Overview

This article delves into the function, evolution, and critical specifications of 12V blowers, essential devices for facilitating air movement across various applications, particularly within the realm of electronics. It highlights that advancements in 12V blower technology—such as enhanced motor designs and increased energy efficiency—have rendered these devices indispensable for effective thermal management in electronic systems. Consequently, this innovation not only extends the lifespan of sensitive components but also optimizes their performance.

Introduction

The 12V blower has emerged as an essential component in contemporary electronics, functioning as a pivotal tool for effective thermal management across a multitude of applications. Its capacity to efficiently circulate air and regulate temperatures not only bolsters the performance and longevity of electronic components but also adapts to the ever-evolving demands of technology.

Nevertheless, as devices become increasingly compact and powerful, a significant challenge persists: how can engineers guarantee optimal airflow while simultaneously minimizing noise and energy consumption?

This article explores the function, evolution, and key specifications of 12V blowers, examining their crucial role within the realm of electronics engineering.

Define 12V Blower: Function and Design

A 12V fan is an electromechanical device engineered to efficiently move air or gas by enhancing its pressure and velocity. Operating on a 12-volt direct current (DC) source, the 12v blower finds extensive use in cooling electronic components, ventilation systems, and automotive applications. The standard design includes a motor, impeller, and housing, which work together to produce movement of air. The impeller, resembling a fan, rotates to draw air in from one side and expel it from the other, producing a controlled airflow that can be tailored to meet specific application needs.

Recent advancements in 12v blower technology have led to improved efficiency and versatility, making 12v blowers essential in various electronic projects. Engineers underscore the essential function of the 12v blower in preserving ideal temperatures, thus improving the efficiency and lifespan of . Practical applications encompass their use in HVAC systems, where they guarantee effective air distribution, and in temperature regulation for high-performance electronics, where precise airflow management is essential.

Gagner-Toomey Associates, being the world’s largest producer of standard and custom air-movers, provides an extensive product range of DC input fans optimized for performance, efficiency, and low noise, serving various industrial applications including electronics and automotive sectors. Specific product offerings include DC input fans ranging in size from 15mm to 225mm, designed to meet various cooling needs.

Contextualize the Role of 12V Blowers in Electronics Engineering

In electronics engineering, 12V fans are essential for effective thermal management, dissipating the heat generated by electronic components. Overheating poses significant risks, including diminished performance, potential component failure, and a reduced lifespan for devices.

By providing efficient airflow, a 12V blower helps maintain optimal temperatures in critical applications such as:

- Computer servers

- Gaming consoles

- Automotive electronics

Their compact design and make them ideal for seamless integration into a variety of electronic systems, ensuring reliable performance even under demanding conditions. Furthermore, the low noise levels associated with many 12V fans make them particularly suitable for consumer electronics, where silent operation is often a key requirement.

Trace the Evolution of 12V Blower Technology

The evolution of 12v blower technology finds its roots in the early electric fans and devices, which were primarily employed for ventilation and temperature regulation in industrial settings. As electronic devices have become increasingly compact and powerful, the demand for has surged. Innovations such as brushless DC motors and enhanced impeller designs have markedly improved the performance and efficiency of the 12v blower. Today’s 12v blower delivers superior air movement while consuming less energy, thanks to advancements in materials and motor technology. Furthermore, the incorporation of smart controls and variable speed options facilitates precise airflow management, tailored to the specific cooling requirements of diverse applications.

is projected to reach USD 2.6 billion by 2034, with a CAGR of 3.66% from 2025 to 2033. This growth underscores an escalating demand for high-performance devices, driven by their adaptability and energy efficiency. Currently, the centrifugal fan market leads the sector, with the Asia-Pacific region expected to experience substantial growth, highlighting the competitive landscape and regional dynamics within the fan market.

Prominent players such as Atlas Copco and Ingersoll Rand are at the forefront of this industry, propelling advancements in air movement technology. The increasing need for energy-efficient solutions, coupled with the challenges posed by noise levels in older fan models, further accentuates the importance of these innovations in meeting the cooling demands of .

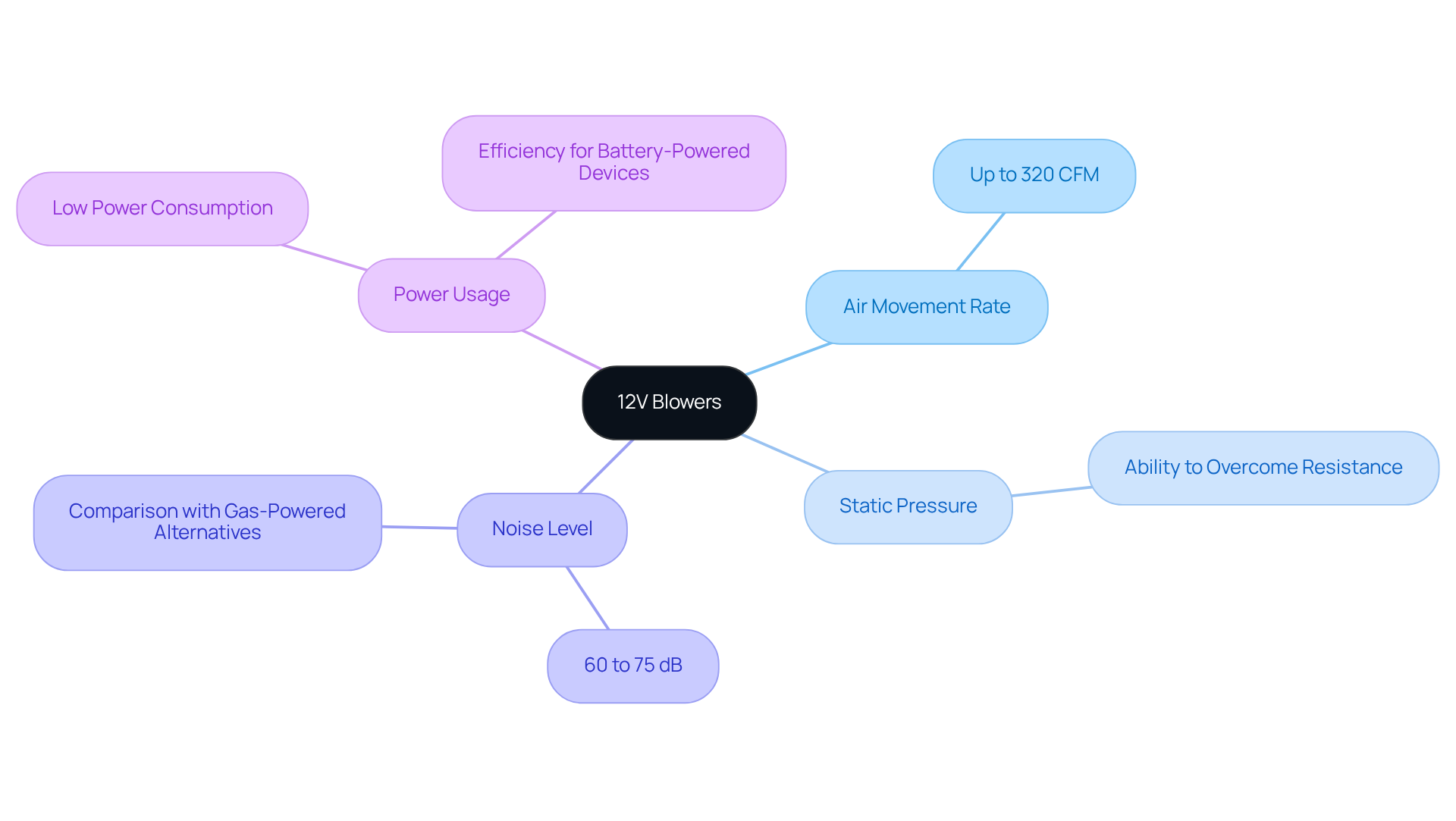

Identify Key Characteristics and Specifications of 12V Blowers

The essential features of the 12v blower from Gagner-Toomey Associates include:

- Air movement rate

- Static pressure

- Noise level

- Power usage

The air movement rate, quantified in cubic feet per minute (CFM), signifies the volume of air the fan can displace, whereas static pressure denotes its ability to overcome resistance within the air passage. For example, contemporary fans can achieve airflow rates reaching up to 320 CFM, rendering them effective for diverse applications.

Noise levels, typically measured in decibels (dBA), are crucial in environments where silent operation is paramount; many 12v blowers function within a range of 60 to 75 dB, significantly reducing noise pollution compared to gas-powered alternatives.

Power consumption represents another critical specification, influencing the . Numerous modern 12v blowers are engineered to operate at low power levels while still delivering adequate airflow, making them ideal for battery-powered devices and energy-efficient systems.

Furthermore, Gagner-Toomey provides an extensive product line of DC input Tube Axial fans and Centrifugal Blowers, available in sizes from 15 to 280mm and 15 to 225mm, respectively, featuring optimized performance and efficiency attributes.

Grasping these specifications is vital for engineers in selecting the appropriate blower for their specific cooling and ventilation requirements, thereby ensuring optimal performance and adherence to noise regulations.

Conclusion

The significance of 12V blowers in various applications is paramount, serving a fundamental role in enhancing airflow and thermal management across electronic systems. These compact devices not only help maintain optimal temperatures but also contribute to the efficiency and longevity of sensitive components. Their ability to operate quietly and effectively has rendered 12V blowers indispensable in both consumer electronics and industrial applications.

Key insights throughout the article highlight the essential functions of 12V blowers in electronics engineering, their evolution from basic ventilation devices to advanced cooling solutions, and their critical specifications, including:

- Air movement rate

- Static pressure

- Noise levels

Advancements in technology, particularly the integration of brushless motors and smart controls, have further enhanced their performance, making them suitable for a wide array of applications, from computer servers to automotive electronics.

In light of the growing demand for energy-efficient and reliable cooling solutions, the role of 12V blowers is set to expand further. As technology progresses, embracing these advancements in blower design is crucial for engineers and designers alike. Whether enhancing the performance of high-end gaming consoles or ensuring the reliability of automotive systems, understanding the capabilities and specifications of 12V blowers empowers stakeholders to make informed decisions that align with their cooling needs and environmental goals.

Frequently Asked Questions

What is a 12V blower?

A 12V blower is an electromechanical device that moves air or gas by enhancing its pressure and velocity, operating on a 12-volt direct current (DC) source.

What are the main components of a 12V blower?

The standard design of a 12V blower includes a motor, impeller, and housing, which work together to produce airflow.

How does a 12V blower function?

The impeller, which resembles a fan, rotates to draw air in from one side and expel it from the other, creating controlled airflow that can be tailored for specific applications.

What are the applications of a 12V blower?

12V blowers are used in cooling electronic components, ventilation systems, HVAC systems for effective air distribution, and temperature regulation for high-performance electronics.

Why are 12V blowers important in electronic projects?

They help preserve ideal temperatures, improving the efficiency and lifespan of delicate electronic parts through precise airflow management.

Who is a major manufacturer of 12V blowers?

Gagner-Toomey Associates is recognized as the world’s largest producer of standard and custom air-movers, offering a wide range of DC input fans optimized for performance and efficiency.

What sizes do 12V blowers come in?

DC input fans from Gagner-Toomey Associates range in size from 15mm to 225mm, designed to meet various cooling needs.