Overview

The article emphasizes the critical importance of heat exchanger units in electronics engineering, detailing their essential role in managing thermal loads to prevent overheating and enhance overall performance. It highlights the necessity of selecting suitable thermal devices tailored to operational needs, alongside the imperative of effective maintenance to ensure optimal functionality. Real-world applications in sectors such as automotive and data centers serve as compelling evidence of their significance.

Introduction

Thermal management stands as a critical pillar in the realm of electronics engineering, where the efficient transfer of heat delineates the boundary between peak performance and catastrophic failure.

Heat exchanger units assume a pivotal role in this intricate process, ensuring that high-performance components operate within safe temperature limits. As the demand for advanced electronic systems escalates, a thorough understanding of the complexities involved in selecting, implementing, and maintaining these essential devices becomes increasingly vital.

Engineers face numerous challenges in optimizing heat exchangers; thus, it is imperative to explore how they can ensure these systems operate at their utmost efficiency.

Define Heat Exchanger Units and Their Importance in Electronics

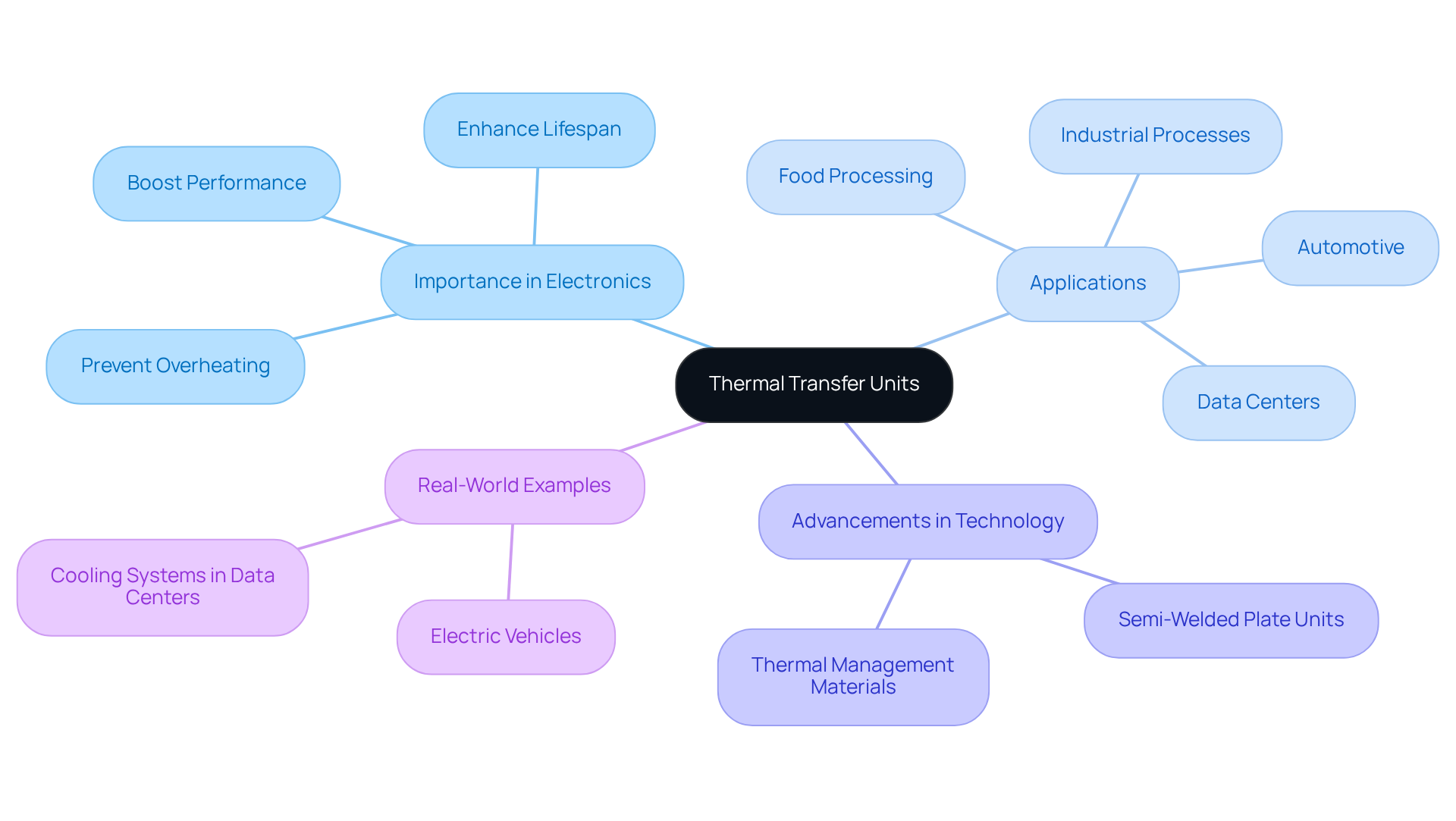

Thermal transfer units are essential instruments that facilitate the movement of thermal energy between two or more liquids without allowing their combination. In the realm of electronics, these units are crucial for dissipating energy generated by high-performance components such as processors and power supplies. Recent advancements in temperature transfer technology, including the development of semi-welded plate units, have markedly improved efficiency and reliability in management systems.

By effectively managing thermal loads, thermal devices prevent overheating, which can lead to component failure and diminished performance. For instance, in industrial applications, thermal devices have been pivotal in maintaining optimal temperatures, thereby enhancing the lifespan and reliability of electronic equipment. Their ability to regulate temperatures ensures that sensitive components operate within safe limits, ultimately extending product longevity and boosting overall performance.

Real-world examples highlight the effectiveness of thermal devices in preventing excessive temperatures. In the automotive sector, for example, advanced thermal transfer devices have been integrated to manage temperature loads in electric vehicles, ensuring optimal battery performance and safety. Similarly, in data centers, thermal regulators are vital for cooling systems that protect servers from overheating, thereby reducing downtime and enhancing operational efficiency.

The integration of thermal transfer devices in electronics engineering is not merely a trend; it is a fundamental aspect that significantly enhances performance, efficiency, and sustainability. As the demand for reliable and efficient electronic systems continues to escalate, the role of thermal devices in maintaining optimal operating conditions becomes increasingly critical.

Explain the Operational Principles of Heat Exchangers

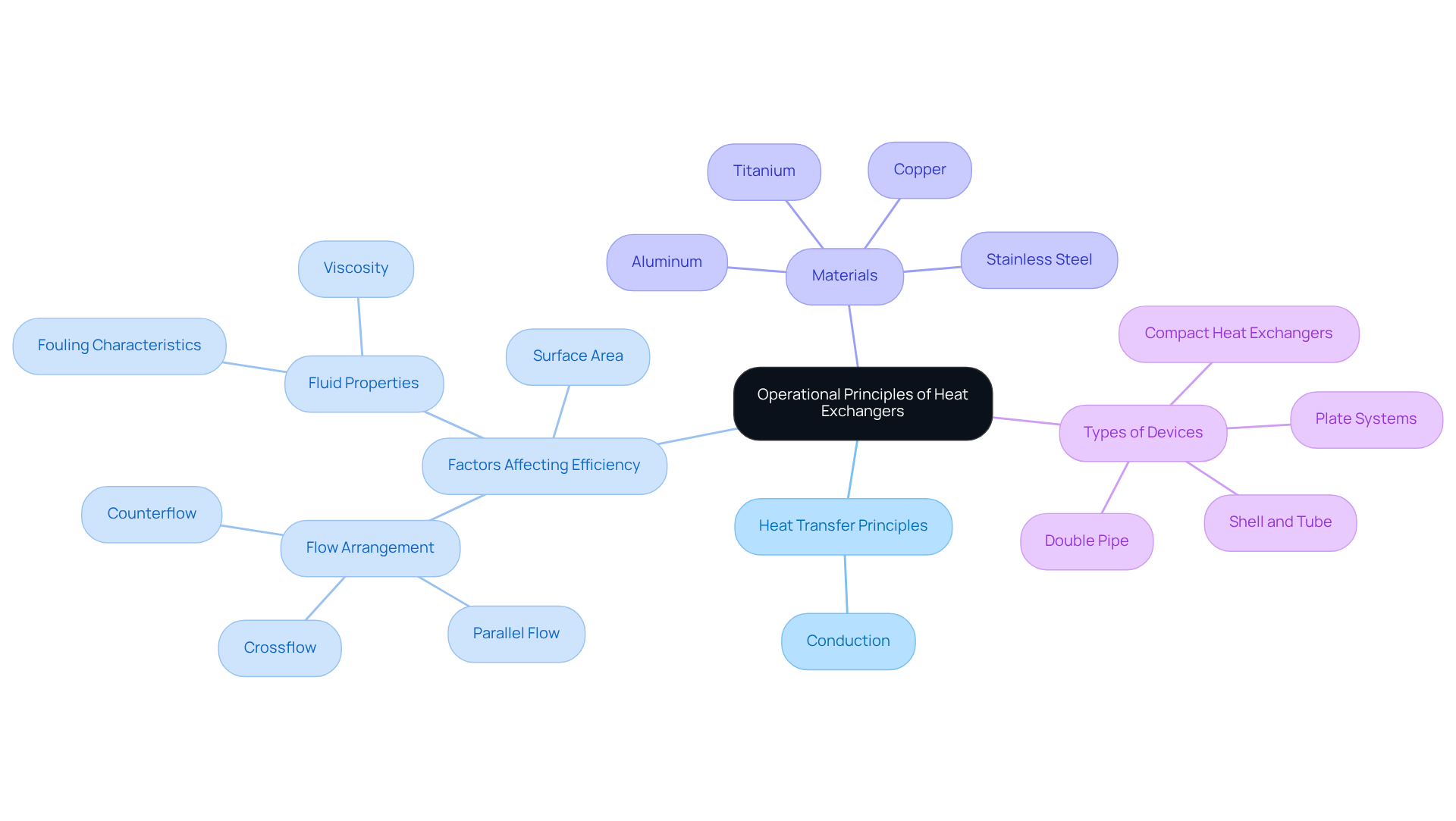

Heat transfer devices operate on the principle of conduction, facilitating the movement of warmth from a hotter liquid to a cooler one. The efficiency of this process is determined by several factors, including:

- Surface area

- Flow arrangement—whether counterflow, parallel flow, or crossflow

- The inherent properties of the fluids involved

In the realm of electronics, temperature regulators often utilize materials with high thermal conductivity, such as:

- Copper

- Aluminum

- Titanium

- Stainless steel

to optimize this transfer.

Compact thermal devices, characterized by transfer surface area to volume ratios of ≥700 m³ for gas-to-gas applications and ≥400 m³ for liquid-to-gas applications, demonstrate exceptional efficiency in confined spaces, particularly within automotive and aerospace designs. A thorough understanding of these principles enables engineers to select the appropriate type of thermal device for their specific applications, thereby ensuring optimal temperature management.

Furthermore, specialist insights underscore the importance of considering fluid viscosity and fouling characteristics, as these factors can significantly affect system performance by influencing flow rates and transfer efficiency. It is also essential to recognize that the payback period for thermal-to-electricity conversions typically exceeds three years, highlighting the financial implications associated with the deployment of thermal transfer devices.

Common types of thermal transfer devices, including shell and tube systems and plate systems, serve as heat exchanger units that play a crucial role across various applications, providing engineers with an array of options to meet their specific temperature control needs.

Guide on Selecting and Implementing Heat Exchangers in Electronic Systems

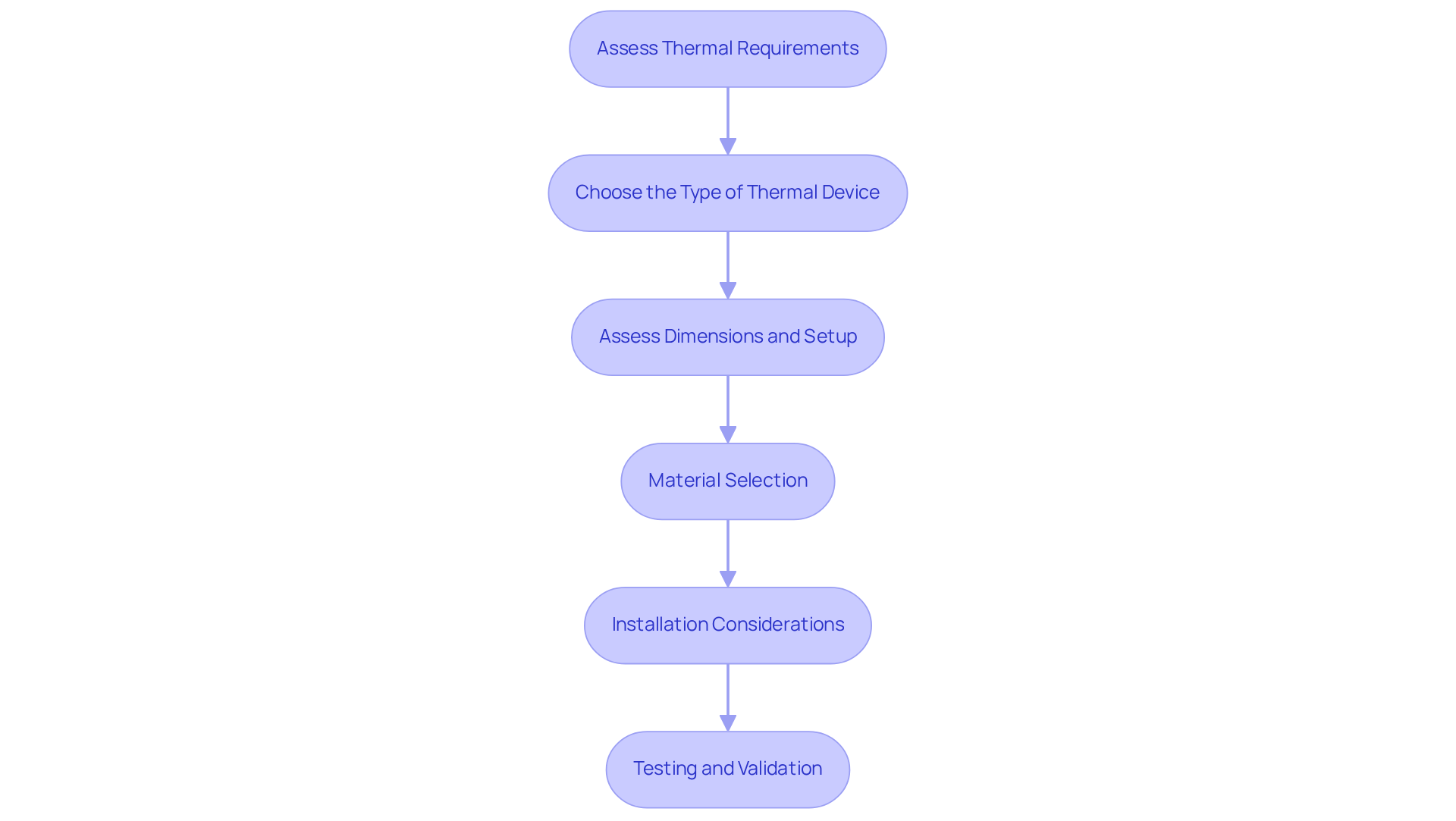

When selecting a heat exchanger for electronic systems, it is essential to follow a systematic approach that ensures optimal performance and reliability.

- Assess Thermal Requirements: Begin by determining the maximum thermal load that needs to be dissipated, alongside the acceptable temperature increase. This foundational step sets the stage for effective thermal management.

- Choose the Type of Thermal Device: Depending on the specific application, select from various options such as air-cooled, liquid-cooled, or phase change thermal systems. Each type presents unique advantages that can be leveraged based on operational needs.

- Assess Dimensions and Setup: Confirm that the chosen thermal device fits within the spatial limitations of the system while providing sufficient surface area for effective thermal transfer. This consideration is crucial for maintaining system integrity and performance.

- Material Selection: Opt for materials that can withstand the operating environment and exhibit excellent heat conductivity. The right material choice significantly impacts the efficiency and longevity of the thermal device.

- Installation Considerations: Plan for proper airflow or fluid flow paths to maximize efficiency during operation. Effective installation is key to ensuring that the thermal device performs as intended.

- Testing and Validation: After installation, conduct thorough thermal performance assessments to verify that the thermal device meets design specifications. This step is vital for confirming that the system operates within desired parameters.

By adhering to these procedures, engineers can efficiently install thermal devices that enhance the performance and dependability of electronic equipment.

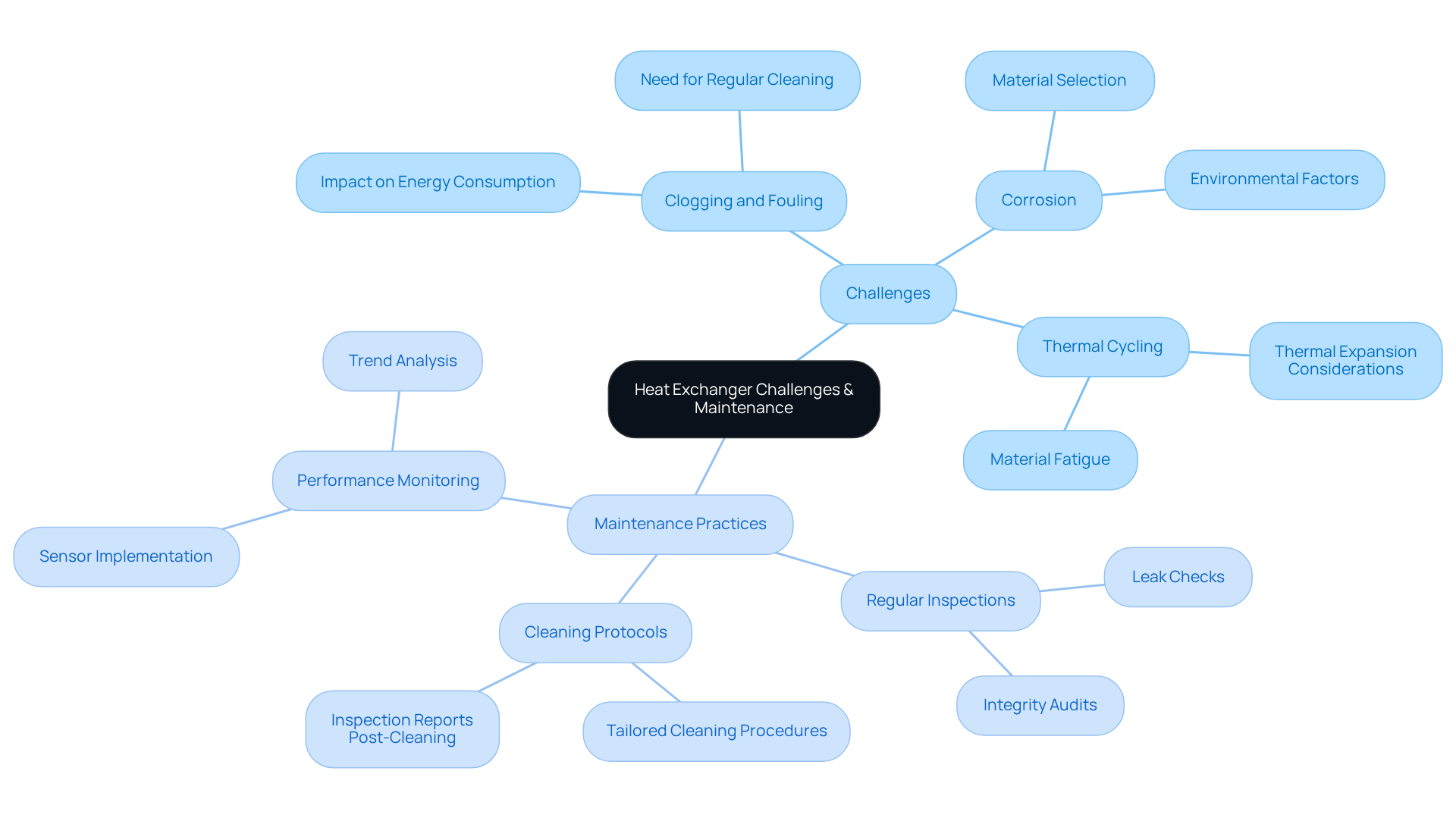

Identify Common Challenges and Maintenance Practices for Heat Exchangers

Common challenges faced with heat exchangers in electronic systems include:

- Clogging and Fouling: The accumulation of dust, debris, or contaminants can significantly impede heat transfer efficiency. In oil and refinery plants, for instance, fouling consumes an additional 0.2 quad of energy annually, underscoring its broader impact on energy consumption. To mitigate this issue, it is essential to establish regular cleaning and maintenance schedules.

- Corrosion: The occurrence of corrosion, influenced by the materials used and the operating environment, can lead to leaks and diminished performance. Selecting corrosion-resistant materials, such as titanium, is crucial, particularly in environments exposed to substances that heighten corrosion risks.

- Thermal Cycling: Repeated heating and cooling cycles can induce material fatigue. Engineers must consider the thermal expansion properties of materials during the design phase to address this challenge.

Maintenance practices include:

- Regular Inspections: Conducting routine checks for leaks, corrosion, and the overall integrity of the heat exchanger is vital. Regular audits ensure compliance with operational limits, reinforcing the importance of systematic checks in maintaining efficiency.

- Cleaning Protocols: Establishing cleaning procedures tailored to the specific thermal device and its operating environment is critical. An inspection report should be generated post-cleaning, complete with photos and recommendations for further action.

- Performance Monitoring: Implementing sensors to monitor temperature and flow rates facilitates early detection of performance issues. Regular monitoring and trend analysis can identify potential problems before they escalate.

By addressing these challenges and adhering to maintenance best practices, engineers can ensure the efficient functioning of thermal devices within their electronic systems. As Alan, Head of Aftermarket at Sterling Thermal Technology, emphasizes, “Regularly clean and monitor your heat exchanger’s condition” to extend its lifespan and enhance operational efficiency.

Conclusion

Mastering the heat exchanger unit is crucial in electronics engineering, as these devices are pivotal in managing thermal energy. By facilitating efficient heat transfer, heat exchangers are integral to maintaining optimal operating conditions for high-performance components, thereby enhancing overall system performance and reliability.

Key aspects highlighted throughout the article include:

- The operational principles of heat exchangers

- Their selection criteria

- Common maintenance challenges

Understanding thermal requirements, material selection, and regular maintenance practices is essential, illustrating how these factors contribute to the longevity and efficiency of electronic systems. Real-world applications in automotive and data center environments further emphasize the critical role heat exchangers play in preventing overheating and ensuring operational efficiency.

As the demand for advanced electronic systems grows, prioritizing effective thermal management through heat exchangers becomes increasingly significant. Engineers and designers must adopt best practices in selecting and maintaining these devices to optimize performance and promote sustainability in electronic engineering. Investing in robust thermal management solutions is not merely a technical necessity; it is a strategic imperative for future-proofing electronic systems.

Frequently Asked Questions

What are heat exchanger units?

Heat exchanger units are thermal transfer instruments that facilitate the movement of thermal energy between two or more liquids without allowing their combination.

Why are heat exchanger units important in electronics?

They are crucial for dissipating energy generated by high-performance components, such as processors and power supplies, preventing overheating and thereby enhancing the lifespan and reliability of electronic equipment.

How do recent advancements in thermal transfer technology improve efficiency?

Recent advancements, such as the development of semi-welded plate units, have markedly improved the efficiency and reliability of thermal management systems.

What role do thermal devices play in industrial applications?

Thermal devices help maintain optimal temperatures, preventing component failure and diminishing performance by effectively managing thermal loads.

Can you provide examples of thermal devices in real-world applications?

In the automotive sector, advanced thermal transfer devices manage temperature loads in electric vehicles for optimal battery performance. In data centers, thermal regulators are vital for cooling systems that protect servers from overheating.

Why is the integration of thermal transfer devices considered fundamental in electronics engineering?

It significantly enhances performance, efficiency, and sustainability, making it critical for maintaining optimal operating conditions as the demand for reliable electronic systems continues to grow.