Overview

Cooling blower fans serve as specialized ventilation devices, meticulously engineered to facilitate efficient air movement for heat dispersion. This functionality is vital in upholding optimal operating temperatures within electronic equipment. The significance of these fans is particularly pronounced in various applications, especially within compact and powerful devices. Here, targeted airflow can markedly enhance performance and reliability, ultimately prolonging the lifespan of critical components. Understanding their role not only underscores their importance but also highlights the necessity for their integration in advanced technological environments.

Introduction

Cooling blower fans play a pivotal role in thermal management, particularly within electronic systems where effective heat dissipation is paramount. These specialized devices not only maintain optimal operating temperatures for sensitive equipment but also significantly enhance the performance and reliability of various applications.

As technology evolves and devices become increasingly compact and powerful, the challenge of effective cooling escalates. Engineers must harness the full potential of cooling blower fans to prevent overheating and prolong the lifespan of electronic components.

This article explores the intricacies of cooling blower fans, examining their operational principles, diverse applications, and the latest innovations that are shaping the future of thermal management.

Define Cooling Blower Fan

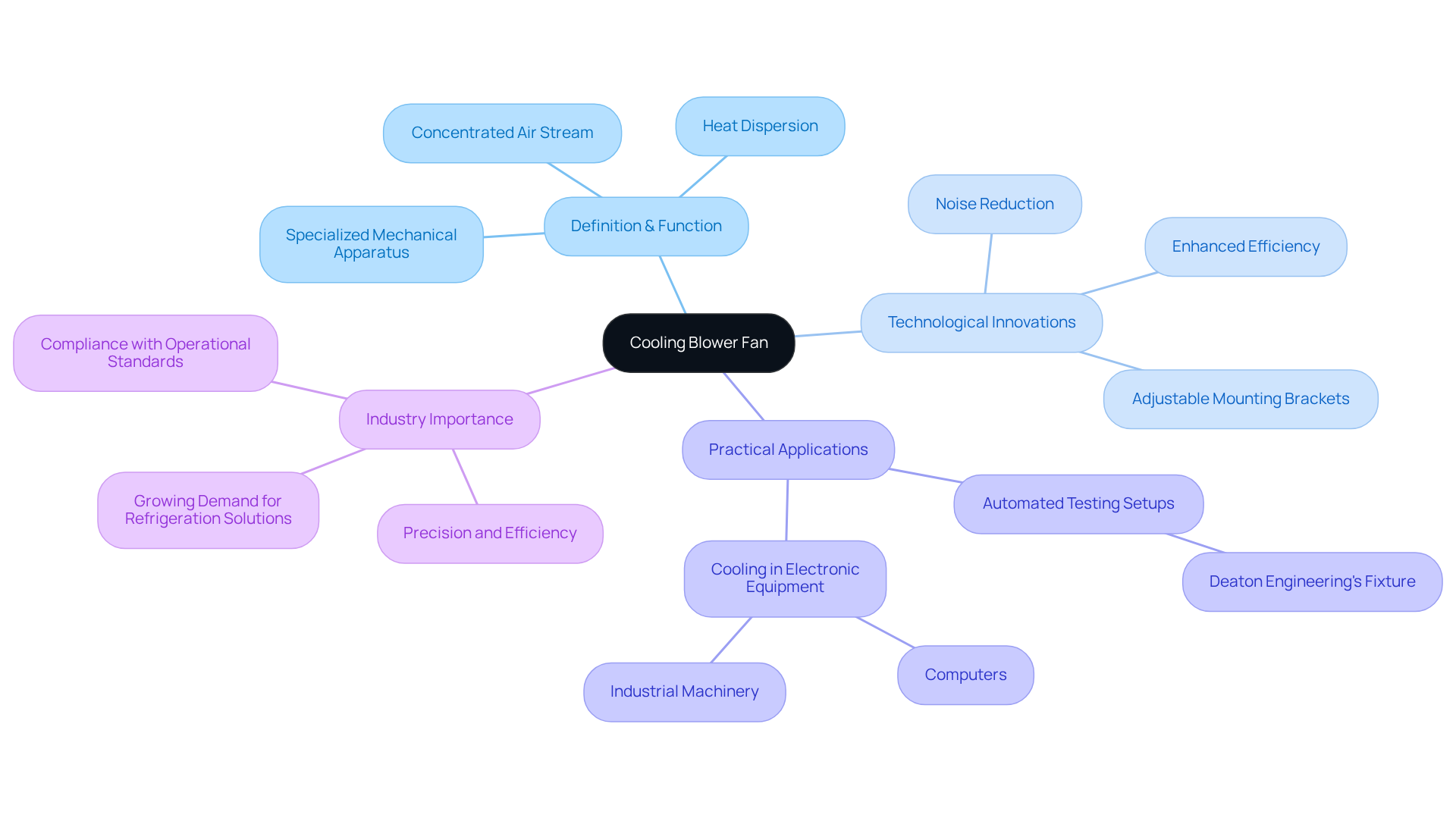

A ventilation fan serves as a specialized mechanical apparatus meticulously engineered to move air effectively across surfaces or through systems, primarily aimed at heat dispersion. In electronic applications, cooling blower fans are vital for sustaining optimal operating temperatures in equipment such as computers, power supplies, and industrial machinery. Unlike standard fans that disperse air broadly, a produces a concentrated stream of air, rendering it particularly efficient in lowering temperatures in specific components or confined spaces within electronic systems.

Recent innovations in ventilation fan technology have focused on enhancing efficiency and reducing noise levels, with a multitude of manufacturers now offering models that integrate advanced materials and designs. For example, the introduction of adjustable mounting brackets provides flexibility in fan testing setups, ensuring optimal airflow while accommodating various fan sizes.

Practical applications of ventilation systems are exemplified by the automated testing setups developed by Deaton Engineering, capable of managing and evaluating up to 450 air circulation units simultaneously. This advancement not only streamlines the testing process but also guarantees reliability and performance across multiple fan models.

Industry leaders recognize the significance of these components in electronic devices, noting that their precision and efficiency are crucial for adhering to stringent operational standards. As the demand for high-performance refrigeration solutions continues to grow, ventilation units with a cooling blower fan remain at the forefront of thermal management technology.

Contextualize the Role in Electronics Cooling

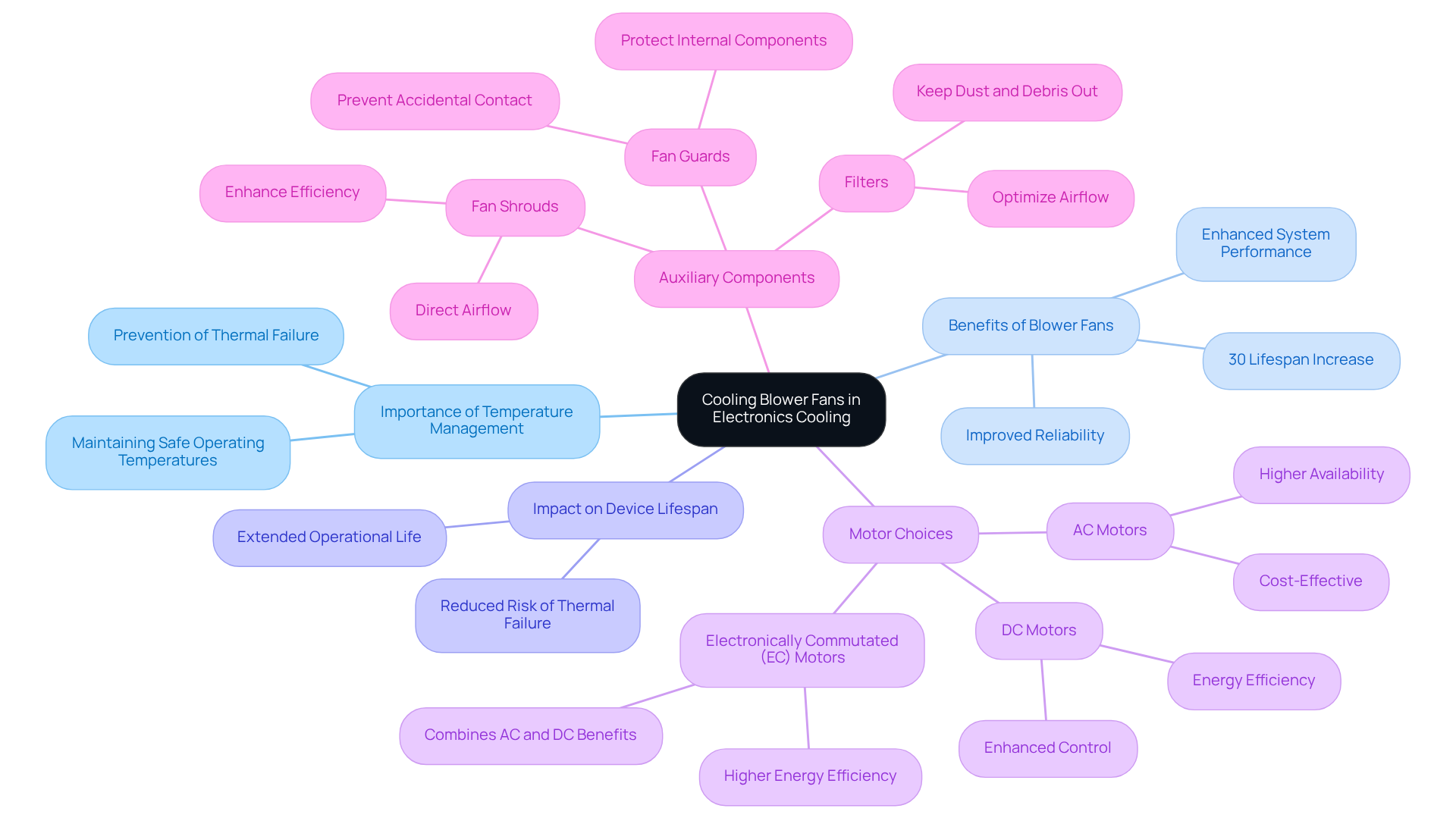

In the electronics sector, efficient temperature management is crucial to preventing thermal failure and extending the lifespan of devices. Cooling blower fans play a vital role in this process, facilitating the dissipation of heat from essential components. As electronic devices become increasingly compact and powerful, the demand for effective temperature management solutions has surged.

In space-limited environments, a cooling blower fan is particularly advantageous, providing directed airflow to critical areas requiring cooling. This targeted approach not only enhances system performance but also significantly improves reliability. Research has shown that systems equipped with a cooling blower fan and other advanced air movement devices can reduce the risk of thermal failure, thereby extending the operational life of electronic components.

Engineers have noted that integrating high-efficiency cooling blower fans can lead to substantial improvements in device durability, with some studies indicating lifespan increases of up to 30% due to effective thermal management. Furthermore, the choice of motor—whether AC for cost-effectiveness or DC for enhanced control—can also influence the efficiency of these devices and their energy consumption.

Auxiliary components, such as fan shrouds, are essential in directing airflow and enhancing overall efficiency, while accessories like guards and filters contribute to improved functionality and safety. Ultimately, the in electronics cooling is indispensable, as they help maintain safe operating temperatures, ensuring that devices function optimally and reliably over time.

Explain Operational Principles and Applications

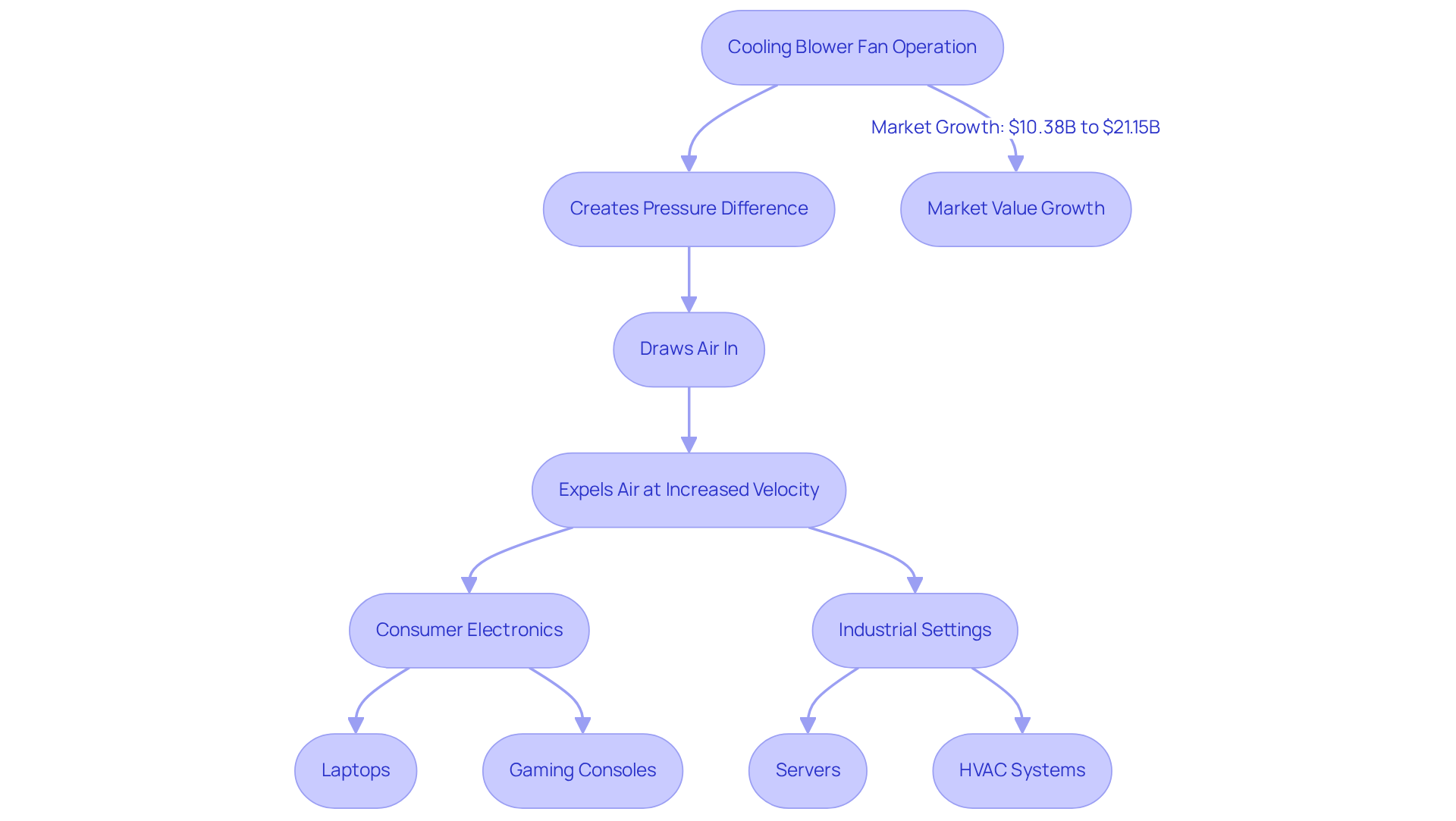

Cooling blower fans operate by creating a pressure difference that draws air in and expels it at an increased velocity. This mechanism is driven by an that rotates to facilitate airflow. The versatility of these devices is evident in their diverse applications across multiple sectors.

In consumer electronics, for instance, the cooling blower fan plays a pivotal role in devices such as laptops and gaming consoles, where effective thermal management is crucial to avert overheating. Similarly, in industrial settings, cooling blower fans are indispensable for the operation of servers and HVAC systems, ensuring that equipment remains within optimal temperature ranges.

According to industry publications, the global air purifier market, which often utilizes fan technology, was valued at $10.38 billion in 2020 and is projected to reach $21.15 billion by 2027, underscoring the growing importance of efficient ventilation solutions.

Furthermore, manufacturers emphasize that the ability of ventilation devices to provide directed air movement is vital for maintaining performance and reliability in both consumer and industrial applications. For example, in HVAC systems, fans are essential for dust extraction and preserving air quality, highlighting their critical function across various operational contexts.

Explore Variations and Use Cases

Cooling ventilation units, which can include a cooling blower fan, are available in a variety of designs, such as axial, centrifugal, and mixed-flow types, each tailored to specific air movement requirements and spatial constraints. Gagner-Toomey Associates, recognized as the world’s largest producer of both standard and custom air-movers, offers an extensive product range of DC input tube axial units that vary from 15 to 280mm, alongside centrifugal blowers ranging from 15 to 225mm, with IP protection available for most models upon request.

Cooling blower fans are particularly effective in applications demanding substantial air movement, efficiently transporting large volumes of air to cool objects or ventilate spaces, making them ideal for larger systems such as high-performance computing setups. Conversely, cooling blower fans are favored in compact environments due to their capacity to generate higher pressure, which is crucial for effective ventilation in confined areas.

For example, mixed-flow ventilators, which utilize a cooling blower fan, combine the advantages of both axial and centrifugal configurations, bridging the gap between the two by delivering high air movement rates while maintaining pressure, thus making them suitable for applications like avionics temperature regulation and industrial ventilation.

Additionally, Gagner-Toomey provides innovative thermal management solutions, including extruded aluminum heatsinks, copper-based heat sinks, and integrated temperature regulation systems that amalgamate fans, heat pipes, and radiators.

Statistics reveal that airflow requirements can vary significantly, with some systems necessitating ; however, it is essential to note that Gagner-Toomey does not manufacture a fan capable of achieving both maximum airflow and static pressure simultaneously.

Engineers consistently emphasize that comprehending the specific cooling requirements and environmental conditions is critical for making informed decisions regarding the cooling blower fan selection, which ensures reliability and efficiency across diverse applications.

Conclusion

Cooling blower fans are essential components in modern electronics and industrial applications, playing a pivotal role in maintaining optimal temperatures and ensuring the longevity of devices. Their ability to deliver concentrated airflow makes them indispensable in environments where effective thermal management is crucial. By facilitating heat dissipation from critical components, these fans not only enhance performance but also contribute significantly to the reliability of electronic systems.

Throughout this article, various aspects of cooling blower fans have been explored, including their operational principles, innovations in design, and diverse applications across multiple sectors. Key insights highlight the importance of selecting the right type of fan—whether axial, centrifugal, or mixed-flow—to meet specific cooling requirements. Additionally, advancements in fan technology, such as improved materials and adjustable designs, have further optimized their efficiency and noise reduction capabilities.

The significance of cooling blower fans extends beyond mere functionality; they are vital for the advancement of technology in various fields. As devices continue to shrink in size while increasing in power, the demand for effective cooling solutions will only intensify. Engineers and manufacturers must prioritize the integration of high-efficiency cooling systems to safeguard device performance and reliability. Embracing these innovations not only ensures compliance with operational standards but also paves the way for future advancements in electronic design and thermal management.

Frequently Asked Questions

What is a cooling blower fan?

A cooling blower fan is a specialized ventilation fan designed to move air effectively across surfaces or through systems, primarily for heat dispersion in electronic applications.

How do cooling blower fans differ from standard fans?

Unlike standard fans that disperse air broadly, cooling blower fans produce a concentrated stream of air, making them more efficient in lowering temperatures in specific components or confined spaces within electronic systems.

What are some recent innovations in ventilation fan technology?

Recent innovations have focused on enhancing efficiency and reducing noise levels, with manufacturers offering models that integrate advanced materials and designs, such as adjustable mounting brackets for optimal airflow in testing setups.

What practical applications demonstrate the use of ventilation systems?

An example is the automated testing setups developed by Deaton Engineering, which can manage and evaluate up to 450 air circulation units simultaneously, streamlining the testing process and ensuring reliability across multiple fan models.

Why are cooling blower fans important in the electronics industry?

They are crucial for maintaining optimal operating temperatures in equipment, ensuring precision and efficiency that adhere to stringent operational standards, especially as the demand for high-performance refrigeration solutions grows.