Overview

This article delves into the critical concept of fan RPM (Revolutions Per Minute) and its importance for engineers tasked with selecting and optimizing fan performance. Understanding fan RPM is not merely a technical detail; it is essential for assessing air circulation efficiency, energy consumption, and noise levels. By grasping these elements, engineers can effectively balance these factors to meet specific cooling and ventilation requirements across various applications. Ultimately, a comprehensive understanding of fan RPM empowers engineers to enhance system performance and achieve optimal operational outcomes.

Introduction

Understanding the intricacies of fan RPM is essential for engineers navigating the complexities of airflow and cooling efficiency. The revolutions per minute (RPM) of a fan not only determines its speed but also significantly impacts its performance, energy consumption, and noise levels. As engineers delve into the relationship between RPM and effective air movement, they face the challenge of balancing optimal cooling capabilities with energy efficiency and operational noise. This critical metric can be leveraged to make informed decisions that enhance performance while minimizing costs.

Define RPM: The Basics of Revolutions Per Minute

The fan rpm meaning quantifies the number of complete rotations a fan’s blades execute in one minute, serving as a critical indicator of a fan’s speed and efficiency. Ceiling circulators typically operate within an RPM range of 300 to 400 at their highest speed. This metric is vital for engineers to assess how effectively a fan can circulate air, which is especially crucial in applications that require optimal cooling and ventilation.

The fan rpm meaning indicates that higher RPM is generally associated with faster blade movement, resulting in increased air movement and enhanced cooling capacity. However, it is essential to recognize that elevated RPM may also lead to higher noise levels and increased energy consumption. For instance, Gagner-Toomey’s DC input Tube Axial devices and Centrifugal Blowers are designed to operate efficiently across various RPMs, making them suitable for a diverse range of applications in electronics, automotive, telecom, and industrial sectors.

Case studies illustrate the influence of RPM on fan performance. For example, Gagner-Toomey’s high-velocity fans are engineered to deliver optimal air movement while minimizing power usage, showcasing how RPM can be optimized for energy conservation. Furthermore, understanding the fan rpm meaning allows engineers to make informed decisions regarding fan selection, ensuring that the selected model addresses the specific cooling requirements of different environments.

Ultimately, engineers must strike a balance between RPM and other performance factors, such as blade design and motor efficiency, to refine fan selection for various applications. This comprehensive approach ensures that the chosen fan not only meets ventilation demands but also operates efficiently, contributing to overall energy conservation.

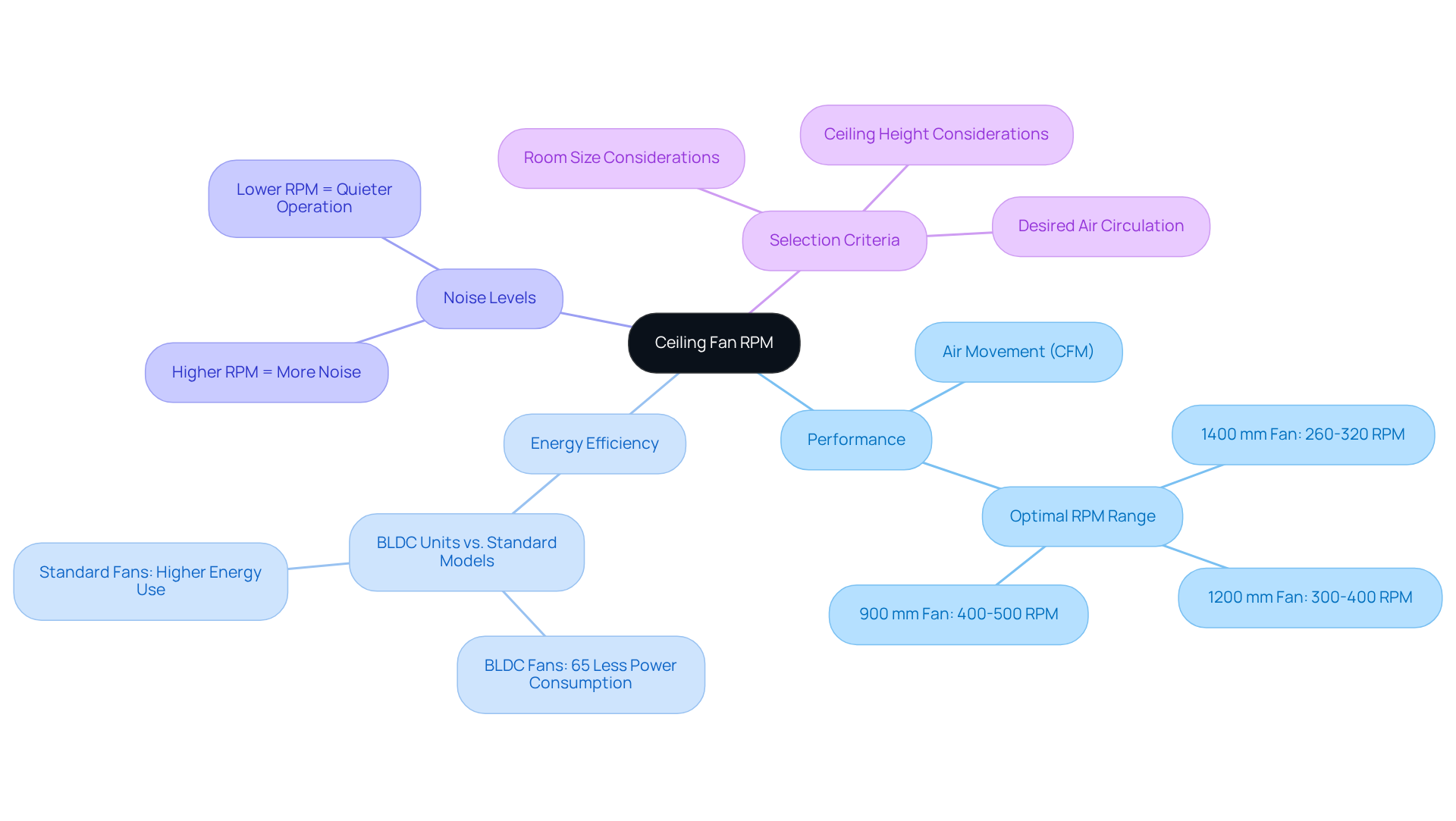

Explore Ceiling Fan RPM: Impact on Performance and Efficiency

The fan RPM meaning is essential as it plays a critical role in the performance and efficiency of a ceiling fan. A fan operating at a higher RPM is capable of moving more air, which proves advantageous in larger spaces or areas that require rapid cooling. For instance, contemporary BLDC units typically operate at RPMs ranging from 350 to 400, providing exceptional air circulation while consuming up to 65% less energy than standard models.

However, this increased speed can also result in higher energy consumption and noise levels. A ceiling fan with an RPM of 400 may deliver sufficient ventilation for a large room, yet it could simultaneously elevate electricity costs. On the other hand, a fan with a lower RPM may offer greater energy efficiency and quieter operation, making it ideal for smaller spaces or environments where noise is a concern.

The optimal RPM for a 1400 mm fan is between 260 and 320 RPM, serving as a benchmark for engineers when selecting ceiling fans based on room size. It is imperative for engineers to evaluate the specific requirements of the space when choosing a fan, balancing RPM with factors such as room dimensions, ceiling height, and desired air circulation.

Understanding the fan RPM meaning in relation to air movement (measured in CFM) and energy efficiency is vital for selecting the most suitable ceiling fan for any application. As HVAC professionals frequently highlight, achieving a balance between fan speed and noise levels is essential for optimal performance.

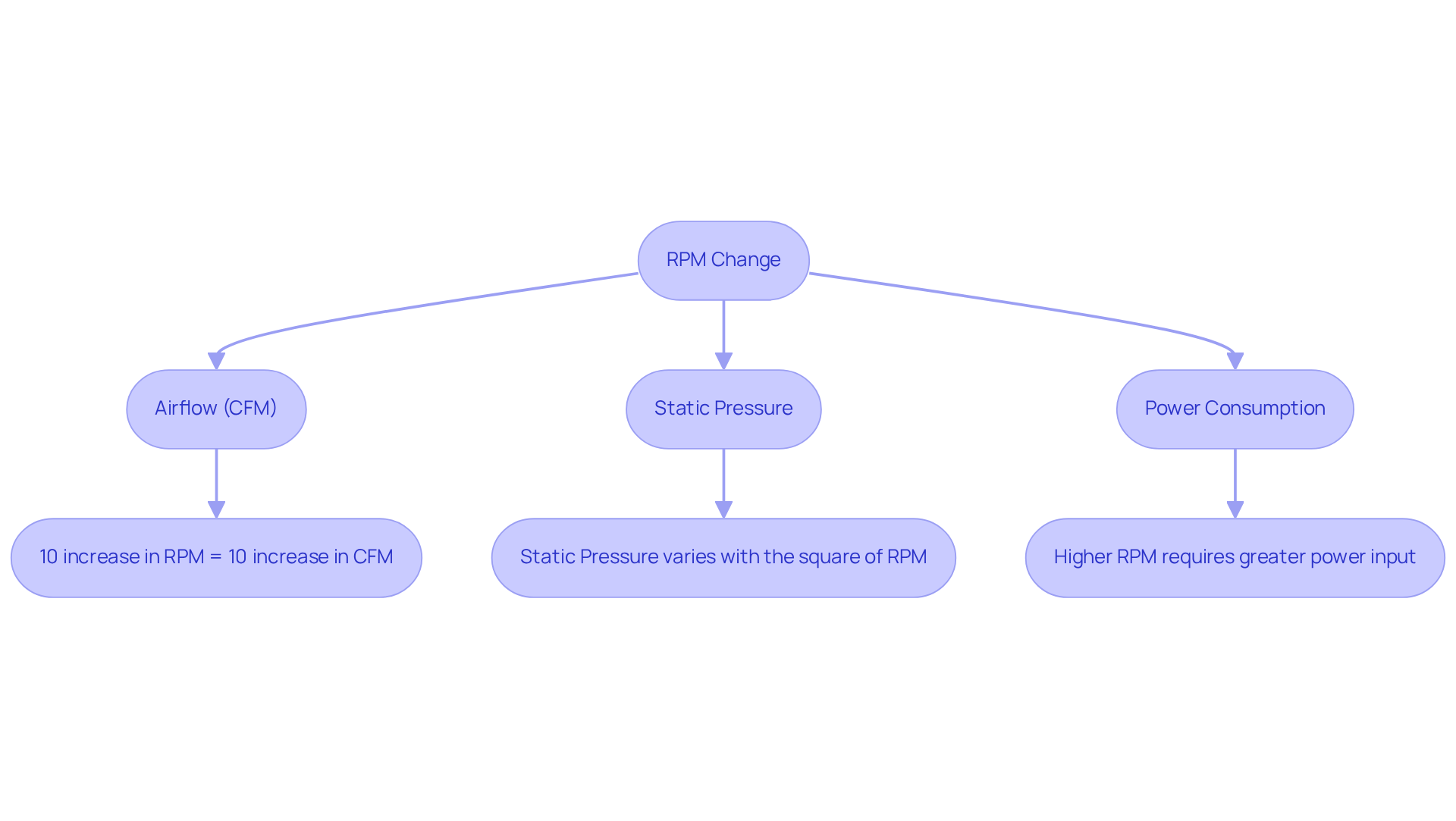

Analyze RPM and Airflow: Understanding Fan Laws and Performance

The interplay between RPM and ventilation is governed by fundamental fan laws that illustrate fan rpm meaning, which are essential for engineers. The first fan law establishes that the movement of air, quantified in Cubic Feet per Minute (CFM), is directly proportional to what is known as fan rpm meaning. For instance, a 10% increase in RPM results in a corresponding 10% rise in air movement.

The second fan law reveals that static pressure varies with the square of the RPM; thus, even a minor increase in RPM can lead to a substantial rise in static pressure. For example, if the RPM is increased from 1,000 to 1,100, the static pressure could increase significantly, impacting system performance.

The third law connects power consumption to RPM, indicating that higher RPMs necessitate greater power input. This relationship is crucial when calculating the required fan rpm meaning to achieve specific airflow rates, especially in cooling applications where maintaining optimal performance is critical.

To attain 6000 CFM, the new RPM must be 923, and the new static pressure (SP) for 6000 CFM is 3.4″ w.c. Understanding these principles enables engineers to make informed decisions regarding fan selection and system design, ensuring effectiveness and reliability in HVAC systems.

Furthermore, the Fan Energy Index (FEI) serves as a valuable measure for evaluating fan performance, with an FEI value exceeding 1 typically being the minimum standard for fan selection. This assists engineers in selecting units that meet energy efficiency goals while minimizing operational expenses.

Tim De Stasio, an HVAC specialist, emphasizes that whether you’re diagnosing a residential system or enhancing a commercial setup, these essential principles influence every decision regarding air movement.

Select the Right Fan: Factors Influencing RPM Choices

Selecting the appropriate fan necessitates careful consideration of various factors that influence the fan rpm meaning in the choices made. Room dimensions are pivotal; larger areas typically require devices with enhanced air movement capabilities, which is closely related to understanding fan rpm meaning for optimal RPM selection. The application type—whether for cooling, ventilation, or other purposes—also dictates specific airflow requirements, highlighting the importance of fan rpm meaning. For example, in cooling applications, Gagner-Toomey Associates offers devices engineered with larger blades that can efficiently shift more air at lower levels of fan rpm meaning, thereby enhancing energy performance. Their extensive portfolio features DC input Tube Axial fans and Centrifugal Blowers, available in sizes ranging from 15 to 280mm and 15 to 225mm, respectively, optimized for performance and low noise.

Design attributes such as blade shape and material significantly impact the fan rpm meaning as well as airflow performance. Industry experts assert that the efficiency of a fan blade is directly correlated with its design characteristics, including the angle of attack, which should ideally range between 12 to 15 degrees for optimal performance. Furthermore, noise levels are a critical consideration; the fan rpm meaning indicates that devices operating at higher RPMs generally produce more sound, which may be unacceptable in sensitive environments. For instance, average noise levels can vary considerably, with fans at 3600 RPM often surpassing the fan rpm meaning of acceptable thresholds in quiet settings.

Additionally, engineers must assess the fan’s energy consumption and maintenance requirements. Gagner-Toomey’s innovative cooling solutions, including integrated custom cooling solutions and thermal management products such as extruded aluminum heatsinks and vapor chambers, underscore the significance of regular maintenance practices. Neglected maintenance, such as improper lubrication or misalignment, can lead to increased downtime and operational expenses. As Kenneth M. Elovitz emphasizes, understanding the interplay between design and operational conditions is crucial for achieving optimal fan performance. Statistics reveal that emergency repairs are substantially more costly than preventive maintenance, highlighting the necessity of regular maintenance practices. By considering these factors, engineers can make informed decisions that align with both performance objectives and cost-effectiveness.

Conclusion

Understanding fan RPM is paramount for engineers responsible for selecting the appropriate fan for diverse applications. It serves as a critical metric that not only indicates the speed of the fan blades but also significantly affects overall performance, efficiency, and energy consumption. By comprehending the intricacies of RPM, engineers can ensure their selections meet the specific cooling and ventilation requirements of various environments.

This article explores several key facets of fan RPM, particularly its direct correlation with airflow and energy efficiency. Elevated RPMs can facilitate increased air movement, which is advantageous for larger spaces; however, they may also introduce challenges such as elevated noise levels and higher energy costs. The principles that govern fan performance, exemplified by the fan laws, highlight the essential role of RPM in achieving desired airflow and static pressure. Furthermore, considerations such as room dimensions, application type, and design characteristics are crucial in determining the optimal RPM for a fan.

Ultimately, making well-informed decisions regarding fan selection necessitates a thorough understanding of how RPM influences performance and efficiency. Engineers should evaluate not only the technical specifications but also the operational context to strike a balance between speed, noise, and energy consumption. By prioritizing these insights, engineers can select the right fan to optimize performance while contributing to energy conservation and operational effectiveness.

Frequently Asked Questions

What does RPM stand for in the context of fans?

RPM stands for Revolutions Per Minute, which quantifies the number of complete rotations a fan’s blades execute in one minute.

Why is RPM important for fans?

RPM is a critical indicator of a fan’s speed and efficiency, helping engineers assess how effectively a fan can circulate air, particularly in applications requiring optimal cooling and ventilation.

What is the typical RPM range for ceiling circulators?

Ceiling circulators typically operate within an RPM range of 300 to 400 at their highest speed.

How does higher RPM affect fan performance?

Higher RPM is generally associated with faster blade movement, resulting in increased air movement and enhanced cooling capacity. However, it can also lead to higher noise levels and increased energy consumption.

Can you give an example of fans designed for varied RPMs?

Gagner-Toomey’s DC input Tube Axial devices and Centrifugal Blowers are designed to operate efficiently across various RPMs, making them suitable for diverse applications in electronics, automotive, telecom, and industrial sectors.

How can RPM optimization contribute to energy conservation?

Case studies, such as those involving Gagner-Toomey’s high-velocity fans, show that optimizing RPM can deliver optimal air movement while minimizing power usage, thus contributing to energy conservation.

What factors should engineers consider when selecting a fan?

Engineers must strike a balance between RPM and other performance factors, such as blade design and motor efficiency, to ensure the selected fan meets ventilation demands while operating efficiently.

How does understanding RPM aid in fan selection?

Understanding the fan RPM meaning allows engineers to make informed decisions regarding fan selection, ensuring that the chosen model addresses the specific cooling requirements of different environments.