Overview

This article delves into the mastery of vapor chamber design, a critical component for optimal thermal management. It highlights their functionality in facilitating efficient heat distribution, particularly for high-performance applications. By elucidating the operational principles of vapor chambers, the article underscores their advantages over traditional heat pipes.

Furthermore, it emphasizes the significance of modeling and Computational Fluid Dynamics (CFD) analysis in enhancing their performance. Ultimately, this discussion illustrates the indispensable role that vapor chambers play in contemporary electronic cooling solutions.

Introduction

In the realm of thermal management, vapor chambers emerge as innovative solutions tailored to efficiently dissipate heat in high-performance applications. By harnessing the principles of phase change, these sophisticated devices enable rapid heat transfer through the conversion of liquid into vapor and back again, thereby ensuring optimal temperature regulation.

As electronic components grow increasingly powerful and compact, the demand for effective cooling solutions has reached unprecedented levels. This article will delve into the functionality of vapor chambers, juxtapose their performance against heat pipes, and explore advanced modeling techniques along with CFD analysis that enhance their efficacy.

A closer examination of recent advancements and practical applications will illuminate the pivotal role of vapor chambers in modern electronics, showcasing their potential to drive innovation in thermal management technology.

Define Vapor Chambers and Their Functionality

Vapor chamber systems are advanced thermal control devices that utilize the principles of phase change for efficient energy transfer. These systems consist of a sealed enclosure filled with a working fluid, typically water or a specialized liquid. When heat is introduced, the liquid vaporizes into gas, forming mist that migrates to cooler regions of the enclosure. Upon reaching these cooler surfaces, the gas condenses back into liquid, releasing stored energy in the process. This continuous cycle enables fluid containers to distribute warmth over a broader area, making them particularly effective for high-performance applications in electronics cooling.

The design of fluid containers often incorporates a wick structure that facilitates the return of the liquid to the heat source, ensuring uninterrupted operation. This reliability is vital, especially in challenging environments where consistent thermal management is paramount. Recent advancements in steam containment technology, including research into biomimicry for aerospace applications, are further enhancing their cooling efficiency, demonstrating the innovative trajectory of the field.

In practical applications, thermal management devices offer significant advantages. For instance, EcoMia’s steam enclosure modules for high-power microwave amplifiers achieved an impressive 85% weight reduction, illustrating their potential for lightweight design without sacrificing performance. Additionally, thermal enclosures play a crucial role in maintaining optimal temperatures for CPUs and GPUs, thereby improving battery longevity and overall device efficiency. The integration of advanced pump technologies, such as solenoid pumps and rotary boost pumps from Gagner-Toomey Associates, further optimizes these systems. With features like precision control, low noise operation, and a maximum pressure of 16 Bar, these pumps ensure effective fluid movement within thermal management solutions, enhancing the performance of gas containers. The materials employed, including NSF and WSAS, further bolster their reliability and efficacy.

As Matthew J. Connors noted, “To ensure the validity of these models, four frames were fabricated and thermally tested,” underscoring the importance of rigorous testing in validating heat transfer device designs. Case studies indicate that their capacity to evenly distribute heat mitigates hot spots, enabling the development of thinner, lighter components while extending operational longevity. As the electronics sector continues to evolve, the role of heat exchange units in temperature regulation remains critical, driving innovation and efficiency. In conclusion, the integration of vapor chambers into electronic designs not only improves heat management but also paves the way for future advancements in technology. For further information, locate a distributor or visit our product website.

Compare Vapor Chambers and Heat Pipes

Vapor chamber systems and thermal tubes are both vital two-phase temperature control devices, but they serve distinct functions and operate on different principles. Thermal pipes are engineered for unidirectional thermal transfer, effectively moving warmth from one location to another. In contrast, fluid systems excel at distributing energy across a broader surface area, making them ideal for applications that require uniform temperature dissipation, such as high-performance CPUs and GPUs. Their design allows gas-filled containers to handle greater temperature transfers and achieve excellent conductivity, owing to their large surface area and flat shape.

While gas-filled containers provide enhanced performance, pipes present a more economical and straightforward production alternative, making them suitable for less demanding temperature regulation scenarios. According to ‘Electronics Cooling’, two performance constraints are significant for terrestrial pipe applications: the wick limit and the gas limit. This highlights the limitations that thermal conduits encounter in specific applications. A noteworthy case study illustrates the collaboration between these two technologies: by integrating vapor chambers and thermal conduits, engineers can significantly enhance temperature regulation efficiency, optimizing energy distribution in complex systems. This adaptability is crucial in high-demand environments where efficient temperature control is essential.

As we look to 2025, the comparison between gas containers and thermal pipes continues to evolve, with industry leaders emphasizing the advantages of gas containers in particular applications. For instance, the typical temperature resistance of the MGW-T gas enclosure achieves an impressive 0.92 K/W under a power load of 60 W, showcasing its efficiency in high-performance settings. However, it is important to recognize that the design of evaporation vessels is generally confined to a flat shape, which can limit their adaptability in certain cases. Ultimately, the choice between gas-filled systems and heat pipes hinges on the specific temperature management needs of the application, balancing performance requirements with cost considerations.

Model Vapor Chambers for Effective Thermal Management

Efficient modeling of evaporation units demands that engineers focus on several critical factors, such as geometry, the choice of working fluid, and wick design. The type of working fluid employed dictates the operating temperature range of a vapor chamber, making it essential for engineers to consider this aspect when selecting fluids for their heat management needs. The utilization of Computational Fluid Dynamics (CFD) software enables the simulation of heat performance under various operating conditions. A foundational step in this process involves defining the dimensions of the heat source and estimating the heat load. Moreover, the model must account for the phase change characteristics of the chosen working fluid and the heat-related properties of the materials within the chamber.

To enhance heat efficiency and reduce heat resistance, engineers can strategically adjust these parameters. Sensitivity analyses prove particularly beneficial, as they identify which design elements most significantly impact performance. Recent studies indicate that the capillary performance of the wick is a crucial factor in overall heat efficiency, with optimal designs striking a balance between capillary pressure and liquid permeability. A comparative study of wick types has demonstrated that a thorough understanding of these characteristics can lead to superior design decisions. By integrating these insights, engineers can refine thermal management designs to meet the demands of high-power-density electronic devices across various sectors, including electronics, power generation, and automotive applications.

As Albert Einstein aptly noted, “The process of conceiving a new and innovative idea is very different from transforming that idea into a viable and usable product.” This perspective highlights the necessity of comprehensive modeling and optimization in the engineering process.

Utilize CFD Analysis for Performance Evaluation

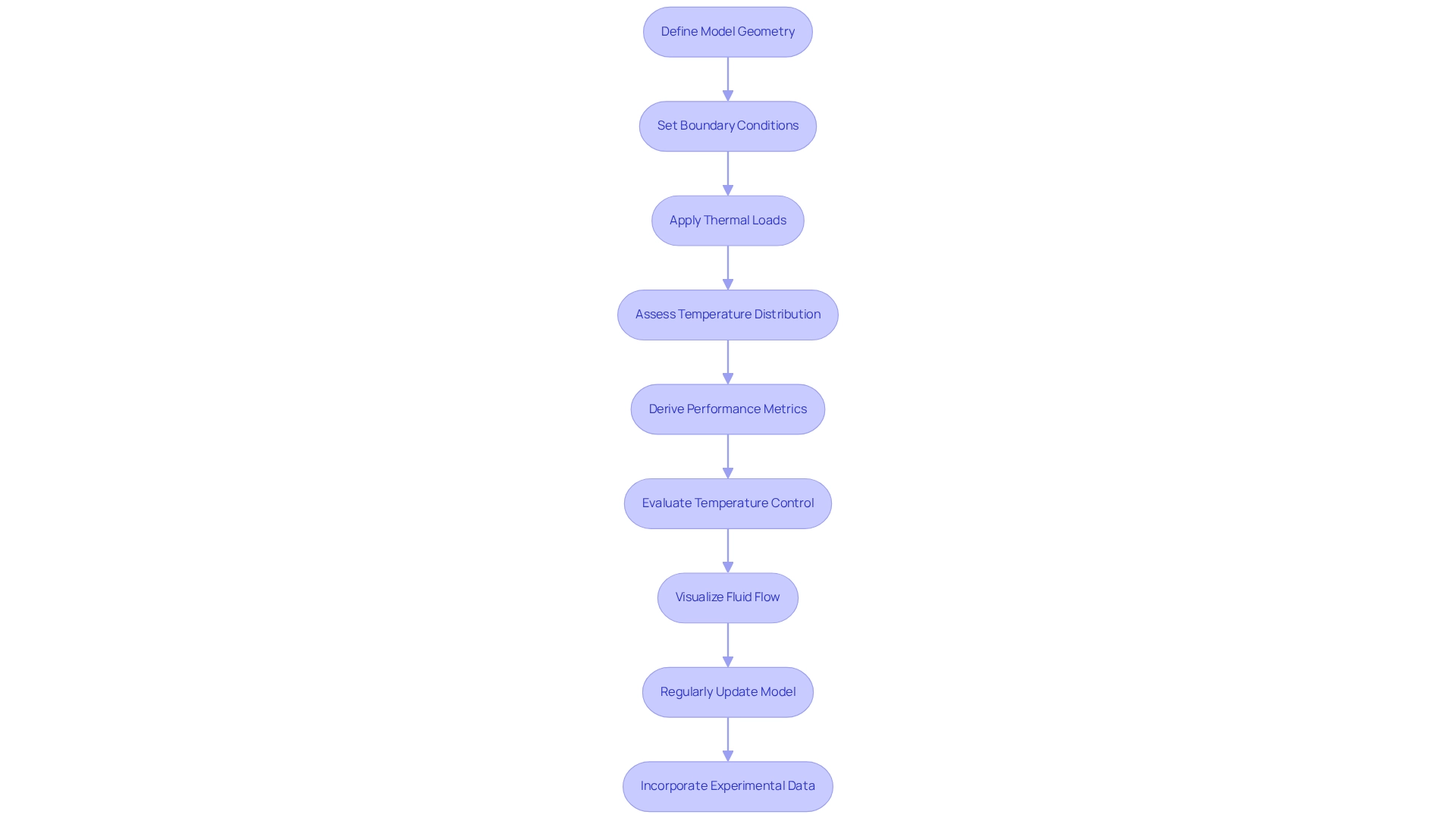

Utilizing Computational Fluid Dynamics (CFD) analysis is essential for modeling the heat performance of fluid units. This process begins with the precise definition of the model’s geometry and boundary conditions. Subsequently, engineers can apply various thermal loads to assess the resulting temperature distribution within the enclosure.

Essential performance metrics, such as temperature resistance and fluid transfer coefficients, are derived from the simulation results. This allows engineers to evaluate whether the evaporation unit meets temperature control requirements. Furthermore, CFD facilitates the visualization of fluid flow and temperature gradients, effectively highlighting potential hotspots and areas ripe for design enhancement.

Regular updates to the model, informed by experimental data, can significantly enhance the accuracy of these simulations. Recent studies have demonstrated that innovative designs, such as hybrid wick structures in heat chambers, can achieve a spreading resistance as low as 0.08 K/W, underscoring the effectiveness of advanced heat management solutions.

Notably, experimental outcomes suggest that new flat plate heat pipes (FPHP) exhibit a resistance reduction of 10-15% compared to conventional FPHP, providing a comparative framework for assessing performance metrics. As M. G. Velikanova emphasized, understanding the connection between temperature and the coefficient of heat conductivity for multilayer insulation cooled by helium gases is crucial in the design management process.

As the demand for high-performance electronics escalates, incorporating CFD analysis in the design of a vapor chamber becomes increasingly vital, ensuring optimal heat management in advanced applications. The development of new thermal management technologies is essential for advancing these high-performance electronics.

Conclusion

The exploration of vapor chambers highlights their essential role in modern thermal management, particularly as electronic components grow increasingly powerful and compact. Utilizing phase change principles, vapor chambers efficiently dissipate heat, thereby ensuring optimal performance in high-demand applications. Their unique design facilitates superior heat distribution compared to traditional heat pipes, rendering them indispensable for cooling high-performance CPUs and GPUs. Significant advancements in vapor chamber technology, including innovative wick structures and integration with advanced pump systems, further enhance their efficiency and reliability.

Comparing vapor chambers and heat pipes underscores the necessity of selecting the appropriate thermal management solution tailored to specific application needs. While vapor chambers excel in high-performance environments, heat pipes present a cost-effective alternative for less demanding scenarios. The synergy between these technologies can lead to optimized thermal management in complex systems, demonstrating the versatility and adaptability required in contemporary electronics.

Effective modeling and CFD analysis are critical for maximizing vapor chamber performance. By strategically adjusting design parameters and employing simulation tools, engineers can refine these devices to meet the thermal management demands of various industries. As the electronics landscape continues to evolve, the ongoing development of innovative thermal management solutions, including vapor chambers, will play a pivotal role in driving technological advancements and ensuring the reliability of high-performance systems. The future of thermal management is promising, with vapor chambers at the forefront of this essential field.

Frequently Asked Questions

What are vapor chamber systems?

Vapor chamber systems are advanced thermal control devices that use phase change principles for efficient energy transfer. They consist of a sealed enclosure filled with a working fluid, typically water, which vaporizes when heat is introduced and condenses back into liquid upon reaching cooler areas.

How do vapor chamber systems work?

When heat is applied, the working fluid inside the vapor chamber vaporizes into gas, which then migrates to cooler regions of the enclosure. There, it condenses back into liquid, releasing stored energy and creating a continuous cycle that distributes heat over a larger area.

What role does the wick structure play in vapor chambers?

The wick structure in vapor chambers facilitates the return of the liquid to the heat source, ensuring uninterrupted operation and reliability, particularly in environments where consistent thermal management is crucial.

What recent advancements have been made in vapor chamber technology?

Recent advancements include improvements in steam containment technology and research into biomimicry for aerospace applications, which enhance the cooling efficiency of vapor chamber systems.

What are some practical applications of vapor chamber systems?

Vapor chamber systems are used in high-performance applications, such as cooling for CPUs and GPUs, and in devices like EcoMia’s steam enclosure modules, which achieved an 85% weight reduction for high-power microwave amplifiers.

How do advanced pump technologies contribute to vapor chamber systems?

Advanced pump technologies, such as solenoid pumps and rotary boost pumps, optimize vapor chamber systems by ensuring effective fluid movement, offering precision control, low noise operation, and a maximum pressure of 16 Bar.

What materials are used in vapor chamber systems to enhance reliability?

Materials like NSF and WSAS are employed in vapor chamber systems to bolster their reliability and efficacy.

Why is rigorous testing important for vapor chamber designs?

Rigorous testing is essential to validate the performance of heat transfer devices, ensuring that they function as intended and effectively manage heat distribution.

How do vapor chamber systems affect the design of electronic components?

Vapor chamber systems help mitigate hot spots and allow for the development of thinner, lighter components while extending their operational longevity, which is crucial as the electronics sector evolves.

How can I find more information about vapor chamber products?

For further information, you can locate a distributor or visit the product website related to vapor chamber systems.