Overview

The article examines the design, types, and applications of vapor chamber heatsinks, which play a pivotal role in the efficient thermal management of electronic devices. It elucidates the operation of these devices based on two-phase thermal transfer principles and categorizes their various types—such as flat vapor chambers and custom units. The discussion emphasizes their critical significance in high-performance computing, consumer electronics, and automotive applications, thereby underscoring their increasing relevance in contemporary technology.

Introduction

Vapor chambers stand at the forefront of thermal management technology, employing advanced principles of two-phase thermal transfer to effectively dissipate heat in electronic devices. By leveraging the unique properties of working fluids within a sealed enclosure, these sophisticated heatsinks not only enhance performance but also significantly extend the lifespan of critical components.

However, with a myriad of designs and types available, how can engineers and designers identify the most effective vapor chamber solution for their specific applications? This article delves into the intricacies of vapor chamber heatsinks, exploring their design, functionality, and diverse applications across modern electronics.

Define Vapor Chambers and Their Functionality

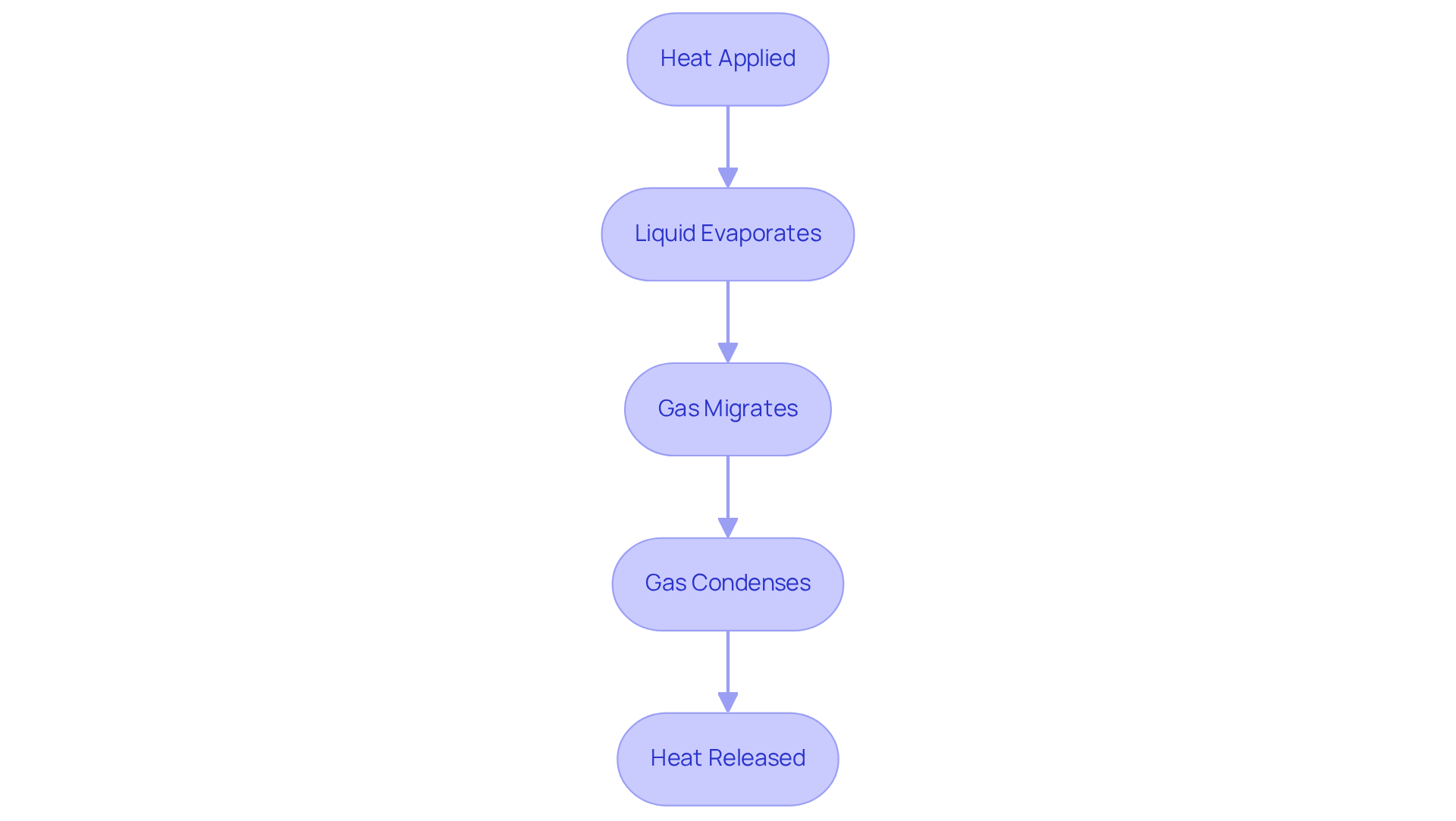

A steam container represents a sophisticated , operating on the principles of . It consists of a containing a small quantity of , typically water or a specialized liquid. When heat is applied to one side of the enclosure, the liquid evaporates, generating of the enclosure. As this gas condenses back into liquid form, it releases heat, effectively transferring energy away from the source. This efficient process enables the to adeptly manage , thereby ensuring and extending longevity.

Explore the Structure and Design of Vapor Chambers

Vapor units are designed as flat, sealed enclosures known as , primarily composed of materials with high , such as copper and aluminum. These materials are essential for effective , as they minimize resistance to temperature changes and enhance overall performance. Typically, the internal architecture features a wick or capillary structure, which is vital for the movement of the working fluid. The design of the wick—whether sintered, grooved, or mesh—significantly influences the pumping capability and heat response time of the fume section, making it a critical factor in the overall design process.

The configuration of steam sections can vary, with some designs incorporating throughout the unit. This design flexibility allows for tailored solutions that meet specific , such as incorporating a vapor chamber heatsink to replace thicker solid metal bases in vertically constrained applications. Moreover, steam compartments can operate in any orientation, further enhancing their versatility across various applications.

Key design elements include the volume of the working fluid and the thickness of the enclosure, both of which have a substantial impact on . For instance, a to guarantee efficient heat dissipation. Expert insights underscore that the , as it must align with the operating temperature range and be compatible with the enclosure materials. As noted by Sarah Lee, “The choice of the working fluid relies on the operating temperature range and the compatibility with the materials of the enclosure.”

By meticulously assessing these design components, engineers can create that not only meet but exceed the heat management demands of modern electronic devices. The vapor enclosure market is projected to experience significant growth, reaching USD 4.5 billion by 2033, underscoring the increasing importance of these solutions within the electronics sector.

Identify Different Types of Vapor Chambers

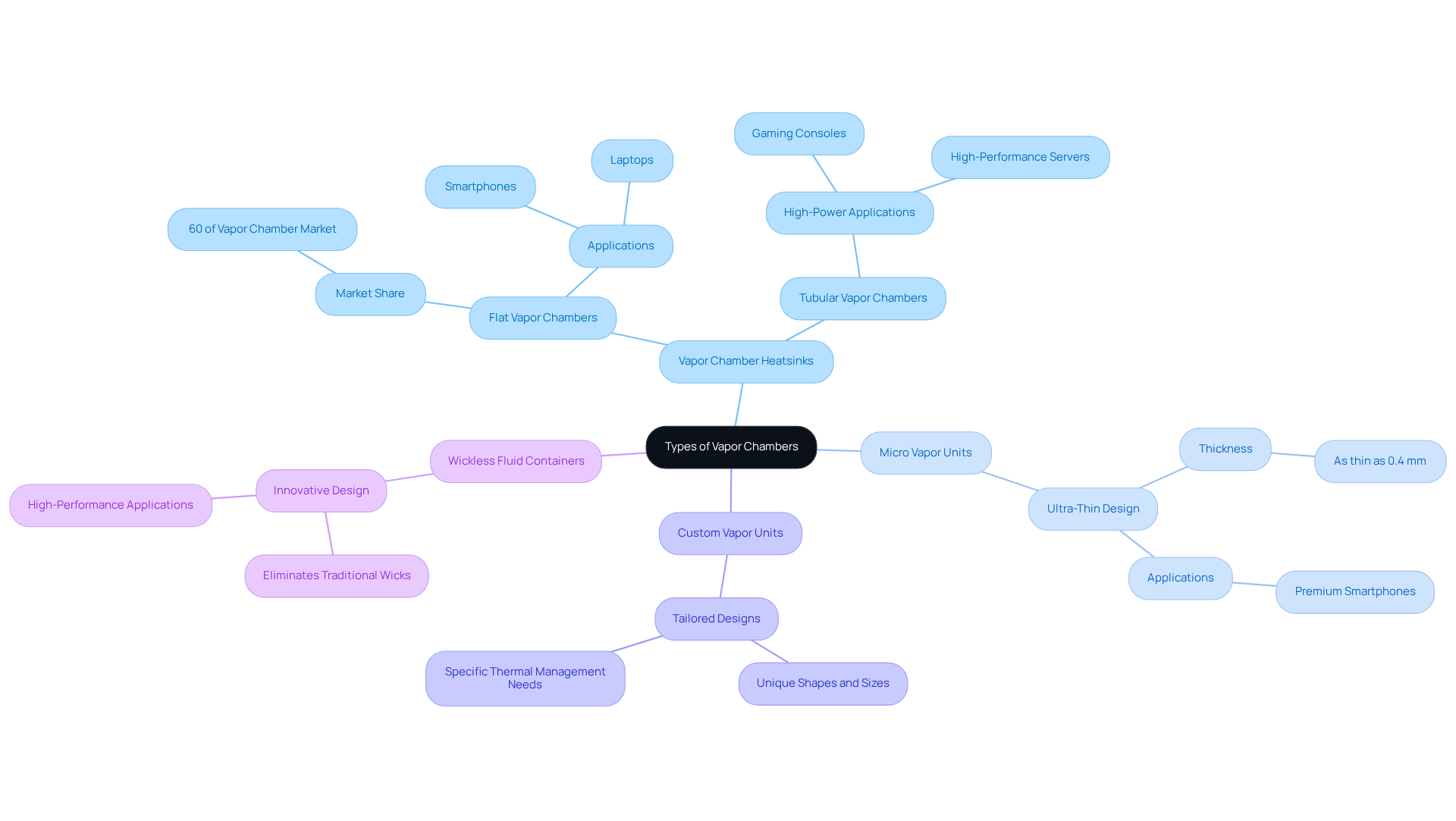

Vapor units play a pivotal role in , with various types engineered for specific applications. The most prevalent types include:

- are widely utilized in compact devices such as laptops and smartphones, as they excel in efficiently dispersing heat across a flat surface. Their design makes them particularly suitable for applications demanding . Notably, flat vapor chamber heatsinks constitute approximately 60% of the , largely due to their integration in .

- : Specifically designed for ultra-thin devices, micro vapor units employ advanced manufacturing techniques to achieve minimal thickness while ensuring optimal performance. Their innovative design is crucial for maintaining heat efficiency in slim electronics.

- Custom Vapor Units: These units are tailored to address specific , allowing for unique shapes and sizes. This customization enhances their effectiveness across diverse applications, making them invaluable in various environments.

- : By leveraging surface tension to transport the working fluid, wickless fluid containers . This innovative design provides significant advantages in high-performance applications where conventional methods may prove inadequate.

In addition to their applications in consumer electronics, the integration of cooling systems in electric vehicles represents a major growth factor, accounting for around 20% of the overall market expansion. The increasing demand for compact and lightweight devices continues to drive the growth of both flat and micro vapor units, which underscores the essential role of vapor chamber heatsink in contemporary electronic design. Understanding the unique benefits of each category is critical for selecting the appropriate solution based on heat load and spatial constraints.

Examine Applications of Vapor Chambers in Electronics

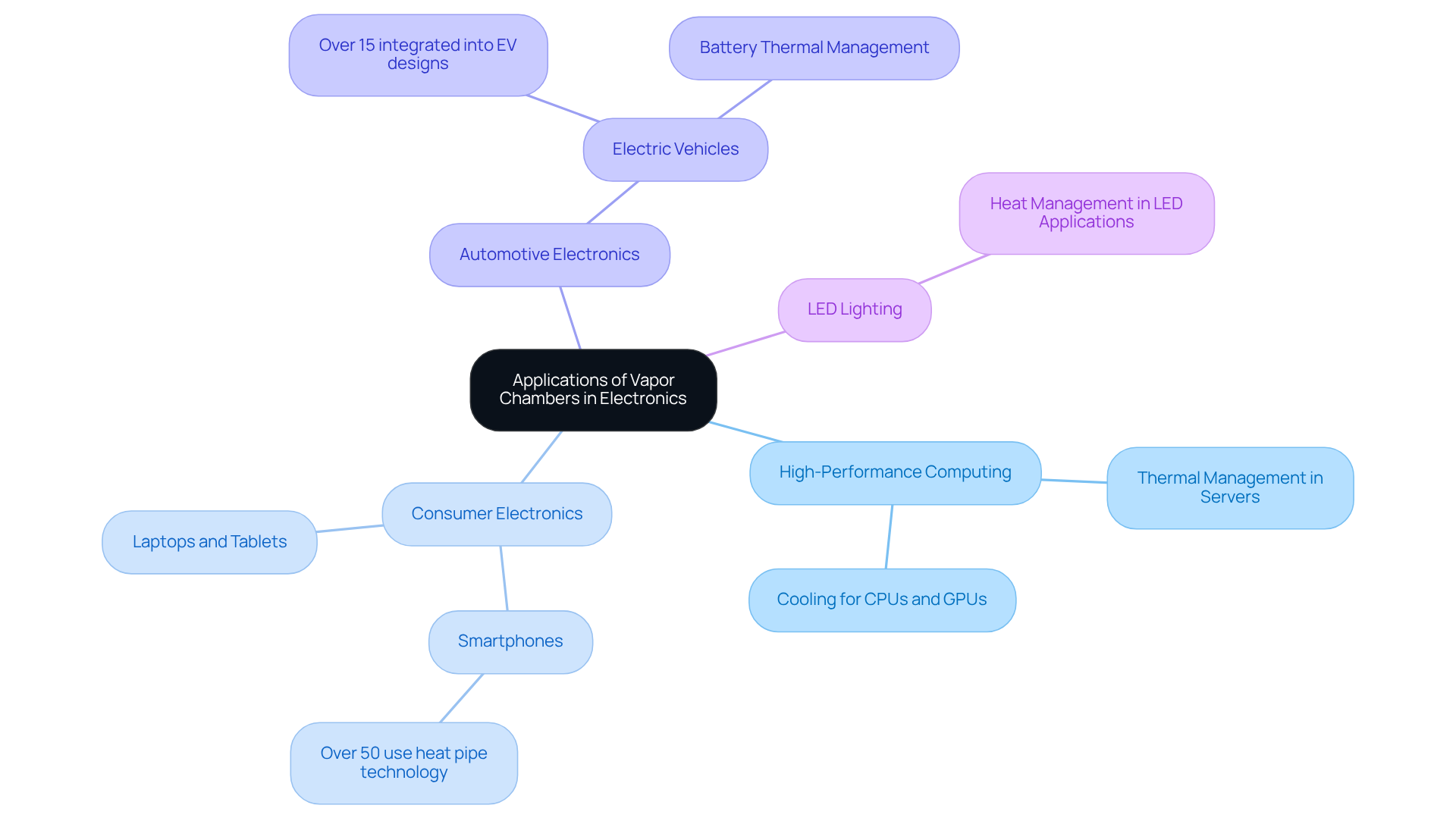

Vapor chamber heatsinks are indispensable in a multitude of electronic applications, renowned for their superior . Key applications include:

- : In servers and workstations, liquid-filled systems adeptly dissipate thermal energy generated by powerful CPUs and GPUs, ensuring stable operation even under heavy loads. This technology is crucial as the demand for processing power escalates, with cooling systems becoming essential for maintaining optimal performance in data centers.

- : Devices such as smartphones, tablets, and laptops increasingly utilize heat pipes to manage temperature within compact designs. This integration not only boosts performance but also enhances user experience by preventing overheating during intensive tasks. Notably, over 50% of next-generation smartphones now incorporate , underscoring its growing importance in the consumer electronics sector. The consumer electronics industry constitutes 45% of the , highlighting its significance.

- Automotive Electronics: The surge in electric vehicle (EV) adoption has led to a marked increase in the use of evaporation systems for cooling high-power components. These systems improve the overall efficiency and reliability of vehicles, with over 15% of to effectively manage heat loads. Vapor units are increasingly utilized in electric vehicles for optimal and cooling of power electronics, emphasizing their crucial role in EV applications.

- LED Lighting: to manage heat effectively, thereby extending the lifespan of components. This application is particularly pertinent as the demand for energy-efficient lighting solutions continues to rise.

These applications underscore the versatility and efficiency of heat transfer devices, particularly the vapor chamber heatsink, in modern electronics, establishing them as fundamental components in advanced thermal management strategies. Furthermore, the is projected to expand at a CAGR of 9.3% from 2026 to 2033, indicating a robust future demand for these technologies.

Conclusion

Vapor chamber heatsinks stand at the forefront of thermal management solutions for modern electronics, leveraging the principles of two-phase thermal transfer to efficiently dissipate heat. These advanced devices not only optimize the performance of electronic components but also extend their lifespan by ensuring optimal operating temperatures. As technology progresses and devices shrink in size, the necessity for effective heat dissipation methods, such as vapor chambers, becomes increasingly critical.

This article explores the intricate design and functionality of vapor chambers, emphasizing their construction from high-conductivity materials like copper and aluminum, along with the essential role of the internal wick structure. Various types of vapor chambers, including micro vapor units and bespoke designs, cater to specific applications, illustrating their adaptability across diverse sectors, including consumer electronics, automotive, and high-performance computing. The anticipated growth of the vapor chamber market highlights their pivotal role in meeting the rising thermal management demands of sophisticated electronic devices.

Given the insights presented, it is clear that vapor chamber heatsinks are more than just a passing trend; they are crucial elements in the advancement of thermal management technologies. As industries continue to innovate, adopting these cutting-edge cooling solutions will be vital for enhancing device performance and efficiency. A comprehensive understanding of the unique features and applications of vapor chambers can empower engineers and designers to make informed decisions that address the ever-evolving challenges of thermal management in electronics.

Frequently Asked Questions

What is a vapor chamber?

A vapor chamber is a sophisticated thermal spreader that operates on the principles of two-phase thermal transfer, consisting of a sealed enclosure containing a small quantity of working fluid.

How does a vapor chamber work?

When heat is applied to one side of the vapor chamber, the working fluid (typically water or a specialized liquid) evaporates, generating gas that moves towards cooler areas. As the gas condenses back into liquid, it releases heat, effectively transferring energy away from the heat source.

What is the purpose of a vapor chamber in electronic devices?

The vapor chamber helps manage temperature in electronic devices, ensuring optimal performance and extending the longevity of the components by efficiently transferring heat away from the source.