Introduction

The 12V centrifugal blower is at the forefront of modern air-moving technology, playing a pivotal role in applications ranging from electronics cooling to HVAC systems. These compact yet powerful devices not only enhance performance and efficiency but also address the growing demand for energy conservation in today’s tech-driven landscape.

With a myriad of options available, navigating the complexities of features, functionalities, and applications can be daunting. How can one select the right blower to meet specific needs? This question is crucial for making informed decisions in a market filled with choices.

Define 12V Centrifugal Blower: Key Features and Functionality

A 12v centrifugal blower is a specialized device that effectively transports air or gases through the use of centrifugal force. These fans, powered by a 12v centrifugal blower, are essential in electronics cooling and ventilation systems. Gagner-Toomey Associates, the world’s largest producer of standard and custom air-movers, offers a diverse range of 12v centrifugal blowers that are optimized for performance, efficiency, and low noise, making them suitable for various applications.

Key Features of 12V Fans:

- High Airflow Rates: These blowers are engineered to produce substantial airflow, making them ideal for cooling sensitive electronic components and ensuring optimal performance.

- Compact Design: Their small footprint allows for seamless integration into confined spaces, such as computer enclosures and HVAC systems, where space is at a premium.

- Energy Efficiency: Operating at low voltage, 12V fans consume significantly less power than larger units, making them particularly suitable for battery-operated devices and contributing to overall energy conservation. Brushless DC motors enhance this energy performance, providing 15-30% greater effectiveness compared to conventional models.

- Durability: Many models are designed to withstand challenging environments, ensuring a long operational lifespan even under demanding conditions.

The operational principle of a rotating fan involves drawing air into the center of the unit and expelling it at a right angle to the intake. This design generates high-pressure airflow, which is crucial for effective cooling and ventilation. Recent advancements in air-moving technology, particularly the incorporation of brushless DC motors, have improved energy efficiency by 20-30%, reinforcing the role of 12V fans in contemporary electronics. Furthermore, innovations in materials and design have led to quieter operation, making these fans suitable for consumer electronics where noise reduction is essential.

As the demand for compact and efficient cooling solutions continues to rise, Gagner-Toomey’s 12V centrifugal blower, available in various sizes and with IP protection options, is poised to play a crucial role in applications ranging from gaming consoles to industrial control units. The global ventilator rotary fan market is projected to expand from USD 40.2 million in 2025 to USD 53.9 million by 2032, highlighting the increasing demand for these technologies.

Contextualize Its Role in Electronics: Applications and Importance

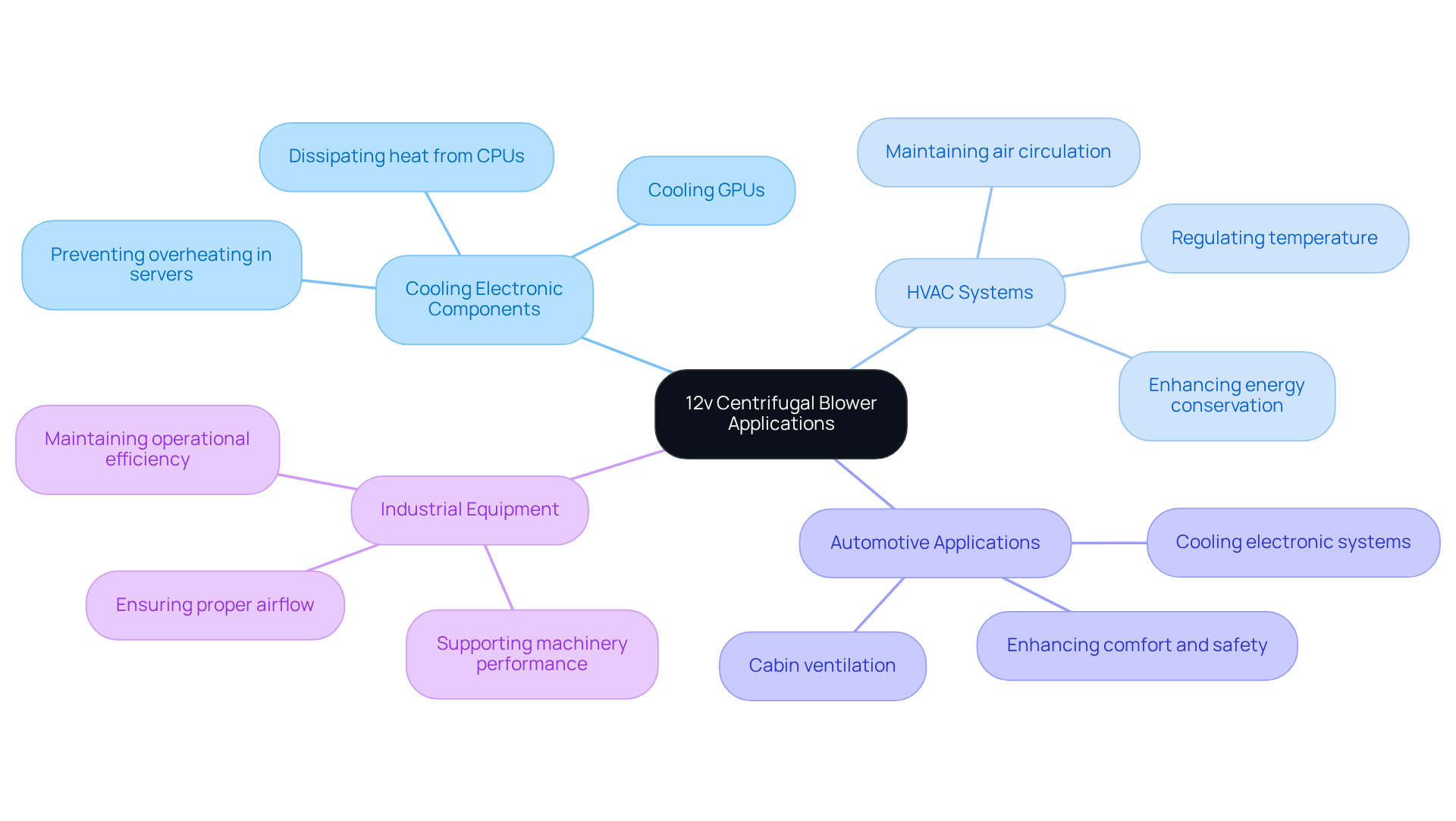

The 12v centrifugal blower is indispensable in the electronics industry, particularly for cooling and ventilation applications. Their primary uses include:

- Cooling Electronic Components: These blowers are crucial for dissipating heat from CPUs, GPUs, and other vital components in computers and servers. By preventing overheating, they ensure optimal performance.

- HVAC Systems: In heating, ventilation, and air conditioning systems, the 12v centrifugal blower plays a key role in maintaining air circulation and regulating temperature, which enhances energy conservation.

- Automotive Applications: In vehicles, the 12v centrifugal blower is utilized for cabin ventilation and cooling of electronic systems, thereby significantly enhancing comfort and safety.

- Industrial Equipment: The 12v centrifugal blower is employed in various machinery to ensure proper airflow, which is essential for maintaining operational efficiency.

The significance of the 12v centrifugal blower lies in its ability to provide reliable and efficient airflow, which is critical for the durability and functionality of electronic devices and systems.

Explore the Evolution: Historical Development of Centrifugal Blowers

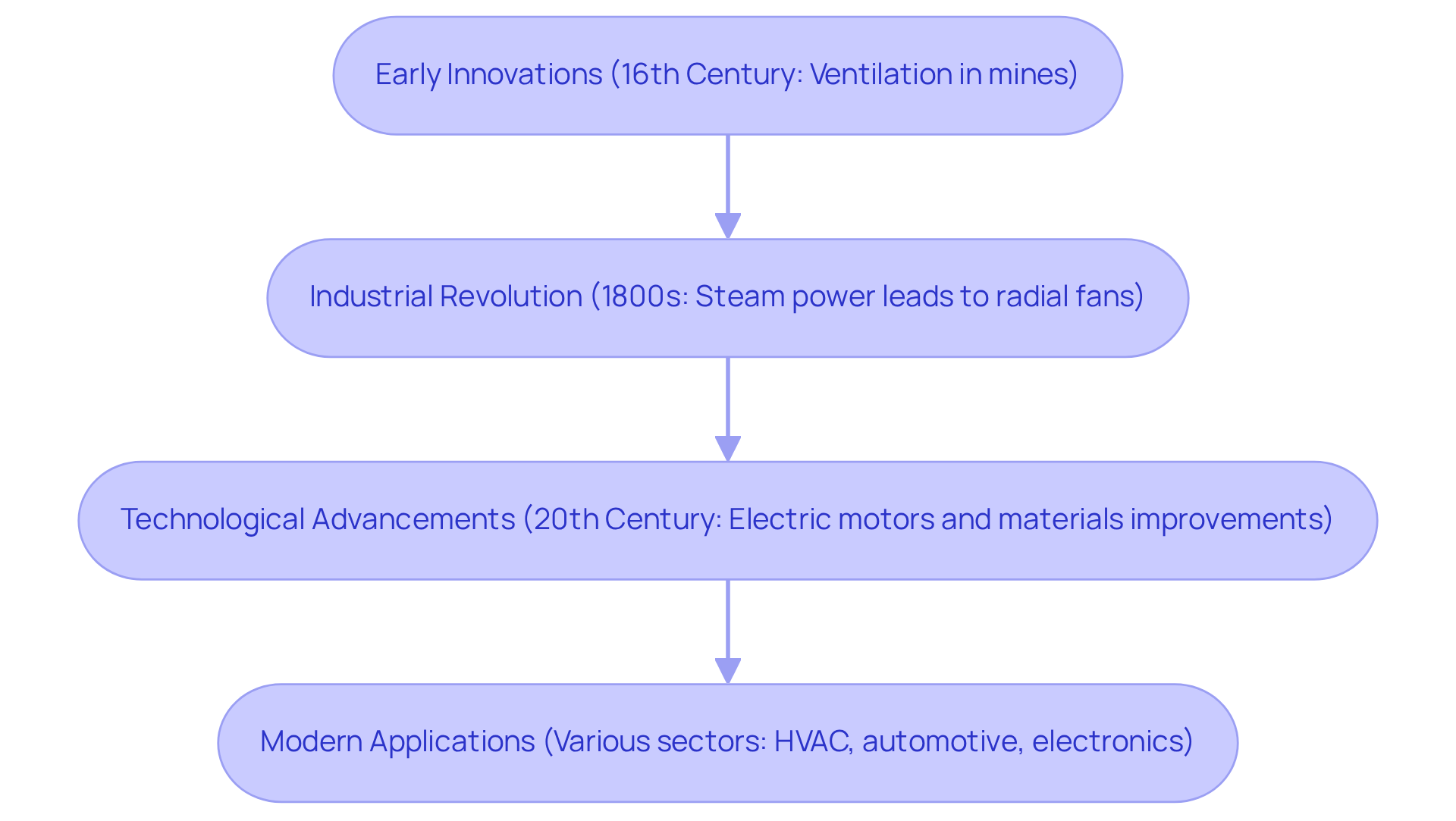

The history of centrifugal blowers is a testament to relentless innovation, tracing back to the early 19th century with several pivotal developments:

- Early Innovations: Centrifugal fans first emerged in the 16th century, primarily designed for ventilation in mines. Their industrial application gained momentum in the 19th century, laying the groundwork for broader use.

- Industrial Revolution: The advent of steam power in the 1800s catalyzed the development of radial fans, enabling the creation of larger and more efficient designs capable of managing increased air volumes and pressures.

- Technological Advancements: Continuous enhancements in materials and production methods have significantly improved the performance and durability of high-speed fans. The introduction of electric motors in the 20th century marked a revolutionary shift, paving the way for more compact and energy-efficient designs.

- Modern Applications: Today, air movers are indispensable across various sectors, including HVAC, automotive, and electronics, underscoring their versatility and essential role in contemporary technology.

This evolution not only highlights the relentless innovation in fan technology but also reflects the growing demand for improved performance and energy conservation.

Identify Key Characteristics and Variations: Types of 12V Centrifugal Blowers

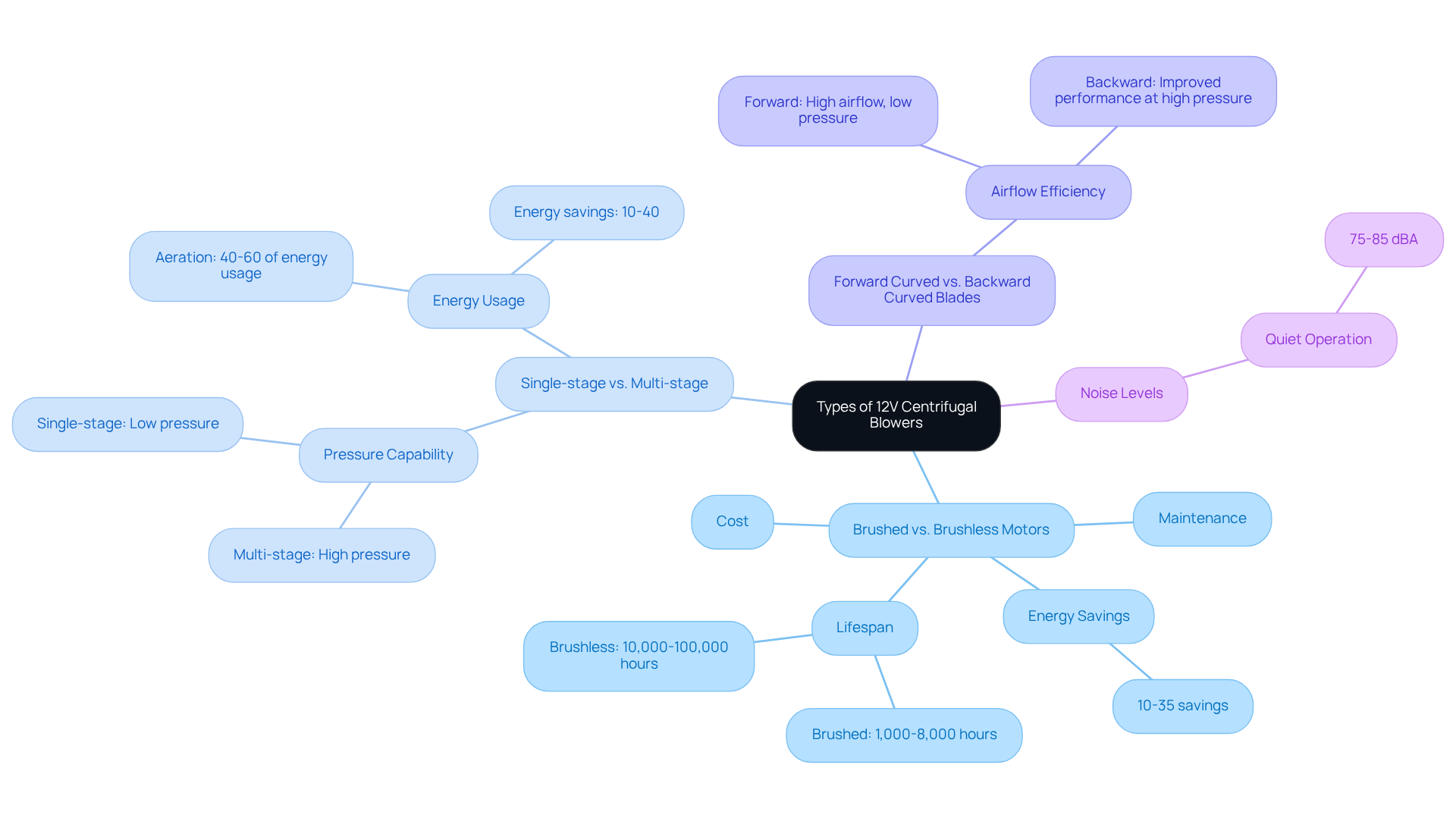

12v centrifugal blowers come in various configurations, each tailored for specific applications and operational environments. Understanding their key characteristics and variations is essential for making informed decisions.

-

Brushed vs. Brushless Motors: Brushed motors are typically more affordable but require higher maintenance due to wear on brushes and commutators. In contrast, brushless motors deliver superior performance, achieving energy savings of 10-35% over conventional designs. They also boast a longer lifespan, often ranging from 10,000 to 100,000 hours. Notably, Inovair operates at an efficiency of 75-80% compared to Positive Displacement devices, underscoring the advantages of brushless technology.

-

Single-stage vs. Multi-stage: Single-stage devices are ideal for low-pressure applications, providing moderate airflow efficiently. Conversely, multi-stage fans excel in generating higher pressures, making them suitable for demanding environments like wastewater treatment, where aeration processes account for 40-60% of energy usage. Recent advancements in geared fans have demonstrated energy savings of 10-40% compared to traditional multi-stage or positive displacement devices, leading to significant operational cost reductions. Furthermore, single-stage centrifugal integrally geared blowers manage airflow and pressure independently, enhancing control and functionality across diverse applications.

-

Forward Curved vs. Backward Curved Blades: Forward curved blades are engineered for high airflow at low pressure, making them efficient in scenarios that require substantial air movement without significant resistance. In contrast, backward curved blades are designed for improved performance at elevated pressures, making them more suitable for industrial applications where pressure is a critical factor.

-

Noise Levels: Certain models are specifically designed for quiet operation, which is crucial in consumer electronics and environments where noise reduction is vital. Innovations in fan design have resulted in models that maintain operational noise levels as low as 75-85 dBA, ensuring minimal disruption in sensitive settings.

By grasping these characteristics, users can select the appropriate 12v centrifugal blower for their specific needs, ensuring optimal performance and efficiency in their applications.

Conclusion

In conclusion, the 12V centrifugal blower is not just a component; it’s a cornerstone of modern technology, playing a crucial role in electronics, HVAC systems, and industrial applications. Its remarkable ability to transport air and gases efficiently through centrifugal force makes it essential for effective cooling and ventilation, thereby ensuring optimal performance in sensitive electronic devices and various machinery.

Key features such as high airflow rates, compact design, energy efficiency, and durability have been thoroughly examined throughout this article. The evolution of centrifugal blowers – from early innovations to contemporary designs – demonstrates their adaptability and the continuous advancements in technology. Moreover, understanding the distinctions between brushed and brushless motors, along with the variations in blade designs, highlights the necessity of selecting the right blower for specific applications.

Recognizing the significance of 12V centrifugal blowers in enhancing performance and energy efficiency is vital for industries that depend on effective cooling solutions. As demand continues to rise, staying informed about the latest developments and applications of these blowers will empower users to make educated decisions. This knowledge ultimately leads to improved operational efficiency and sustainability in their respective fields. Therefore, it is imperative to engage with ongoing advancements and leverage the capabilities of 12V centrifugal blowers to stay ahead in the industry.

Frequently Asked Questions

What is a 12V centrifugal blower?

A 12V centrifugal blower is a specialized device that transports air or gases using centrifugal force, commonly used in electronics cooling and ventilation systems.

What are the key features of 12V centrifugal blowers?

Key features include high airflow rates, compact design, energy efficiency, and durability, making them suitable for various applications.

How do 12V centrifugal blowers achieve high airflow rates?

They are engineered to produce substantial airflow, which is essential for cooling sensitive electronic components and ensuring optimal performance.

Why is the compact design of 12V blowers important?

Their small footprint allows for seamless integration into confined spaces, such as computer enclosures and HVAC systems, where space is limited.

What makes 12V centrifugal blowers energy efficient?

Operating at low voltage, they consume less power than larger units, and the use of brushless DC motors enhances energy performance by 15-30% compared to conventional models.

Are 12V centrifugal blowers durable?

Yes, many models are designed to withstand challenging environments, ensuring a long operational lifespan even under demanding conditions.

How do 12V centrifugal blowers operate?

They draw air into the center of the unit and expel it at a right angle, generating high-pressure airflow essential for effective cooling and ventilation.

What recent advancements have improved the performance of 12V centrifugal blowers?

Innovations include the incorporation of brushless DC motors, which improve energy efficiency by 20-30%, and advancements in materials and design for quieter operation.

What applications can benefit from 12V centrifugal blowers?

They are suitable for a range of applications, including gaming consoles and industrial control units, due to their compact and efficient cooling solutions.

What is the projected market growth for ventilator rotary fans?

The global ventilator rotary fan market is expected to expand from USD 40.2 million in 2025 to USD 53.9 million by 2032, indicating increasing demand for these technologies.