Overview

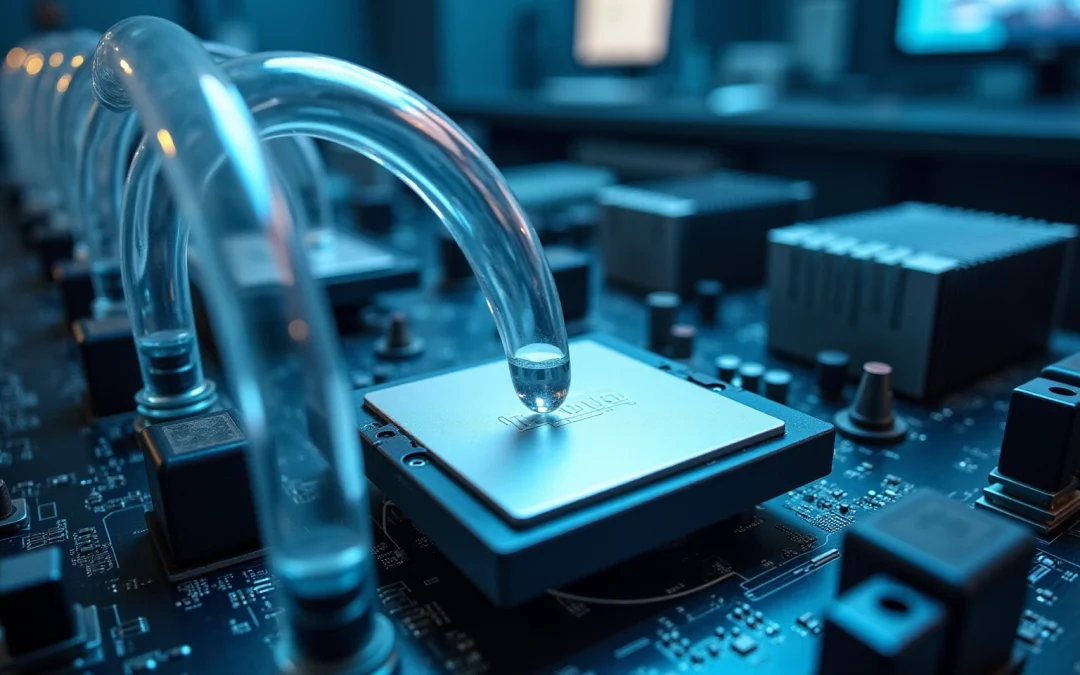

Customized cooling solutions in electronics engineering represent specialized thermal management strategies meticulously crafted to address the distinct temperature regulation requirements of electronic components and systems. This article underscores the critical nature of these tailored solutions, which encompass advanced technologies such as liquid cooling systems and heat sinks. By effectively managing heat dissipation, these technologies are indispensable for enhancing performance and reliability, ultimately optimizing operational efficiency.

Introduction

The rapid evolution of electronic devices presents increasingly complex thermal management challenges that standard cooling solutions frequently fail to address. Customized cooling solutions in electronics engineering not only enhance performance but also ensure the longevity and reliability of critical components.

As engineers strive to optimize temperature regulation, pressing questions emerge:

- How can tailored approaches effectively meet the unique demands of modern electronics?

- What innovative technologies are paving the way for more efficient cooling systems?

Exploring these facets reveals the transformative impact of personalized thermal management in today’s high-performance environments.

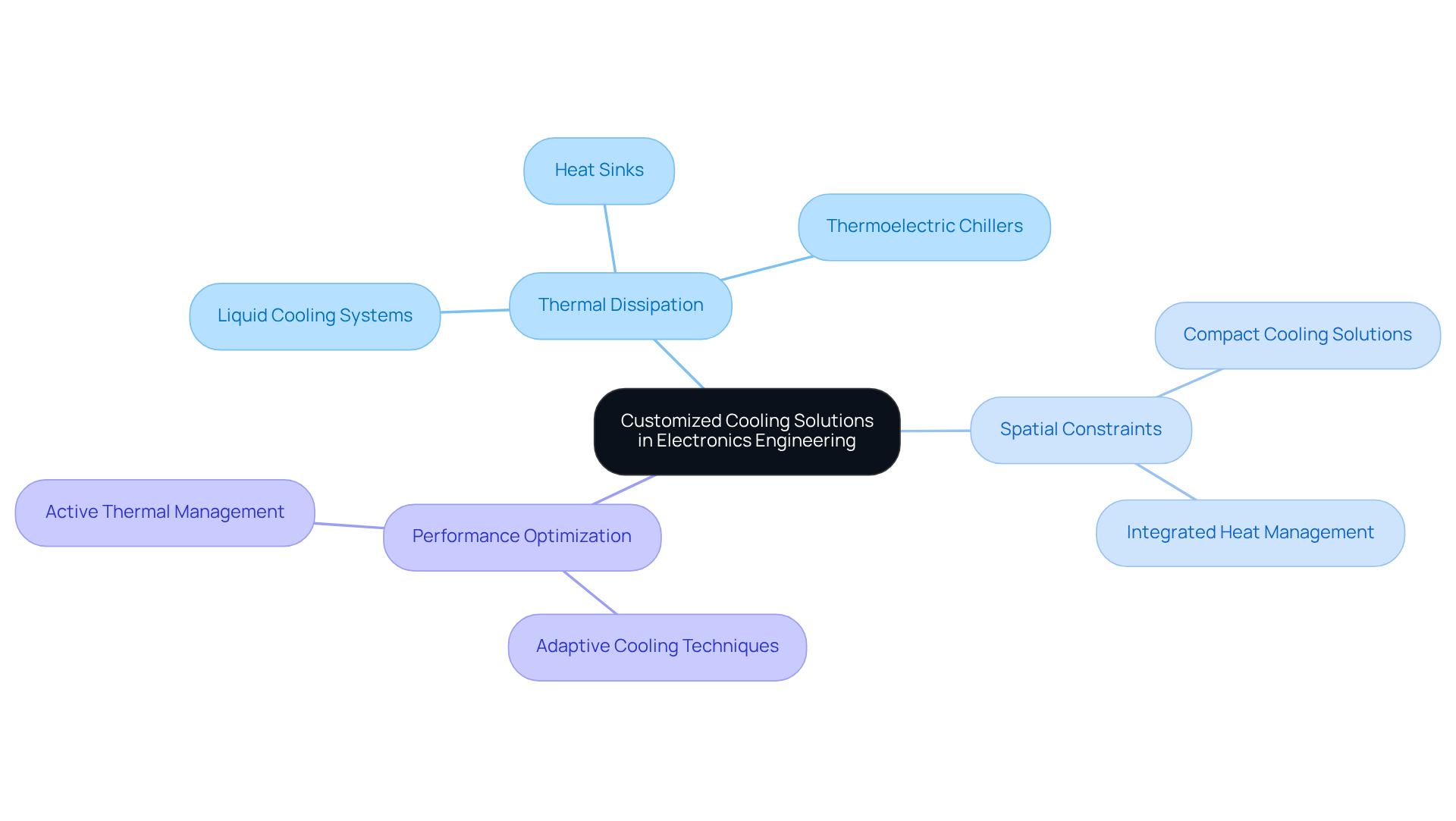

Defining Customized Cooling Solutions in Electronics Engineering

Personalized thermal management approaches in electronics engineering represent specialized methods designed to address the distinct temperature regulation requirements of electronic components and systems. Unlike off-the-shelf temperature management solutions, these tailored setups provide a customized cooling solution to effectively resolve specific challenges such as:

- Thermal dissipation

- Spatial constraints

- Performance optimization

They can encompass a variety of technologies, including:

- Liquid cooling systems

- Heat sinks

- Thermoelectric chillers

All aimed at enhancing the efficiency and reliability of electronic devices. The personalization process often involves collaboration between engineers and manufacturers to ensure that the thermal management solutions include a customized cooling solution that aligns with the operational demands of the electronic components they support.

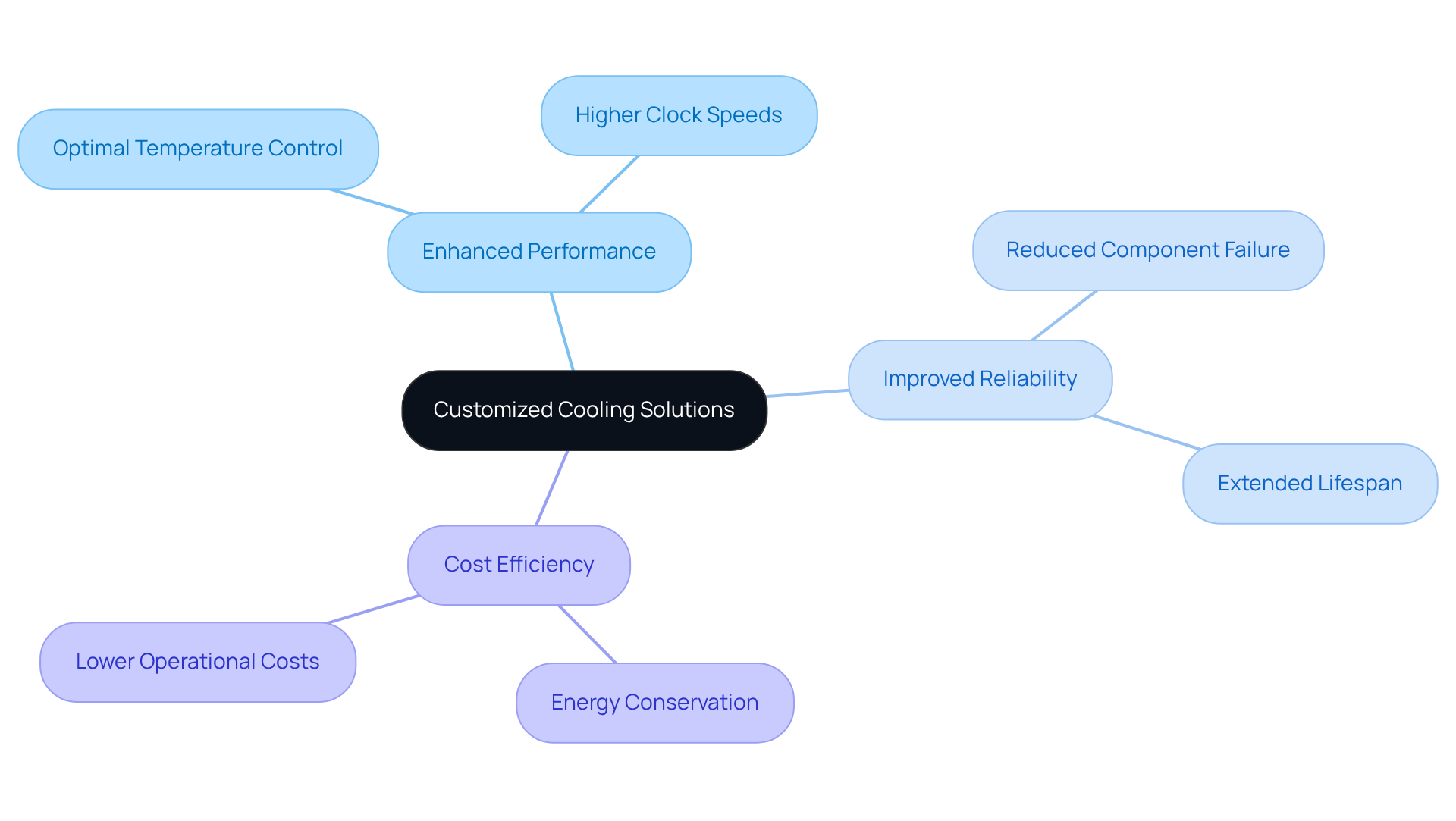

Importance of Customized Cooling Solutions for Performance and Efficiency

Tailored temperature control methods are crucial for enhancing the performance and efficiency of electronic systems. Excessive warmth poses a significant risk, leading to component failure, reduced lifespan, and diminished operational efficiency. By implementing a customized cooling solution, engineers can ensure that electronic devices operate within their optimal temperature ranges, thereby improving reliability and performance.

For instance, in high-performance computing environments, tailored liquid temperature regulation systems can effectively manage the heat generated by processors, allowing for higher clock speeds and improved processing capabilities. Furthermore, these methods contribute to energy conservation by reducing the need for larger, less efficient climate control units, ultimately resulting in lower operational costs.

Key Components and Technologies in Customized Cooling Solutions

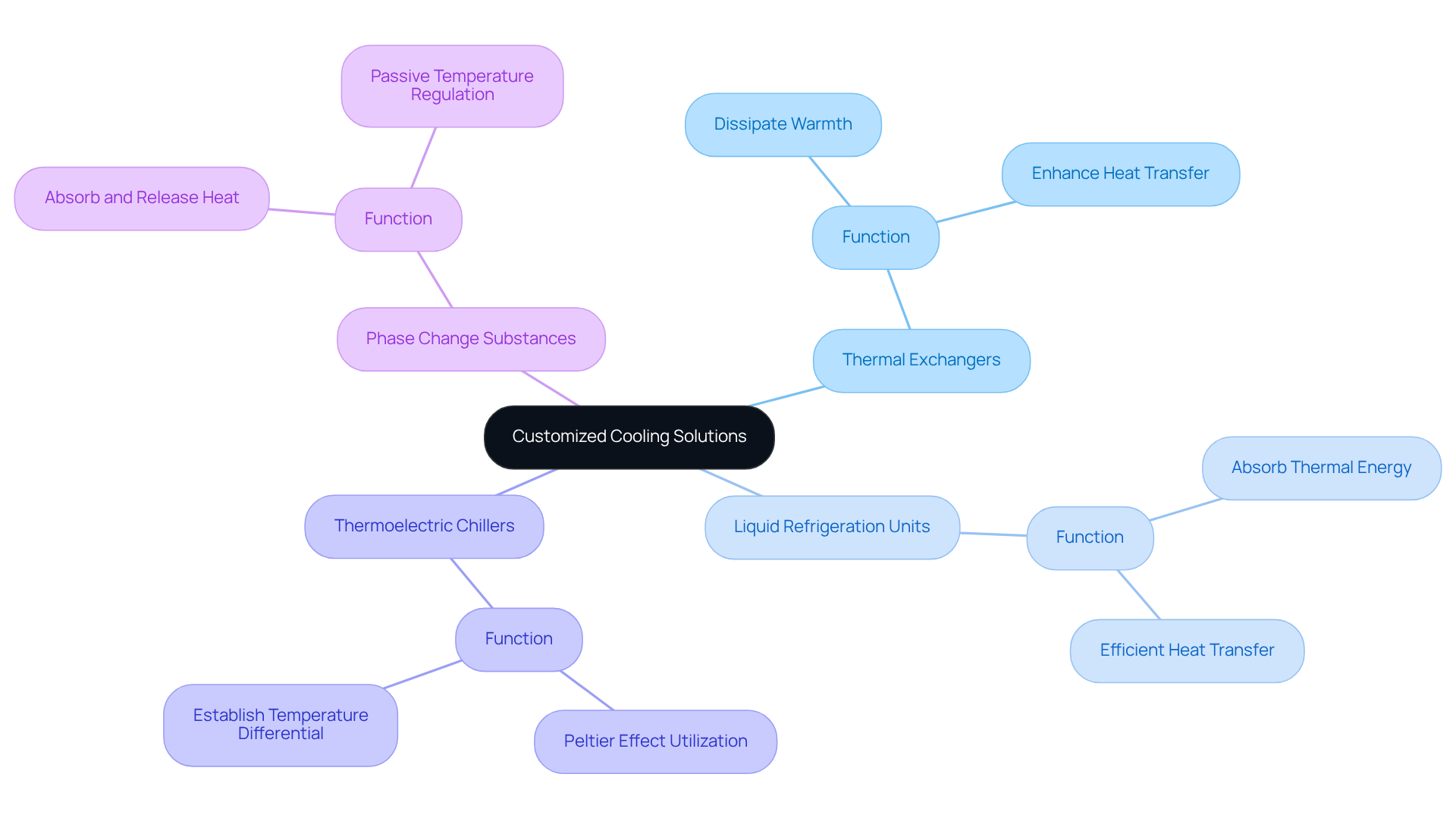

The essential elements of tailored temperature management encompass:

- Thermal exchangers

- Liquid refrigeration units

- Thermoelectric chillers

- Phase change substances

These components are critical in addressing the challenge of effective thermal regulation in electronic systems. Heat sinks are engineered to dissipate warmth from vital components, while liquid solutions utilize a fluid medium to absorb and transfer thermal energy efficiently. Moreover, thermoelectric coolers exploit the Peltier effect to establish a temperature differential, thereby enabling precise temperature control. Phase change substances further enhance this system by absorbing and releasing heat during phase transitions, offering a passive method for temperature regulation. Each of these components can be meticulously tailored to create a customized cooling solution that meets the specific requirements of an electronic system, ensuring optimal thermal management and performance.

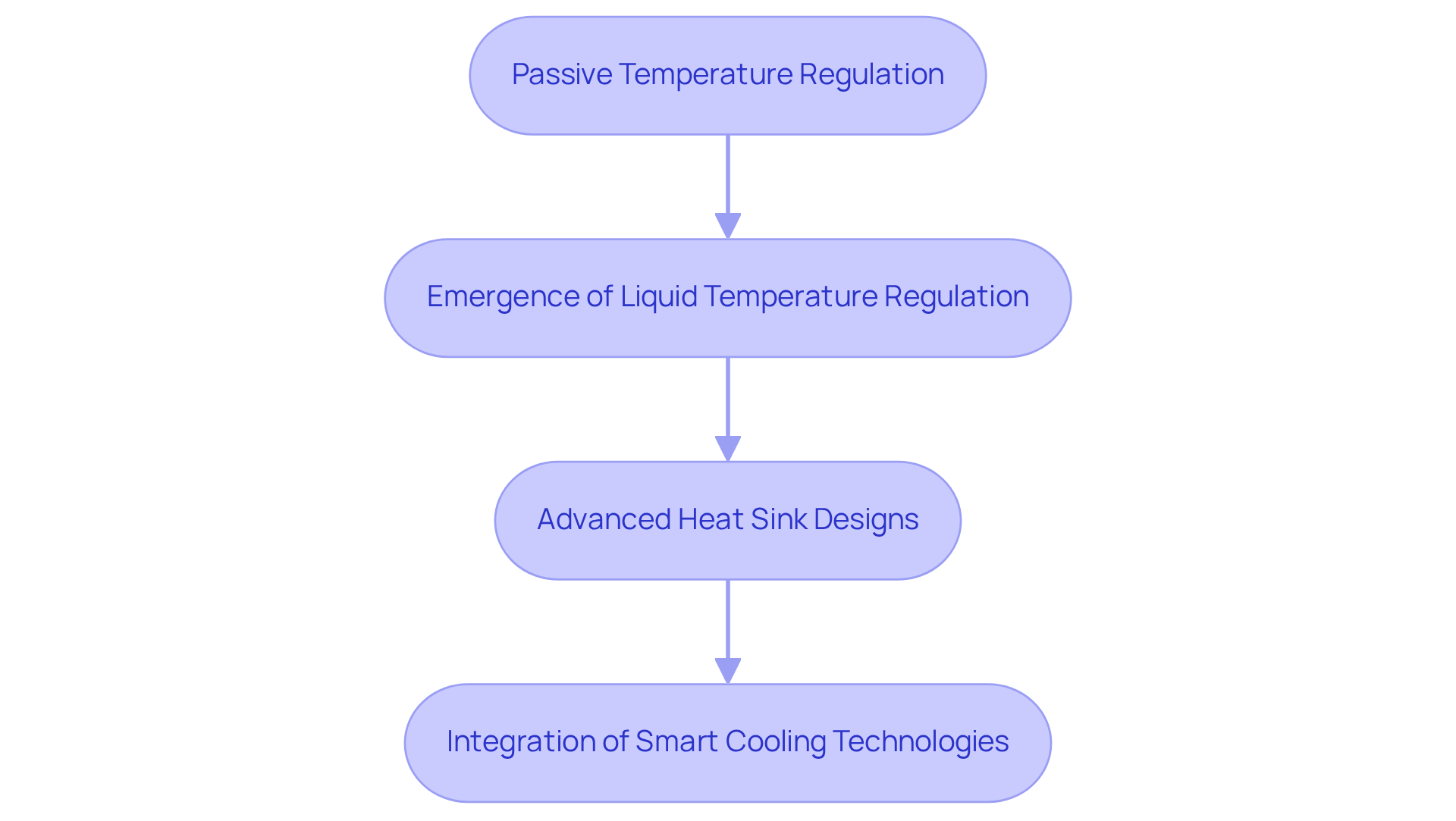

Evolution of Customized Cooling Solutions in Electronics Engineering

The advancement of tailored thermal management systems in electronics engineering has been significantly driven by the increasing complexity and power density of electronic devices. Initially, passive temperature regulation techniques, such as natural convection and basic sinks, sufficed. However, as devices evolved to become more powerful and compact, the necessity for more efficient temperature control methods emerged.

Innovations, including liquid temperature regulation and advanced heat sink designs, have gained prominence, facilitating superior heat dissipation in high-performance applications. Recent developments feature the integration of smart cooling technologies that leverage sensors and AI to optimize cooling based on real-time data, thereby further enhancing the efficiency and effectiveness of customized cooling solutions.

Conclusion

Customized cooling solutions in electronics engineering are essential for addressing the distinct thermal management needs of electronic components and systems. By transcending generic temperature control methods, these tailored approaches guarantee that devices function efficiently and reliably, reducing risks associated with overheating and boosting overall performance.

This article explores several critical aspects of customized cooling solutions, emphasizing the necessity of effective thermal management for device longevity and efficiency. It examines various technologies, including liquid cooling systems, heat sinks, and thermoelectric chillers, each engineered to confront specific challenges such as thermal dissipation and spatial constraints. Moreover, the evolution of these solutions has been propelled by the increasing complexity of electronic devices, resulting in the adoption of innovative methods that utilize real-time data for optimal cooling.

The importance of customized cooling solutions is paramount. As electronic devices continue to evolve in power and compactness, the demand for efficient thermal management will inevitably escalate. Embracing tailored cooling technologies not only enhances performance and reliability but also fosters energy conservation and cost savings. By investing in customized cooling solutions, engineers can ensure that electronic systems are equipped to meet current demands and are prepared for the future of technology.

Frequently Asked Questions

What are customized cooling solutions in electronics engineering?

Customized cooling solutions in electronics engineering are specialized methods designed to address the specific temperature regulation requirements of electronic components and systems, unlike standard off-the-shelf solutions.

What challenges do customized cooling solutions aim to resolve?

Customized cooling solutions aim to resolve challenges such as thermal dissipation, spatial constraints, and performance optimization.

What technologies are included in customized cooling solutions?

Customized cooling solutions can include technologies such as liquid cooling systems, heat sinks, and thermoelectric chillers.

How do customized cooling solutions enhance electronic devices?

They enhance the efficiency and reliability of electronic devices by providing tailored thermal management that meets the unique operational demands of the components.

Who is involved in the personalization process of customized cooling solutions?

The personalization process typically involves collaboration between engineers and manufacturers to ensure that the thermal management solutions align with the operational demands of the electronic components they support.