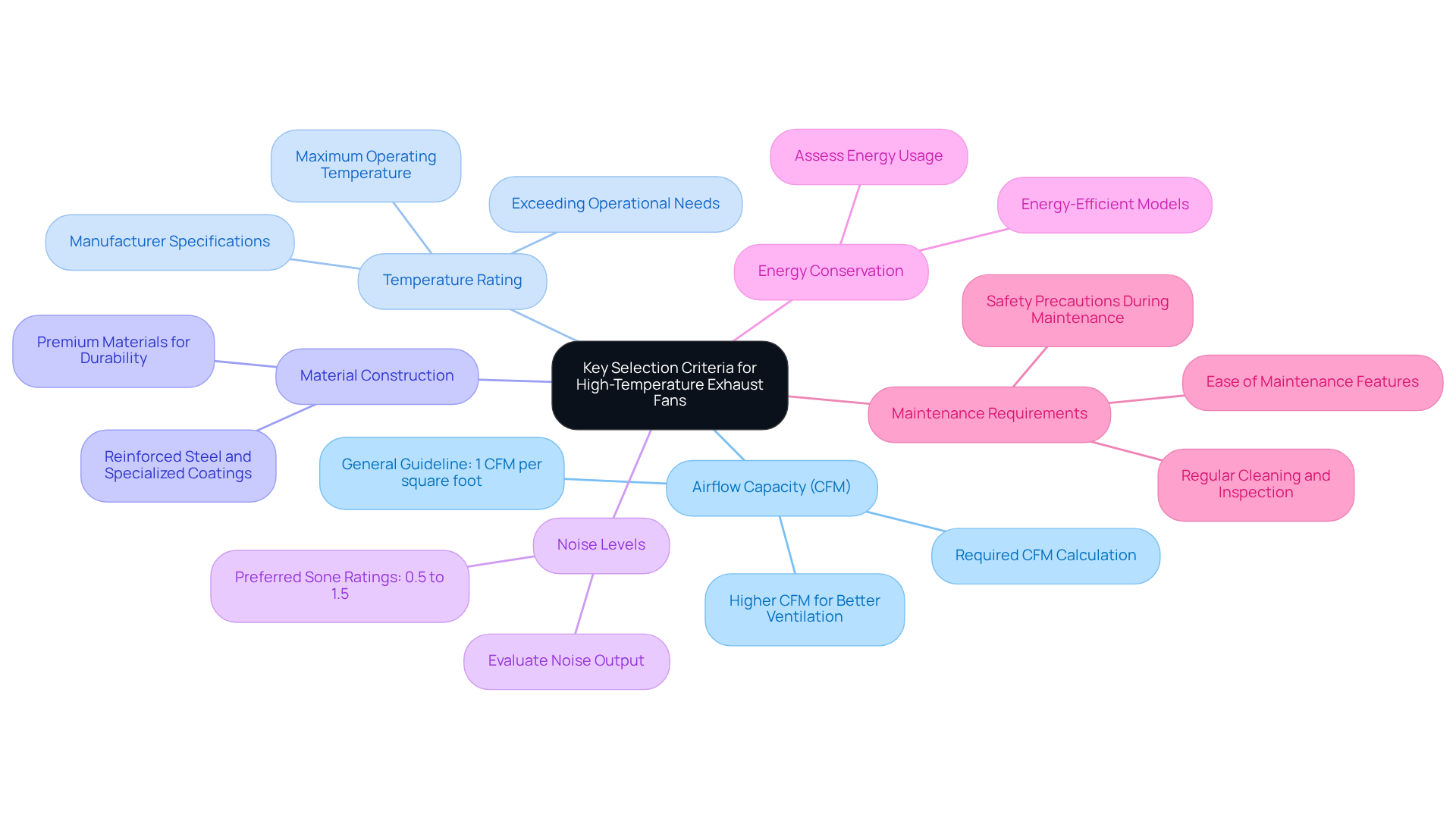

Identify Key Selection Criteria

When selecting a high-temperature exhaust fan, several key criteria must be considered to ensure optimal performance and reliability:

-

Airflow Capacity (CFM): It is essential to determine the required cubic feet per minute (CFM) based on the size of the area being ventilated and the specific application. A general guideline is to aim for at least 1 CFM per square foot of space, which ensures adequate ventilation to mitigate heat buildup. A higher CFM rating indicates better ventilation, which is crucial for effective cooling.

-

Temperature Rating: Ensure that the fan can operate at the maximum expected temperature. Manufacturers typically provide specifications detailing the temperature limits; thus, selecting a fan that exceeds operational needs is crucial for reliability in high-temperature environments.

-

Material Construction: Choose devices made from premium materials that can endure high temperatures without bending or deteriorating. Common materials include reinforced steel and specialized coatings designed for durability in harsh conditions.

-

Noise Levels: Evaluate the noise output of the fan, particularly if it will be installed in noise-sensitive areas. Fans with lower sone ratings, typically between 0.5 and 1.5, are preferred for quieter operation, thereby enhancing workplace comfort.

-

Energy Conservation: Assess the fan’s energy usage and performance ratings. Energy-efficient models not only reduce operational costs but also contribute to overall sustainability efforts in industrial settings.

-

Maintenance Requirements: Consider the ease of maintenance for the fan. Features such as removable access panels and designs that facilitate cleaning can significantly reduce downtime and maintenance efforts, ensuring optimal performance. Always turn off and unplug the fan before maintenance to prevent accidents.

By concentrating on these standards, engineers can select high temp exhaust fans that not only satisfy operational requirements but also enhance safety and efficiency in their applications.

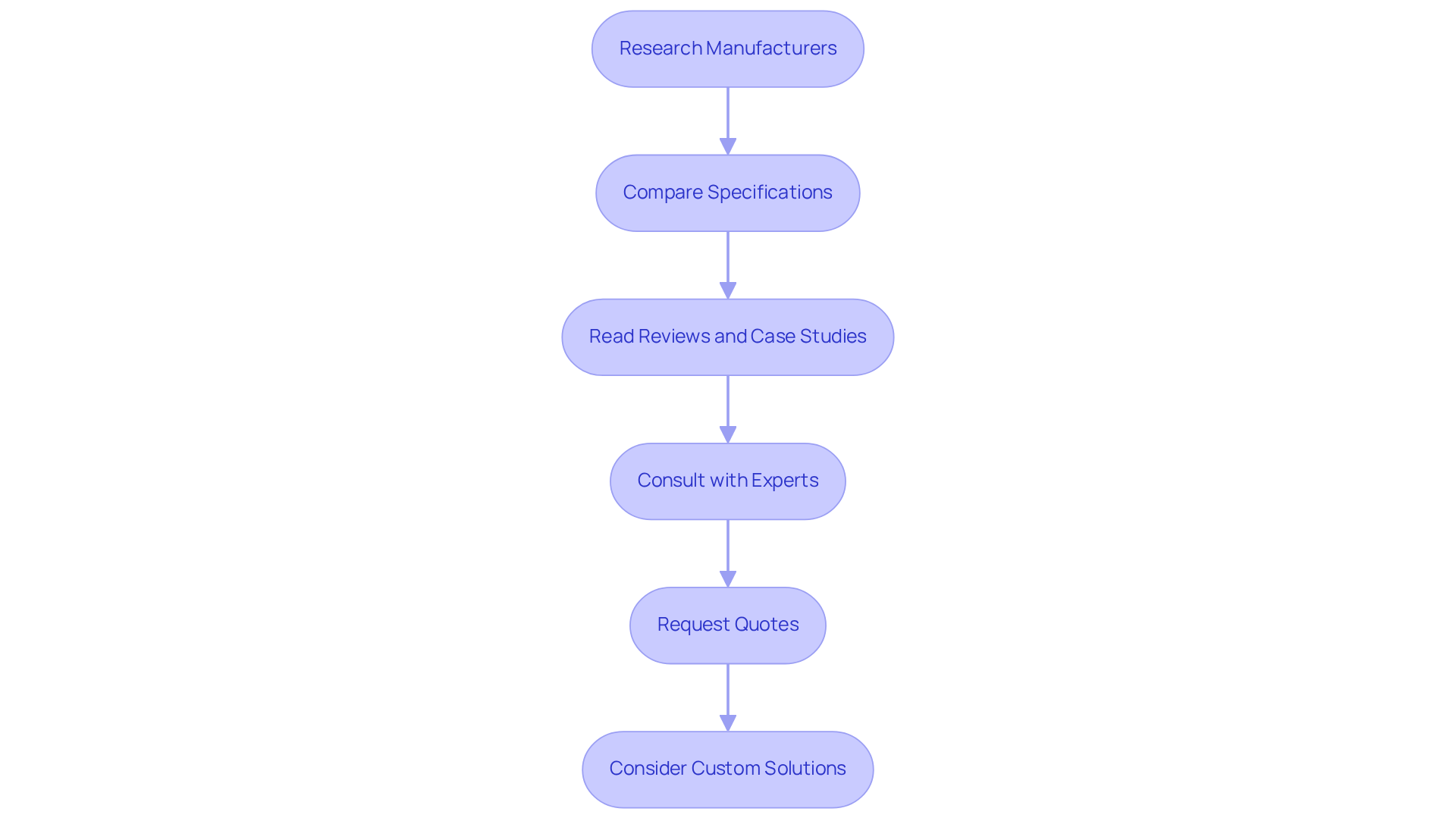

Evaluate Available Options

To effectively evaluate available options for high-temperature exhaust fans, consider the following steps:

- Research manufacturers by identifying reputable ones known for their expertise in producing high temp exhaust fans. It is essential to prioritize companies with a strong industry reputation and a track record of reliability.

- Compare Specifications: Create a comprehensive comparison chart that details key specifications of various models. This should include airflow capacity, temperature ratings, noise levels, and energy efficiency. Such a visual tool allows for straightforward side-by-side evaluations, facilitating informed decision-making.

- Read Reviews and Case Studies: Actively seek out customer reviews and case studies that highlight the performance of specific fan models in real-world applications. These insights often reveal critical information about reliability and operational effectiveness. For instance, research has shown that proper installation of industrial ventilation units is crucial to prevent malfunctions, and regular maintenance can potentially reduce repair costs by distinguishing between repairable components and those that are beyond salvage.

- Consult with experts: Engage with industry specialists or colleagues who possess experience with high temp exhaust fans. Their insights and recommendations can significantly impact your decision-making process. Notably, specialists like Aaron Saldanha, who has extensive knowledge in fan performance, can provide invaluable perspectives.

- Request Quotes: Once you have narrowed down your options, it is prudent to solicit quotes from multiple suppliers. This step will clarify pricing structures and any additional costs associated with installation or maintenance.

- Consider Custom Solutions: If standard models do not meet your specific requirements, explore the possibility of custom solutions. Many manufacturers offer tailored designs that can accommodate unique operational needs.

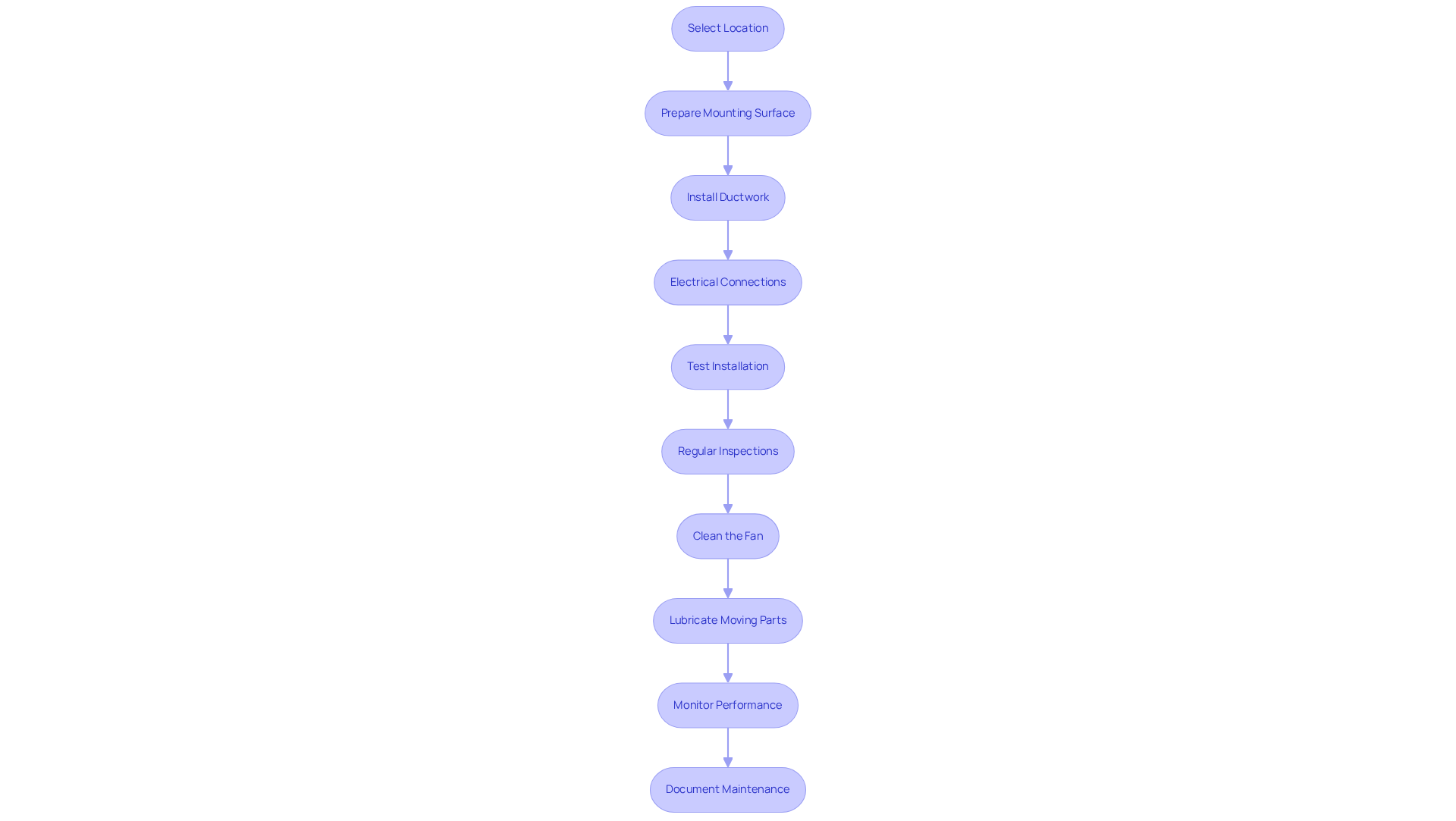

Install and Maintain Your Exhaust Fan

To ensure the effective operation of your high-temperature exhaust fan, it is essential to adhere to the following installation and maintenance guidelines:

Installation Steps:

- Select the Location: Choose a strategic location for the fan, ensuring it effectively removes hot air and contaminants from the area.

- Prepare the Mounting Surface: Ensure the mounting surface is clean, stable, and capable of supporting the fan’s weight. Reinforce if necessary to prevent structural issues.

- Install Ductwork: If applicable, install ductwork designed for high temperatures. Utilize insulated ducting to minimize heat loss and sustain performance. According to industry standards, proper ducting can significantly enhance airflow capacity, which is crucial for effective cooling.

- Electrical Connections: Connect the fan to the power supply, ensuring compliance with local codes and standards. Engaging a qualified electrician for this step is advisable to ensure safety and reliability.

- Test the Installation: After installation, conduct a thorough test of the fan to confirm it operates correctly and efficiently. Listen for any unusual noises or vibrations that may indicate issues. Regular testing can prevent costly downtime, as noted by Tom’s Commercial, which emphasizes the importance of maintaining HVAC efficiency.

Maintenance Tips:

- Regular Inspections: Schedule routine inspections to assess wear and tear, particularly on bearings and motor components, which are common failure points in high-temperature environments. Statistics show that regular maintenance can extend the lifespan of exhaust fans significantly.

- Clean the Fan: Periodically clean the fan blades and housing to eliminate dust and debris that can impede performance. A damp cloth with mild detergent is effective for this task. Keeping the fan clean is crucial for maintaining optimal airflow and performance.

- Lubricate Moving Parts: Ensure all moving parts are adequately lubricated to reduce friction and prevent overheating, which can lead to premature failure. Proper lubrication practices can improve the fan’s performance.

- Monitor Performance: Keep track of the fan’s performance metrics, such as airflow and noise levels, to identify potential issues early. Regular monitoring can prevent costly downtime. As highlighted in various case studies, proactive performance monitoring is key to effective maintenance.

- Document Maintenance: Maintain a detailed log of all maintenance activities, including inspections and repairs, to track the fan’s performance over time and facilitate future troubleshooting. This documentation can be invaluable for identifying trends and addressing recurring issues.

By adhering to these guidelines, you can enhance the lifespan and performance of your high temp exhaust fan, ensuring it functions effectively in challenging environments. Incorporating these practices not only enhances performance but also contributes to energy savings, as exhaust fans help reduce the workload on air conditioning systems.

Conclusion

High-temperature exhaust fans are critical in various industrial environments, expertly engineered to manage extreme heat and pollutants with efficiency. Their robust design and capability to function in harsh conditions render them indispensable in sectors like metalworking and chemical processing. For engineers aiming to optimize ventilation systems and enhance workplace safety, a thorough understanding of the diverse types of high-temperature exhaust fans and their specific applications is paramount.

When selecting the appropriate high-temperature exhaust fan, key considerations include:

- Airflow capacity

- Temperature ratings

- Material durability

- Noise levels

- Energy efficiency

- Maintenance requirements

By adopting a structured approach to evaluate options—researching manufacturers and consulting experts—engineers can make informed decisions that lead to enhanced performance and reduced operational costs. Furthermore, proper installation and regular maintenance are essential to ensure these fans operate at peak efficiency, protecting both equipment and personnel.

Ultimately, the importance of high-temperature exhaust fans transcends mere functionality; they are vital in fostering a safe and efficient working environment. Engineers are urged to implement the insights from this guide, ensuring effective selection, installation, and maintenance of these critical systems. By prioritizing these practices, industries can not only improve operational efficiency but also contribute to broader sustainability objectives, establishing high-temperature exhaust fans as a cornerstone of modern industrial applications.

Frequently Asked Questions

What are high-temperature exhaust fans designed for?

High-temperature exhaust fans are engineered to function in extreme conditions, capable of withstanding temperatures up to 2000°F (1093°C), and are essential for eliminating hot air, smoke, and pollutants in industries such as metalworking, chemical processing, and food production.

What materials are high-temperature exhaust fans made from?

These fans are constructed from durable materials like reinforced steel and heat-resistant coatings, designed to endure harsh operational settings.

Who is a leading manufacturer of high-temperature exhaust fans?

Gagner-Toomey Associates is recognized as the world’s largest manufacturer of both standard and custom air-movers, offering a comprehensive range of elevated-temperature ventilation solutions, including high temp exhaust fans.

What is the projected market growth for high-temperature exhaust fans?

The global market for elevated-temperature axial blowers is forecasted to reach USD 4.11 billion by 2033, with a compound annual growth rate (CAGR) of 5.7% from 2025 to 2033.

What types of high-temperature exhaust fans are there?

The main types are centrifugal blowers, which manage high static pressures and are ideal for ducted systems, and axial units, which are preferred for direct airflow applications due to their efficiency in transporting large air volumes.

When should centrifugal fans be used?

Centrifugal fans are frequently employed in environments that require robust airflow against resistance.

When are axial fans more suitable?

Axial fans are commonly utilized in situations that demand high airflow rates with minimal pressure drops.

Why is it important to select the appropriate high-temperature exhaust fan?

Selecting the appropriate fan type can significantly reduce maintenance and operational costs, ensuring a safer and more efficient working environment, and enhancing performance and reliability in challenging industrial contexts.